Countersink drill (step drill) DIN8374 HSS 90°

Countersink drill, Type n HSS 900 with shortened part of small diameter for through holes Drilling and countersinking in one process Note: set the drilling speed for the large diameter and the feed for the small diameter

| Countersink drill for metal DIN 8374 HSS 90° Ruko (Germany) | vendor code | Price with VAT * |

| Countersink drill for metal Ruko DIN8374 HSS VAP 90° M3 3.2/6x9mm S=6mm 102601 | 102601 | 3722 |

| Countersink drill for metal Ruko DIN8374 HSS VAP 90° M4 4.3/8x11mm S=8mm 102602 | 102602 | 4320 |

| Countersink drill for metal Ruko DIN8374 HSS VAP 90° M5 5.3/10x13mm S=10mm 102603 | 102603 | 5389 |

| Countersink drill for metal Ruko DIN8374 HSS VAP 90° M6 6.4/11.5x15mm S=11.5mm 102604 | 102604 | 6066 |

| Countersink drill for metal Ruko DIN8374 HSS VAP 90° M8 8.4/15x19mm S=15mm 102605 | 102605 | 10002 |

| Countersink drill for metal Ruko DIN8374 HSS VAP 90° M10 10.5/19x23mm S=19mm 102606 | 102606 | 12689 |

*Prices valid as of November 12, 2022, wholesale price , conditions for bargaining. organizations upon request

What are the types

There are many countersinks on the market; an inexperienced user may not understand why so many are needed, but each type has its own purpose and peculiarity in operation. Some are suitable for increasing the diameter of the hole, while others will be most effective when working with the end part of the part. Most often, when working with wood, a basic set of attachments is used:

cylindrical;

solid conical,

one-piece attachment.

Each wood countersink is designed to work the corresponding holes, indicated in the name. But in some cases, in particularly labor-intensive situations, you can resort to using a nozzle on an extended mandrel. This tool has special legs that trim the end simultaneously with the countersinking process. Therefore, it is best to purchase a kit that will contain several models by type and size at once; it will be more profitable and efficient.

Cooling and lubrication of carbide drills

As mentioned above, to make machining with carbide drills more efficient, it is necessary to ensure internal cooling of the tool. When using such drills, you can avoid using lubricating and cooling liquid in cases where the depth of the hole being formed does not exceed one tool diameter.

The quality of the hole being made, as well as the speed of its drilling, is influenced not only by the amount of coolant supplied to the internal cavity of the drill (at least 12–15 l/min), but also by the pressure value (at least 12–15 atm). The lubricating and cooling liquid supplied to the processing zone in such quantity and with such pressure provides not only intensive cooling of the tool, but also effective removal of chips and other drilling waste.

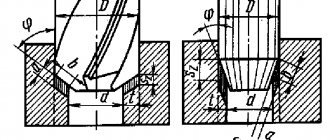

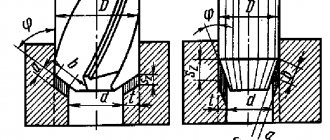

Drilling with external coolant supply

Overview of species

In construction stores, buyers will be able to find a huge number of models of such tools with these attachments. These include the following samples:

- conical solid;

- one-piece mounted;

- cylindrical.

Each of them is used depending on what kind of hole needs to be made in a wooden structure. For particularly labor-intensive work, you can use such a slightly elongated attachment. The latter option has small legs designed for trimming the ends of products. The best option for users would be to purchase a whole set with several varieties of such tools.

Cylindrical types of drills, as a rule, are coated with a special layer during the manufacturing process, which significantly increases the level of wear resistance of the product and its durability. The number of cutting parts can vary from 4 to 10. Externally, the design is similar to a regular standard drill.

In addition, a special trunnion is placed at the end of the cylindrical models. This element is designed to fix the position of the tool itself during operation. Such products are equipped with limiters; they can be removable or act as an integral part of the whole structure.

Models with a removable drilling depth limiter are considered the most practical. They suggest the possibility of installing an additional cutting type attachment.

Removable varieties are attached to the structure itself using small hidden screws. These stops are sometimes attached using a hex wrench.

If you need to make several holes at once on one wooden product, and they must have the same depth, then it is better to use drills that are equipped with special holders with movable or fixed drilling stops.

The attached conical drill model is a design that works at a certain angle, the value of which will depend on the purpose of this model. The angle can be from 60 to 120 degrees. The number of cutting elements can be from 6 to 12 pieces.

The solid socket drill also looks like a regular screw socket. It is most often used specifically for processing holes made in wood.

Various materials can be used to produce countersinks. Most often in stores you can see such building elements made of steel of various grades. Thus, they can be made from tool, alloy, carbon, high-speed or carbide steel base.

If you need a drill to process various metal products, then carbide models can be the best option, because this particular type differs from all others in its special resistance to constant loads.

Also, countersinks for wood processing can differ in the diameter of the holes being machined. The following options are considered the most common:

- standard models - the diameter will be from 0.5 to 1.5 mm;

- models for holes with a diameter of 0.5 to 6 mm - such samples can be produced with a fuse that allows you to control the drilling depth;

- products for holes from 8 to 12 mm - this group, as a rule, includes special countersink drills with a shank.

Types and purpose of countersinks

A countersink resembles a type of drill that is used for countersinking. The operation is similar to countersinking, but the final task differs. The countersinking procedure is needed in situations where there is a need to form rounded recesses to hide the marks of the fastener heads.

The cultivation of parts by countersinking is considered a semi-finishing method, and is carried out before the deployment operation.

According to the design of the countersinks, they are divided into:

- Rounded;

- Conical.

A separate category includes countersinks consisting of hard alloys. They are used as grinding actions. To process openings and remove chamfers in difficult areas, another type of tool is used - a reverse countersink. To ensure the necessary processing of metal products and wood, it is recommended to purchase a countersinking kit rather than using individual tools.

The structure of the cone-type countersinks accommodates the shank and the operated element, with an angular index of 60, 75, 90 and 120 degrees. The number of teeth varies between 6 and 12 units, depending on the diameter of the tool. To ensure the alignment of the cultivated opening, a trunnion is used.

The rounded countersink has a wear-resistant coating. This mechanism is used for chamfer cutting. In design, it resembles a drill, but has a large number of blades - from 4 to 10, it all depends on the diameter of the device. There is a guiding pin at the end of the element. With its help, the position of the tools during operation is recorded. The trunnion can be detachable or integral. In practice, devices with detachable pins are used due to ease of use. You can also attach an attachment cutter to the countersink.

To process several openings into equal recesses, you should use a countersink with holders, which includes various stops. When processing a product, the cutting element is installed in the holder and moves out of the stop by an amount equal to the recess of the opening.

Countersinks are made from various types of steel, including carbide. Tools made of carbide alloys are excellent for processing metal parts, as they can withstand extreme loads for a long time. For processing products made of non-ferrous metal alloy or wood, devices made of high-speed steel are used, since it is subjected to minor loads. It is worth noting that when processing, for example, cast iron products, it is necessary to introduce additional cooling of the tools. For this purpose, special emulsion compositions are used.

Metal countersinking rules

At home, for countersinking recesses (for example, for bolt heads or to change the diameter of a hole to a larger side), a simple drill attached to an electric or even a hand drill is also suitable. On a production scale, countersinking is an operation that requires considerable power and precision of the equipment used. That is why, in production conditions, to perform countersinking, as well as countersinking, the following equipment is used:

- turning (most often);

- drilling (no less often);

- boring (often as one of the secondary operations);

- aggregate (as a secondary operation of an automated line);

- vertical or horizontal milling (rare).

When processing a hole made in a product during its casting, it is advisable to first bore it with a cutter to about 5–10 millimeters in depth so that the countersink takes the correct initial direction.

When processing steel products, it is recommended to use cutting fluids. The process of countersinking cast iron and non-ferrous metals does not require cooling. The correct selection of metal-cutting tools used for both countersinking and countersinking is a very important step

To do this, pay attention to certain factors:

- The type of tool is selected depending on the material of the part and the nature of the processing performed. The location of the hole and the serialization of the processes performed must also be taken into account.

- Based on the specified depth, diameter, and required processing accuracy, the size of the tool for countersinking and countersinking is selected.

- The design of the countersink and countersink is determined by the method of mounting the tool on the machine.

- The material of the tool for performing countersinking or countersinking operations depends on the material of the workpiece (for example, there are countersinks specifically for woodworking), the intensity of the operating mode and some other factors.

Countersinking on a CNC vertical drilling machine

The countersink is selected from reference books or guided by a regulatory document such as GOST 12489-71. The tool must comply with certain technical conditions of use, which is also stipulated by GOST 12489-71.

- Products made of structural steel with holes up to 40 millimeters in diameter are processed with a countersink made of high-speed steel, having a diameter of 10–40 millimeters and 3–4 teeth, respectively.

- For difficult-to-machine products and when boring, equipment with carbide plates with a diameter of 14–50 millimeters and having 3–4 teeth is used.

- In products made of structural steel, holes up to 80 millimeters in diameter are bored with a high-speed steel countersink, using socket heads with a diameter of 32–80 millimeters.

- In products made of non-ferrous metals and cast iron, a feather countersink is used for boring blind holes.

- Blind holes with a diameter of 15–25 millimeters are processed with a special countersinking tool, the body of which has a channel through which the cutting fluid is supplied to the cutting zone.

A necessary condition for countersinking is maintaining allowances. The diameter of the selected tool should ultimately coincide with the final diameter of the hole after processing. When, after countersinking, it is planned to ream the hole, the diameter of the tool is reduced by 0.15–0.3 millimeters. If rough boring or drilling for countersinking is planned, it is necessary to leave an allowance on the side of 0.5 to 2 millimeters.

Types of countersinks and countersinks

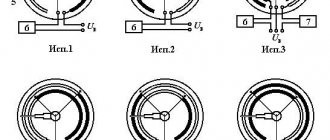

The production of metal cutting tools is subject to the main category of country standards (GOST) and technical regulations for the use of the finished product. On units with partially automated control, the following types of countersinks are used:

- Cylindrical, with diameters from 10 to 20 mm. This set of blades is produced with a coating of wear-resistant elements. Regulated by GOST 12489-71.

- Indivisible conical, from 10 to 40 mm. Manufactured from alloy steel with wear-resistant coating. Subject to TU 2-035-923-83.

- Whole, in the form of attachments, with a diameter from 32 to 80 mm. Regulated by GOST 12489-71.

- Conical or mounted, subject to GOST 3231-71. They are marked by the presence of special plates made from hard iron alloys.

A countersink is also a tool with numerous blades, but it has clear differences from a countersink in terms of use. These devices are divided into several types:

- Conical countersink. It has an operating head with a cone angular coefficient of 60,90, 120 degrees. It is mainly used for cultivating bases for fasteners and removing chamfers, that is, to blunt sharp edges. Regulated by GOST 14953-80 E.

- Rounded countersink (cylindrical). The device can have a rounded or conical end, having a wear-resistant coating on the base. Mainly implemented as a treatment for supporting bases.

The difference between countersinking and related operations

Countersinking is similar to reaming holes; the cutting edges of the tool remove excess material from the stenoctium, reduce roughness and increase the diameter. This is a semi-finish operation, which means it is followed by another processing step. Deployment is the final procedure. During countersinking, defects in drilling, stamping and casting are eliminated. In the process, you can slightly adjust the binding to achieve better alignment for the future connection. Accuracy can be increased to 5, and sometimes even to 4th class.

When setting the cutting mode, you need to remember that the thickness of the metal removed during countersinking is equal to half the allowance for a given hole diameter. Compared to drilling, the feed can be made 1.5-2 times larger, but the speed can remain the same. Specific cutting parameters are calculated using formulas given in the regulatory literature.

Since a countersink has greater rigidity compared to a drill, due to the increased number of sharp protrusions, the accuracy of the direction of movement increases, as well as the quality of processing, smoothness and cleanliness of the surface. For comparison, drilling gives a roughness of 20 microns and grades 11–12, countersinking gives a roughness of 2.5 microns, grades 9–11, and reaming gives a roughness of 0.25-1.25 microns and grades 6–9. Quality is the precision of manufacturing a part; as its value increases, tolerances increase and accuracy decreases. If the technological process for processing a product requires both countersinking and reaming, then they are performed in one installation and alignment of the workpiece on the machine.

This type of machining creates recesses to accommodate fasteners flush with the surface of the part. In addition to chamfering, a countersink is used to cut conical-shaped recesses. Another purpose will be to clean and process recesses before installing fasteners; this is done using flat or end countersinks, also called counterbores, which is more correct.

The most widely used on the market are conical countersinks with working angles of 90 and 120º, which create recesses to hide the heads of bolts and screws. In the metalworking industry, countersinks with a flat tip are also used, used for cleaning recesses for fasteners. Countersinks are installed in the same machines as other tools for processing holes for fasteners.

Countersink

Countersink

Metal processing by countersinking is similar to drilling - this is the rotation of a countersink around its axis. When countersinking, the hole is improved to 9-11 accuracy grades. Also, with the help of a countersink, the roughness of the hole is improved to Rz 2.5 microns.

Main purposes of the countersink:

- Calibration of ready-made holes for fasteners (bolts, studs)

- Improving hole quality before tapping or using a reamer.

Countersinking is not done using a conventional drill or any other manual method. After all, the purpose of this operation is aimed at improving the quality of the hole, which is almost impossible to do with a drill. Therefore, countersinking is performed using a machine tool using drilling, turning, and milling machines.

If we divide countersinks into groups, then in metalworking there are two groups according to accuracy:

- Countersink number 1 - Mainly used for semi-finishing as preparatory work before reaming or cutting threads.

- Countersink with number 2 - Used for final work. Has a relatively high accuracy class H11

According to the design, two types of countersinks are used - solid and mounted (disassembled). If we talk about solid ones, they are used more often, and they have a cone-shaped end. It has a groove for chip removal and cooling and cutting teeth. If we talk about mounted countersinks, their design is distinguished by a removable tip, which is attached through an internal hole.

There are also countersinks that are used much less frequently, in special cases. Namely, these are countersinks with welded plates made of the hardest metal, welded or prefabricated countersinks.

The material from which the countersink tip is made

In solid countersinks, P18 or P19 steel is used to make the cutting teeth. If a countersink is made for processing carbide metals, then its teeth are made of metal-ceramic alloys VK4, VK6 or VK8. If steel products are to be processed - T15K6

Features of countersinking

Countersinking is the mechanical processing of holes to create various geometric recesses for the hidden placement of fasteners. It is also used for cutting internal chamfers. For these purposes, there is a special tool - a countersink, which has different shapes. The choice of countersink depends on the desired end result.

Main types of countersinks

- Cylindrical countersinks. They are used to produce cylindrical recesses in drilled holes for installing bolts and screws.

- Conical countersinks. Used for cutting cone-shaped holes inside a part, as well as for cleaning sharp edges, chamfering and preparing recesses for fasteners. The most commonly used tools are those with a cone angle of 90° and 120°.

- Flat or end countersinks, you can also see the name counterbore. Mainly used for cleaning and processing recesses before installing fasteners.

The countersink consists of a working part and a shank with a special pin that acts as a guide belt. The journal is necessary to control alignment during the process of cutting recesses.

Terminology

A countersink is a multi-bladed cutting tool used for making holes in metal parts. After processing, conical/cylindrical type recesses are obtained, you can create a reference plane near the holes, and chamfer the center hole.

Countersinking of holes is the secondary preparation of finished holes for placing hardware heads - bolts, screws, rivets

A countersink is a cutting tool with a multi-bladed surface. Used in machining cylindrical/conical holes in workpieces to expand the diameter, improve surface characteristics and accuracy. This type of processing is called countersinking. This is a semi-finish cutting process.

A - drilling with a drill B - boring on a lathe C - countersinking with a countersink D - reaming with a reamer E, F - counterbore with a counterbore G - countersinking with a countersink H - thread cutting with a tap

Countering holes is the process of reworking the top of an opening in order, for example, to remove burrs from the edge of a hole or to create recesses to hide the head of a rivet or screw and level it with the surface of the part. The tool used for this task is called a countersink.

How to choose the right step drill?

To choose the right step drill, you need to decide on the purposes for which the tool will be used. Thus, it is necessary to determine what size holes need to be drilled

The value of the smallest and largest diameters that are planned to be performed is especially important

You should also decide on what hand tool or machine the drill will be used. The type of shank that should be on the drill depends on this. Therefore, you should carefully study the drill chuck connector and clearly know the shape and dimensions of the shank. If the shank does not fit the existing connectors, you will have to separately purchase a special adapter.

It is important to decide on the manufacturer and level of the tool. As already noted, bright golden-colored stepped conical drills are made with cobalt and titanium impurities, with an abrasive coating and have high hardness

They will last longer and allow you to work with thick rolled products, stainless and alloy steels.

Purpose and types of drills with countersinks

First of all, you need to define the concept of “countersink”. It is often confused with another metalworking tool - a countersink. Despite their similar sound, they are intended for completely different processes. Countering a surface is the recessing of the top of a pre-drilled hole.

A cylindrical countersink is called a counterbore, and a similar device for repairing valve seats of internal combustion engines and other roughing and grinding work is known as a cutter.

A countersink drill is a multi-edged metal-cutting tool. It is classified as equipment for semi-finishing of existing holes. Use before applying the reamer.

Universal drills with countersinks are most often used in the woodworking industry. In the serial production of furniture, the quality of the holes comes first. The reliability of the assembly depends on this. The tool in question allows you to get a neat hole for a self-tapping screw with a countersunk head, a screw or other fastener. In addition, a countersink drill increases productivity by reducing machining operations.

An alternative is to drill out the existing hole with a larger diameter tool. This is what they do when there are no special requirements for the accuracy of the work. However, this method is quite labor-intensive, so it is used mainly in everyday life - when installing a wooden floor or installing a mortise door lock.

The drill plays the role of a guide element, which allows you to obtain a high-precision hole.

In the process of manufacturing middle-class furniture, special fasteners are used - Euro screws. To prepare holes for these hardware, processing devices that look similar to countersink drills are used. They are also classified as combined instruments. The two-stage design allows you to drill a hole and chamfer a Euroscrew in one pass.

Tool design features

Drills with carbide inserts are characterized by a number of design features. Let's list the most important ones.

- The working length of the drill is reduced by 20–35% due to the fact that its regrinding is carried out only on a carbide plate. The length of drills of this type, if they are used in conjunction with a jig, can be the same as that of a high-speed tool.

- The increase in the diameter of the drill core towards the shank is within 1.4–1.8 mm for every 100 mm of length, as with drilling tools of other categories.

- The angle of inclination of the helical groove of the tool depends on how deep the hole needs to be made.

- On the transverse edge of the drill, it is necessary to make a point with dimensions of 1.8–3.5 mm, which allows to reduce axial forces and reduce the load on the tool body.

- The tapered shank, with which the drill is fixed in the machine spindle, must be precisely adjusted to the seating part, which will increase the rigidity of the drill fastening and minimize the risk of vibration loads, which can cause chipping of the carbide insert and even its breakage.

- To increase the reliability of using carbide drills for metal, a hole is often made in their inner part to supply coolant. This allows you to reduce the cutting temperature, reduce the intensity of tool wear, and also facilitate the process of removing chips from the processing zone.

Design of a drill with removable plates

To give the working part of the drill the required hardness (56–62 units on the HRC scale), the tool is subjected to heat treatment, which, as a rule, is performed simultaneously with soldering of carbide plates.

High processing performance, as well as stability of drills in this category are ensured by a number of parameters. This includes the shape of the carbide plate, the geometric parameters of its front surface, as well as the material from which such a plate is made. Currently, the most widely used tools are those with carbide inserts of regular three- and tetrahedral configurations, which allow drilling holes with an almost flat bottom.

Drills with such inserts, the cutting part of which is made in the shape of a wave, allow processing using step-by-step cutting technology. The use of the latter not only ensures stabilization of the position of the tool at the moment of its cutting into the material being processed, but also minimizes the risk of its withdrawal during further processing. In addition, a drill with a wave-shaped cutting edge can significantly reduce the cutting forces generated during the drilling process.

Drills with mechanical fastening of replaceable polyhedral inserts (drills with MNP)

The design of drills equipped with removable carbide inserts allows them to be used not only for drilling, but also for such technological operations as boring pre-made holes and chamfering. In such cases, a peripheral carbide insert mounted on the tool is used.

Design features

If we look at the countersink, we can highlight some of its parts

- Cutting part. This is the main part that performs the countersinking process. Consists of several cutting edges located at an angle from the center to the sides.

- Shank. Using a shank, the countersink is secured in the tool or machine in which the work will be performed. The shank can be tapered or cylindrical.

- The part between the shank and the cutting part has a particularly thin shape in one place. This part acts as a fuse. If the countersink gets stuck, in order to avoid serious consequences, it is in this part of the countersink that it breaks.

The structure of a countersink

One of the varieties of a countersink has welded blades on the working part, which makes it possible to process hard metal alloys.

Rules for working with a countersink

When performing work on a lathe or drilling machine with a countersink, you need to remember and follow a number of simple rules. Before starting work, check the condition of the chuck on the machine. After all, if the cartridge is in a faulty condition, it will not be possible to secure the countersink well, and thus you will not be able to get a high-quality machined hole. Countersinking of holes is carried out in accordance with the following rules:

- To perform the work, the countersink must be strictly in the center of the hole being machined.

- When processing hard metals such as cast iron, you need to take breaks from work and use special solutions to remove heat. In everyday life, technical oil is used for such purposes.

- When operating, do not exceed the speed specified by the manufacturer. Failure to comply with this rule will result in rapid wear of the cutting edges due to heating.

- Select the correct countersink diameter for the hole being machined. If you choose the wrong size, the processing will not be of high quality, namely incorrect centering, uneven edges.

Areas of application

The areas of application of countersinks include use on machines such as: - lathes; — drilling; — milling; — boring; — turning-turret; — aggregate. In terms of the level of purity, the countersinking procedure, as a technological process, is classified as semi-finish processing. It is usually used before drilling holes in blank elements made of various materials. Carrying out such a technological operation must be performed at low machine speeds. Some types of countersinks are also used for processing and chamfering holes that are located in hard-to-reach places - these are reverse-type tools.

How to countersink metal correctly

If an amateur craftsman can take a drill and a drill for countersinking, then in an industrial environment the following machines can be used for this:

- drilling;

- turning;

- boring;

- milling;

- aggregate.

The countersinking process takes place in strict accordance with the technology, the general points of which can be described in the form of the following recommendations:

- In cast parts with an uneven margin for subsequent metalworking, it is necessary to bore the hole to a depth of 5–10 mm for the correct direction of movement of the cutting tool.

- For the countersinking operation, an allowance of 1–3 mm is left, depending on the final diameter.

- Countersinking of steel products is not complete without cooling with special oil solutions. When working with cast iron, as well as non-ferrous metal, it is not mandatory.

- The optimal version of the countersink and the operating mode are selected taking into account the required hole diameter, processing accuracy, its depth, the metal of the part and the options of the production machine.

- The cutting tool mount must fit into the slot that is on the workstation.

- In the case where finishing processing by reaming is expected, then during countersinking a part of the allowance, from 0.15 to 0.3 mm, is left for further work.

- To process products made of hardened and alloyed steels, countersinks with carbide inserts with a diameter of 14-50 mm and 3-4 teeth are used.

- When processing non-ferrous metals and iron alloys with a high carbon content, feather countersinks are used.

- High-speed steel tools are used to process products made from ordinary structural steel. For holes larger than 40 mm, the equipment is supplemented with nozzles with a diameter of 32–80 mm.

The discrepancy between the process and the established technology is often the cause of defects. If the tool wears out a lot, the resulting hole will be smaller than the design. When the master has overestimated the feed, or waste has stuck to the teeth of the countersink, the cleanliness of the processing may not satisfy the quality. Other defects: part of the surface is not processed, the resulting diameter is larger than required, are the result of an incorrect choice of countersink or its incorrect installation.

Cone countersink design

This device is intended for passing cone-shaped openings of small depth. The main feature in the design of the element is the presence of straight teeth and an absolutely flat outer base. The number of cutting elements, in accordance with calibration, can vary from 6 to 12 units.

Countersinking holes is considered a manual procedure, carried out through a turning unit on which the countersink is mounted. The workpiece is clamped in the machine's grip, and its correct location in the recess is checked. The axial centers of the electric spindle and the rear assembly of the machine must be at the same level. This reduces the risk of the technically movable sleeve (quill) flying out. The tip of the tool is inserted into the hole to be finished manually.

To obtain an opening of the required diameter after the countersinking operation, an allowance of 2-3 mm is made during drilling. The exact allowance values depend on the calibration of the recess in the workpiece being processed. It is more difficult to implement the countersinking process for forged and dense products. To simplify your task, you should bore the countersunk hole by 5-9 mm in advance.

Countersinking can be done in cutting order. In this situation, the tool feed is doubled than when drilling, but the travel speed remains the same. The cutting recess with a countersink is laid at approximately 50 percent of the allowance for the diameter. Countersinking of holes with a tool is carried out using cooling materials. The mechanism made of hard alloys does not require the introduction of auxiliary coolant.

When processing openings, a countersink guarantees high accuracy, but defects cannot be avoided at all. The most common processing defects are:

- Increased opening diameter. The main reason for the occurrence of such a defect is considered to be the use of a device with incorrect sharpening.

- Reduced diameter of the recess. It happens that the wrong tools were chosen for the job or a damaged countersink was used.

- Defiant purity. This flaw can be caused by a number of reasons. Usually, a decrease in cleanliness lies in poor sharpening of the device. In practice, the cause of the defect can also be excessive viscosity of the product material. Therefore, the element sticks to the tool belts. Damage is also caused by the error of the turner, who made an incorrect feed and acceleration of the cut.

- Partial processing of the opening. This reason usually occurs as a result of incorrect fixation of the part or an incorrect countersink allowance saved after drilling.

Countersinking on metal and wood. Peculiarities

First, the design of the countersink is selected. For example, the processing of workpieces made of non-ferrous metals and alloys can be carried out with a conventional countersink, and for countersinking high-carbon steels, a metal tool with 3...4 teeth is suitable, and the angle of the truncated cone can vary in the range of 60...90º.

The technology for producing these operations includes:

- Checking the straightness of the axis of the previously made hole. To do this, use a bore gauge, and the part is laid on a flat, rigid plane.

- For workpieces made of cast alloys - test boring to a depth of 5...10 mm. This makes it possible to exclude the influence of possible discontinuities in the cast structure of the workpiece on the countersink runout.

- Wetting the leading edge of the hole with coolant (for cast iron workpieces, as well as products made of non-ferrous metals, this is not necessary). Subsequently, coolant is supplied through the existing helical grooves.

- Power supply of the countersink as it penetrates the metal (the force will increase by 2.5...3 times, but this is not the cause of the malfunction).

- Gradual reduction in feed as you approach the opposite end of the hole.

After processing the workpiece with a countersink with a developed guide, subsequent passage of the tool through the hole is not necessary.

Of particular interest to home craftsmen is the combination drill-countersink tool. It is a step drill with a countersinking part at the end. To reduce wear and longitudinal feed force, this part is equipped with hemispherical grooves, into which coolant is periodically supplied and the resulting chips are removed.

Since the countersink drill operates under different conditions as it goes deeper into the metal, a number of additional requirements are imposed on its performance:

- A working tool with a high-resistant surface coating made of titanium or tungsten nitride will have the greatest durability. A blued tool (black) will have slightly less durability;

- Sets of several standard sizes of countersink drills help, when finishing the hole, to form a conical transition part at its end for fasteners of the required size;

- The working part of the drill must be the minimum acceptable, which ensures stable processing: long tools sharply lose their stability from longitudinal bending, which, given the increased hardness, will instantly lead to breakage.

Wood countersinks differ not only in material, but also in the shape of the end of the working part. It is also convenient to use a special countersink attachment, which is placed on top of a regular drill and attached to it with a screw. In this case, the quality of drilling is ensured by proper sharpening of the drill and the optimal choice of its material. For deep workpieces (sizes above 40...50 mm), it is more rational to use drills made of blued tool steel, while for less thick products, carbide countersinks show better durability.

The countersinking attachment for the main tool has another operational advantage: it is double-sided, therefore, being mounted on the drill with its opposite part, it can be effectively used as a depth limiter for machining a cavity.

Main features of wood countersinks:

- Working end shape made at an angle of 90°.

- Number of teeth increased to 5.

- Can also be used for countersinking a hole without changing its diameter.

- Dependence of the number of cutting edges on the material being processed: for soft wood species - pine or linden - usually one cutting edge is sufficient. At the same time, if it is necessary to process wood along the grain, due to the danger of chipping, the number of cutting edges is two or more.

Centering drills: what are they, their characteristics

Anyone who has ever drilled holes knows how important it is to ensure that the holes are straight and made exactly where they need to be. After all, usually, if the hole is uneven, made at an angle or slightly in the wrong place, the part or material has to be thrown away

That's why they came up with a special tool called centering drills.

Let's figure out what this tool is. Metal centering drills (or, as they are also called, centering drills) are special multifunctional (they have several work areas to perform different operations) tools for cutting metal.

Appearance of a center drill

They are usually quite short, have a thin working cutting area, tapered cutting edges and a thicker tail (a couple of times thicker than the working part), which provides improved tool rigidity.

The essence of the countersinking process

Countersinking and drilling are closely related. Typically, countersinking is carried out along a finished hole, but there are cases when it is necessary to make a recess without pre-drilling. In both versions, a countersink tool of different designs is used.

The countersinking process itself is very simple: a special cutter is used to chamfer the hole. The more metal removed, the larger the depression. The countersink shape is usually conical. The main thing here is to maintain strict alignment of the cutting element and the hole: there must be perfect alignment. Otherwise, there will be a displacement of the recess relative to the hole, and the screw head will not be able to fit into it.

To perform a countersinking operation to obtain chamfers and recesses, it is necessary to go through the following process steps:

- Measure the head of the threaded hardware for which the recess will be made (this means both the diameter, height, and bevel angle if the head has a countersunk design).

- Select the appropriate countersink and secure it in the drilling or turning equipment.

- Strictly observing the relationship of the axes, fasten the workpiece with the hole opposite the cutter.

- Turn on the drilling equipment and set the required number of revolutions (if the circuitry of the machine allows it) or deliberately select the necessary tool for the equipment parameters.

- Countersink the hole.