HomeHands from the right placeKerno. We drill where we need to!

Anyone who has ever tried to drill into solid surfaces knows how difficult it is to make a hole exactly in the intended location. The drill tries to slide at least a little to the side. I have to try again several times. But if there is already at least a small hole in the right place, the process goes much faster. But how to do it? For this purpose, a special core tool was invented, also known as a center punch.

The process of marking cores (holes for installing a drill) goes like this. Hold it with your left hand. The sharp end of the tool is placed at the location of the intended hole. With the right hand, a precise blow is applied with a hammer to the butt plate (flat part). A mark from the punch (core) appears on the surface being processed. This word should not be confused with the concept in geology, where it refers to rock obtained by drilling.

To prevent the hand from sliding over the tool during operation, the cylindrical surface is covered with special notches or knurling. The conical (working) part is sharpened at a certain angle. The sharper it is, the higher the marking accuracy. A core with a sharpening of 30-45° marks the centers of circles, 75° is used when marking a hole for a drill.

There is no point in sharpening the core with emery, since its material cannot be processed in such a way.

Application

Using a core, you can make marks on any surface. It is advisable to use it when working with smooth materials. These are tiles, polished surfaces. Most often it is used when drilling metal. Therefore, core samples are often referred to as metalworking tools.

Masons also actively use it. Special mason cores have been created for this purpose. They are not much different from locksmiths. They are often powder coated in a bright color to make them easier to find if lost.

A core is also used to make the processing lines visible. To do this, the applied markings are passed through with frequent cores, making it dotted.

What are they?

- manual;

- automatic;

- electrical;

- with special capabilities (a center finder for applying a core on cylindrical or spherical parts, a device for applying markings at the required distance from the edge of the workpiece).

Automatic center punch allows you to:

- Review: Automatic core AliExpress - Great idea! Useful and convenient tool.

- mark with one hand;

- work without a hammer;

- adjust the force when working with delicate materials;

- obtain marks of the same depth;

- get the job done faster.

Automatic core allows you to make up to 50 shots per minute with a distance of 2 cm between holes.

Instead of a core tip, you can insert a stamp into the rod and brand the parts.

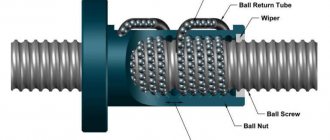

An automatic (mechanical) core looks a bit like a metal fountain pen. It consists of two chambers, each of which has its own firing pin. The first one is made in the form of a cut cone. There is a striker there, which will apply cores to the surface. Behind it is a spring-loaded striker with a guide rod. Its spring is slightly offset to the side.

Behind it, inside the housing, there is a through hole. In the second chamber there is a piston with a beveled edge, spring-loaded by a powerful spring.

When the tool is placed on the surface and the thrust cap is pressed with the thumb of the right hand, the striking pin rests against the edge of the spring-loaded piston, lifting it. The spring behind it compresses and creates counter pressure.

At the end of the compression process, centering and alignment occurs towards the primary chamber. This leads to the rod breaking off and falling sharply into the hole.

The spring pressure is transmitted to the firing pin through intermediate elements. It hits the surface of the material, and a hole from the automatic center punch remains on it.

- Do-it-yourself multi-tasking spring center punch

In some models, the lower striker can be changed, thus extending the service life of the tool.

The impact force of the automatic core can be varied by turning the stop cap at the top of the tool. In this case, the spring underneath is weakened or compressed. The minimum impact force is 10 kg, the maximum is 15 kg. The depth of the hole is from 0.2 to 0.3 mm.

Electrical core

In electric punches, inside the body there is an electromagnet coil, a tip, a spring and a striker. After pressing the body, it lowers; the washer of the tip, which does not move at this time, closes the electromagnet circuit. The impact occurs when the solenoid retracts the ferromagnetic striker. He hits the tip, leaving a mark on the surface.

Types of center punches - photos

In addition to the manual version of this tool, there are other varieties of it.

- A punch compass , in addition to clear punching around the circumference from a given (and punched) center, allows for punching at a predetermined distance from the edge of the workpiece, which is convenient if there should be a lot of such cores. In addition, the leg can be replaced with a simple extension device and, again, set aside the required distance from the edge, reducing the number of marking lines.

- The punch bell is designed primarily for punching spherical surfaces. Installed on the ball, it will flawlessly self-install on its top, which is why it is also called a center finder. The base line can be a circle drawn along its skirt. Also, using a center finder, it is easy to core the centers of the ends of cylindrical figures, of course, if the diameters are suitable.

- A mechanical spring punch allows you to punch with one hand; it is only important to set it strictly perpendicular and not change this position when pressed. Among its advantages is also the same depth of the obtained cores. And the ability to adjust the force makes it possible to work even with fragile or soft materials without fear of damaging them.

The factor of obvious increase in the speed of core punching is also important.

4. In an electric punch, an induction coil retracts a spring-loaded firing pin. Everything else is very similar to the mechanical version of the instrument.

Which core to choose?

A simple core is the cheapest, an electric one is much more expensive. When choosing a tool for yourself, decide how often you are going to use it. If only from time to time, then a regular or inexpensive automatic one is enough (so that you can do without a hammer). For professional activities, buy a high-quality mechanical or electrical one.

Home > Technologies > Marking of metal products

In the production of metal products, the source material - castings, sheet and profile products - does not correspond in size and shape to the designer's drawing. To cut off excess metal, drill, stamp, weld, or otherwise process a workpiece, key points of the drawing are applied to it. Applying to these points and lines, the processing is carried out.

What is markup

The operation of applying the dimensions and shape of a product to workpieces is called marking. The purpose of the operation is to designate the places where the part should be processed and the boundaries of these actions: drilling points, bend lines, weld lines, markings, etc.

Marking is done with points, which are called cores, and lines, which are called risks.

Marks are scratched into the metal surface with a sharp tool or applied with a marker. Cores are filled with a special tool - a center punch.

- What is a center punch, its types, working methods, photos

Defining markup Markup tools

According to the method of execution, there are such types of markup as:

- Manual. It is made by mechanics.

- Mechanized. Performed using mechanization and automation tools.

Based on the application surface, they are distinguished

- Superficial. It is applied to the surface of the workpiece in one plane and is not associated with the lines and marking points applied to other planes.

- Spatial. It is carried out in a unified three-dimensional coordinate system.

Notes on straightening and marking for thin sheet metal

The choice between surface and spatial markings is determined, first of all, by the complexity of the spatial configuration of the part.

Applying marks

The standard regulates the procedure for drawing marking lines:

- horizontal;

- vertical;

- inclined;

- curvilinear.

Applying curved elements after straight ones provides another opportunity to check their accuracy. The arcs must close the straight lines, the interface must be smooth.

Direct marks are carried out with a well-sharpened scriber, without tearing off, in one step. At the same time, the scriber is tilted away from the ruler or square so as not to introduce distortions.

Parallel lines are drawn using a square and moving it along the reference ruler to the required distance.

Applying mutually perpendicular and parallel marks Applying marks at an angle to each other

If the workpiece already has holes, then a special tool, a center finder, is used to attach marking lines to them.

In order to mark inclined lines, use a marking protractor with a hinged ruler fixed at its zero point.

For particularly precise markings in plumbing, calipers are used. They allow you to measure distances and scratch marks with an accuracy of hundredths of a millimeter.

Marking marking lines

In order to more accurately carry out the risk, cores are placed at its beginning and end. This allows you to visually control the position of the ruler while drawing.

On long risks, auxiliary cores are also placed every 5-15 cm.

Circle lines are marked at four points - the ends of perpendicular diameters.

If already treated surfaces are marked, then punching is used only at the beginning and end of the marks.

Marking marking lines

After finishing, the marks are extended to the side surfaces and the cores are placed on them.

Marking techniques

The following techniques are used in plumbing:

- According to the template. Used in case of small-scale production. The template is made from rolled metal, the entire batch is marked (or even processed) through once marked slots and holes in this sheet. For parts with complex shapes, several templates can be made for different planes.

- Following the example. The dimensions are transferred from the part - the sample. It is used in the manufacture of a new part to replace a broken one.

- Local. Used in the production of complex multi-component products and structures. Blanks are placed on a plane or in space in the order in which they enter the final product and are marked together.

- Pencil (or marker). Used for workpieces made of aluminum alloys so that the scriber does not destroy the passivated protective layer.

- Accurate. It is done using the same methods, but special precision measuring and marking tools are used.

Techniques for marking metal parts

The selection of techniques is carried out in accordance with design and technological instructions.

Marriage during marking

First of all, when marking, defects that were made at previous stages of production emerge. Products from procurement sites or workshops, as well as materials purchased from other enterprises, reveal:

- violation of dimensions

- shape distortion

- warping.

Such castings or rentals are not subject to further marking operations, but are returned to the department or organization that caused the defect to correct it.

At the marking stage itself, defects can be caused by the following factors:

- Inaccurate drawing. The mechanic, without hesitation, displays incorrect dimensions on the part, and during further processing, defective products come out.

- Inaccuracy or malfunction of instruments. All marking tools are subject to mandatory periodic verification by the metrological service of the enterprise or an authorized metrological center.

- Incorrect use of tools or marking accessories. There are known cases when instead of calibrated measuring pads, ordinary pads were used to set the level. In this case, erroneous application of angles and slopes is also possible.

- Inaccurate placement of the workpiece on the marking table or plaza. They lead to distortions when setting aside dimensions, violation of parallelism and coaxiality.

- Wrong choice of reference planes. It is also possible that some of the dimensions were applied from the base planes, and some from the rough surfaces of the workpiece.

Marriage during marking

Separately among the reasons for defects are the marker's errors. These include:

- Incorrectly read drawing. It is possible to apply a radius instead of a diameter and vice versa, inaccurate application of the centers of holes relative to the center marks, etc. If any difficulties arise, the mechanic must seek clarification from the foreman or foreman.

- Carelessness and inattention when punching and drawing lines.

The human factor, unfortunately, is the most common cause of marking defects.

Negligence can be committed by both the mechanic himself and his supervisors, who did not check the tool on time or issued inappropriate marking devices.

Typically, marking operations are entrusted to the most experienced and responsible workers, counting on the fact that they will not mechanically transfer dimensions from the drawing to the workpiece, but will treat the matter thoughtfully and promptly notice and eliminate the reasons for possible defects on their own or by contacting their managers.

If you find an error, please select a piece of text and press Ctrl+Enter.

A punch is a metalworking tool, shaped like a metal rod, one side of which is sharpened, and the other is prepared for striking with a hammer.

This tool is also called a core; its purpose is to create holes that make further drilling of the material as convenient as possible.

This recess prevents the drill from suddenly slipping and ensures that the hole is created in the desired location.

How to make a punch with your own hands

For those who do not want to pay 300 - 500 hard-earned rubles for a center punch of more or less normal quality, there are several options for making this tool on your own. We have already mentioned the first one - from a hexagon.

To make a simple punch from this material, it is enough to grind its striking part, sharpen its tip to a given angle and harden it and the striker. And this can be done even on a regular gas stove, heating the metal until it glows bright pink. Although it is much faster to do this with a gas torch or a gasoline blowtorch, which, we hope, you already have in your workshop.

The heated metal must be lowered for 4-5 seconds. into the water, then for 1 second. remove and lower again another 10 -15. If you perform the same procedures, but dip the tool in oil, it will turn blue, which is even better.

You can also quickly make a primitive, but quite workable center punch from an old drill whose side edges have lost their functionality, and therefore cannot be sharpened, by simply sharpening its end.

However, we still do not recommend using such a tool in its pure form - it is very fragile and can break upon impact and cause injury. As a last resort, put a piece of high-pressure hose on it, as in the version in the photo, but better - select a metal sleeve from a tube of suitable diameter or grind it.

In addition to the options mentioned, there is a way to make a center punch from almost any steel, but only carbon steel can be hardened. If you are not sure about the carbon content in it, then you can check this by sparking when processed on a grindstone. And here is the video:

And if you did not see the long-awaited stars when sharpening a suitable rod for making a center punch, then you can carry out the cementation process, which we mentioned at the beginning of the article. There are two ways to do this at home. If you have a welding machine on your farm, then the one shown in the video is the most acceptable and simple.

And if purchasing a welding machine is still in your plans, then look for a nearby metalworking plant where they sharpen cast iron parts and collect cast iron shavings, the smaller the better.

Or buy cast iron powder online. Having heated the metal to the same bright pink glow, lower the part of the workpiece that needs to be quenched into cast iron shavings. The carbon from the cast iron will move into the surface layer of your mild steel and allow it to harden.

The procedure can be repeated several times, but sharpen the center punch before it. However, the instrument can be repaired in the future in the same way.

We recommend other articles on the topic

Miter box - from simple to precision, how to use the tool correctly

Construction rule - how to choose and use tools correctly

Vernier caliper - device, how to use the tool, photo

Sharpening a kitchen knife at home

Device and characteristics

As mentioned above, the device is made in the form of a cylindrical rod.

One side is prepared for striking with a hammer, it is called a striker or butt plate, the other is sharpened in the shape of a cone, and the sharpening angle is 120 degrees.

Working with a manual punch is carried out in a simple way: the sharp side of the device is installed at the place where it is planned to drill in the future, and then a blow is struck on the opposite side of the device with a hammer.

The procedure requires some physical effort and time, which is why modern punches are made mechanical or automatic.

The design of a mechanical tool is based on the tight compression of a spring built inside and its subsequent release.

The impact on the butt plate is carried out due to the cocking and trigger mechanism.

In this case, a hammer is not required for applying cores.

In an electric automatic device, work is started due to the action of an electrical circuit built inside the punch.

Moreover, the process takes little time and in one minute the master is able to make at least 50 holes.

Mechanical (spring) center punch

The device of a spring punch In addition to manual punches, there are also automatic punches - “crossbows” with a cocking-trigger and spring mechanism.

The design of a mechanical tool is based on the tight compression of a spring built inside and its subsequent release. Among automatic punches, the most common are manual mechanical ones, which allow you to apply markings with one hand. Most of them use a Sweet mechanism with an intermediate pusher, and only high-force industrial models use other types of mechanisms without pushers.

Design of Gorin's mechanical center punch The tool contains a spring mechanism inside that drives the striker. The advantage of this modification is that, firstly, it allows marking with one hand, without the use of impact tools, and secondly, the impact force of such a center punch can be adjusted, which can be significant when working with soft or fragile materials or critical parts, requiring increased processing accuracy; marks on parts obtained using an automatic center punch have the same depth. Thirdly, the use of an automatic center punch allows you to increase the speed of marking.

Types of core samples and their purpose

Types of core differ in their operating principle and main purpose. In the arsenal of locksmiths you can find the following types:

Manual locksmith

Designed for working with metal, tiles, and other types of polished or smooth surfaces.

Center punch compass

It differs from the classic version in that it allows you to make holes at a preset distance.

Kerner bell

Used for punching surfaces shaped like a ball.

Adjustable centering core

The name speaks for itself, the tool can be adjusted.

Mechanical center punch

Allows you to carry out work with one hand and without using a hammer, while the depth of the holes is always the same.

This device is ideal for working with fragile, soft materials.

Automatic center punch

It differs from the mechanical type only in that it contains a solenoid inside itself, which draws a spring-loaded striker into itself, due to which the impact is carried out on the material.

The automatic device is the most convenient to use because it does not require any physical effort.

Homemade core

It is used to work with a wide variety of materials: from plastic to copper, bronze and other types of non-ferrous metals.

For professional use, both an automatic and a classic device are usually purchased, but for home use, when the use of a center punch is required extremely rarely, you can get by with a homemade one.

Electric punch

The electric punch contains a solenoid inside itself, which draws a spring-loaded striker into itself, due to which the material is struck.

Design of an electric punch An electric punch consists of a body, springs, a hammer, a coil, and a punch. When the tip is pressed on the material, indentation occurs and the electrical circuit is closed. The current passing through the coil creates a magnetic field, the striker is instantly drawn into the coil and strikes the punch rod. During the transfer of the punch to another point, the spring opens the circuit, and the spring returns the hammer to its original position.

What you need to know about the center punch

When choosing a core sample, you need to remember several important points about this type of instrument.

Firstly, it does not matter at all what cross-sectional shape the tool rod has.

It is much more important to pay attention to its other characteristics.

Secondly, you should buy a device based on the diameter and type of drill with which it will be used.

Thirdly, if you plan to use a center punch when working with soft metals, it is better to choose one with a smaller sharpening angle and vice versa.

Kerner - what is it?

The center punch is a metal rod made of tool steel with a sharpened striking part, sharpened at an angle of predominantly 120° and hardened to a length of 20 - 30 mm, and a striker on the other side, also heat-treated, but 10 - 15 mm. It is also called the butt plate. Used in metalworking to obtain holes or cores necessary for the convenience of drilling material.

Most of the tool remains unhardened, and therefore less fragile, which is done primarily for the purpose of safety of its use. The cross-sectional shape of the punch rod does not play a special role: it can be round, and then it is often knurled to make it more convenient to hold it in the hand, or maybe hexagonal. The material of the hexagons is carbon steel, amenable to heat treatment, therefore, if you need to quickly make a center punch at home and find a hexagon with a suitable cross-section, you can safely use it - it will accept hardening without carburization (saturation of the surface layer of steel with carbon).

Punching, in almost all cases, is carried out for subsequent drilling of the material, so that the drill does not slide along the surface of the workpiece at the initial stage of drilling. But there are also options...

Depending on the diameter of the drill, the dimensions of the punch are also selected, but this more often happens in production during mass punching to produce holes of different diameters.

Also, the sharpening angle of the punch may be different, because for soft metals the drill is sharpened at a smaller angle.

How to use a center punch

Like any other professional tool, all types of center punches require compliance with certain rules for working with them.

Only in this case can we guarantee the best results and safe operation.

While there are ways to rework an incorrect core, they will require more skill than the original hole punching.

Pneumatic punch

The pneumatic punch is used for various core drilling operations using compressed air. For convenience, it is equipped with a handle located at an angle to the body axis and a start button.

Design of a pneumatic punch A pneumatic punch works as follows. Under the influence of compressed air, the striker inflicts periodic blows on the shank, which bounces off the workpiece and transmits shock impulses through the axle box to the body. Due to the high efficiency of reducing the energy of shock pulses by elastic damping elements, both in the punching mode and in the idle mode, only a small part of the shock pulse energy will be transferred to the body.

Basic Rules

In order to correctly perform the procedure for working with any type of punch, you need:

1. Markings are applied to the material on which holes need to be made.

2. The striking part of the center punch is aligned with the intersection of the marking line.

3. After this, the device is installed strictly perpendicular to the material.

4. Depending on the type of device, impact is applied (with a hammer, using a trigger mechanism or other available method).

If each step is strictly followed, the result of the core will be accurate, and the hole will be of the correct shape, which will allow you to drill an even hole in the future.

Techniques for working with a center punch

There are only two ways of punching: one is correct, the second is incorrect.

For core you need:

- Align the tip of the striking part with the intersection of the marking lines;

- Place the punch strictly perpendicular to the surface of the workpiece;

- Apply one confident, accurate blow to the striker with a hammer, trying to ensure that the vector of the blow coincides with the axis of the punch.

That's all, failure to follow these rules will lead to a violation of the accuracy of the core or the shape of the hole, which may cause the drill to move away.

If you made a mistake when punching, then do what no plumbing textbook will advise you to do:

- Gently, with light blows of a hammer, bring the edges of the core funnel down to the level of the workpiece; if necessary, treat this area with emery cloth mounted on a flat block;

- Resume the marking lines;

- Take a punch of a smaller diameter with a sharpening angle of about 60° (for such cases you need to keep it in your home workshop);

- Perform the punching procedure with extreme care, but with less impact force;

- After making sure the location of the new core is accurate, take a standard punch and, aligning its tip with the new hole, perform the core with one strong blow.

How to choose the right core

To choose the most suitable type of device for yourself, you need to be guided by two factors: your own financial capabilities, the purpose of purchasing the device.

The cheapest type is a regular bench punch, which will be sufficient if you plan to use it in rare cases.

The most expensive type is the electric automatic center punch.

It, as well as mechanized types, are purchased by professional mechanics for daily work.

How to make a core with your own hands

You can make the simplest type of tool yourself, using a hexagon as a basis.

At the same time, its striking part is ground, and the tip is sharpened with a certain amount of coal, after which the tool is hardened on both sides.

A regular gas stove is suitable for hardening.

The metal needs to be heated to a bright pink color, and then placed in water for a few seconds, pulled out, and immediately lowered again, but holding the tool in the water a little longer.

This simple type of device is quite suitable for home repairs, and its production will take no more than an hour.

Do-it-yourself center punch

You can make a center punch yourself, but it is important to use high-strength steel.

As a base, you can use an unnecessary drill for a hammer drill, a chisel or a valve stem from a car engine. True, with high labor costs, homemade devices are significantly inferior in quality and ergonomics to factory ones. It is much easier, in the absence of a center punch, to replace it with an ordinary mounting dowel-nail. For their production, high-strength carbon steel grade Art. 70, and the hardness on the Rockwell scale ranges from 53 to 56 HRC. Based on the mounting dowel, it is possible to produce a core punch that is significantly superior to specimens from China.