Any plasterboard construction, with rare exceptions, requires a frame made of a metal profile. It can be cut in different ways - for example, with a hacksaw or a grinder. But with fasteners everything is more complicated - making them in the traditional way is not always effective and convenient. To do this, it is better to use a tool specially designed for the procedure - a profile cutter. Let's talk in more detail about how to choose this tool.

Using a cutter for metal profiles: positive aspects and purpose of the device

Installation of a metal profile frame is an important step in cladding various surfaces or creating new interior partitions. To fix the guides together, the best option is to use a cutter, since it can significantly speed up construction work. This device has many positive qualities due to its design features. They look like this:

Tips and tricks

You need to know the following:

- to create a hole or high-quality fastening, you need to use only the tool that is designed for the appropriate thickness of the metal profile;

- when punching, it is prohibited to make sudden shifts of the parts and the cutter itself, as this will lead to insufficient quality of the cut area;

- hitting the tool to enhance the breakdown is prohibited;

- install the cutter only in position 900 to the material being joined;

- in areas where metal profiles join or where the profile has been extended, punching a groove is prohibited;

- The connecting joint of the cutter parts must be regularly lubricated with the appropriate type of lubricant.

Advantages and disadvantages

The cutters can have very different shapes depending on the manufacturer.

The cutter is a device for fastening profiles together. Many people have mixed views on him. The majority agrees that it is necessary; a minority considers this method of fastening to be very unreliable. Let’s understand the situation by showing what positive qualities a profile cutter has.

- Saves time. But really, with such a tool the work goes much faster. Using rivets or screws for metal takes much longer.

- After using the cutter, there are no burrs, dents or roughness left on the profile surface on the front side. As a result, the drywall will lie evenly on the frame. If you fasten it with self-tapping screws, the drywall will protrude slightly at the fastening point due to the thickness of the cap.

- Saving money on fasteners. You will not need to buy small metal screws to fasten the guides with them. There is also no need to buy anything extra for the tool itself.

- Easy to use. Working with the tool is simple and intuitive. You just need to have enough force to apply pressure on the handles.

- A high-quality drywall cutter creates a reliable fastening. Such a unit can withstand not only a sheet of drywall, but also much larger loads.

I would like to immediately dwell on the negative aspects. The last paragraph talked about a quality tool, but not all of them are like that. Cheap cutters can make weak notches that are easily loosened, which leads to weakening of the fastening. Sometimes more expensive cutters also do this. Therefore, before choosing a tool, you need to make sure that it makes the correct cuts. In this case, there is no need to spare money.

Kinds

What kind of cutter do you use?

NormalReinforced

There are 3 types of metal profile cutters:

- Regular

The cheapest options are named. Suitable for relatively small amounts of work.

They have the following distinctive features:

- less durable (compared to other varieties) connection of parts;

- less durable material;

- less penetration force;

- less work resource.

Expert opinion

Levin Dmitry Konstantinovich

Due to the low penetration force, most models in this category are not capable of working with profiles thicker than 1.5 mm.

Reinforced

Heavier and more expensive instrument. Has greater penetration power and lasts longer. Capable of working with metal profiles from 1.5 cm. In this case, jamming does not occur.

Reinforced models are often used by professional builders.

- Professional tool

Designed for use by professional craftsmen and capable of penetrating even a fairly thick layer of metal. It has a more massive design: everything in it is reinforced, from the punch and frame to the spring.

Devices are classified according to other criteria. For example, depending on how many hands are involved in the work, they are:

- one-handed;

- two-handed.

The latter provide greater penetration power, and the latter provide greater operating speed.

Different models may differ in the diameter of the bracket. The smaller it is, the more difficult-to-reach places installation can be carried out. However, this also has disadvantages - the penetration force is limited, and the thickness of the metal available for work is reduced.

Working with the tool step by step

Before you start installing a profile using a cutter, you first need to make sure that the tool is in working order and works with this thickness of metal. To do this, you can make several test connections, inspect them carefully, and then try to forcefully separate and shake them. By the way, the strength of the connection depends not only on the cutter, but also on the quality of the profile metal. If it does not comply with the standard, then even with good flaring you can get a fragile structure. Connecting two profiles using a cutter is performed in four steps:

The best hand models

Let's look at several current models of hand tools.

Sparta

A simple and inexpensive, but very convenient tool. Made of durable stainless steel coated with anti-corrosion coating. The handles have polymer pads that prevent slipping and improve grip. Designed for connecting metal profiles up to 1-1.2 mm thick.

Thanks to the small diameter of the bracket, it is quite maneuverable and easily allows you to connect the profile even in hard-to-reach places.

The average cost of the model in Russian stores is 500-600 rubles.

SIBIN 3132

Inexpensive cutter. Structurally, it is almost no different from Sparta, but has a larger diameter bracket and is a little more massive. Thanks to this, the model can be used to work with profiles up to 1.5 mm thick.

The average cost in Russian stores is in the range from 700 to 800 rubles.

DEXX 31391

An inexpensive but high-quality cutter that can be purchased for 500-600 rubles. It stands out among other budget devices due to its high-quality assembly. Capable of working with metal profiles up to 1 mm thick.

DIY profile cutter

One-time household work related to strengthening racks or guide rails can be carried out with some types of pliers, previously modified into the shape of a teether. The latter, like pliers, is equipped with lever handles, a cutting edge, a spring and a rotating mechanism. To turn them into a stitcher for galvanized structures or thin-walled sheets, you need to install a bushing on one lip and a tool steel punch on the other.

Of course, a homemade divider will differ from an industrial one in some inconveniences, but it’s also not worth buying a specialized tool for a one-time use.

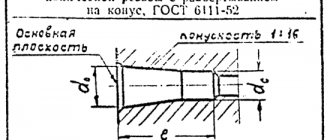

Profile cutter device: 1 - bracket, 2 - first leg, 3 - second leg, 4 - bracket opening, 5 - bracket base, 6 - stop, 7 - recess, 8 - working gap, 9 - punch, 10 - working end, 11 - fixed handle, 12 - base of the fixed handle, 13 - free end of the fixed handle, 14 - hinge, 15 - hinge travel limiter, 16 - frame, 17 - frame opening, 18 - movable handle, 19 - ring, 20 - free end movable handle, 21 - hook, 22 - fixed axis, 23 - first movable axis, 24 - second movable axis, 25 - third movable axis, 26 - corresponding holes, 27 - second guide slot, 28 - rocker arm, 29 - first end turn , 30 - second final turn, 31 - parts to be fastened

A cutter for metal profiles for plasterboard is an innovative working tool for the builder, renovator and home craftsman. Redevelopment or insulation of walls, a simple partition or a figured ceiling - everything is within the power of this stitcher. With it you will forget about screws, screwdrivers, and bruised fingers.

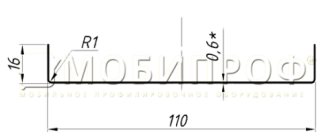

What are the types of plasterboard profiles: types and sizes

For the manufacture of the profile, cold-rolled metal sheet treated with galvanization is used. The products are strong, practical and reliable. After all, corrosion is not dangerous for a galvanized surface, and therefore this profile is destined to have a very long life.

The metal frame used to install drywall is simple in design. It includes horizontal and vertical parts. The latter are called load-bearing, or rack-mount, elements. The guides, or starting elements, are located perpendicular to them. Choosing a suitable profile for plasterboard partitions is not so difficult. First, let's list all their types.

Rack profile (CD or PP profile)

Rack profiles (also called ceiling profiles) are one of the most popular. They, according to Knauf markings, are designated by the letters CD. Similar products of the Giprok brand are called PP profiles. Thanks to their optimally selected dimensions, space is used rationally and economically. When working in rooms of any size, there is virtually no waste left.

This profile is used to make a frame for cladding walls and suspended ceilings.

Profile sizes:

- Length – from 2.5 to 4 m;

- Width – 60 mm;

- The height of the shelves is 2.7-2.8 cm.

Guide profile for cladding (UD or PPN)

UD (or PPN) profiles are frame guide elements. When covering a wall with plasterboard or constructing a suspended ceiling, you need to mount such parts along the entire perimeter of the plane. Since when installing these profiles the drill passes directly through them, it is desirable that they be perforated. After all, it will be much easier for the drill to enter the holes.

They are used as guides into which rack profiles are inserted.

Drywall guide dimensions:

- Length – 3 m;

- thickness – 0.55 mm;

- width – 2.7 cm;

- height – 2.8 cm.

Profiles for creating partitions - UW or PN

Guide profiles for creating partitions are marked UW or PN. To make it possible to make a partition of any thickness that is needed, these parts are produced in a wide range of standard sizes, in particular widths.

They are used in the frame as guides when creating partitions.

Profile sizes:

- Length – from 2 to 4 m;

- shelf height – from 3.7 to 4 cm;

- width – 4.2; 5; 6.6; 7.5; 10; 12.5; 15 cm.

Profiles for partitions - CW or PS

Rack profiles for walls are marked with the letters CW or PS). Their width matches the starting elements. High-quality products always have a special notch to facilitate the laying of communications. The PS profile part from Giprok has an additional stiffening rib, which creates a bent edge.

Used to create a frame when installing partitions.

Profile dimensions for plasterboard:

- Length – from 3 to 4 m (special lengths are made to order);

- shelf height is 5 cm for Knauf and 4 cm for Giprok;

- width - in accordance with the UW or PN profile.

Arched profiles

Special curved profiles can have both convex and concave surfaces. They are used when it is necessary to make a structure of complex shape, with bends and curved planes (for example, an arch). However, if necessary, our craftsmen have learned to make do with rack profiles.

Dimensions of arched profiles:

| Concave | Convex | ||

| Radius, mm. | Length, mm. | Radius, mm. | Length, mm. |

| 500 — 1000 | 2600, 3100, 4000 | — | — |

| 1001 — 2000 | 1001-2000 | 2600, 3100, 4000 | |

| 2001 — 3000 | 2001-3000 | ||

| 3001 — 4000 | 3001-4000 | ||

| 4001 — 5000 | 4001-5000 | ||

| > 5000 | > 5000 |

Operating principle and cost of various device models

The operating principle of the cutter is always the same and is based on the action of physical force, which creates a mechanical torque through a lever. When you press the movable lever, it feeds the punch into the eye, and the roller additionally fixes it. Depending on the applied force, the mechanical component acting on the metal also changes. In this case, the main lever remains stationary and holds the punching mechanism, creating all the necessary conditions for the operation of the device.

Read also: How to crochet bells?

An example of the correct use of a cutter

The punch passes through the metal base, leaving a hole in it. At the moment of penetration, the iron edges of the two profiles bend outward, interlocking with each other. The result is an excellent attachment point that can withstand the applied loads. In this case, several punctures are made for better fixation.

Today, on the shelves of construction stores there is a wide range of cutters, differing in their appearance and functionality. However, their purpose does not change depending on the design and is to speed up the process of installing a metal frame. Depending on the manufacturer of the device, its price also varies, which can differ significantly:

- Sparta - 400-500 rubles;

- Matrix - 800-1 thousand. R.;

- Stanley - 8-10 thousand rubles;

- Bison - 800-1 thousand. R.;

- Knauf - 5-6 thousand rubles;

- Knipex - 10-12 thousand rubles.

Devices for carrying and maintaining drywall sheets

When working with drywall, it is not very convenient to perform some actions, since massive slabs often have to be moved from one place to another. Also, certain difficulties may arise in cases where it is necessary to hold the mounted material at a height. Special devices that are used by many professional craftsmen help cope with such tasks.

Carrying handles for drywall

There are models of carrying handles designed both for work in pairs and for one person. In the first case, a set of two handles is used, which allows you to grab the plasterboard at the required height and carefully move the material, holding it in the desired position with your free hand.

For work performed alone, a carrier made of plastic or metal is intended, due to the design of which the sheet is sufficiently securely fixed. This device is convenient to use at home if repairs are carried out without the involvement of assistants.

Three wheel trolley

To transport drywall on a large construction site, it is advisable to use a trolley on which up to 400 kg of material can be loaded. The length of such a device is usually about 1.2 m, and the width is at least 0.6 m. If it is necessary to transport sheets, they are installed on the edge, maintaining a small angle of inclination. It should be noted that the larger the diameter of the trolley wheels, the easier it is to transport through an area that has not been cleared of construction waste.

Mounting support

This tool for working with drywall is a device in the form of a lever located on a stand, which is equipped with a metal movable stop necessary to hold the material. In the process of covering walls, as well as creating niches and partitions, such a device ensures the vertical position of the sheet, which is attached to the profile. At the same time, the integrity of the lower edge of the mounted gypsum board is preserved.

Pedal lift

Allows you not only to quickly fix sheets during wall covering, but also to press drywall to the ceiling. However, it will be difficult to install drywall without the help of a partner, since such a design limits the movement of the master.

Frame lift

For some complex work, in particular those related to the installation of ceiling structures or ventilation elements, the ideal option would be to use a mobile device such as a frame lift. It can be used to move and install sheets in both vertical and horizontal positions. This tool for installing hypocardboard allows you to securely fix the material on the frame, which is especially convenient when creating continuous suspended ceilings. The lift is equipped with wheels, due to which the gypsum boards are moved almost effortlessly, which in turn has a positive effect on the quality of installation.

The total weight of such a device is usually about 26 kg. At the same time, it can be used in work performed at a height of up to 3 m. The maximum permissible weight of transported materials is 50 kg. With such a device at his disposal, one person can easily install sheets of drywall without involving assistants.

Some technical characteristics of models offered by different manufacturers may vary slightly. In addition, there is such a device as a spacer lift. It is mainly used when working with suspended ceilings.

With a limited budget, not every home craftsman can afford to purchase a special device. However, it will be quite difficult to efficiently install a solid suspended ceiling without auxiliary equipment. In this case, it makes sense to make two T-shaped supports yourself. The length of the stand of such a product is determined based on the height of the room, so that the material can be ensured a tight fit to the ceiling. Craftsmen successfully used such devices before the first lifts went on sale. A partner is expected to be present during the installation process.

Features and Benefits

Installation of plasterboard facing sheets involves two main options for their fastening:

- fastening with glue;

- fastening to a metal frame.

The latter method, of course, will to some extent “eat up” the usable free space of the room, but craftsmen prefer to use it. The choice of this option is optimal in order to firmly secure the guides to each other. This connection has maximum strength and reliability compared to other methods.

How to choose a good model

When the question arises about choosing a cutter model for installing a metal profile, then first of all it is necessary to decide what volume of work we are talking about and how long it is planned to be used. If this tool is needed to install a couple of partitions, cover several walls, or construct a panel covering a toilet cistern, then almost any inexpensive model that has a good reputation among users will do. When choosing for professional use, you should first pay attention to the following points:

Device

The cutter, or, as it is otherwise called, profile pliers, consists of several components.

Parts of the cutter:

- The bracket has two legs; the bracket has a stop with a recess;

- Fixed handle firmly attached to the bracket;

- A movable handle mechanically connected to a lever and a punch.

It is worth mentioning the loop: it serves for convenient storage of the cutter in a closed state. Movable axes are responsible for the movement of working parts.

The device of the cutter

Choosing the Right Tool

The question of which cutter is best for connecting profiles does not have a single answer. However, it is possible to outline the qualities that a tool must have to be considered good enough for the job. And in general, it’s worth paying attention to how this device works.

Detailed device of the cutter

Just 10 years ago it was difficult to find a cutter that could be used to assemble a drywall frame. Now there are no such problems. In fact, there are so many cutters that it is difficult to make a choice. They come in different brands, models and types. According to their design, they are divided into the following types:

- manual. The most popular and cheapest variety. This tool is shaped like pliers that punch a hole in the profiles, which allows them to stay together. Expensive models also bend the antennae on the back side of the profile, making the fastening more reliable. A manual cutter for metal profiles under plasterboard is usually designed to be used with both hands;

- pneumatic. This is a professional device that is not advisable to buy for one repair. Such a tool can create several holes at once, and working with it requires a minimum of effort;

- machine tool Such devices are needed only in industrial production and operate automatically.

The simplest model of a cutter is of no less quality than its expensive counterparts. The bracket (eye) of a cutter must be quite large. This is necessary so that the profile can fit into it and the tool is maneuverable enough. This is especially true when working with rack and guide profiles. Sometimes the bracket is so small that you can only work comfortably with the guides, but not with the ceiling profile.

When choosing a tool, you should pay attention to reinforced models. Durable materials are used in their manufacture, and the cutter practically cannot break during operation. Its cutting part can always be replaced if it becomes dull.

Rating of budget representatives

Sparta 87952

One of the popular budget products that is suitable for high-quality connections. Made from durable steel that does not rust or deform over time. The metal part is equipped with special jaws. They promote effective penetration of the material, and also bend the edges into the inside. The maximum fixation thickness is 9.5 mm. The tool is equipped with a rubberized handle, which improves ergonomics.

Sold at price: 510 rubles.

Sparta 87952

Advantages:

- Strength;

- High service life;

- Efficiency;

- Ergonomics;

- Price.

Flaws:

- Not found.

"888" 300 mm 6850501

A good tool for home use, which can be found at a price: from 480 rubles. Thanks to it, stitching a metal frame and connecting drywall will become easier. But it is only suitable for infrequent use, as it has a limited service life.

Made from cheap steel. On the one hand, strength is present and a person will receive a good tool at a low cost, but with frequent use the chance of breakage is 75%. “888” 300 mm 6850501 is suitable for those cases when a person needs to carry out minor repair work.

Sold at a price: from 485 rubles.

"888" 300 mm 6850501

Advantages:

- Low price;

- Stitches well;

- Light weight;

- You can perform operations with one hand;

- Compactness.

Flaws:

- Rubberized handles wear out quickly;

- Small work resource.

Anchor cutter for metal profile 250 mm

The model will provide high-quality connection of metal profiles up to 0.8 mm thick. For fixation, the cutting method with a bend is used. The working part is made of class A structural alloy steel, which increases strength and resistance to corrosion. The handles are completely rubberized, so they do not slip during complex operations and increase ergonomics.

Enkor 250 mm does not provide a wide working area, which can cause difficulties when connecting corner sections. All operations are carried out only with two hands, since there is no return spring.

The average cost is 570 rubles.

Anchor cutter for metal profile 250 mm

Advantages:

- Reliable connection;

- Comfortable handle with anti-slip coating;

- High-quality alloy steel was used in production;

- Optimal price.

Flaws:

- Small work area.

FIT for drywall

This option is more expensive than the previous ones, but allows you to create a high-quality connection in any area. Work is performed only with two hands. The advantages of the model include a wide working space.

The fastening time is 2-3 seconds, and the strength obtained is in no way inferior to traditional methods of fixation. The body is made of tool steel. The handles are made of durable plastic, which ensures comfort.

The average price is 660 rubles.

FIT for drywall

Advantages:

- Good working area;

- Inexpensive;

- Can be used to attach a ceiling profile;

- Simplicity;

- Convenience;

- Reliability.

Flaws:

- In some cases, it is necessary to further strengthen the connection;

- There are models with incorrect sharpening of the punch.

SIBIN 3132, 300 mm

A popular model that belongs to the mid-budget class. The maximum thickness of connected elements is 8 mm. Made from tool steel, which increases corrosion resistance and increases reliability. However, more effort is required during operation, which creates some problems, such as the handle slipping. The firing pin is also often warped, which negatively affects the quality of the connections.

The average cost is 660 rubles.

SIBIN 3132, 300 mm

Advantages:

- Possibility of connecting the guide and ceiling profile;

- Wide working space;

- Easily copes with small amounts of work;

- Durable housing.

Flaws:

- At times the firing pin warps;

- Inconvenient handles;

- The insulating material may come off.

Varieties

There are three main types of cutters:

- manual;

- reinforced (pneumatic);

- professional.

The manual cutter has a convenient lightweight design, fits in one hand, is inexpensive and can withstand the stress of home repairs. The reinforced, or pneumatic, cutter is popular among users. It is made of tool steel and often has a removable cutting structure. Its service life increases significantly thanks to replaceable parts. Professional tools are larger in size, more difficult to operate and are suitable for large repair projects.

Conventionally, according to their functionality, cutters are divided into the following types:

- small-sized types of cutters are more popular because they are cheaper in cost and more convenient to use when talking about repairs that are carried out occasionally;

- the enhanced version of the flasher is convenient for the work of small teams of repairmen, if they mean work in domestic and utility premises;

- A professional cutter should be used when implementing large-scale projects, large volumes of capital construction, and when installing partitions in premises.

The first two types of such instruments are attractive due to their low cost and relatively small size. The third type of cutter also has its advantages - it can be used for a long time, it can perform more functions. There are also flexible cassette cutters that use a needle roller.

It is necessary to make a small remark: some dividers are used to work with profiles from the same manufacturer, therefore, they cannot be called universal. Therefore, before purchasing it, it is necessary to determine the types of profile that are going to be used, as well as the company that produces the tools and consumables.

How to use the cutter

Installation work can be completed efficiently by adhering to the following rules for using pliers.

How to fasten a ceiling profile (PP) with a guide profile (PPN) using a conventional cutter

- You should start by checking the functionality of the tool. To do this, it is suggested to make several test connections. Based on the nature of the passage of working elements into the plane of the profiles and the quality of the holes, appropriate conclusions are drawn.

- The next step is to check the strength of the connections. Under the influence of forces, the reliability of the frame is controlled. A negative result may indicate low quality of the metal from which the profiles are made. In this case, it is better to make connections with self-tapping screws or replace weak material. Professional flaring does not guarantee a long service life of the frame structure when connected with a cutter.

- Installation work begins with installing the profile. To do this, make markings by placing two parts overlapping.

- The junction is grabbed with pliers. Next, the steel sheet is slightly split.

- The junction of the steel elements is fixed by squeezing the handle. The grip is weakened when using a mechanism with a return spring.

- After releasing the tool, check the strength of the connection.

The quality of the equipment directly influences the result of the connection. If, after fixing the joint, the antennae do not unbend completely, the problem lies in the pliers themselves. When working with a professional device, you should focus on the grip strength of the handle. Heavy pushing is often caused by insufficient impact, so the attempt should simply be repeated (passing through the same holes).

Which company should I buy cutters in the mid-price segment?

BRIGADIER 63046

The well-known model is equipped with a rotary type head. The country of registration of the brand is Russia, but assembly is carried out in China. Such instruments are rarely equipped with rotating heads, so this model is considered an exception to the rule. It is equipped with a hinge and a movable element, which allows connections in hard-to-reach places, which is its main advantage. A cutter from the budget segment can also cope with the tasks, but in some cases such a model will come to the rescue.

Price – 1300 rub.

BRIGADIER 63046 Advantages:

- the presence of ergonomic handles, for the manufacture of which a composition based on plastic and polyurethane is used;

- fits comfortably in the hand;

- does not slip out;

- practicality;

- durability.

Flaws:

- small angle of inclination;

- the weak point is the punch.

STAYER "GRAND"

A popular product from a German manufacturer, which is assembled in the Middle Kingdom. There are several types of cutters on the market. This particular device combines a system of two levers (mechanical) and a punch. Making holes and fastening will require a minimum of effort due to the installed (hidden) force transmission mechanism. It is located inside the case, which should be designated as a disadvantage, since access to it is limited. The professional model is made of steel. There are no polyurethane inserts on the handles, and they are made of durable plastic.

Cost – 1900 rub.

cutter STAYER “GRAND” Advantages:

- durability;

- practicality;

- reliability;

- professional model;

- straight holes.

Flaws:

- if the main mechanism breaks down, replacement is not carried out;

- ergonomics;

- obvious savings on materials.

BISON 3135

The model is recognized as one of the most convenient one-handed ones. It is produced by a domestic company, which indicates a high level of reliability and quality of the product offered. Based on the declared parameters, the design is equipped with a movable head, which cannot be said about the majority of cutters offered on the market. This function will be extremely convenient if you need to get the tool into a hard-to-reach area where there is no room for additional maneuver. The tilt is carried out in relation to the handles through a proprietary hinge. The rotation angle is small, but this indicator may be more than enough. The handles are made of plastic and polyurethane foam.

Price – 1250 rub.

BISON 3135 Advantages:

- strong connections;

- movable head;

- acceptable rotation angle;

- reliability;

- does not slip in the hand;

- professional model;

- modern modifications.

Flaws:

- hinge of questionable quality;

- impossibility of carrying out independent repairs.

STAYER 250 mm 31381

Comfortable to use model with a length of 250 mm. It is used for the construction of free-standing plasterboard elements and partitions. The cross-section of the working material is 1.2 mm. The product weighs 530 g, which will allow you to hold it in your hand for a long time. The assembly is of high quality, so holes are made quickly and without much effort. You only need one hand to operate, so there is no need for assistants. The punch is made of high-strength steel, which allows it to retain its original shape and appearance for a long time.

If necessary, the element can be replaced. Such accessories can be ordered online or purchased in specialized stores. The handles are covered with three layers of rubber. The grip is amazing. In addition, the element does not slip in the hand and calluses will not appear soon either.

Cost – 1450 rub.

STAYER 250 mm 31381 Advantages:

- axles are replaced;

- convenient dimensions for work and storage;

- High-strength steel is used as the main raw material;

- elongated jaw design.

Flaws:

- brackets allow you to fix only the rack profile in relation to the guide;

- It's difficult to climb up from the wall.

Advantages and disadvantages

Using a cutter during installation of a metal profile for plasterboard has a number of advantages:

- Speed . If you make holes with a drill or by screwing screws into the profile, it takes quite a lot of time. Using a cutter reduces the time it takes to make one hole to a fraction of a second.

- Accuracy . The tool allows you to make a neat, even hole without deforming the profile. Often this cannot be achieved when using a drill or screw. The hole deviates from the required position and becomes slightly inclined. Metal often wrinkles (especially true for soft aluminum profiles).

- Evenness . The front side of the metal profile frame remains absolutely flat. When connecting with screws or bolts, this cannot be achieved - the head always remains on the surface.

- Economical . Using a drill or screwdriver involves the consumption of electrical energy. The cutter is a completely mechanical tool. This allows you to save on electricity. There is also a saving in the absence of the need to purchase additional fasteners (for example, screws).

- There is no need to hire an assistant . Often, when assembling large structures made of metal profiles, a second person is needed to hold the material while drilling. When using a cutter, the need for it practically disappears - all the necessary actions can be performed alone.

Despite the large number of advantages, the tool has one significant drawback. The connection made using it is not as reliable as installation using screws. The fact is that the thread of the screws better resists the tensile load. An absolutely smooth connection made by a cutter is much less reliable.

Due to insufficient fastening reliability, the cutter is used as a temporary solution or in combination with screws. Especially if the drywall will experience significant loads. For example, when covering a wall, it is recommended to fasten the main connections with screws, and use the cutter only on the transverse ones.

Why are cutters good?

When connecting metal profiles with a cutter, no additional materials (screws) or tools (drill) are needed. By pressing the handles of the device, which act as levers, you punch through the profile walls intended for connection. On the inside of the cut hole, petals of metal bent inwards appear, which hold the connected parts together. Since the connection is made with one click, the speed of work increases several times.

Another important advantage is that on the front side the surface of the profile punched by the cutter remains absolutely smooth. If the frame was assembled using self-tapping screws, their heads protrude above the surface, creating gaps between the drywall and the profile

Unlike installation with self-tapping screws, the sheets of drywall fit closely to the frame assembled with a cutter.

Pros and cons of using cutters

This type of instrument is not very popular yet. It’s difficult to name the reasons, because the thing is really good. Especially for those who install plasterboard systems, and for home craftsmen, this is also a necessary thing. What are the advantages:

- Fast and reliable connection of profiles. The speed of installation of the frame under drywall increases significantly. The principle of operation is simple: insert the parts to be connected between the jaws, squeeze the handles, move, repeat. And so on as many times as required.

Punch for drywall profile. This is also what this instrument is called. - No need to use fasteners. This saves time and money.

- The tool is hand-held, so no electricity is needed. You can work on any objects.

- There is no protrusion at the junction of the profiles. When mounted with rivets or self-tapping screws, the head protrudes above the surface of the profile. Self-tapping screws have more, rivets have less. This prevents the sheet of drywall from laying flat without bending. When using a cutter, the bends remain on the “wrong” side of the profile. The front is obtained without protrusions. The sheet lays flat, which reduces the time for putty and its consumption.

For installing drywall, the absence of protrusions is definitely a plus

Few of those who have tried to work as a cutter return to self-tapping screws. Although, I must say, there are some. Sometimes in difficult places, the connection is “grabbed” with a self-tapping screw, then a cutter is used, and the self-tapping screw is unscrewed. But these are those who like to play it safe. With some work skill, additional fixation is not required.

Flaws

Now about the cons. Using a plasterboard profile cutter really saves time. But the tool is manual and requires the application of muscle force. With large volumes of installation, namely structures made from profiles, fatigue quickly accumulates. And by the end of the working day, the speed of work drops. The better the tool, the less effort is required, but it is still needed. And this is a minus.

The second drawback is the difficulty of disassembling. To separate the two profiles, you need to bend the metal petals. It takes more time than when unscrewing screws. But less than when removing rivets. It seems that these are all the difficulties and disadvantages of working with a cutter.

Not everywhere you can crawl up and make a cut. Then you have to use screws and a screwdriver

There is another drawback, which is due to the shape of the working part. Some components - jumpers, clamps - are simply impossible to “reach” with a cutter. The punch won't fit in there. There are models with very large “windows”, but they are not very good for regular connections. For professionals, having several different models is normal, but for home use it is clearly overkill.

Self-tapping screws or notches

It has already been said that when using cutters the sheet lies flatter. And this is a clear plus in favor of the expanded connection. The second unconditional plus is saving time. The third is the lack of consumables.

The disadvantages of joining GK profiles with a cutter include insufficient fastening strength. Self-tapping screws are more reliable. Perhaps, but the strength of the frame is needed only until it is sheathed with gypsum boards. And it will be enough, even if you make only one fastener for each connection. But it’s up to you to decide which is better - a cutter or self-tapping screws.

What is a sheet metal cutter?

A cutter or punching pliers is a hand-held tool for joining sheet metal products. The connection occurs due to the formation of a through hole in the parts being connected. The parts to be connected are fixed by bending the resulting metal petals. That is, to connect sheet metal products using a cutter, no fasteners or additional actions are required.

We placed the working part of the tool in the right place and pressed the handles. The metal breaks through, its pieces bend. All. Due to the fact that the metal is “pierced”, another name for this tool came to be - a profile punch. The same tool can be found under the name “pliers for connecting HA profiles.” This is exactly how some manufacturers position it. There are other names - perforation, profile hole punch. This is already from the jargon of builders and home craftsmen.

Metal profile cutter: roller type device

Externally, a cutter is the same pliers, but with long handles and an unusual structure of the working part. Like regular ticks, they have two jaws, but they are different in shape. On one side there is a stop, on the other there is a punch. A punch is a protruding part that makes a hole in metal. The stop is a thickened part with a hole into which the punch fits.

Photo of how the cutter works. He makes a through hole in the parts to be connected and bends the metal petals

The shape of the working part is designed so that the metal petals that are formed when making a hole are slightly bent. This ensures reliable fixation of the products relative to each other. The hole shape is usually rectangular, but can be square or round. Rectangular is preferable because it gives a more “rigid” connection.

When is a cutter not suitable for joining profiles?

Cutters are indispensable for home repairs. They speed up and facilitate the installation process.

- But for fastening ceiling structures, self-tapping screws are still used, which provide a more rigid and reliable fastening.

- Also, self-tapping screws can be used to secure hard-to-reach areas (long tool handles do not fit everywhere).

- On perfectly flat walls, drywall can be strengthened with glue (it is applied to the sheet and the wall). However, gluing requires quick work, since the glue dries in a short period of time.

What else can you use a cutter for? Making holes

It should be noted that the cutter can be used not only for stitching profiles together and, accordingly, fastening plasterboard sheets.

- This tool is successfully used for punching holes in thin and brittle materials. For example, plastic.

- You can also use it to make a keyhole, or use it to punch holes in wooden parts.

- It makes not only round, but also polygonal or oval holes (this depends on the cutting edge).

Advantages of working with a cutter

Ease of use, quality of work, availability and a wide selection of models make cutters a popular tool used by both professionals and beginners. It has many undeniable advantages:

- no dents on the frame;

- no screws or self-tapping screws are required (and this is a significant budget saving for large rooms);

- the holes do not need to be further processed - they are perfectly smooth;

- there is no need to make preliminary markings - all holes will be at the same distance.

Learning to use hand cutters is quite simple. Taking the tool in hand and making a few fasteners, any man turns into a real master of covering rooms with plasterboard. Have an easy repair!

Guest. Welter. It is necessary to describe the technology and then explain it with illustrations. And here are pictures that are used to try to describe the technology, but the description of the pictures is done incorrectly.

Dmitriy. I have long planned to make a suspended ceiling, but I wanted it with high-quality sound insulation. I chose slabs made of padding polyester. I traveled to different companies. In some places the slabs are greenish, in others they are prickly, in others the density is low. I wanted it to contain no phenol. I chose MaxForte EcoAcoustic. The material met all requirements. The slabs are white, odorless, with optimal density. EcoAcoustic secured everything to the ceiling with dowels. Installation is simple: the slabs do not generate dust or itch, unlike mineral wool. The master then stretched the ceiling. I'm happy with the result, I got a beautiful stretch ceiling with excellent and most importantly environmentally friendly sound insulation.

Elena. The very detailed manual turned out to be useful, some of the tiles have already been laid, it turns out great, now it’s a matter of technique, as they say, thank you.

oxana. Thank you for the article! Quite simple and useful recommendations. The first time I decided to putty the ceiling myself. It turned out pretty good. I generally like this site. All your articles here are great! I will recommend him to my friends and acquaintances.

Where can I buy?

The cutter for drywall profiles is sold in large construction chain supermarkets, on online sites, in stores selling repair products and on the market. A wide selection of cutters, clear terms of warranty and service are offered by such flagships of the building materials and tools market as:

- "Obi";

- "Maxidom";

- "Leroy Merlin";

- "220 volt".

In offline stores you have the opportunity to touch the instrument, evaluate the quality of its workmanship, weigh it in your hand and get a quick consultation. When buying a cutter on online sites, rely on reviews and choose reputable suppliers.

Of course, no one is stopping you from purchasing a tool on the market, but in this case, all possible risks are placed on you.