Conductive glue is a handy adhesive for many cars and radio enthusiasts. It is used to repair glass heating filaments in cars, to seal wiring, and to solder contacts in keyboards, remote controls, household appliances, and other devices. An adhesive that does not conduct current may impair the performance of the equipment being repaired.

Features and Properties

The first electrically conductive compound was developed by Germany at the beginning of World War II. Initially it was used only in mechanical engineering. Over time it became universal. Now it is used as a solder when laying heated floors and heating systems, which is due to the ability of the adhesive solution to withstand high temperatures.

- It dries quickly, so gluing must be carried out without interruption.

- It has a high viscosity, which prevents the mixture from flowing into the boards.

- High adhesive characteristics ensure reliable adhesion to the surfaces being processed; it is well fixed on glass, plastic, etc.

- After drying, it can withstand temperatures up to +160 °C while maintaining its structure.

- Safe for humans and nature.

- The elasticity of the composition allows for spot application.

The conductive composition has low electrical resistance. Its use helps protect parts from damage, shock and vibration loads. Thanks to the conductor adhesive, the boards will not react to temperature changes.

Before use, you need to carefully study the composition of the glue and do not use products containing water. The composition and instructions for use are indicated on the original packaging of the glue. For microcircuits, wire contacts, cables, and other electrical elements, the water base is destructive. This composition will take a very long time to dry.

The current-carrying component in the adhesive is often graphite or nickel powder, silver or any other metal. The higher the content of the electrically conductive component, the worse the adhesion of the glue to the surface.

Purpose:

- you can repair computer cables and microcircuits;

- used when installing heating baseboards;

- used as linoleum adhesive when laying antistatic flooring;

- Defects in car electrical systems are eliminated, rear window heating is repaired;

- piezoelements are fastened in radio equipment;

- used when replacing the soldering of light-emitting diodes.

Work with conductive mixtures takes place indoors to minimize environmental pollution.

Areas of application

Amateur radio circuits and homemade designs. In confined spaces, it is difficult to manipulate the soldering iron and solder. Some chips and other expensive electronic components are damaged when overheated. These and other practical problems are solved with the help of conductive adhesive compositions. Examples:

- fastening of piezoelements in radio equipment;

- restoration of heating “strips” on the rear window of a car, torn tracks of printed circuit boards;

- connecting miniature parts while simultaneously creating a conductor;

- reproduction of cold soldering technology.

If necessary, conductive varnish will provide protective functions. The application of such adhesive compositions is used to create “flat” heating elements of a heated floor system.

Choosing glue in the store

Construction and hardware stores have a very wide selection of factory-made electrically conductive glue.

Contactol

Produced in Germany by the Keller concern. 3 products in this series have become famous.

- "Single-component contactol." It is possible to organize or restore a conductive connection on dielectrics (glass, polymers, textolite, etc.). Contains silver and synthetic resins. Has high adhesion and moisture resistance.

- "Kontaktol Radio". The base is graphite powder. The properties are similar to the previous composition, but the price is two times lower.

- "Kontaktol conductive marker". The basis is silver powder, palladium, and PVC resins. It has a convenient release form, you can glue parts in hard-to-reach places. Repair jumpers and conductive paths.

Contactol sets quickly. Complete polymerization of the seam in 6-7 hours. To speed up the final gluing, heat the treated area with warm air.

Permatex

Permatex glue (Permatex) is a two-component composition for the restoration of heating contacts. The connection made is resistant to vibration loads, not subject to ultraviolet radiation and temperature changes. It is better to work with glue at an ambient temperature of at least 10 °C.

TPK-E

It glues carbon fiber, aluminum and stainless steel, and any combination of materials can be used. On the treated area, you can create an electrical connection with a transition resistance. The composition and thickness of TPK-E allows static charges to be removed from the processed part.

Forbo 615 eurostar lino el

Floor coverings (linoleum, carpet) are “slung” onto Forbo electrically conductive glue. This is a translucent composition without a characteristic odor.

Done deal

Done Deal glue is made in the USA and has a polymer-silver composition. Used to restore contacts in cars and to restore heating filaments on windows. High quality adhesive with excellent adhesive properties.

Homakoll

It was developed specifically for gluing floor coverings that are produced in rolls and have a fabric or fleecy backing.

- The composition contains no toxic or volatile components.

- Minimum water content.

- Does not shrink after complete drying.

- After initial adhesion to the surface, the likelihood of shifting and peeling is minimal.

- Easy to apply with a notched trowel.

- Incombustible.

Mastix

Mastix adhesive based on nickel powder. It is used for the restoration of rear window heating threads in cars, filling gaps, cracks and holes, and gluing metal. The characteristics are similar to cold welding.

It is permissible to work at low and high temperatures. The quality of the connection in both cases does not decrease.

VolgaKhimProm

Restoration and reinforcing composition. Complete hardening, depending on the thickness of the applied layer, occurs in a maximum of an hour. Used in everyday life and industry. The glue is safe, without harmful effects on human skin, respiratory tract and mucous membranes.

Other brands

- Conductive adhesive Abro Masters. Produced in the United States of America. Repairing the rear window heating filaments.

- Forbo 523 adhesive for gluing linoleum and other floor coverings. Refers to dispersion compositions, frost-resistant, odorless, does not contain solvents.

- Baku BK 426 is an electrically conductive paste for restoring traces on microcircuits.

- Astrohim. Used in repairing glass heating filaments.

- Irpol 5. Elastic composition based on polyurethane components. Bonds antistatic floor coverings.

- Elekont. Epoxy resin based adhesive. Used when repairing a car. Ineffective, sometimes the application has to be repeated.

What are the conclusions?

Of course, there are other recipes for homemade glue, and only the simplest and most common ones are discussed above. Whatever recipe you use, the main thing is that the glue you prepare yourself or buy in a store should have the lowest possible resistivity. And like any other, such glue must provide a strong, reliable and durable connection.

Conductive silicone elastomer ZIPSIL REP-01 is a silicone rubber base with dispersed metal inclusions.

The electrically conductive elastomer has low electrical resistivity and very high microwave shielding efficiency. Products made from this conductive rubber can be of almost any shape, both flat gaskets and in the form of bundles.

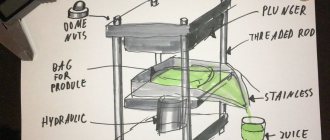

DIY conductive glue

Conductive mixtures can be made based on graphite, silver and aluminum.

Graphite based

The easiest way to make conductive glue at home is from graphite. Its main components are pencil lead and nail polish.

You can take the cheapest varnish, it is important that it is transparent, since colored varnishes contain paint that can disrupt the electrical conductivity of the glue. A paste or liquid for gluing false nails is suitable; you can buy the cheapest quick-drying glue, such as “Moment”, “Second”, “Elephant”.

The graphite composition is prepared as follows:

- if you are using nail glue rather than polish, unroll the foil of the tube from the back side;

- remove the lead from a simple pencil, the pencil should be soft (M2, M4);

- grind the lead into a fine powder;

- pour the powder into a tube or bottle;

- mix the ingredients thoroughly with a toothpick;

- Close the tube with the graphite composition again, and clamp the edge with pliers.

If the tube is not closed tightly, the contents may dry out prematurely. Avoid getting air inside. If the resulting glue accidentally spills or is applied unsuccessfully, remove the excess with acetone or nail polish remover.

Graphite can be obtained not only from a pencil. It is found in copper-graphite brushes or salt batteries. You can use sandpaper or a needle file to transform the graphite into powder. The extracted powder can be mixed in a 1:1 ratio with tsaponlak until a creamy mass is formed. An adhesive mixture based on graphite from brushes will be more effective, since it contains an admixture of copper, which increases the electrical conductivity of the product.

Silver based

To make conductive silver-based adhesive, the following components are needed:

- formalin 1%;

- silver nitrate or nitric acid;

- ammonia 5%.

Silver and formaldehyde are mixed in equal parts, and then diluted with a few drops of ammonia. After a couple of minutes, a reaction will occur and silver powder will settle to the bottom of the container. To extract it, the liquid is filtered. The resulting powder is dried at a temperature of 120-150 °C.

To make glue, silver powder is added to varnish or glue, as in the instructions for making graphite glue. Before mixing the components, a little alcohol is dripped into the adhesive solution to slightly dilute it.

There are several more recipes.

- Combine 0.13 kg of silver powder and 12 g of graphite. 8 g of nitrocellulose, 0.05 kg of acetone and 3 g of rosin are mixed into them. If the mass is too thick, dilute it with acetone. The product can be used immediately after preparation, but for the most part not for gluing parts, but as an electrically conductive primer.

- 0.03 kg of graphite is mixed with 0.07 kg of silver powder, 0.07 liters of acetone and 0.06 kg of vinyl acetate are poured into the mixture. After mixing the components, an electrically conductive syrup is obtained, which can be used to coat other adhesives, for example, BF.

Aluminum glue

To create it, aluminum powder is added to epoxy glue or resin.

Epoxy polymerizes quickly when a hardener is added, so aluminum powder must be added to the resin before the liquid component is added.

Aluminum and epoxy are mixed until creamy, then a portion of the homogeneous mixture is measured and combined with a hardener in a ratio of 1:10.

Additional Recipes

Graphite dust is not the only component that can be used to prepare conductive adhesives. There are several more complex mixtures that have better electrical conductivity or adhesive properties:

- A mixture of silver powder (130 g) and graphite (12 g) are conductive components, and the binders are nitrocellulose (8 g), acetone (50 g) and rosin (3 g). In the order listed, everything is mixed in a mortar until smooth and the glue is ready. If the glue thickens, it must be diluted with acetone. This composition is more designed as conductive - you should not expect it to hold any parts like glue.

- Graphite (30 g) and silver (70 g) powder, acetone (70 ml) and vinyl chloride-vinyl acetate (60 g) - after mixing, they become a syrupy conductive liquid with adhesive properties. Store in an airtight container to prevent the acetone from dissipating. Use it to dilute the mixture if it thickens.

- The powder from the graphite rod of the AA battery and the ceponlac are mixed until a creamy mixture is obtained.

Specifics of using homemade glue

If you need to repair expensive electronics, it is better not to save money and buy high-quality store-bought glue, or even give the equipment into the hands of a specialist. If you need to repair the remote control or have a simpler task, you can prepare a homemade mixture according to the recipes above. This will save you money on buying a ready-made product. The only problem that is typical for all homemade adhesives is that they have a limited shelf life. You need to prepare a small portion, which is used at a time.

Price overview

How much does Kontaktol-Keller conductive adhesive cost in different cities of Russia, Belarus and Ukraine:

| City | Price per 100 grams (approximate) |

| Vladikavkaz | 155 |

| Ekaterinburg | 150 |

| Kyiv | 145 |

| Krasnodar | 160 |

| Krasnoyarsk | 166 |

| Minsk | 158 |

| Moscow | 150 |

| Omsk | 170 |

| Samara | 175 |

| Kharkiv | 156 |

| Saint Petersburg | 160 |

Before purchasing, be sure to check the seller’s certificate, this is very important, otherwise you may buy a fake.

Sheets of conductive silicone ZIPSIL REP-01

The RT-Technologies company provides prompt, mass production of conductive sheets of various thicknesses for the highest requirements of electromagnetic compatibility in modern high-precision devices and instruments.

Standard sheet size: 250x250mm, thickness 0.8mm.

In addition, it is possible to produce sealing gaskets of unique shapes from electrically conductive sheets using laser or mechanical cutting.

The sheets are operational in the temperature range from minus -60 0 C to plus +200 0 C.

Gaskets made from ZIPSIL 101 REP-01 sheets provide dust resistance and moisture protection up to IP66/IP67/IP68/IP69 (with appropriate design of the device housing).

An example of a designation for ordering a conductive rubber sheet made of ZIPSIL REP-01 material:

Sheets made of electrically conductive elastomer material ZIPSIL REP-01 are manufactured according to the following specifications:

- Technical specifications for electrically conductive rubber material ZIPSIL REP-01 – TU 2512-001-24624998-2014 (pdf)

- Technical specifications for electrically conductive sheets ZIPSIL REP-01 – TU 2541-004-24624998-2014 (pdf)

Electrically conductive profiles, elastomer harnesses ZIPSIL REP-01

In addition, we produce rubber conductive silicone elastomers of various profiles, shapes and sections.

Our serial production includes sealing profiles of the following sections:

- solid O-harness

- hollow O-harness

- solid D-harness

- hollow D-harness

- hollow E-harness

It is also possible to produce profiles and harnesses of unique sections according to your technical requirements.

Standard sealing harness profile: round, can have a diameter from 1.2 to 5 mm.

An example of a designation for ordering a round harness with a diameter of 2.5 mm made of REP-01 material:

The profiles are operational in the temperature range from minus -60 0 C to plus +200 0 C.

ZIPSIL REP-01 conductive harnesses provide dust resistance and moisture protection up to IP66/IP67/IP68/IP69 (with appropriate design of the device housing).

Harnesses and profiles made of electrically conductive rubber ZIPSIL REP-01 are manufactured according to the following specifications:

- Technical specifications for electrically conductive rubber material ZIPSIL REP-01 – TU 2512-001-24624998-2014 (pdf)

- Technical specifications for electrically conductive harnesses, profiles ZIPSIL REP-01 – TU 2541-004-24624998-2014 (pdf)

Comparison of conductive elastomer REP-01 with foreign analogues

Electrically conductive silicone sealing harnesses made of ZIPSIL REP-01 material, developed and produced by RT-Technologies LLC, Tomsk, Russia, were compared with foreign electrically conductive harnesses from Laird Technologies, USA.

For this purpose, round cross-section bundles with a diameter of 2 mm were chosen.

The measurement results are presented in the graph.

Tests were carried out on conductive sheet silicone ZIPSIL REP-01 TU 2512-001-24624998-2014 (pdf), developed and manufactured by RT-Technology LLC, Russia, as well as similar EMC material from a foreign manufacturer, 8860-0032-324-81, manufactured by Laird Technologies, USA.

The result of a comparative test of ZIPSIL REP-01 and product 8860-0032-324-81 from Laird Technologies, USA:

| Indicator name | Electrically conductive silicone rubber ZIPSIL REP-01 from RT-Technology, Russia | Electrically conductive silicone rubber Laird Technologies, USA | Test method and conditions |

| Specific volumetric electrical resistance no more than, Ohm×cm | 1 Ohm×cm | 0.89 Ohm×cm | GOST 20214-74 |

| Shielding efficiency at 10 GHz, dB | not less than 115 | not less than 110 | MIL-DTL-83528C |

| Tensile strength, MPa | 2.0 MPa | 3.3 MPa | GOST 11262-80 |

| Elongation at break, % | at least 100% | not less than 150% | GOST 11262-80 |

| Operating temperature range, °C | from minus 60 °C to +200 °C | from minus 60 °C to +160 °C | GOST 7912-74 |

Flaws

Despite all the advantages of conductive glue, it is not without its disadvantages, which include:

- high cost of glue due to the presence of fine silver, gold, palladium and nickel in its composition;

- the product contains synthetic resins , polymers, metal additives that are unsafe for human health ;

- You can find out how glue of a particular brand will demonstrate its conductive properties only during application;

- does not attach to every surface;