In 1902, the structure of the steel crystals obtained after hardening was called “martensite” in honor of the German metallographer Adolf Martens (1850 – 1914). It had a specific needle-like appearance.

As a result of heating carbon steel to the state of austenite and subsequent rapid cooling, structural changes occur in the crystal lattice of carbon steel: the cubic lattice of austenite turns into a tetragonal one. This happens because carbon does not have time to separate from austenite and is retained in the ferrite structure, distorting its shape.

Alloying elements dissolved in austenite produce a similar effect. The newly formed phase has a needle-like or plate-like structure and is called martensite, and the process of rearrangement of the crystal lattice is martensitic transformation. Martensitic structures are characterized by strength and hardness.

Martensitic transformation has been studied in the heat treatment of steel, and the term was initially used for the process of martensite formation in steel, but it was later discovered that similar transformations could be extended to other polymorphic materials.

Martensitic transformations in steels

Theory of production of martensitic steels

During hardening of carbon steel containing more than 0.25 - 0.3% carbon, a sharp change in its properties is observed. The steel acquires a martensite structure. At a certain heating temperature and subsequent cooling, martensite crystals form from austenite grains.

The basis of the polymorphic martensitic transformation is the diffusion-free mechanism of transformation of gamma-iron austenite with a face-centered cubic crystal lattice (FCC) of austenite into alpha-iron with a body-centered lattice (BCC) of martensite.

The recrystallization process occurs at high, almost subsonic speeds, due to the coherent connection of growing martensite crystals with the original austenite crystals. The greater the structural and dimensional correspondence, the thinner the martensite needles.

The martensitic structure is a supersaturated solution of carbon in alpha iron; its crystals are prismatic in shape. The concentration of carbon and alloying elements determines the increase in the length of the prism and the decrease in its base, and, accordingly, the increase in the strength and hardness of martensitic steel. Due to the high elasticity and low mobility of atoms, the martensitic transformation occurs through cooperative coordinated displacement of atoms to distances less than interatomic ones. The newly formed martensite phase is a nonequilibrium system.

Due to the lamellar (needle-like) shape of the crystals and the plastic deformation (phase hardening) that occurs as the mismatch in the positions of the atoms increases and the coherence is broken, martensitic structures have higher strength, hardness and lower ductility compared to the original crystals of the austenitic structure. There are hypotheses about the wave nature of the process of plastic deformation.

Properties of martensite

The hardness and strength of martensite characteristic of martensite are due to:

- Distortion of the crystal lattice from the introduction of carbon or alloying elements.

- By crushing subgrains, or block structure.

- Increasing dislocation density.

4 types of martensitic steel crystals

- Thin-plate.

- Butterfly-shaped.

- Lamellar (lenticular, twin).

- Batch (massive, rack, non-double).

Packet type of martensite (plates form a package). The batch structure of steel grades 10Kh2G3M, 12Kh2N4, 40KhN, 37KhN3, 30KhGS, 45KhNMFA.

In some high-alloy steels, thin-plate martensite forms.

The butterfly type in its structure has the articulation of the plates of two plates, similar to a butterfly. Common in alloy steels.

The lamellar type of martensite on a cut has a lens-shaped structure resembling needles. This structure after hardening is observed in carbon steels U2, U12 and high-nickel steels N31, N32.

The package type is characterized by packages formed from blocks of plates. Packet structure of steel grades 12Х2Н4, 37ХН3, 30ХГС.

Precipitation hardening stainless steels

These steels are also called high-strength stainless steels. Precipitation hardening stainless steels contain aluminum, niobium or tantalum and obtain their properties through quenching, strain hardening, age hardening and martensitic transformation. The steel is first heated and hardened to transform austenite into martensite. Reheating causes the precipitation of strengthening particles such as NiAl3 from the martensite. The high strength of these steels is achieved even with low carbon content.

Dispersion-hardening steels include steels 07Х16Н6, 09Х15Н8У, 08Х17Н5М3, 04Х25Н5М2, ХН40МДТУ according to GOST 5632-72.

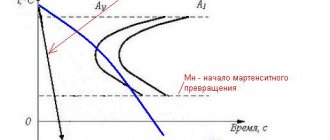

Martensitic points

The main characteristic of alloys under a certain hardening regime is martensite points.

The temperature at which martensitic transformations begin is designated Mn. When the steel cooling temperature reaches Mn, an instantaneous avalanche-like process of steel recrystallization begins. Temperature Mn is determined for each steel grade experimentally at metallurgical enterprises. The Mn value decreases with an increase in the amount of carbon and alloying elements in the steel composition.

The temperature at the end of martensitic transformations is designated Mk. In the temperature range between Mn and Mk, a diffuse-free restructuring of the steel crystal lattice occurs. When the temperature Mk is reached, diffuseless recrystallization stops. For high-carbon alloy steels it can be negative.

Practice of heat treatment of steels for martensite

In large-scale and mass production, automatic conveyor lines are used for hardening steel products, which carry out a full cycle of obtaining the necessary martensitic structure for certain grades of steel.

In tool shops and pilot plants, tools and parts are hardened manually by heating the tool in muffle furnaces, in baths with oils, salts or molten metals. Cooling is carried out in different media: water, oil, air. The temperature and hardening process parameters are developed by the technologist in accordance with technical standards and steel grades.

Surface heating is carried out in cases where it is necessary to increase the strength of the outer layers of products while maintaining a soft core. Surface hardening is carried out in high frequency generators.

Depending on the required heating temperature, various salts or mixtures of salts are used; So, for high-temperature heating (1000-1300 degrees), molten barium chloride is used; for heating up to 750-950 degrees, mixtures of salts of barium chloride, potassium chloride and sodium chloride are used. For low-temperature heating of 300-550 degrees, mixtures of potassium and sodium nitrate are used.

Liquid media of varying cooling abilities are most often used as cooling media for martensite quenching. Usually water is used, and the rate of heat removal is increased by adding caustic soda. Softer coolants include mineral and transformer oils.

Types of hardening for martensite

- Continuous, or hardening in one environment.

- Hardening in two environments.

- Step hardening.

- Cold treatment.

After heating the steel product to the temperature of the austenite fraction, it is sharply cooled either in water (the simplest option), or in heated oils, or in air, depending on the composition of the steel. With this cooling method, warping and sometimes cracks appear.

To avoid risks, hardening is used in two environments. After heating, the product is immersed in water, kept for some time, and then further cooling to a temperature of Mk occurs in a softer environment. This method is suitable for mass production.

With a stepwise cooling scheme, the steel is immersed in a coolant with a temperature exceeding MP by 60-100 degrees, maintained for the estimated time, and then cooled in still air. Small-sized tools made of medium- and low-alloy steels are subjected to this type of cooling.

Cooling in cold (liquid nitrogen) is usually resorted to in cases where Mk for a steel grade is below zero. These are high-alloy carbon grades used for the manufacture of measuring tools and elements of rolling bearings.

Application of martensitic steel grades

Alloying elements are added to martensitic steels to obtain the desired properties of the alloys: strength, wear resistance, cold-heat resistance, corrosion resistance. One grade of alloy steel can contain up to 7 alloying elements. Steels are alloyed with nickel, chromium, nitrogen, tungsten, beryllium, vanadium, silicon, molybdenum, copper, and boron.

Usually, the designation of steel encodes alloying additives and their quantity (38ХН3МФА), some experimental ones are encrypted with the letter E. In this case, the letter does not reflect the composition of the steel - EI, EP3. Sometimes steels intended for the manufacture of aircraft and automobile exhaust valves are abbreviated as silchrome.

Alloyed martensitic steels are able to withstand aggressive environments: acids, alkalis, salts, aggressive gases. According to their application, martensitic steels are classified as corrosion-resistant, heat-resistant, heat-resistant and special-purpose steels.

Corrosion-resistant steel grades (15Х28, 20Х13, 12Х18Н9) are used in pilot production and in the chemical industry.

Heat-resistant steel grades (KhN60Yu, 12Kh25N16G7AR, (15Kh6SYu)) are used for the manufacture of parts that operate under moderate loads at temperatures up to 1000 degrees.

Products made from heat-resistant steel grades (15Х6СУ, 08Х13, 14Х17Н2) can operate under load for a very long and long period at high temperatures.

Special steels include steels from which armored sandwiches are rolled. A special place is occupied by Hadfield steel (1.1% carbon, 13% magnesium). When working under high pressure conditions, spontaneous plastic deformation occurs and, accordingly, the degree of its strength increases. The unique mechanical properties have not yet been fully studied.

Magnetic properties of martensitic steel

The martensitic structure of the steel lattice has pronounced magnetic properties. Martensite is a ferromagnet in its pure form. However, maintaining an ideal chemical composition is difficult. Carbon martensitic steels alloyed with molybdenum, cobalt and chromium (EX9K15M2), cobalt and chromium (EX5K6), chromium (EX3) can be classified as hard magnetic materials.

Alloying with cobalt is most effective from the point of view of magnetism - cobalt atoms have a magnetic moment, thus, the residual induction of martensite increases. Low price and ease of mechanical and heat treatment makes it possible to use martensitic steels in magnetic systems as switches for changing direction when supplying control signals.

Weldability of martensitic steels

Welding technologies for martensitic alloys are complicated by the increased fragility of the metal after hardening. These types of steel are cooked after preheating from approximately 200 to 450 degrees, the ambient temperature should not be negative. Typically, parts made of martensitic steel are welded using manual arc welding methods using electrodes coated with special compounds. Sometimes other types of welding are used: argon arc, electroslag, submerged arc.

The effect of chromium on the corrosion resistance of steel

It is chromium that makes steel stainless. In addition, chromium is an element that increases the stability of ferrite. Figure 1 illustrates the effect of chromium on the iron-carbon phase diagram. Chromium causes the austenitic region to shrink while the ferritic region expands in size. At high chromium content and low carbon content, ferrite is the only phase up to the liquidus temperature.

Figure 1 - Effect of 17% chromium on the iron-carbon phase diagram. With a low carbon content, ferrite is stable at all temperatures. The letter "M" stands for "metal", such as chromium or iron, as well as other alloying elements.

There are several types of stainless steels based on differences in crystal structure and strengthening mechanisms.

Martensitic transformations in polymorphic crystals

Similar martensitic transformations, when atoms do not change places, but only shift relative to each other at distances smaller than interatomic ones (shortening interatomic bonds and changing the angles between them), are observed not only in iron alloys, but also in other polymorphic crystals.

Such transformations, also called metamorphoses, take place in steels, pure metals: iron, cobalt, titanium, lithium, at least 35 metals, in solid solutions based on them, in semiconductors and polymers, in intermetallic compounds.

In contrast to normal equilibrium polymorphic transformations, martensitic transformations are diffuseless and metastable. These transformations are of a non-equilibrium nature. The physics of metals says: nonequilibrium states must be self-organized.

From the point of view of the second law of thermodynamics, martensitic transformations in substances occur with a decrease in entropy. This means that the crystal structures of such transformations are the result of self-organization, and their parameters approach supercritical ones.

The structure of the intermetallic nickel monoaluminide after martensitic transformation is capable of withstanding temperatures up to 1300 degrees under high loads, but due to increased fragility it is used only as a heat-resistant coating for gas turbine engines.

Some intermetallic compounds with martensitic structures containing platinum are used as catalysts in the production of nitrogen. In connection with the tightening of environmental standards for cars, developments are underway to burn combustion products using intermetallic compounds.

On crystals of some semiconductors (silicon, germanium) one can observe direct or reverse diffuseless phase transitions of states. Experiments on heat treatment of silicon wafers were implemented in production with a 20% economic effect.

By studying the process of reversibility of martensitic transformations on recrystallization of the TiNi alloy (intermetallic compound), a change in the size of the samples was discovered.

Memory effect

Further experiments with various materials showed that many polymorphic crystals can exhibit properties such as shape memory effect, superelasticity and superplasticity.

Deformation and its reduction or even complete restoration of the original shapes during the reverse occurrence of martensitic transformations is called the shape memory effect. And all phenomena associated with martensitic transformations in substances are united under one name “unusual physical and mechanical properties.”

The shape memory effect is already used today in hydraulic couplings in shipbuilding and aviation, in damping devices, in thermal relays, in medicine for the treatment of scoliosis, joining broken bones, in heart surgery, and in dentistry.

Ferritic stainless steels

Ferritic stainless steels contain up to 30% chromium and no more than 0.12% carbon. Due to their body-centered crystal structure (BCC), ferritic steels have good strength and decent ductility, which are achieved through solid solution strengthening and strain hardening. Ferritic steels are ferromagnetic or, in simple terms, “magnetic”. They are not amenable to heat treatment. Ferritic steels have excellent corrosion resistance, moderate workability, and are relatively inexpensive.

Ferritic stainless steels include steels 08Х13, 12Х17, 08Х17Т, 15Х25Т, 15Х28 according to GOST 5632-72.