To this day, a huge amount of minerals are mined in the world. These include metals, precious stones, and fuel. It is impossible to imagine everyday life without them. If we turn to the metals that are most mined in the world, then third place belongs to copper, after iron and aluminum. It’s hard to imagine, but without this simple and ordinary metal, problems will arise in such industries as electrical engineering, heating engineering, medicine, and many others. Copper - what kind of ore is it? What properties does it have? How is it mined? And what are the world's reserves?

Properties and characteristics

Copper ore is a special compound of chemical elements in which the concentration of copper reaches a value of at least 0.5–1%. Only such ore is suitable for processing and further use. It occupies number 25 in the periodic table and has the name “cuprum”, from Latin.

Copper is a fairly flexible and soft element that has a golden-pink hue. This metal is easily oxidized, and therefore, at the slightest contact with air, it becomes covered with a reddish acid film. This material is characterized by:

- good electrical conductivity;

- high thermal conductivity;

- resistance to corrosion and destructive effects.

Copper also has antibacterial properties. It easily destroys all kinds of influenza viruses, as well as bacterial infections.

If you mix it with another mineral, you get interesting alloys. People use many of them in everyday life, without even realizing that they are holding copper in their hands. Thus, the following are known: brass, bronze, various babbits and jewelry alloys.

Crystal optical properties in thin preparations (sections)

In polished sections, pink in reflected light. Reflectivity (in%): for green rays - 61, for orange - 83, for red - 89. Isotropic. Refractive indices (according to Kundt) in prisms for red light - 0.45, for white - 0.65, for blue - 0.95; in reflective light (according to Drude) for Na-light 0.641, for red - 0.580. The absorption coefficient for Na-light is 4.09, for red light is 5.24.

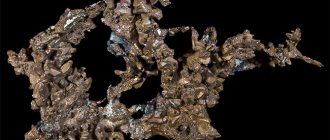

Copper. Branched dendrites. Russia

Copper. Branched dendrites. Russia

cougar

Copper. cougar

Applications of copper ore

Due to the beneficial properties of copper, it is used in electrical engineering. This metal is used to make wires and power cables that are necessary in human daily life.

It is also interesting that when copper is mixed with other materials, no less useful things are obtained. For example, an alloy with nickel is necessary in instrument making. A mixture with tungsten is used for filaments in conventional light bulbs. In addition, copper is necessary in the manufacture of radiators and air conditioners because it has good thermal conductivity.

This metal is also used in the following industries:

- mechanical engineering;

- construction;

- shipbuilding.

There is another useful property for which this metal is highly valued and is often used in construction. It is slightly susceptible to corrosion. Products made from it will last for several decades before they begin to disintegrate.

Copper is also used in jewelry. Sometimes jewelry is created exclusively from this metal, sometimes with an admixture of gold. Since the material is soft and flexible, it is convenient to create delicate and sophisticated jewelry. Now there is a trend to introduce door handles and railings made of copper, as it has antibacterial properties.

This is interesting! The Statue of Liberty was clad in copper. It took 80 tons to make. In the kingdom of Nepal, this metal is considered sacred.

In agriculture, copper plays an important role. It is added to many fertilizers. Many gardeners are familiar with copper sulfate, which they use to treat plants against harmful insects.

Chemical composition

Sometimes it contains impurities of Fe, Ag, Pb, Au, Hg, Bi, Sb, V, Ge3 (silver copper with 3-4% Ag, ferruginous copper - 2.5% Fe and golden copper - 2-3% Au). Impurities are observed more often in primary native copper; Recycled copper is usually purer. Composition of native copper from the Shamlug deposit (Armenia): Cu - 97.20 -97.46%, Fe - 0.25%; 98.3% Cu or more was determined in copper from Altai deposits.

Crystallographic characteristics

Syngony. Cubic.

Class. Hexoctahedral.

Crystal structure

The crystal structure is characterized by a face-centered lattice; Copper atoms are located at the corners and in the centers of the faces of the elementary cube. This is a formal expression of the fact that in the structure of copper there is a close packing (the so-called cubic close packing) of metal atoms with a radius of 1.27 A and a distance between nearest atoms of 2.54 A with a space fulfillment of 74.05%. Each Cu atom is surrounded by 12 similar ones (coordination number 12), located around it at the vertices of the so-called Archimedean cuboctahedron.

Main forms : a (100), d (110), o (111), l (530), e (210), h (410).

Groups of copper ores

Copper is a metal that has a huge number of varieties, each of which has its own properties. There are more than 200 species. However, no more than 20 are used in production. Scientists combine all these varieties into several groups.

Stratiform - a group characterized by deposits that were formed by sedimentary methods. Slate is often found with this metal.

- Pyrite is a group consisting of a combination of copper and nuggets. This type of metal is widely used in jewelry.

- Hydrothermal - a group whose characteristic feature is that these deposits often contain gold, silver and other minerals along with copper. Their number exceeds the norm.

- Skarn rocks - deposits of such ores are local. They are found among limestone rocks. Here the copper concentration does not exceed 30%. Moreover, it is uneven.

- Igneous—this group includes species in which mixtures of copper and nickel predominate. Such rocks are the result of magmatic processes, that is, the solidification and change of magma or lava.

- Carbonate - this group consists of mixtures of iron and copper. So far, only one such deposit has been discovered in the whole world - in South Africa.

Deposits on the world map

The largest ore reserves are located in Chile - 34% of the world's total. The USA and Peru each have 9% of fossil deposits. Eastern Siberia, the Urals and the Kola Peninsula account for 5% of the deposits.

The world's copper deposits are located on the African continent, South America, Canada, and Australia. Of the European countries, Poland is the richest in them. There are known deposits in China and Mongolia.

Porphyry and vein deposits are located in the Western Pacific belt and Mediterranean regions. Kazakhstan, Armenia, and Uzbekistan have them.

Map of copper deposits in the world

What ores do copper come from?

Copper is extremely rare in the form of nuggets. It is always mined with additional impurities. The largest nugget was found in the USA. It weighs more than 420 tons.

A total of 20 types are used in heavy industry. The most famous and widely used of them are chalcocite, chalcopyrite and bornite. What are their properties?

- Chalcocite is the most concentrated copper. Here its concentration can be up to 80%.

- Chalcopyrite is copper, which is part of polymetals and has hydrothermal origin.

- Bornite - this type has a bluish tint due to impurities of iron and silver. Concentration - more than 60%.

- Kovelin belongs to the hydrothermal group, like chalcopyrite. The concentration is 64%.

It is from these ores that most of the metal is obtained, which is then used by humans.

COPPER ORES

COPPER ORES, natural mineral formations containing copper in such compounds and concentrations at which their industrial properties. use is technically possible and economically feasible. It is known that St. 170 copper minerals; prom. less than 20 are important, the main ones being: native copper (98% $\ce{Cu}$), chalcopyrite (34.5% $\ce{Cu}$), bornite (63.3% $\ce{Cu} $), chalcocite (79.8% $\ce{Cu}$), cubanite (22–24% $\ce{Cu}$), covellite (66.5% $\ce{Cu}$), tennantite ( 57.5% $\ce{Cu}$), tetrahedrite (52.3% $\ce{Cu}$), cuprite (88.8% $\ce{Cu}$), tenorite (79.9% $ \ce{Cu}$), malachite (57.4% $\ce{Cu}$), azurite (55.3% $\ce{Cu}$), chrysocolla (36.1% $\ce{Cu} $), brochantite (56.2% $\ce{Cu}$). According to their genesis, primary, oxidized, and mixed microorganisms are distinguished; according to mineral composition - actual copper (native copper) and complex (sulfide, carbonate, silicate, sulfate, oxide, etc.). In the primary ores of most industrial processes. In deposits, copper is present in the form of sulfides (chalcopyrite, bornite and chalcocite, cubanite), in oxidation zones (oxidized and mixed ores) it is represented by carbonates, silicates, sulfates, oxides and other classes of minerals. M. r. in deposits mainly complex. Up to 80% of copper is extracted from sulfide ores, the rest comes from carbonate, oxide, silicate and copper itself. In all types of sulfide deposits, in near-surface conditions, complex zones of oxidation, leaching, and secondary sulfide enrichment are formed, in which native copper, chrysocolla, cuprite, azurite, malachite, chalcocite, covellite, etc. are developed.

Deposits of the M. river containing reserves of St. 5 million tons are classified as unique (18 such deposits have been identified, 4 of them are in Russia), large deposits have reserves from 1 to 5 million tons, medium ones - from 0.2 to 1 million tons, small ones - less than 0 .2 million tons. Rich ores contain St. 2% copper, ordinary - 1-2%, poor - less than 1%. Wed. The copper content in mined ores is 1–0.8% (constantly decreasing: in the 19th century ores with an average content of 10% were mined, in the early 20th century – 3.8%). Rich ores are smelted without enrichment, ordinary and poor ores are enriched. The complexity and methods of beneficiation of ores depend on their mineral. composition and textural-structural features.

Average copper content in decomp. types of ores geological-industrial types of copper deposits range from 0.3–6%. The content in them is basic. associated components varies to an even greater extent, amounting to avg. for platinoids, $\ce{Au, Re}$ 10–6–10–4%; for $\ce{Ag, Se, Te, In, Tl, Ga, Ge}$ 10–4–10–3%; for $\ce{Mo, Bi, Cd, Co}$ 10–3–10–2%; for $\ce{Zn, Pb, Ni, R, Ti, V}$ 10–1 – n%; for $\ce{S\:and\: Fe}$ (magnetite) n–n·10%. As harmful impurities in M. p. arsenic and antimony are often found (10–3–10–2%), sometimes mercury (10–4%).

Prom. M. river deposits divided into 6 genetics. groups in which at least 8 main groups are distinguished. geological-industrial types. Among the magmatic ones there are 2 geological and industrial processes. type – sulfide copper-nickel and copper-titanium (or vanadium-iron-copper); in carbonatite and skarn rocks - according to one type, the genetic one of the same name. group; among hydrothermal plutonogenic there are 2 types - copper-porphyry and sulfide-quartz veins; in pyrites - a type of copper-pyrites, in stratiforms - a type of cuprous sandstones and shales. Geological-industrial types are very unequal in their economics. meaning. Among foreign deposits of M. river. Porphyry copper deposits predominate (from 65 to 70% of the world's proven copper reserves), from 15 to 20% of reserves are concentrated in deposits of cuprous sandstones and shales, 5–8% in copper-pyrite deposits, 2–2.5 in sulfide copper-nickel deposits %, in skarns 2–4%, in carbonatites 0.5–0.7%. In Russia the main Three types of deposits are important in terms of reserves and production: sulfide copper-nickel (44.7% of the country's total), copper-pyrite (28%) and cuprous sandstones and shales (20.9%); the remaining types - porphyry copper, iron-copper, skarn, etc. account for 6.4%. Identification of new geological and industrial types of deposits M. river. associated with the development of minerals. ocean resources (for example, stratiform deposits of sulfide copper ores in ocean sediments, sulfide structures).

Porphyry copper deposits are associated with hypabyssal porphyry intrusions of moderately acidic composition. Ore bodies are represented by stockworks of isometric, elongated or complex shapes. Porphyry copper ores have vein-disseminated textures, Ch. minerals – pyrite, chalcopyrite, chalcocite, bornite, molybdenite. The ores are complex, the copper content in them ranges from 0.4 to 1.2%, the average is 0.6–0.7%. Among them, based on the composition of the ores and the ratio of copper, molybdenum and gold, four types are distinguished: proper copper-porphyry and gold-copper porphyry, molybdenum-copper-porphyry, copper-molybdenum-porphyry and proper molybdenum-porphyry. In addition to copper, molybdenum and gold, rhenium, silver and other metals are extracted from ores. The sizes of ore deposits are, as a rule, large, their area is often measured in square kilometers, volumes reach 1 km3 (sometimes more). In unique deposits of this type (Chukicamata, El Teniente in Chile) reserves exceed 20 million tons. There are three planetary belts of distribution of porphyry copper deposits: Pacific (Chile, Peru, Mexico, USA, Canada), in which the predominant part of reserves is concentrated ; Mediterranean (Serbia, Macedonia, Bulgaria, Armenia, Turkey, Iran, Afghanistan, Western Pakistan, Northern India); Kazakh-Mongolian (Kazakhstan, Uzbekistan, in Russia – Tuva; Mongolia, China). Known approx. 150 porphyry copper deposits, among the most famous: Kounrad (Kazakhstan), Kajaran (Armenia), Kalmakyr (Uzbekistan), Peschanka (Russia), Bingham, San Manuel (USA), Valley Copper (Canada), Majdanpek (Serbia) and etc.

Deposits of cuprous sandstones and shales are associated with formations of red-colored, variegated, gray-colored sand-shale, originally sedimentary (sometimes volcanogenic-sedimentary) rocks, which later experienced noticeable transformations as a result of the processes of dia- and catagenesis and under the influence of underground hot mineralization. water Ore bodies preem. sheet-like shape, length and width - from pl. hundreds of meters to several kilometers, thickness up to 30 m (sometimes more). The deposits are characterized by large sizes and are often classified as unique in terms of reserves. The copper content in ores ranges from 1 to 6%, the average is 3.5%. The ratio of ch. ore-forming elements $\ce{Pb\:: Zn\: : Cu}$= 1 : 0.5 : 10. Sulfide ores. The most common miner. types of ores: chalcopyrite-bornite-chalcocite; galena-chalcopyrite-bornite-chalcocite (primary); brochantite-cuprite-native copper-malachite mixed (secondary and oxidized). The textures of the ores are layered-banded and veined-disseminated. Related industrial components – lead, zinc, silver, platinum group metals, rhenium, selenium, tellurium, cobalt, uranium, cadmium, germanium. The largest stratiform deposits are located in the Copper Belt of Central Africa (Nchanga, Mufulira, Nkana and others in Zambia; Kamoto, Musoshi in the Democratic Republic of the Congo), Kazakhstan (Dzhezkazgan), Poland (Legnitsko-Glogow ore field), Afghanistan (Ainak) , Russia (Udokanskoe in the Trans-Baikal Territory).

Copper-pyrite deposits are associated with volcanogenic and volcanogenic-sedimentary basaltoid formations of the early stages of development of fold belts. Massive, disseminated and veinlet-disseminated ores also have a sulfide composition. Continuous massive ores are stacked in the main. pyrite with an admixture of chalcopyrite, sphalerite; sometimes galena, fahlores, and other sulfides are present in small quantities. Disseminated and veinlet-disseminated ores are usually represented by hydrothermally altered sedimentary and volcanogenic rocks with dissemination and veinlets of the same sulfides. There are several types of ores depending on the ratio of the predominant sulfides - chalcopyrite-pyrite, chalcopyrite-sphalerite-pyrite, etc. Copper content - from tenths of a percent to 2-3%, on average. OK. 1.4%. Along the way, zinc, lead, sulfur, gold, silver, cadmium, selenium, and tellurium are extracted from ores. The most famous foreign deposits: Kidd Creek, Flin Flon and others (Canada), Skouriotis (Cyprus), Rio Tinto (Spain), Bessie (Japan); in Russia – Yuzh deposits. and Wed. Urals (Gaiskoe - unique in terms of reserves, Sibaiskoe, Blavinskoe, Uchalinskoe, Podolskoe, etc.) and Northern. Caucasus (Urupskoye, Khudesskoye).

Sulfide copper-nickel deposits are associated with layered intrusions of mafic and ultramafic composition and were formed as a result of liquation. Ore bodies of sheet-like, lens-shaped and irregular shapes, as well as veins. The length along strike and dip ranges from tens to many hundreds of meters. The thickness is many tens of meters. The textures of the ores are disseminated, massive “schlieren”, veinlet-disseminated, breccia. The composition is complex (main ore minerals: pentlandite, chalcopyrite, cubanite, pyrrhotite), in addition to copper, cobalt, platinum group metals, gold, silver, selenium, and tellurium are extracted from them. The most famous deposits: Fruit, Grayton, Thompson, Mystery Lake (Canada), Bushveld Complex (South Africa), Kambalda, Mount Keith (Australia); among the Russians deposits - two are considered unique (Talnakhskoye and Oktyabrskoye in Eastern Siberia).

Skarn deposits are formed in exocontact zones of granitoid intrusions that cut through limestones and calcareous-terrigenous rocks. The calcareous skarns of granite-pyroxene composition that arise under these conditions develop both along the host rocks and granitoids. Prom. ore bodies are located in exoskarn zones at a short distance from the contact. They are characterized by complex morphology, small sizes, and complex composition of ores. Combinations of bornite-chalcopyrite and magnetite mineralization are common in these deposits. The ores are veinlet-disseminated. The copper content is high, but uneven, on average. 1.5–3%. Associated components are iron, gold, cobalt, silver, selenium, tellurium, molybdenum. In Russia, the deposits of the Turinsky group in the Urals belong to the skarn type, for example. Vadimo-Alexandrovskoe and Gumeshevskoe; abroad: Sayakskoye, Irisu (Kazakhstan), Clifton, Bisbee (USA), Dolores (Mexico), Tintaya (Peru), Sengan, Anzhert (Iran), etc.

Prom. The type of carbonatite copper deposits was identified due to the discovery of a unique in terms of reserves, but so far the only industrial one in the world. Phalaborwa field in South Africa. This is a complex deposit confined to a massif of ultrabasic alkaline rocks.

Copper-titanium deposits (vanadium-iron-copper) are few in number and have small reserves. They are confined to differentiated gabbroid massifs in platinum belts. Vanadium-titanium-containing iron-copper sulfide ores; Ch. ore minerals: bornite, chalcopyrite, chalcocite, vanadium-containing titanomagnetite; vein-disseminated textures. Wed. copper content 0.65%. This type includes, for example, the Volkovskoye deposit in the Urals.

Quartz-sulfide vein deposits are also few and small in reserves. Associated with granitoid intrusions. Ore bodies are represented by veins and vein zones ranging in length from tens to several hundred meters, with a thickness of 1 to 10 m (sometimes more). Sulfide, copper and lead-zinc-copper ores containing gold and silver; Ch. ore minerals: chalcopyrite, pyrite, galena, sphalerite. Textures are nested-veined and veined-disseminated. The copper content in them varies widely from 1.5 to 6%. Among the deposits of this type is Zolotushinskoye in the Urals.

Identified world resources M. r. (2006, in terms of metal) for 94 countries amounted to 1683.6 million tons, the largest (79% of the world) are concentrated in 2 parts of the world - in America 57.7% and Asia 21.3%; in Africa – 9.9%, in Australia and Oceania – 6.5%, in Europe – 4.6%. Confirmed reserves recorded in 59 countries are 554.3 million tons, of which: in America 52.2%, Asia 26.5%, Africa 10.6%, Europe 7%, Australia and Oceania 3.7%; for 12 countries with the largest confirmed reserves (million tons): Chile 150, USA 35, Indonesia 33.9, Mexico 30, Peru 30, Poland 26.7, China 26, Democratic. Republic of Congo 25.8, Zambia 19, Russia 18.5, Kazakhstan 18.1, Australia 18.1.

Copper ore mining is carried out in 49 countries (2006). Wed. the copper content in the mined ores is 0.6–0.7%. The global production of copper concentrates (including the production of metal by leaching from the subsoil and dumps) amounted to 17.8 million tons (in terms of copper), including base. producing countries (million tons): Chile 7.1, USA 1.8, Peru 1.2, Australia 0.9, Indonesia 0.8, China 0.8, Russia 0.7, Zambia 0.7, Canada 0.6, Poland 0.5, Mexico 0.5, Kazakhstan 0.4, Iran 0.2, Papua New Guinea 0.2, Argentina 0.2. Copper concentrates are processed at copper smelters to produce an intermediate product - blister copper. World production of blister copper (2006, million tons) – St. 14, carried out in 43 countries, including: China (2.4), Japan (1.6), Chile (1.6), India (0.6), Poland (0.6), Germany (0.5), Canada (0.5), USA (0.5), Republic of Korea (0.5), Kazakhstan (0.4), Peru (0.4), Australia (0.4), Zambia (0.3), Mexico (0.3), Spain (0.3), Bulgaria (0.2), Iran (0.2), Philippines (0.2), Brazil (0.2), Sweden ( 0.2), Indonesia (0.2), Finland (0.2), Uzbekistan (0.1). Volume of production of the final product – refined. copper in 47 countries (million tons, excluding production from recycled materials) is 17.4, including: in China 3, Chile 2.8, Japan 1.5, USA 1.3, Russia 0 .9, Germany 0.7, India 0.6, Republic of Korea 0.6, Poland 0.6, Peru 0.5, Canada 0.5, Zambia 0.5, Australia 0.4, Kazakhstan 0.4, Mexico 0.4, Belgium and Luxembourg 0.4. In addition, 2.1 million tons of refiners are extracted from secondary raw materials. copper

13 sulfide copper-nickel deposits have been explored in Russia. Wed. The copper content in ores of deposits of this type is 1.24%, but in deposits that are unique in terms of scale and quality of ores (Oktyabrskoye and Talnakhskoye), the copper content in solid (rich) ores reaches 4.9 and 3.5%, respectively. In 55 copper-pyrite deposits, the ore is, as a rule, of high quality (cf. the copper content in them is 1.61%); in addition to copper, they contain zinc, lead, gold, silver, cadmium, sulfur, tellurium and other components. The largest deposits of this type are concentrated in the Urals: Gaiskoye (Orenburg region), Podolskoye, Yubileinoye (Bashkiria), Uzelginskoye (Chelyabinsk region). Small and medium-sized deposits of the Urals with high quality ores also play an important role: Bakr-Tau (copper 3.25%, zinc 5.53%), Severo-Podolskoye (copper 3.60%, zinc 3.08%), Chusovskoye ( copper 5.18%), Aleksandrinskoe (copper 4.40%, zinc 5.48%), Safyanovskoe (copper 3.03%), etc. Ore reserves geological and industrial. type of cuprous sandstones are contained in the Udokan deposit, containing St. 20% of the country's reserves. The reserves of the Volkovsky iron-copper deposit in gabbros (Ural) account for 2.5% of all-Russian deposits, 2 skarn deposits (Ural) - 0.2%. The remaining reserves are distributed between porphyry copper deposits (Salavatskoye in the Urals, Aksugskoye in Tuva) and other deposits (where copper is mined as a by-product). Copper is not extracted from the ores of some complex (magnetite, partly polymetallic) deposits, being lost during processing. Extraction of M. river in Russia it is carried out at 42 fields. For two bases copper mining region - Vost. Siberia and the Urals account for 92.8% of production. In addition, production is carried out in the North. The Caucasus, Altai Territory, Kola Peninsula and the Far East. Almost half of the explored copper reserves are contained in the ores of exploited deposits. Its average content in mined ores is 1.6%, which is significantly higher than in proven reserves (1.1%) in the Russian Federation and the world.

World copper exports – 11 million tons. The structure of exports is dominated by refiners. copper – its share accounts for 60% of exports, copper in ores and concentrates – approx. 30%, for blister copper – 10%. Export of refineries copper amounted to (2006, million tons) 7.1, leading exporters: Chile (2.6), Zambia (0.5), Peru (0.4), Kazakhstan (0.4), Japan (0.3) , Poland (0.3), Australia (0.3), Canada (0.3), Russia (0.3), China (0.2), Belgium (0.2), India (0.2), Germany (0.1), Republic of Korea (0.1), Philippines (0.1), USA (0.1), Indonesia (0.1), Sweden (0.1), Austria (0.1), Mexico (0.1), Brazil (0.1), Finland (0.1). World copper imports – St. 10 million tons (2006), share of refiners. copper in it is 66%, copper in concentrates is 26%, blister copper is 8%. Import of refineries copper amounted (2006) to 6.6 million tons. Ch. importers of refiners. copper (million tons): USA (1.1), Germany (0.9), China (0.8), Italy (0.8), Taiwan (0.6), France (0.5), Republic of Korea (0.4), Thailand (0.3), Turkey (0.2), Brazil (0.2), UK (0.2), Netherlands (0.2), Greece (0.1), Japan (0.1), Spain (0.1), Canada (0.1). World consumption of refiners. copper reached (2006) 17.3 million tons. Main. consumers (million tons): China (3.6), USA (2.3), Germany (1.4), Japan (1.3), Republic of Korea (0.8), Italy (0.8), Russia (0.7), Taiwan (0.6), France (0.5), India (0.5), Mexico (0.4), Brazil (0.3), Spain (0.3).

Copper ore mining methods

As already mentioned, copper has different ways of formation and origin. Some layers are closer to the surface, some further. Depending on this, the method of extracting this metal is determined. So, there are closed and open methods.

The closed method is used if minerals are located underground at a distance of more than 600 meters from the surface. Most often they lie much deeper. In this case, long mines are built that stretch for several tens of kilometers. They are equipped with all the necessary equipment, in particular machinery. To mine copper, you need special machines that have a drilling mechanism with spikes. The machine literally crushes and scratches rocks, thereby extracting copper. Drilling can also be classified as closed methods.

The open method is used more often, but only if the minerals are located at a depth of no more than 500 meters. In this case, the top layers that have no value are removed. Then the copper mining itself occurs. Explosive devices are often used to make the job easier. This method of extraction is extremely harmful to the environment. After the deposit dries up, it is abandoned, and the pit remains on the surface of the earth. Water accumulates in it and soil corrosion occurs, which leads to the formation of ravines.

Natural minerals containing copper

Bornite. Sulfide ore, its composition is determined by the expression Cu5FeS4. There are two polymorphic types - low-temperature and high-temperature. The melting point of which, respectively, is less than or greater than 228 degrees.

There is an early unstable sulfide that is easily destroyed by water and wind. The other type is endogenous, and has a variable chemical composition due to admixtures of elements such as galena, pyrite, chalcocite, and chalcopyrite. Bornite is called variegated pyrite. The characteristics of these minerals depend on their origin.

Chalcopyrite. The formula CuFeS2 determines its composition. Known as copper pyrite. Refers to polymetallic. It can exist in the form of skarns and mountain greisen.

Chalcocine. Contains 79.8% copper and 20.2% sulfur. Very beautiful, the mirror surface has a grayish tint, sometimes black.

There are rare fossils containing copper elements:

- cuprite (Cu2O), an oxide, is seen among deposits of malachite and nuggets;

- covellite, contains 66.5% of the main element and sulfur. First found surrounded by the Vesuvius volcano. Mined in the USA, Greece, Chile;

- malachite. A stone that is used for various crafts. Polymetallic ore. Nizhny Tagil is the place of large deposits of this mineral;

- azurite This is azure, a blue stone. The main places of its production are Africa, Australia, England, and the Balkan countries. Occurs near sulfide deposits.

Porphyry copper forms include molybdenum, gold, chalcopyrite, and pyrite. They are found in deposits of poor rocks. They have the form of veined stockwork-type inclusions.

Copper production process

After the metal has been removed from the bowels of the earth, it must be processed and the product itself must be produced. There are three technologies in total:

The first method is pyrometallurgical, which involves processing ore using fire refining. During this processing, all minerals and their elements are extracted from the ore. This technology makes it possible to extract copper even from the most scarce rocks, where its concentration is below 0.5%.

The second method - hydrometallurgical - is used less frequently, and only for processing already oxidized copper or its nuggets with a poor metal concentration. These technologies make it possible to use all the copper that is in a particular ore.

The third method is electrolysis, a special process in which ore is purified using electricity and liquid. This method appeared relatively recently.

Form of being in nature

The appearance of crystals . The shape of the crystals is cubic, tetrahexahedral, dodecahedral, less often octahedral (possibly pseudomorphs of cuprite). The edges are often rough, with depressions or elevations. Simple crystals are rare.

Doubles.

Intergrowth twins along (111) are common, sometimes polysynthetic, often lamellar in the direction of the twin axis or elongated parallel to the diagonal twins of the plane. Typically, crystals (simple and twins) are unevenly developed: elongated, shortened or deformed. Characteristic are dendritic forms, which represent uniform accretion of many crystals (uniformly deformed or regular) in any one direction. These are, for example, twin (111) crystals, elongated along the 2nd order symmetry axis and accreted parallel to the faces of the rhombic dodecahedron) or intergrowths of regular twin crystals, branching in the direction of the edges and diagonals of octahedral faces, as well as parallel intergrowths of crystals elongated in the direction 4th order axes. In continuous deposits of native copper during etching, signs of collective crystallization are revealed with the development of large grains at the expense of smaller zonal grains of irregular shape.

Aggregates. Distorted crystals, in single irregular grains, dendrite-like intergrowths, thread-like, wire-like, mossy formations, thin plates, concretions, powdery accumulations and solid masses weighing up to several hundred tons.

Dendrites

Mining of copper ores in the world

The deposits do not have any system that allows them to be found. It is distributed in a wide variety of geographical areas and is located randomly. Thus, copper is mined in many countries, in particular in the USA, Peru, Kazakhstan, Chile, Russia, China, Indonesia, and Cuba. All types of copper are mined, regardless of its concentration in the ore. For example, chalcocite copper is produced in America.

It is interesting that there are practically no rich deposits left in the world. Copper has been mined for several hundred years, and therefore all major sources have long since dried up. So now there is an active reduction in the process of using concentrated material in production. Most often, ore with a concentration of this metal not exceeding 0.5% is used. This allows you to spend the necessary material more economically.

Copper deposits and mining

The largest copper deposit in the world is located in Chile - the Esconida quarry. Huge deposits of native copper were discovered here.

Other large deposits:

- Mines on the Keweenaw Peninsula (USA, Michigan);

- Chuquicamata mine in Chile (up to 600 thousand tons per year);

- Corocoro mine in Bolivia;

- Gumishevsky mine (Middle Urals, Russia) - now depleted;

- Valley of the Levikha River (Middle Urals, Russia);

- Gabbro massif (Italy).

According to the US Geological Survey, the largest copper deposits belong to Chile. Next come the USA, Russia, Peru and Mexico.

Copper mining methods:

- Open;

- Hydrometallurgical - when copper is leached from the rock with a weak solution of sulfuric acid;

- Pyrometallurgical – consists of several stages (concentration, roasting, smelting for matte, purging and refining).

Production technologies

The mined ore has a low concentration of copper. To obtain one ton of metal, on average, 200 tons of ore will be needed. To extract it, the modern metallurgical industry uses the following technologies:

- hydrometallurgical;

- pyrometallurgical;

- electrolysis.

The pyrometallurgical method of rock enrichment uses chalcopyrite for processing. This common technology uses two stages of operation. The first is oxidative roasting, the so-called flotation. The resulting rough concentrate contains 10–35% pure substance. Then the copper is refined and vitriol is added to the solution. As a result, non-ferrous metal is released with almost one hundred percent purity.

With the hydrometallurgical method, the metal is leached, then sulfuric acid is added. As a result, a solution is obtained in which copper and various metals, which may be precious, are released. This technology is applicable for the production of copper from poor rocks.

For oxidative roasting of minerals with a high sulfur content, the ore is heated to 700–8000 degrees, and the amount of sulfur is halved. The result is an alloy of sulfides. Side airflow in the convector allows you to obtain blister copper of 91%. To achieve a higher purity of the metal, electrolytic refining occurs to obtain a 99% composition.

In industry, this element is practically not used in its pure form. The most famous alloys are:

- brass – an alloy with zinc;

- bronze – with tin;

- various babbits - an alloy with lead;

- cupronickel – nickel is added to the composition;

- duralumin – connection with aluminum;

- jewelry alloys, where gold is added in various percentages.