Many people know and love the taste of smoked meat, but the products sold in stores are very far from ideal, so you have to dodge and prepare the products yourself. To prepare the right smoked meats, the correct smoking technology is very important, compliance with which is a guarantee of obtaining a quality product. Despite the fact that the types of smoking are approximately similar, the structure of the smokehouse differs significantly. All this will be discussed in the next article.

Smoking meat

Operating principle of a cold smoked smokehouse

When considering options for building a smokehouse with your own hands, it is important to understand the principles by which products are smoked using the cold smoking method. At home, with minimal costs of materials and time, it is possible to assemble various types of smokehouses

Most often, devices for hot smoking are assembled. They are considered simple, reliable and trouble-free in operation. However, the resulting products as a result of smoking often have significant disadvantages, for example, they have a short shelf life, and the risk of simply burning meat and fish in such a hot smokehouse is much higher than in a cold smokehouse.

A cold smoked smokehouse is another matter; the fundamental difference with other types is that the hearth that produces the smoke is located at a certain distance, after which it cools down to an acceptable +25C +30C. It is the low-temperature mode of food processing that makes this type of culinary processing the most successful for obtaining home-made smoked meats.

The structure of a smokehouse is similar to the structure of similar structures; among the required elements is a hearth where wood is burned, a chamber where the process of saturating meat, cheese, vegetables and fruits with smoke occurs, and a chimney that connects the hearth and the chamber, supplying and simultaneously cooling the smoke. It is the presence of a chimney in the design that causes the temperature of the smoke to decrease when entering the smoking chamber. In general, the work process can be described as follows:

- After loading the meat into the chamber, the oven is lit;

- The wood burns in the stove, emitting smoke;

- From the firebox, smoke enters the chimney at a temperature of about 100 degrees;

- After passing through the chimney, it cools down to about 35-40 degrees;

- Filling the chamber volume, the smoke cools to a temperature of approximately 25-27 degrees;

- Depending on the time of year and day, the combustion process is regulated by valves - opening the supply of oxygen and smoke or reducing it.

During smoke treatment, products are impregnated heterogeneously, some absorb it quickly, others take longer due to their size. But unlike hot smoking, when temperature significantly affects the cooking process, in a cold smoking chamber the temperature factor is completely eliminated. This point is the most important fundamental difference from other types of food processing using smoke.

The absence of high temperature in the chamber allows you to preserve more nutrients and at the same time does not allow the food to dry out too quickly. On the other hand, the natural smoking temperature does not stop biological processes in the same meat or lard, so the started processing procedure can last 24, 72, or even more hours. Actually, in order for the meat to dry well, it takes at least 5 days, but for pork ham this procedure should last about 14 days. But after this, the same piece of meat can be stored for about 3 weeks.

Stationary and mobile smokehouses

To build a smokehouse with your own hands, it is important to understand what type of structure it will be. A massive stationary structure made of brick and wood is usually built at a dacha or in the courtyard of a private estate. A mobile structure makes it possible to cook in any place where it is convenient, for example, in the courtyard of the house or near the garage. The difference lies in how correctly and accurately the assembly of the device is done.

The advantage of the stationary option is that it is planned in the general ensemble of courtyard buildings. A cold smoked smokehouse can be included in the overall construction of garden stoves that are so popular today with a barbecue and a fireplace for a cauldron. Or maybe it was built separately, for example, as a temporary structure in the far corner of the garden. Such a structure does not require large expenses and it can be used as a training place to start a culinary career.

The mobile version allows you to expand the possibilities of using the device, for example, if you make it collapsible or in the form of a transformer, then it can be used both as a barbecue and as a barbecue oven, and of course for its intended purpose. And if it is also equipped with a smoke generator, then the smoking process can be made almost automatic.

As for materials, much depends on the goals that are set before starting construction. If this is a building that will be used from time to time for personal needs in the future, then it is better to use inexpensive materials, for example, find a 200 liter barrel and 50-70 pieces of red brick. If you plan to start smoking as a business, then it is better to immediately make capital investments and build a large stationary stone smokehouse. Moreover, it makes sense for a business to allocate a separate spacious room in which the marinating of products before loading into the chamber and the ventilation process after unloading will take place. Particular attention must be paid to this point - after lard, meat or fish are removed from the smoking chamber, they must be ventilated in the open air for at least 24 hours in order to reduce the concentration of harmful substances in the tissues of the products.

Cold smoking process of fish

Stock up on fuel so that there is enough for the first 8 hours of smoking. This is necessary to effectively maintain smoke. It is not advisable to interrupt during such time periods. Control the fire to prevent the fish from catching fire. Otherwise, cold smoking will quickly become hot.

The fish is smoked at a temperature of 30 degrees. Small carcasses take no more than two days to prepare; large ones take seven days. After completing the process, let the fish hang for 2 days. Then the taste will be rich and the color will be golden.

As an example, let's look at how to properly cook mackerel in an automatic smoker.

Clean large specimens, rinse, gut and dry salt. Keep the fish for 8 hours, then remove it, wash it from excess salt and hang it in the air. During the drying period, in order not to spoil the product, do not allow insects to enter.

Now we need to prepare the equipment. The automatic smokehouse consists of:

- cabinet;

- air duct;

- smoke generator;

- fuel compartment;

- racks

The smoking process goes like this:

- load sawdust into the fuel compartment;

- place the fish in the smoking cabinet;

- connect power;

- set the optimal temperature.

Smoking will be automatic; you do not need to constantly monitor it. The fish will produce tasty and elastic meat.

Main rules of smoking

The entire smoking process is based on three pillars that have been used at all times. Therefore, regardless of the choice of smoking method and location, you must adhere to the following rules:

- Heating and the flow of smoke should occur gradually. The meat must be evenly immersed in smoke and heat, otherwise any product will lose most of its components, which will spoil the taste and significantly add harmfulness;

- The smoke contains both light and heavy substances, and if in the case of the first, they will be welcomed in the smoking chamber, they will be useful and it is with the help of them that cooking will be carried out, then all the soot from the heavy components must settle on the pipe, or leave into condensate. Otherwise, the result will be the same as when cooking meat over an open fire, only there will be no fire, and only smoke will remain;

- Smoke should not leave the smoking chamber ahead of time. It is possible to achieve unique taste and aromatic qualities only when the smoke evenly enters the product, lingers there until it fizzles out, and only then leaves the meat and is replaced by fresh meat. It is not difficult to provide such a scheme, since at high temperatures the smoke is light and goes up on its own; you just need to hold it in the right place.

And, of course, you need to remember that the size of the smokehouse does not affect anything. It will be enough to strictly follow the construction technologies - there should be 2 or more cm from the product to the wall.

Tips for use

A cold smoked smokehouse at home is convenient and practical. But when using the device you must follow the safety rules:

- avoid contact with flammable materials;

- do not touch hot surfaces with an unprotected hand;

- do not install the structure on an unstable base;

- do not allow water to get into the electrical wiring and the smoke generator compressor;

- do not use sawdust with traces of paint, varnish, or impregnation;

- do not leave small children unattended around;

- do not install the smokehouse near a residential building to prevent smoke;

- control the temperature to prevent overheating;

- Do not process products that have expired.

Smokehouse at a safe distance from home

The chimney and chamber must be periodically cleaned of carbon deposits, and the grates and hooks must be washed with detergents. When the smokehouse is not working, it is advisable to leave it slightly open for ventilation.

Food preparation

Lard, game, fish or meat are prepared in a certain way before smoking, since the products are processed with smoke at low temperatures. Smoking has preservative properties and extends shelf life, but this does not happen immediately, but gradually. To prevent the delicacy from spoiling during a long process, pre-salting is required.

Salting fish before smoking

Cut the lard into pieces 7-15 cm, soak in a marinade of water, salt and spices. The brine must be concentrated so that the raw egg floats. Keep in the refrigerator. After 3-5 days, remove the lard, dry it and put it in a smokehouse for further processing for 1-2 days at a temperature of 30°C.

The fish must first be gutted and washed. Place in a bowl, sprinkle generously with salt. After 2-3 days, remove, rinse thoroughly in running water and soak for 1-2 days. Then the fish should be allowed to air well in a draft until it is semi-moist. The time depends on the size and structure of the pulp. Smoke for 2 days at a temperature of 30-40°C.

Meat is salted dry, wet or a combination. Keep in the refrigerator under pressure from 5-7 days to 2-3 weeks. Then the semi-finished product is dried for about 5 days in a draft and sent to smoke for 2-3 days.

How to store smoked products

Cooking smoked products occupies a special place in the life of every food lover, but it is not enough to prepare a high-quality dish, you also need to be able to preserve it to prolong the pleasure. Therefore, the storage of products prepared by smoking must be approached in a special way.

If the food was obtained during hot smoking, then the product can simply be stored in the refrigerator, but no more than 4 days, since such food is intended to be eaten quickly. But if you need to increase the storage time, you can take a saline solution, soak a cloth in it, and then pack the finished product in it. To preserve the aroma, parchment paper is used, which is also used to wrap the food.

Cold smoked products are stored much longer - about six months, but be sure to rub the food with salt; using this method will not only increase the shelf life, but also preserve all the beneficial substances.

If the smokehouse was assembled independently, then after cooking the food should be thoroughly cooled and placed in a place that is slightly humid and well-ventilated. With this storage method, products can be stored for several years.

It is important to remember that you cannot store smoked meats in places of high humidity. Because in such conditions mold forms. If a white coating with a bad smell appears on the food, you should rinse the food well with brine and then smoke it again.

With each smoke treatment, the product dries out more and more.

If smoked meat gives off an unpleasant odor, then you should not eat it. Most often, such products spoil from the middle, so you can pierce the meat with a knife in the center and make sure that there is no smell, and only after that you can eat it.

Interesting video

The benefits and harmful properties of smoked meats

Fish smoked using the cold method can be beneficial for the body if the cooking rules are followed. If the process technology is violated, smoked meats can be harmful.

Benefits of snack

The benefit of eating homemade smoked meats is that if the step-by-step process is followed, pathogenic bacteria do not remain in the thickness of the fish. Amino acids and proteins remain in the meat, which are involved in the construction of muscle tissue.

During the cooking process, the product does not become fattier, which has a beneficial effect on the figure. Cooking with your own hands will provide confidence in the freshness and quality of the raw materials.

Possible harm

The harm from consuming cold smoked meats lies in the possible negative impact of carcinogens from smoke on fish fibers

It is important to choose the right wood and not to pour household chemicals on the fire for ignition.

Improper storage can cause spoilage of the product, so you need to pay special attention to the quality of the raw pulp

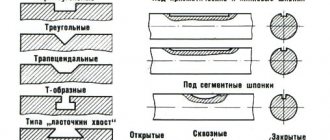

Types of smoking

People began to use this method of preparing fish and meat a long time ago. Scientists have discovered quite a few rock paintings with corresponding scenes. At the moment, there are only three main smoking methods:

- hot;

- semi-hot;

- cold.

The first technology is characterized primarily by the high speed of product preparation. You can smoke fish or meat using this method in just a few hours. The advantage of this method is that in this case all harmful parasites or microorganisms die in the product. The semi-hot smoking method has approximately the same advantages. It is these two technologies that are most often used by summer residents when preparing “smoky” products on their own.

However, sometimes owners of suburban areas use a more complex and expensive cold smoking technique. Using this technology, you can get much tastier products. At the same time, cold-smoked fish and meat can be stored much longer. The main disadvantage of this technology is the length of the process. Fish or meat can be smoked using this method for several days.

Hot smoking.

All types of fish are suitable for hot smoking, but river perch

, carp, burbot, eel, bream, tench, cod.

Usually, they are smoked at a temperature of 90-130 degrees for 20-120 minutes. Before smoking, small fish (Baltic smelt, capelin) are salted without gutting, and large fish are gutted. This is a fast, reliable and easy way. At home, it is often used because fish is smoked quickly, and immediately after smoking it can be served without cooling. See the article smoked fish for dinner Home smoking in ovens

is done on alder wood without leaves with the addition of a small amount of juniper, cleared of needles.

The oven is heated before placing the fish. Pre-salted fish is placed in the oven for baking. When the fish is baked until tender, proceed to the final smoking phase. Close the pipe valve and extinguish the fire in the firebox by covering it with alder sawdust. The duration of smoking depends on the design of the stove; it is necessary to determine its properties in practice. Smoking in the oven lasts an average of 2-3 hours. Keep in mind that fish can easily be spoiled by choosing the wrong wood for smoking. Under no circumstances burn coniferous species (spruce, pine) in a smokehouse. The fish will taste bitter. They are usually smoked on alder, aspen, willow or on branches of fruit trees. Leaves and green branches are of little use; it is better to smoke on rotten logs. Home smoked in a box.

Sawdust is poured onto the bottom of the smokehouse, a baking tray is placed to catch the fat that drains, and grates for fish carcasses are placed above it. Then close the box with a lid, heat and smoke for 20-30 minutes at a temperature of 130 degrees. Sometimes the smokehouse is placed on a primus stove or gas burner. In this case, the smoking time increases to 2 hours at a temperature of no more than 90 degrees. Hot smoked fish is made less salty, usually no more than 7%. Home-smoked fish is not designed for long-term storage; it is slightly salted and less saturated with smoke, so in summer it should be eaten on the day of preparation. The meat of properly smoked fish is evenly baked, easily separated from the skin, and crumbly. If smoked carelessly, the fish tastes bitter, sticky, or undercooked. If the fish is falling apart and leaking fat, these are signs that it was in the smokehouse longer than expected or that it was too hot.

Smoking preserved fish.

To preserve their catch, fishermen often salt fish while still at sea, especially in the warm season. They make the ambassador cool. Preserved fish are intended for smoking later, on the shore. If the fish has become too salty, it is better to soak it in cold water, changing the water every 2 hours.

How does a hot smoker work?

The hot smoking method has many advantages:

- The smokehouse is easy both to use and to build;

- The smokehouse can be used anywhere;

- The food preparation process is quick and uncomplicated;

- There is no need to process the resulting product.

If we talk about the design of a hot smoked smokehouse, it is extremely simple. You need to take a large container, place a wire rack in it, put the food there, and then the preparations will be completed. It is necessary to weld special corners inside in advance, on which the gratings will be placed. You also cannot do without a tray, which is placed above the source of smoldering; it is necessary so that the fat flowing from the meat does not fall on the coals and does not burn, as this can spoil the taste of the product.

Important! The lid of the device should cover the entire container, but at the same time be easily removed in order to be able to regulate the smoke output.

And the hot smoking technology itself is based on maintaining a certain smoke temperature. To do this, you need to put well-smoldering wood at the bottom of the container, previously crushed to the state of sawdust. But it is important to remember that you need a lot of wood, and therefore this should be taken into account when chopping. There are different types of hot smoked smokehouses; if the container size is small, then a few branches will suffice, but larger sizes should be approached individually.

Hot smoked smokehouse device

Choosing a smokehouse

Smokehouses are used both industrially and homemade. They can be stationary and mobile.

Smoking with a smoke generator

You can smoke cold smoked fish using a smoke generator. You can buy it in a store or make it yourself at home. The advantages of a smoke generator are undeniable:

- you can refuse bulky smokehouses;

- it is used for both hot and cold smoking;

- you don’t need to be nearby all the time, it automatically regulates the flow of smoke into the processing chamber;

- mobile, lightweight, you can take it with you wherever you want and cold smoke fish wherever you want;

- saves the amount of wood materials - wood chips, sawdust.

Smoking fish using a smoke generator

These devices are simple and convenient to use. Wood with a moisture content of no more than 14% is placed in the smoke generator housing. A tube connects it to the processing chamber. The wood chips are ignited. Smoke is pumped into the chamber of the smokehouse for cold smoked fish and the products, under the influence of heat and smoke components, acquire new smoking tastes.

The latest generation of smoke generators is equipped with a multi-stage smoke purification system, which allows you to obtain environmentally friendly, harmless smoked fish.

Homemade smokehouse

Using the advice of smoking professionals, you can make a smokehouse for cold smoked fish with your own hands.

Usually, for the processing chamber, they take old refrigerators, cabinets, metal barrels, washing machines, or build a structure made of brick or wood. The chamber is connected by a chimney pipe, the length of which is from 4 to 8 m, with a firebox in which a fire is lit. Passing from the firebox to the chamber, the smoke is cooled to the desired temperature, enters the lower part, enveloping the products, saturating them with smoking substances and heating them.

Homemade smokehouse from a barrel

Such a DIY smokehouse will allow you to prepare smoked products that are not inferior in quality to store-bought ones, as well as to those prepared in industrial smokehouses.

Smokehouse for one-time smoking of fish

Disposable smokers are very easy to use. Most often, cold smoked river fish is prepared with them while fishing.

Disposable fish smoker

The kit may include alder chips, salt, pepper, and most importantly - trays. Wood chips are placed in an even layer in a large tray, a second tray is placed on top - perforated (with holes), fish is placed in it, covered with a lid and placed over the coals. To prevent the fish from being cooked, increase the distance to the coals. You can use a stand for the Taganka.

One set includes smokers - 3 pieces, each for 1 serving of fish.

If, while fishing, you didn’t have anything to create a smokehouse in your trunk or backpack, you can build a smokehouse from whatever is at hand. Since the temperature in the cold smoking chamber is not high, you can use various available materials to arrange it - for example, a two-layer polyethylene film is stretched over racks of poles (170 cm high), and the ceiling is covered with burlap. They dig a hole in which to build a fire, and dig a shallow trench from it instead of a chimney. Metal sheets and turf are placed on the trench to prevent smoke loss during smoking.

Smokehouse in the ground

Stationary smokehouse

Very good news is the fact that no special costs are expected, and if the necessary materials are found in the household of a zealous owner, then all you need to do is make an effort.

Smokehouse device

The principle of operation of the smokehouse

The diagram shows the structure of a classic smokehouse, where:

- Smoke generator (furnace).

- Chimney channel.

- Smokehouse.

Now let's start manufacturing, using ready-made drawings or developing your own diagram according to our recommendations.

| Let's decide on the location and dimensions of the smokehouse | To build such a brick smokehouse, we will use a small plot of land with a length of 4 m. It is very good if it is possible to install the smokehouse on a small slope, since in this case it will be easier to install the chimney at the desired angle. |

| In accordance with the specified dimensions, we will dig holes and trenches | So, the site has been selected (in our case, on a slope), and now earthworks can begin. Let's start with the fact that to create a chimney you will need a pipe with a total length of about 3 m and Ø150-200 mm. If there is one, what is its length? If it’s 2.9 m, then it’s okay. It’s just that the distance between the pits needs to be made in such a way that the edge of the pipe does not reach the brickwork, but ends up inside it. Simply put, make the distance between the holes 25–30 centimeters less than the length of the existing pipe. The stove should be at the bottom, so a pit is made under it in such a way that its width will be 50 cm, length 70 cm, and depth - a couple of spade bayonets. |

| Dig a hole 60x60 centimeters | On a higher part of the slope (it’s good if the difference in the location of the pipe is at least 50 cm), dig a 60x60 cm hole to make a foundation for the smokehouse. Depth – a couple of bayonets below the pipe location. (It may be less - it all depends on the type and density of the soil that was dug up, but there is no need to make a foundation on black soil). By the way, we will still need clay, so it needs to be placed separately from the ground. |

| Let's check how the pipe is laid | After digging out the hole, we’ll check how the pipe fits and whether we made a mistake with its length. If everything is in order, then you can continue working. |

| Let's make a foundation for the firebox | Now let's fill the dug holes with concrete. Under the smokehouse - level with the pipe (or slightly lower). And for the firebox - 10 cm below the pipe level. |

| Let's start building a firebox | After the concrete has set, we will begin making the firebox. Having mixed a low-fat clay solution, we lay it on the foundation. On top, along the entire length of the firebox, we will lay refractory bricks, laying them flat on the clay mortar so that the base is under the pipe. This pillow will be the base of the firebox, so we will build the firebox on it, as shown in the photo. Some people prefer to use cement-sand mortar for masonry, but this is not the best option, since with high heat the bond between the bricks will be broken. |

| We will concrete the edge of the pipe so that soil does not fall into the firebox | Having laid out the walls, we will ensure good heat transfer from the pipe to the ground by sprinkling it with clay. By the way, if there is no suitable pipe, then the chimney can be made of red brick. |

| Now let's install the cast iron door | It’s good if you have a cast-iron door in advance, then the size of the firebox is adjusted to fit it. After installing the door, we will cover the oven. We had a slab of a suitable size, but if we don’t have one, we can lay reinforcement and make a cover from fire bricks. |

| We will make a pipe-shaped base for the smokehouse from bricks | Now let's start making a pipe-shaped base for the smokehouse. Its size is 50x50 cm, and we will do the masonry with simple red bricks on cement-sand mortar. |

| Here's what we got | Such a structure should work out. The height of the base is made slightly above ground level. |

| Everything works perfectly | Let's do a test fire - everything works great! |

| Let's start assembling the smokehouse frame | Now let's start making a smokehouse, the dimensions of which will be 60x60 cm. |

| Having assembled the frame, we begin to sheathe it with boards | To make the frame, we will use 4x4 cm bars. We will nail the first layer of boards onto the finished frame in a vertical position. We will install a metal chimney on the roof. In this case, the tree does not need protection from fire, since the smoke temperature is very low. |

| Let's make sure in advance that the rods can be installed | Since we planned that the products will be hung, we will need to attach boards with cut grooves for metal rods on the sides. |

| We'll cover the outside with pine clapboard | The second layer will be a lining made of coniferous wood; we nail it in a horizontal position. The same applies to the door. Such a device will help minimize smoke loss. |

| Thanks to the installed thermometer, you can find out the temperature inside the chamber | Also, in the previous photo you saw a pin sticking out of the door - this is part of the thermometer. Its dial is located outside, so you can control the smoking process. |

| The smokehouse must be attached to the base | The time has come to put everything together, for which you need to secure the smokehouse cabinet to the brick well. We remember that the base was made 50x50 cm, and the cabinet 60x60 cm. This was done specifically so that water would not get inside the base. To fasten it, we will use metal dowels, fastening it through the lower block to the brick base. There is an alternative option - attach metal corners to the base, and a cabinet to them. All existing cracks are covered with solution. |

| The roof must be protected from precipitation by covering it with roofing material. | To complete the work, all that remains is to open the wood with a protective agent and cover the roof with corrugated sheets or metal tiles. All that remains is to carry out the tests. |

| A mesh must be placed on the tubular base | Cases are different, so it is better to play it safe by placing a metal grate on the base - even if some product falls off the hook, it will not fall to the bottom, and its smoking will continue on this protective device. |

| Dry wood is burning in the firebox | We have already talked about what kind of wood can be used for smoking. Do not ignore the advice of people who have been preparing food this way for many years. We light the stove. |

| The smoke went well, so you can start smoking | The smoke flows well, so you can close the door, remembering to control the temperature inside the smokehouse. |

| Since firewood burns out quickly, you need to add new ones. | Don't forget to check the firebox and add firewood. |

| Smoked meats can be eaten | And now, the smoking process is completed - the products are ready for consumption. |

| All that remains is to make a path, and the smokehouse can be used at any time of the year | The space around the smokehouse can be improved by making a path. |

Wood used

What kind of firewood and sawdust is best to use for the fireplace?

The technology of cold smoking fish involves the use of hardwood. The most commonly used trees are maple, aspen, oak, rowan, pear and apple, which practically do not emit resins, but produce antibactericidal smoke.

It is noteworthy that the type of wood used affects the taste and aroma properties of the smoked product. For example, ash gives fish a rich taste, hazel gives a sharp and intense aroma, and maple imbues smoked fish with the taste of meat.

Many people think that only dry wood should be used for a smokehouse. However, this is not necessary. It all depends on your desire and preference.

If you want your finished fish to have a tart taste and an enhanced brown color, you can use slightly damp wood. And if you want the smoked product to have a bright golden crust and a delicate aftertaste, then choose well-dried branches.

In general, you can experiment with using all kinds of wood, creating different combinations. For example, blackberry, currant and grape leaves and twigs added to the hearth give a characteristic unique taste. Fish and hornbeam sawdust will impart a unique, specific taste.

It is best to use several types of wood fuel, while maintaining a simple ratio: there should be a little more fruit wood than regular wood.

When conducting taste and culinary experiments, it should be remembered that it is best not to use coniferous trees for smoking fish, as they impart an unpleasant bitterness to the product and release resins that settle on the surface of the smoked dish as a thin layer of soot.

You should also not add firewood contaminated with fungi, mold and rot. Before using wood, it is necessary to remove the bark, since during combustion it can release toxic substances and give products an undesirable bitter taste.

You should be very careful when using birch wood, as it can impart unnecessary bitterness to the smoked product. It should also be mentioned that under no circumstances should you fan the fire in the hearth.

During cold smoking, the wood should smolder actively and intensively; for this purpose, the broken branches should be covered with fine sawdust

It should also be mentioned that under no circumstances should you fan the fire in the hearth. During cold smoking, the wood should smolder actively and intensively; for this purpose, the broken branches should be covered with fine sawdust.

Having decided on the type of wood for making a fireplace, let's now think about how to prepare our fish directly for the smoking process.

Smoking material

There are whole legends about the choice of material, so we also decided to pay attention to this. Various sources indicate that the most suitable wood is fruit trees, but it does not specify in what form they should be presented or how to prepare the material in practice.

A short course on the smoldering process wouldn't hurt. It is known that combustion is a reaction of a compound with oxygen, and the products of this reaction do not always include only carbon dioxide. The output is various resins, phenols, aldehydes, which are presented in light and heavy volatile compounds.

Heavy fractions are called carcinogens; they are harmful to the body, but during combustion, when the temperature is high, the process of pyrolysis (burnout of gases) occurs.

Of all types of crushed material, shavings are the most favorable for pyrolysis. But it is quite difficult to use them, since there is a high probability of fire, which is categorically unacceptable when smoking.

If we consider sawdust, then they are not as good for smoking as many claim. They contain very little oxygen, so pyrolysis is practically impossible. The best option would be wood chips, chopped so that the dimensions of one piece do not exceed 2-3 cm. When selecting the material, they are guided by the possibility of its preparation. Wood chips are easy to make yourself and are also available commercially. For self-cooking, the wood is sawn across the grain, and then the sawn layer is split into small pieces.

To select the type of wood, you must have solid experience or use special tables. Let’s immediately make a reservation that you cannot take conifers or birch with bark elements. They contain a lot of resins, so the product will acquire a bitter taste. Other hardwoods can be used either in combination or independently.

The mentioned tables indicate how to smoke this type of product and whether it is necessary to add other breeds for flavoring. If you don't have similar reference materials on hand, choose alder chips or beech chips. These types are considered universal and go well with meat, fish and poultry.

Smoking recipes

Cold smoked fish at home turns out elastic, appetizing and aromatic.

Delicacy salmon

Smoked salmon is the king of gourmet fish. You can prepare tender pulp from the following ingredients: salmon steaks or half-steaks, 1 liter of 20% brine. The cooking recipe is as follows.

Soak red fish steaks in 20% saline solution for 12 hours. Wash the semi-finished products and dry the pulp. Place the steaks on a greased grill and smoke for 2 days. Rich and flavorful salmon goes perfectly with butter, caviar, vegetables and salads.

How to smoke fish at home

Omul

Moderately fatty omul requires smoking in 2 stages. Required list of products: 5-6 pieces of omul fillet, 1 tsp. coarsely crushed pepper, 1 tsp. medium ground salt. The step-by-step cooking method is as follows. Rub the omul fillet pieces with salt and pepper. Leave on the refrigerator shelf for 12 hours.

After a while, rinse the pieces, remove crushed pepper and place on a wire rack. The first time, smoke the fish for 4 hours, then moisten the flesh with a cloth soaked in vodka, sprinkle with a mixture of peppers and return to smoking for 18 hours. The glowing pulp can be cut into thin slices of carpaccio and added to sandwiches or salads.

Whole carp

To make the carp appetizing and there are no bones left, you need to cut the carcass on the side, salt the flesh, put a bay leaf, black peppercorns, dill and an onion ring into the cut.

Place the semi-finished product in a bag, dig the workpiece into the ground and leave for a couple of hours. Dig out the fish, turn it over and bury the bag again for 2 hours. Next, remove the carcasses, rinse and hang upside down in the smokehouse

Cook for 2 days, paying attention to maintaining the temperature at 25-30℃

You should choose balyk or fillet in plates for storage

Cold smoking technology at home: meat preparation

This product is also cold smoked at the dacha quite often. They prepare the meat for processing depending on what they ultimately want to get. So for basturma you will need:

- 1 kg pork fillet;

- 100 g of saltpeter mixture;

- 1 liter of water;

- ½ tsp each of sugar and cumin;

- 1 clove of garlic.

The garlic is first crushed, and then all the ingredients are poured into water. Pour the prepared brine over the meat and leave the pan in a cool room for 4 days. Next, the fillet is removed, thoroughly wiped with a towel and dried for 24 hours. This meat is smoked at a temperature of 25 °C until cooked.

To prepare raw smoked ham, the following ingredients are used:

- 7 kg ham;

- 700 g salt;

- brine of 3 liters of water, 350 g of salt, 2 g of sodium nitrate.

The thickness of the fat on the ham chosen for smoking should not be less than 3 cm. In this case, the chilled meat is rubbed with salt and placed in some container. Next, a load is placed on top and kept for 1-3 days at a temperature of 4 °C. The remaining salt is first poured onto the meat.

At the next stage, the pickled pieces are poured with chilled brine and left to marinate for 10-15 days. After this, the meat is removed from the container and hung in a cool room to dry for 3 days. Next, the ham is soaked for 2-3 hours, washed with water and dried with a towel. Smoking of meat prepared in this way should be done with thick smoke at a temperature of 35 °C. The pieces should be placed in the barrel for a period of 3 hours every day for a week.

Cold smoking method

During the smoking process, moisture is removed first from the surface of the semi-finished product, and then from the inner layers. The fish becomes dehydrated and becomes denser. The fact that the products are cooked at low temperatures leaves the fish proteins not curdled, so the flesh does not soften, as with the hot method, and does not crumble when slicing. During this type of smoking, fat does not melt, but is distributed inside the pulp and on the surface of the product. This makes them juicy.

The types of smoking apparatus and features of the technology for cold smoking fish are discussed above.

Fish in a smokehouse on grates

For smoking, fish of the same size and type are loaded into the chamber so that it is evenly smoked and at the same time reaches culinary readiness. Place them on grates (preferably with their backs down or skin-side down if they are layers) or hung on hooks. Leave gaps between products of at least 1 cm. Before loading, the grate can be greased with edible fat so that the products do not stick.

If 2 or more gratings are installed, the distance between them should be at least 10 cm.

Add smoke and close the lid.

Cold smoked smokehouse

Smoking is carried out at a temperature of 20-25 °C. At the end of smoking, you can raise it to 30-35 °C. The temperature is checked using a thermometer. The processing mode depends on the type of raw material.

The time for smoking fish in a cold smokehouse can last from 18-20 hours to 4-5 days. Larger and fattier specimens take longer to smoke.

The readiness of products is determined organoleptically by consistency, color, taste and smell. Towards the end of the process, the color becomes golden yellow, the consistency becomes dense, the taste and smell become with pronounced notes of smoke.

It is allowed to leave the finished products in the smokehouse for a while to cool by opening the lid or door and stopping heating. After cooling, the fish is hung under natural conditions to ventilate from excessive smoke aromas and to ripen the flesh from several hours to 2-3 days. Choose a place with good ventilation and no direct sunlight. If smoked meats are exposed to air, they will become tough.

The process of smoking fish in a smokehouse

You need to make sure that flies do not land on the fish. The larvae they may deposit on the product can be harmful to those who try the smoked meat.

The smoky matte surface of the finished products can be wiped with a cloth dipped in sunflower oil.

The shelf life of cold smoked fish at a temperature of 2-4 °C is 2 weeks. For longer storage, products are placed in vacuum packaging or frozen. The peculiarity of smoked fish is that during storage they lose their pronounced taste. It's better to eat them quickly.

During storage, the head and flesh near the spine begin to deteriorate first. If foreign odors appear in these places, do not risk eating the product.

Smoking - harm and benefit to the human body

In terms of taste, many smoked products are superior to their raw materials prepared in another way. However, the amount of treats consumed is very limited.

- On the one hand, the limiting factor is the high cost.

- On the other hand, there is an established stereotype according to which an excess of carcinogens contained in combustion products causes cancer.

- Finally, on the third side is the well-known energy balance, because it is not plant foods that have to be smoked, and all products of animal origin have a high calorie content.

Our article will act as a kind of “lawyer” who, if he does not elevate smoking above other types of cooking, then he will not allow his favorite smoked meats to be put in last place.

Most of us purchase products at the market or in specialized stores. Everyone noticed that the smoked product costs much more than its raw materials. Suppliers explain this difference in prices by the costs that go into smoking. If we remember that often even in factories a liquid extract is used instead of natural smoke, then the desire of the manufacturer, supplier and seller to make maximum profits becomes obvious.

This fact of dishonesty alone suggests the idea of self-smoking. If we also take into account the variety of recipes, the ability to vary tastes, availability and low cost, it turns out that smoking meat, for example, can be quite profitable.

As for the content of carcinogens, it is necessary to understand the importance of observing the consumption of smoked products. They cannot be used as everyday food for many reasons. If delicacies are served as snacks, then the share of heavy compounds is reduced to a minimum. The correct choice of temperature, material that produces smoke, as well as compliance with all technological standards will reduce the content of harmful substances, so the volumes of consumed products will be dictated by other considerations, but not by the intake of carcinogens.

Finally, the third point applies not to smoked meats, but to any product. People who are prone to obesity can gain weight from a completely harmless product. If we consider the chemical composition of fish or meat, it turns out that with a sufficiently high protein content, there are practically no carbohydrates. They contribute to the deposition of fats in the body.

By the way, meat and lard contain a lot of easily digestible fat, but this is not where you should look for the problem of metabolic disorders. Although meat is high in calories, it is unlikely that its rationed consumption will interfere with a “good figure.” There are even cases where the diet includes certain types of meat, that is, smoked meats can be consumed, but only in reasonable quantities.

Hot smoked fish technology

The hot smoking process consists of three stages:

- Preparation. The fish is thoroughly washed, the head is removed, and the entrails are removed. If the fish is small, you don't have to gut it. There is no need to remove the scales; they will protect against harmful carcinogens entering the fish tissue.

- Salting. Fish can be salted dry or in brine. Dry salting will save time. To do this, rub them thoroughly with salt on all sides and leave for an hour. To make the brine, boil 1 liter of water with 100 g of salt, cool, and place the fish in it for 2 hours.

- Smoking. After salting, place the fish on the smokehouse grate, leaving small gaps between the carcasses. Place the smoking device on a lit fire, tightly covering it with a lid. After 6-8 minutes, thick white smoke will begin to come out of the smokehouse. From this time smoking begins. For small fish it will take no more than 30 minutes, if the carcasses are large, smoke for 40-50 minutes.

The temperature in the smokehouse should be 100-110⁰С

You can determine the readiness of the product by paying attention to its color. If the smoked meat is pale golden in color, you should still keep it in the smokehouse

If the fish is a rich dark golden hue, you can finish the process.

After finishing the process, let the dish cool in the smokehouse, then let it ventilate in the fresh air for an hour.

What kind of firewood can you use?

Firewood from different types of trees

Not all firewood can be used. Firewood from the following trees is best suited:

- plum;

- cherry (without bark);

- pear;

- Apple tree;

- dogwood;

- apricot.

If you need to give smoked meats a tart taste, then the following are suitable:

- elm;

- oak;

- nut;

- beech.

For smoking fish caught in heavily polluted waters, it is recommended to use the following wood:

- willow;

- broom;

- willow.

If there is no firewood from fruit trees or if the smokehouse is made in camping conditions, the following trees can be used:

- Linden;

- poplar;

- alder;

- aspen.

Coniferous trees and those affected by fungus are unsuitable for smoking. In addition, since the pores of the fungus are easily carried by the wind, all trees located within a radius of 50 m around the infected tree automatically become unusable.

A smoke generator will help us

This type of smokehouse is very simple to build with your own hands without special skills. However, recently many innovations have appeared that help smoke fish even better and more productively. The introduction of such innovations in cold smoked fish technology saves you energy and frees up time. They will improve the taste of the finished product and help you smoke with joy and pleasure.

One of the pleasant modern innovations is the installed smokehouse with a smoke generator. The essence of this device is to produce the required amount of smoke and supply it to the smoking container, while working in autonomous mode.

You can build a smoke generator with your own hands from a fan, thermometer, compressor, several types of pipes, fittings and connecting wires, as well as from other components that are at hand. The housing for the generator can be metal cans or pans, and the smoke pipe can be any pipe made of refractory material.

To assemble a homemade smoke generator, you will need a grinder and a welding machine, as well as some skills and abilities. The most difficult thing in this matter is to weld the chimney fitting to the pipe, and also to make doors for the lids and firebox. But the result will be worth it - you will get tasty, evenly smoked fish meat without much effort.

Typically, the smoke generator should be loaded once a day with a small amount of wood chips - approximately one liter in volume. This homemade unit can be stored in a garage or closet; it is very compact and mobile.

However, do not forget that this device should be carefully looked after: regularly clean the container from decayed ash, wash the casing, etc.

Also, when using a smoke generator, it is necessary to comply with basic safety requirements:

— install the device on a hard surface.

— make sure that the electrical wiring is kept away from sources of high voltage and high temperature.

— the smoke generator must be grounded.

- keep children and animals away from the operating device.

It is necessary to listen to similar advice when smoking without a smoke generator. For example, you should build a fireplace in a fire-safe place, out of reach of small children

It is also important to put the necessary firefighting tools near the smokehouse - a shovel, a fire extinguisher, a bucket of water

So, our smokehouse (homemade or purchased) is already ready. Now let's discuss the important conditions of cold smoking.

Smokehouse from a barrel

Of course, you can use any barrel for our design, instead of a wooden smoking chamber, but this would not simplify the design much. You can make a smokehouse from a barrel more compact, even portable, only in this case you will have to make a smoke generator.

Making a simple smoke generator working with a compressor

The described design will be assembled from what is on the farm, but if the necessary parts are not available, they can be purchased inexpensively.

| Here's what we need to make a smoke generator | To assemble the smoke generator, we used 4 pineapple cans and a piece of copper pipe. We also purchased 2 quarter-inch clamps with nuts and 4 metal clamps to fit the cans. |

| Here we will make a hole for the tube | In the bottom jar we will make one hole for the drive. |

| This hole is needed to burn wood chips. | The second hole of a smaller diameter will serve as an igniter. |

| Let's make a small hole for the air supply tube | The third hole is made to fit the small diameter copper tube opposite the first hole. A little later we will look at how this design can be improved. If you choose the second option, then this hole (and the copper tube itself) will not be needed. |

| This way the squeegee will be secured inside the can. | One of the bends will be inside the jar, reaching its edge. |

| It will be necessary to make such a groove in the drive | Using a grinder, we cut out a groove 4 cm long and about 8 mm wide, as shown in the photo. |

| The tube must be significantly smaller than the internal diameter of the drive | The copper tube should not fit tightly into the fitting. |

| It is necessary that the tube ends further than the groove | And it shouldn't be short. |

| Let's secure the first bracket, and then screw the second one to it | Having secured the first bracket, screw the second one to it and insert the tube. |

| The shield will protect the chimney channel from sawdust getting into it | To prevent the groove from becoming clogged with sawdust, we will install a metal shield made of thick metal on top (possibly from a pipe). This protection should be above the squeegee, so its fixation can be ensured by screwing support bolts to the can in the right places. |

| Shield needs to be secured | Having placed the shield inside, you can move on. |

| We use clamps to fasten the remaining boxes from which the bottom was previously removed | The generator itself will consist of three cans, and we will cut the fourth into strips, wrap them around the joints of the cans and secure them with clamps. |

| If the need arises, the chimney pipe can be extended | If such a need arises, the tube can always be extended, but we recommend using a coupling rather than a nut for the connection. |

| An aquarium compressor is enough to operate the smoke generator. | For our design we will use an aquarium compressor with adjustable air supply. |

| We will use alder chips | Now let's pour wood chips inside. |

| With the compressor running, ignite the wood chips | Turn on the compressor and set fire to the wood chips. |

| By moving the copper tube inside the squeegee, we achieve the greatest smoke emission | By adjusting the seating depth of the copper tube, we make adjustments to ensure that there is as much smoke as possible. Everything works perfectly! |

| In a more advanced model of the gas generator, the air supply is done differently | Now let's look at how this model can be improved, since this modification will help reduce the temperature of the smoke. |

| The holes in the bottom of the jar will serve to pour out the ash. | You can also make sure that the ash spills out of the generator and does not accumulate in it. In this design there will be no inner tube - the squeegee is screwed to the edge of the can, and to prevent sawdust from getting into it, we will make a petal from tin from the inside, making many small holes in it. |

| Ash will fall into the jar | At the bottom of the jar we will screw a screw cap from a glass jar with two bolts, and then we will drill a lot of holes. |

| Let's connect our container | It will be enough to insert the jar, turning it slightly, and the sealed ash container is ready. |

| The air supply will be carried out through the chimney pipe | As we have already warned, in this design there will be no copper tube; air will be supplied through an external exhaust. |

| The fitting can be either new or used | To do this, we use a purchased (or used) fitting to bleed air from the brake system (preferably from a domestic car, since it is cheap). To do this, you need to drill a hole in the drive, and, having selected a suitable tap, cut the thread. There is a side hole at the top of the valve; if it is small, it needs to be drilled out to Ø2 mm. After screwing it in, the hole should be directed towards the smokehouse. |

| Connect the tube to the fitting and turn on the compressor | This fitting is specially made so that a rubber tube can be pulled over it while bleeding the brakes, so there will be no problems connecting the hose from the compressor. |

| Add wood chips | Now you can add wood chips and set it on fire. |

| The system performed well | Tests have shown that the system operates smoothly, producing the required amount of smoke. |

Preparing fish for smoking

The success of cooking depends on preparation. The choice of fish for smoking begins with inspection:

- it must be fresh;

- it is unacceptable for it to be frozen and defrosted several times;

- Fish for hot smoking should have strong scales. This way the top layer will not collapse and the meat will not fall apart.

Gutting and cleaning

Cutting and gutting are important points, as this directly affects the taste of the finished product. Uneviscerated fish will taste bitter. The cutting must be done correctly:

- carcasses less than 400 g are used without entrails;

- the scales are left to preserve the juiciness of the meat; it will also prevent disintegration and prevent soot from getting on the meat;

- if the head is to be smoked, remove the gills;

- the black film is removed to preserve the taste of the product;

- Fish that are too large are cut into pieces or filleted, since it is better to smoke fish of approximately the same size in a smokehouse.

Marinade

For hot smoking, the fish is pre-salted. With dry salting, prepared carcasses are rubbed with salt half an hour to an hour before cooking and placed in the refrigerator under pressure. This way, salt penetrates the fibers of the meat and frees it from excess moisture, and at the same time destroys pathogenic microflora. If the carcasses are large, the time is increased to 1.5-2 hours so that the fish is completely salted. Afterwards you will need to soak to free the meat from excess salt.

Instead of dry salting, it is possible to marinate the carcasses in brine: per liter of water you need 2 tbsp. l. salt, a teaspoon of sugar, 3 bay leaves, a teaspoon of black pepper. You can add herbs. The marinade needs to be boiled and cooled. The carcasses are dipped into the solution and left in the refrigerator for a day. This method will help give the product an original taste.

It is usually recommended to marinate carcasses for cold smoking if disinfection of meat is needed. For red fish, the amount of spices is reduced to preserve the natural taste. The fish are soaked in olive oil with lemon juice and onions.

Drying

It is better to smoke pre-dried fish, otherwise it will turn out more boiled than smoked. Pickled carcasses are pre-dried and left in the fresh air for up to two hours. In summer, the preparations are wrapped in gauze soaked in a vinegar solution to prevent insects from getting to the meat. After drying, the carcasses are rubbed with sunflower oil.

Smokehouse from a gas cylinder

First of all, let's talk about safety precautions, since cutting a gas cylinder without first preparing it is very dangerous. Watch an educational video on this topic.

Video: how to safely cut a gas cylinder

| First, let's wash the bottle. | As already mentioned, the cylinder must be prepared properly. |

| Let's do the marking | Now you can start applying markings. |

| Cross markings | It is convenient to mark round parts using a metal meter. |

| Cut out a hatch in the cylinder | Now you can start cutting out the hatch in the cylinder using a grinder. |

| Remove the cut out part | It is advisable not to go beyond the markings, but in this case you will have to pry the cut out part with a crowbar to remove it. |

| You need to cut close to the seams, where the metal is thinner | This is what should happen. As you can see in the photo, the cut was made close to the welding seams - where the metal is thinner. |

| Cutting off the supporting part | A “sole” is welded at the bottom of the cylinder, thanks to which it becomes stable. Since we don't need it, we'll cut off this part. |

| You also need to cut out a hatch in the receiver | We will use a receiver from a truck as a smoke generator. There are no explosive vapors in it, so you can cut out the door without preparation. |

| Cut identical holes in the receiver and cylinder | On the same side where the door is cut, we cut holes on both cylinders, the radius of which should be as close as possible to the diameter of the other cylinder. |

| The parts fit together, otherwise you will have to weld large gaps later | We check how tightly they fit together and adjust if necessary. |

| The parts are welded so that there are no gaps left | Now all seams need to be thoroughly welded. |

| We weld the hinges | The hinges are welded. |

| Doors should open and close without jamming | The doors should open without jamming, and when closing, fit tightly into the opening. By the way, you can weld a stopper from the inside if the door falls inward. |

| Cut a damper hole in the receiver | At the end of the receiver we will make a hole for the damper. |

| It doesn't need to be made big | It will be small, as it will be needed to regulate the air flow inside the smoke generator. |

| Let's make a damper from a small piece of metal | Then we take a larger piece of metal and make a damper from it, securing it in the upper part with a bolt and nut. There is no need to tighten the fasteners, since the damper will need to be moved from time to time, changing its position, so screw the locknut over the first nut. |

| The flap should be tight and not loose | The damper should move to the side with some effort. As you can see, a plastic handle is screwed to it, but practice shows that it also gets very hot, so you can weld a piece of rod. |

| We will weld the chimney from two pipes | Let's start making a chimney by welding it at an angle from two pipes. As for the angle, it does not need to be 90˚ - it must be turned out. |

| Draw the outline of the pipe on the cylinder | Let's mark the cylinder by outlining the pipe with a scriber or marker. |

| The hole had to be cut with an electrode, since there is no cutter | Drilling such a hole is very tedious and expensive, so it is better to do it with a cutter. If there is none, then many people cut a hole with an electrode, setting the welding machine to maximum current. |

| Now let's weld the chimney pipe | Once the pipe is inserted, its position must be adjusted and then welded. |

| This pen won't burn you | It is very convenient if the lids have handles on a wooden base, since you won’t get burned when touching them. |

| Let's weld the legs and shelf | Legs and a table were welded to the smokehouse, on which it would be possible to place dishes with products prepared for smoking. Inside we will install a grill from an old refrigerator, bending it to the size of the cylinder. |

| Smokehouse from a cylinder is ready for use | All that remains is to charge the smoke generator, place the food on the grid, and you can smoke. At the same time, it is important to monitor the smoke generator - firewood or chips should smolder and not burn. |

The considered methods of smoking products allow you to prepare high-quality food that is not harmful to the body. We do not claim that smoked meats are beneficial for the human body. However, products prepared in some ways are such that experts in this matter will not even touch them. Watch a video on this topic.

Design in detail

When planning cold smoking at home, it is important to understand in detail the design of the smokehouse. Below is a version of the drawings of a cold smoked smokehouse with your own hands (without specifying materials, the design is suitable for both wooden and metal chambers)

Below is a version of the drawings of a cold smoked smokehouse with your own hands (without specifying materials, the design is suitable for both wooden and metal chambers).

In this version of the device, the smoking channel is made as a box rather than a pipe. For it, you can use boards with mandatory sealing, metal sheets or bricks.

Smokehouse in the apartment

For those who are deprived of the opportunity to build a smokehouse in a private home with their own hands, there is a chance to acquire a mini-smokehouse for apartment use. For these purposes, a regular goose chaser is suitable. A hole with a diameter of 10 mm is drilled in the lid, after which a fitting is inserted into it and firmly fixed. A tube about two meters long is connected to the fitting.

Holes for bolts (10 mm) are also drilled in both handles of the track. A paronite gasket is cut out under the cover with the appropriate diameter.

You need to insert a baking tray into the casserole dish, and its side edges should be at a distance of 2 cm from the walls of the casserole dish. The baking tray is attached to a stand. In addition, you will need a stainless steel grill for laying out food.

Useful tips

- When cold smoking, you should definitely add chopped cherry and apple branches, which add a special aroma to the delicacies.

- Recently slaughtered game should be kept in the cold for 3 days, and only then begin cold smoking.

- It is best to start smoking in the morning on a clear and windless day. It is also recommended to find out the weather forecast for the next 3 to 4 days in advance. You should not start smoking in inclement weather.

- In the smoking process, you definitely need trays that are installed at the bottom of the chamber. They will protect fallen pieces or carcasses from contamination, and also prevent drops of fat from falling on smoldering wood chips (sawdust).

Source

Preparation and marinating

When planning to smoke meat or fish outside in the cold, it is best and most correct to turn to the folk recipes of the peoples of the north. For example, the Buryats still use brine, a strong salt solution, to prepare fish.

It's easy to do. Pour 2/3 of water into a bucket (for 16 kg), put on fire and gradually add salt (about half a pack), checking the concentration with a potato. Place a whole vegetable into the boiling liquid. It will float when the salt concentration becomes sufficient. Remove the potatoes, add the rest of the spices and cook your marinade for another 10 minutes.

Marinade:

- salt - 450 g;

- sugar - 80 g;

- ground red pepper - 1 bag;

- black peppercorns - 1 bag;

- grated nutmeg - 1/3 tsp;

- cloves - 1 tsp;

If you want to marinate chicken meat for smoking in the same way, add to the brine in addition to salt:

- 1 liter of water to reduce salt concentration;

- 2 lemons, cut into wedges;

- orange cut into slices;

- 3 chopped onions;

- 4 cloves of garlic;

- a pinch of sage, rosemary and thyme;

- sugar, cinnamon and pepper 1 tbsp. l.

Cool the resulting aromatic brine and pour it over meat or fish. Keep the meat in the marinade for at least 12 hours. For small cleaned fish, 3-4 hours will be enough.

Do-it-yourself smokehouse manufacturing technology

If you decide to start making a cold smoked smokehouse, then you do not need to have certain skills. Before starting work, you should prepare a certain set of tools and some materials. Sheets of iron should be placed at the bottom of the firebox, thanks to which the coals will smolder evenly. Now the master digs a chimney, the depth of which should be equal to the bayonet of the shovel, while the width should be equivalent to the width of the shovel. After this, you need to use slate or a sheet of iron to close the chimney, covering it with earth. This is done to prevent smoke from escaping.

Before starting work, you need to familiarize yourself with what types of smokehouse designs there are. This knowledge can help you in the process of manipulation. Next, you need to prepare an ordinary barrel, in the lower part of which the grate is strengthened. This is necessary to install a filter that will protect products from soot and resin. Burlap can act as a filter. A steel pipe is fixed in the upper part; smoking products will be attached to it. Stainless steel is a very good material for such a pipe. When choosing a hook, you need to be guided by the dimensions, which should not be less than 10 millimeters. The top of the smokehouse should be covered with a sheet of iron.

What is a cold process smoker?

In the process of making a cold smoked smokehouse, you will need to create a device in which cold smoke will be directed away from the product. The smoke should be continuous and even throughout the entire treatment period. Its temperature is no more than 25 degrees. In order to ensure such conditions, the smokehouse must be divided into two separate parts. One of them will be the firebox, while the other will be the container. The first part should be 2 meters away from the other, and a chimney should be located between them.

Supplying the smokehouse with additional elements

If you purchase an industrial smokehouse, you will not have to worry about its design features, since this device already has everything. Whereas if you decide to make such equipment yourself, you can equip it with additional elements. One of them is a thermometer, which is equipped with a bimetallic plate in the form of a spiral. It needs to be removed from the same old slab. You can decide for yourself where to install this thermometer, but experts advise placing it in close proximity to the product that is supposed to be smoked. Such a smokehouse, reviews of which are often only positive, should have small holes on the side wall for attaching a thermometer. The indicator must be located outside. After dismantling, only the handle and nameplate will remain on the refrigerator door. You can save yourself the hassle of fixing the door; it can remain in the closed position thanks to an ordinary hook.

Such smokehouses for home smoking must undergo testing after completion of work; for this, the chamber must be calcined to eliminate foreign odors. The stove can be heated for several hours, adding firewood from time to time. It is not necessary to close the door completely. The appearance of the refrigerator body after such use may be slightly changed: the paint will come off or turn yellow. If you are not afraid of these metamorphoses, then the smokehouse does not need to be decorated with anything.

Of course, a cold smoked smokehouse, the price of which is about 20,000 rubles, can be purchased in a specialized department. However, many home craftsmen prefer to make such structures themselves. During operation, you will receive great pleasure from using the product, and a minimum amount of money will be spent on manufacturing. Some specialists do without visiting a store at all.

Smokehouse for winter

If in summer you have to make efforts to cool the smoke, then in winter at the smoke generator outlet it may have a temperature slightly higher than the ambient temperature, that is, less than the required 20 degrees. Craftsmen have adapted to install electric stoves, infrared lamps and other heating devices inside smoking cabinets. Also a mandatory design element is a temperature sensor.

Smokehouse in Buryat style

For those who are concerned about the question of whether it is possible to smoke fish outside in winter, the same Buryats will dispel their doubts. Their winter smokehouses, without undergoing major design changes, have been serving northerners for many centuries to prepare animal meat and fish for future use. The Buryats of the Baikal region laid a wooden box in the ground. Sawdust was poured into it. Another large sealed box was built 3-3.5 m from the first. A pipe was laid between them, in which the passing smoke not only cooled, but was also cleaned of resins and unnecessary impurities that settled on the walls of the pipe. The temperature of the smoke was regulated by the intensity of sawdust smoldering. Of course, when preparing cold-smoked products in this way, you cannot leave the cooking area for a long time.

DIY smokehouse for winter

You can, of course, purchase special equipment for smoking products in the store. But it is much more interesting and profitable to make a smokehouse yourself.

Wood selection

The technology of smoking fish involves careful selection of wood. This gives the final product different flavors. Coniferous trees are not suitable for smoking due to their high resin content. This will give the fish a bitter taste. Juniper and alder are ideal for smoking. Also used:

- maple;

- beech;

- oak;

- hazel;

- ash;

- Apple tree;

- cherry;

- pear;

- Rowan;

- plum.

Each type of wood adds a special taste, shade and piquancy to the finished product. Some craftsmen use birch for smoking, but then the fish will acquire a tarry smell, and only a narrow circle of gourmets like it. Several types of wood can be used for the process.

Dry wood will give the product a golden hue and a delicate taste, while wet sawdust and coals will give the fish brighter colors and a tart aroma. The bark is completely stripped off before smoking.

The wood is then reduced to sawdust and chips. Material affected by mold or fungus should not be used for smoking. Otherwise, the release of harmful substances can cause human poisoning.

Recommendations for carrying out work

At the first stage, the technician must inspect the cylinder from all sides; if it is rusty, then it will not be possible to use it for work. If there is a certain amount of gas inside, this indicates that the product is in working condition and is suitable for making a smokehouse. A smokehouse at home from a gas cylinder can only be made after careful preparation of the product.

To do this, you need to get rid of the remaining gas by turning the product over and unscrewing the valve. This will prevent a possible gas fire. Even after this procedure, propane residues will remain in the form of condensate. It is worth considering the fact that they are also dangerous. It will be quite difficult to get rid of the oily liquid that has settled on the walls. Water is most often used for this.

After you can get rid of the remaining gas, you will need to draw a line on the body with chalk along which the cut will be made. The cylinder must be divided into two parts, which are then connected by hinges. The next step will be to install the handles, weld the legs and install the grille inside. At this point we can assume that the design is ready. Using this principle, a smokehouse can be assembled from a gas cylinder, which, if necessary, can be easily moved from one place to another.

If you decide to make stationary equipment, then you need to start work by retreating a certain distance from the edge. Then a line is drawn three centimeters below the weld. This will result in two circles. Straight lines should divide the balloon in the middle. After this, the container is filled with water, which does not need to be drained when making the first cut. The water that flows out will be able to extinguish the sparks, preventing a fire from starting. Once you have made the holes, you can drain the water and continue cutting. After one semicircle has been obtained, the same work can be done on the other side. The semicircles should connect to each other. This will allow you to get the finished lid in a closed form, which will help provide cover for the flame from the wind.

Semi-hot (warm) smoking

Half-hot smoking of fish is a technology for processing carcasses with smoke at an optimal temperature of 50 to 60 degrees. Before the procedure, carcasses are salted for 18 hours. If the individuals are small, the time is reduced to twelve hours. Then the fish is washed and dried with a towel.

For smoking, either a special apparatus or a regular potbelly stove can be used. The fish is suspended by the tail or eyes in a place where smoke and air mix. Carcasses are smoked for 10 to 12 hours. All this time it is important to maintain the desired temperature. This method is quite complicated and for beginner smokers it is better to use other processing methods.