A smoke generator is a device typical for a cold smoked smokehouse. With hot smoking, smoke is usually produced directly in the smoking chamber, so a separate apparatus for producing smoke is not required. For a cold smokehouse, it is important that, firstly, the smoke reaches the products already cooled to room temperature, and secondly, that the process proceeds autonomously for a long time, without requiring supervision. A drawing of a smoke generator for domestic use, as well as a brief description of its assembly, can be found below in this article.

Smoking options

There are two main methods of smoking - cold and hot. Designs of smoking installations are being developed for these methods. Both methods have their own advantages and disadvantages, so it is very difficult to say for sure which method is better.

For example, with hot smoking, the temperature is usually in the range from 50 to 120 degrees, and the main advantage is the speed of cooking. But, at the same time, such processing cannot be called “gentle”, since high temperature can destroy most of the beneficial vitamins and microelements contained in products.

Cold smoking, on the contrary, allows you to cook food in a more gentle way, preserving nutrients, unlike hot smoking. The smoke temperature at which cold smoking occurs ranges from 20 to 35 degrees, but the cooking time will not take 2-3 hours, but from one to three days. Such a long processing period allows the products to retain their freshness longer and be suitable for consumption for another 3-5 weeks after smoking. Therefore, people who want to cook food immediately for a long period of time choose the cold smoking method, and a homemade smokehouse with a smoke generator is suitable for this.

We recommend a simple, cheap smoke generator for a home smokehouse. Compressor with ejector included. Chamber volume from 500 grams of sawdust. Delivery across Russia. All payment methods.

Preparation

Initially, everything should be prepared for work. Conventionally, this moment can be divided into several stages.

- Fuel preparation. It consists in choosing sawdust or wood chips. It is highly not recommended to use pine sawdust, as when smoked the product will acquire a bitter taste. It is worth paying attention to such options as alder, pear, apple, which can be found on sale. The color and smell of the products may differ depending on the choice of fuel. Rosemary sprigs, almond shells and other herbs with a pleasant smell are often added for a piquant aroma. During smoking, you can use both wet and dry wood chips; the former produce more smoke, while the latter are the classic option. The disadvantage of wet wood chips is a large amount of burning, which is compensated by installing a special grill or using a damp cloth. It is strictly not recommended to use painted material or material coated with varnishes or other chemicals.

- Preparation of equipment. It is necessary to thoroughly clean the chamber, chimney and smoke generator from traces of previous use. You should always keep equipment clean. After cleaning, the empty structure should be heated to a temperature of +200 degrees, and then cooled to the desired temperature. Now you can fill up the combustion products. Experts recommend adding 2 to 6 tablespoons at first, then monitoring for burning and adding more as needed.

- Product preparation. Usually meat or fish is used for smoking, but lard, cheeses, brisket, vegetables and fruits can also be smoked. Before smoking, the meat still needs to be salted. If for hot smoking this is only a recommendation, then for cold smoking it is a must. Usually salted from several hours to several days. There are as many variations as there are recipes.

What is a smoke generator?

Any smokehouse should have a compartment in which firewood or chips are placed, the smoke from which affects the smoked product. But the problem is that cold smoking, as mentioned above, can last two to three days, which makes life much more difficult, since you need to constantly maintain the desired temperature, avoiding overheating or, conversely, lack of heat. For these purposes, people came up with such a design as a smoke generator for a smokehouse.

A smoke generator for cold smoking is a device that produces a sufficient amount of smoke necessary to support the smoking process, and also transfers this smoke to the smoking cabinet.

Sketches or drawings of a smoke generator can be easily found on the Internet. Despite the apparent complexity, if you have a certain skill, simple materials at hand and advice from home craftsmen, you can make the device yourself. Its main advantage is that it can operate automatically and does not require constant monitoring.

The smoke generator device is simple. The main source of smoke in it is shavings, sawdust or wood chips that are inside the generator and slowly smolder. Features of the choice of sawdust can be considered separately, but it is necessary to pay attention to an important subtlety - do not use sawdust from coniferous trees. For smoking, as a rule, exclusively hardwood is used, and fruit chips are also allowed.

The main task of the master is to assemble all parts of the generator housing in such a way as to ensure a uniform supply of smoke to the smoking cabinet.

Rules for using a smoke generator: photos and operational features

After completing the installation of the smoke generator, you need to check its effectiveness. Using this device is quite simple. Let's look at how to properly operate a smoke generator made at home.

First you need to load wood chips into the structure. The amount of fuel may vary. As a rule, its total weight is about 0.7-0.8 kg. An important point is the choice of the type of wood used to produce the smoke necessary for smoking. It is strictly forbidden to use coniferous trees, as when heated they emit resins that will spoil the products loaded into the smoking apparatus. For smoking, it is recommended to select firewood and sawdust made from deciduous and fruit trees (for example, oak, maple or apple tree).

The technology for using this device is explained in detail in the corresponding videos. After filling with sawdust, the smoke generator must be closed, and then the chimney tube must be connected to the smoking tank. The device can be attached directly to the camera. In this case, it is simply installed in its place - close to the wall of the smokehouse.

After completing the installation of all the necessary components of the smoke generator, you need to check its functionality.

In order to ignite the sawdust, you need to open the side door. After they are ignited, the compressor turns on, dispersing the air. After completing all the above manipulations, the smoking process begins. All that remains is to wait the required time that will be required to cook the food in the smoker.

Design

In order to make a smoke generator for cold smoking with your own hands, you will need the following elements:

- A piece of metal pipe. The pipe can be round or square, with a diameter of approximately 100-140 mm. The pipe will be the basis of the device - the chamber in which the formation and movement of smoke will occur.

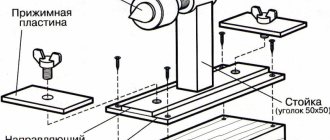

- Smaller diameter tubes for making an ejector. The ejector structure is visible in the figures.

- A spring that will be located inside the chamber. It is only needed so that smoke from the lower layers of sawdust can easily rise upward.

- A compressor that will supply air to the ejector.

- Thermometer. Using a thermometer, it will be possible to determine the temperature inside the smoke generator to avoid the possibility of cooling or overheating of the container in which the smoke is generated.

In short, the operating principle of any smoke generator comes down to a simple diagram:

- The smoke generator chamber is heated from below by an external heat source, or the sawdust itself smolders in it.

- Sawdust gives off smoke smoke.

- The smoke rises up and, with the help of an ejector, goes into the chimney, from where it is then directed through a tube into the smoking chamber.

Thus, the smoke generation process is completely automated and does not require any human intervention.

By and large, all these components can be purchased at any hardware or hardware store. To connect the parts of the smoke generator, you will also need construction tools such as an angle grinder and a welding machine, but all this can be borrowed from someone for a while.

Smoke generator stove for cold smoking

If you need to install higher productivity, cook a simple stove. It can be made from the same large-diameter pipe or a rectangular body can be welded from metal. Weld the door and make a chimney fixed at an angle. That's all the difficulties. It is also necessary to divide the internal space into two parts using a horizontally fixed metal sheet. The lower part is larger, the upper part is smaller. A fire is lit below and sawdust is poured onto the sheet. The rest of the process is known.

A pipe is laid from the stove chimney to the smoking cabinet. It should have an upward slope, albeit a small one. In this case, the entrance to the cabinet should be located in the lower part so that the smoke envelops all the products. Therefore, the cabinet is installed on a platform, legs, or pedestal. To save space, you can install a smoke generator stove under a cabinet by welding a structure from a metal corner.

Smoke generator - free-standing stove

But with this design, the smoke can be too hot. Additional measures are needed to cool it. An alternative is to find a larger diameter pipe and put it on the main chimney. Install the cooler so that the air flow is directed into the gap between the pipes.

Another option is to make something like a water jacket, receiving hot water while smoking. But where to put it is the question. Although, warm water is always useful in the household.

A smoke generator for cold smoking of this type requires more costs - metal or a thick-walled pipe, plus a chimney. Moreover, it is better not to make a chimney from galvanized steel - zinc is not a metal that is good for health. Asbestos should not be used either. Firstly, it does not remove heat well, and secondly, it is even more harmful than zinc. Therefore, the choice in this regard is small - order pipes made of black steel or buy stainless steel. Here everyone decides for himself.

Video on the topic

Compressor

Often people who are planning to build a smoke generator ask the question “how to make a compressor.” In fact, everything turns out to be simple - just like a smoke generator compressor, a regular computer cooler can work. It is glued from the inside to a piece of plastic bottle, and a hose is put on the neck of the bottle, which goes to the smoke generator. Such a device may well work, although it looks unpresentable.

You can also use an aquarium compressor, many people do this. You can do without a compressor at all, and the smoke generator will also work, but, however, not as efficiently. Air will flow into the smoke generator by gravity, and natural draft will not be enough. Subsequently, this will lead to smoking taking a much longer time, and the result will not be what was expected. That is why it is better to spend a little time and money, but install the simplest compressor in the smoke generator.

Assembly

As mentioned above, the main components of a smoke generator are: a chamber (a piece of pipe), a chimney, dampers and a compressor. Now the question remains how to put it all together. Everything will be told in order.

First you need to build a camera. Usually the height of the smoke generator reaches 70-80 centimeters. It should have a removable lid on top so that there is access to the inside of the device - for filling with fresh sawdust and for cleaning. At the bottom it is necessary to provide a container for collecting ash.

In the simplest versions of the smoke generator, sawdust is poured directly onto the bottom, which is tightly welded to the lower edge of the pipe. In this case there is no ash pan, and to clean the smoke generator it is simply turned over and shaken out.

In more accurate designs, sawdust is poured onto a grate, which is fixed at some distance from the bottom. The ash formed during the smoldering process spills down through the grate. In such devices, the bottom is often made removable - for example, in the form of a glass, the diameter of which is slightly larger than the diameter of the container in which the sawdust is located. That is, the glass is simply put on the smoke generator from below and fixed to it with bolts. You can also equip the ash pan chamber with an opening damper, like a stove door. For cleaning ash, this is the most labor-intensive option.

In any of the options, you need to drill a hole with a diameter of 5-6 millimeters in the lower part of the smoke generator for air access. No more is needed, otherwise the sawdust inside may simply catch fire, but they should only smolder, producing smoke.

Read also: The best steel grades for hunting knives

At the top of the chamber, approximately 7-9 cm below the top edge of the pipe there will be a chimney. As can be seen in the drawing, the smoke exhaust pipe is attached to a hole in the wall of the generator; its length can be 7-8 centimeters, so that it is convenient to put on a long plastic tube that goes to the smokehouse. But generally speaking, in stationary versions, the smoke generator is attached directly to the wall of the smokehouse, and the chimney tube directly enters the smoking chamber.

Now you need to assemble the ejector. This is a device that sucks smoke from the smoke generator and directs it into the chimney. Its design is clear from the drawings. A thin tube into which pressure is supplied from the compressor extends a few centimeters into the wider chimney pipe. Due to the movement of air, a slight vacuum appears, and the smoke from the smoke generator chamber goes into the chimney.

Ejector

The ejector is a key working unit of the smoke generator, which is installed at the exit from the combustion chamber.

It looks exactly like this if we are talking about a design with an upper intake pipe. If the intake pipe is located at the bottom of the combustion chamber, then the ejector is mounted outside (in the upper part of the reflux condenser) - on the pipe connecting the lower intake pipe and the upper pipe supplying smoke to the smoking chamber.

The principle of operation of the ejector becomes clear if you look at the working diagram of the device.

The main dimensions of the ejector are the diameters of the outer and inner tubes of the device, as well as the distance to which the inner tube (supplying clean air to the system) enters the smoke generator output system.

We already know the dimensions of the outlet hole - this is the flow diameter of the pipe ¾ inch. As for the bore diameter of the inner tube: 6-8 mm is optimal.

If the blower is not very powerful, then it is advisable to use a tube for the ejector with an internal diameter of 8...10 mm. Although, people also set it to 6 mm.

With the help of some simple ingenuity and materials that can be purchased at any hardware store, the ejector can be assembled within a few hours (maximum).

How far should a small pipe fit into a larger diameter pipe? This parameter is of great importance, because the level of traction and stable smoldering of the chips depend on it. Optimally, a thin tube should go into the pipe ¾ inches by 2 cm or 1...1.5 cm from the green mark (see photo). Before carrying out a test run, it is recommended to make the inner tube with a margin of length. It can be shortened to the optimal size based on the results of the experiment.

Job

Now that all the main parts are connected and securely fastened, all that remains is to assemble the smoke generator to test its operation:

- Wood chips are placed inside the smoke generator, weighing approximately 700-800 grams. As has been repeatedly said, mainly deciduous or fruit trees should be used as sawdust, but not coniferous ones.

- The lid closes tightly and the device is installed in its place on the wall of the smokehouse. Or, if you have a freestanding structure, a hose is attached to the chimney leading into the smokehouse.

- Through the side hole, the sawdust inside is ignited and the compressor is turned on.

These three simple steps will get the generator up and running and the owner ready to enjoy the most delicious smoked food possible.

What does it consist of?

The basis for the smoke generator is a cylinder or box; the thickness of their walls can vary. There are two main requirements for the housing: tightness and sufficient volume. Pear, apple, and alder are usually used as fuel. These breeds produce quite good smoke for smoking. To obtain the largest amount of fuel, it should be compacted and ignited through a hole at the bottom of the body itself. In a few minutes the device will be ready for use.

The air supply is carried out using some kind of fan or compressor , which must be connected correctly. You can often see in the design a regular pump for inflating an inflatable boat or mattress, which is also well suited in this situation. Smoke penetrates faster with this flow into the product chamber, since this flow literally pushes the smoke into the chamber.

Automation is most often used. It is quite possible to make a homemade steam generator with your own hands. To do this, you need to make drawings, purchase all the necessary materials and follow the recommendations of specialists.

Useful tips

All materials used in this article for the design and assembly of the smoke generator are average, that is, approximate. Let's say, if you haven't found a steel pipe, you can use a milk can, an old fire extinguisher, a deep saucepan or any metal containers, even the lightest and softest metals.

The same applies to sizes. The drawings are approximate dimensions and you should refer them to your specific application. Everything will depend on the design of the smokehouse itself.

Also, do not forget that if your smoke generator is connected to the smokehouse with a long hose, then condensation will accumulate in it. The smoke comes out of the device hot and cools as it moves through the hose, so it will inevitably release moisture. If you do not remove it, it can completely clog the hose! Therefore, provide a tee on the hose through which water will flow into the bottle.

Smoke generators for smoking products are very popular among those who love food with “smoke” and are widely used in the food industry. They are valued not only because you can use them to prepare smoked products yourself, but also because they are easy to manufacture and maintain.

What is a smoke generator?

A smoke generator is a special device that generates or creates smoke smoke for smoking various food products. In a smoke generator, smoke is generated by the smoldering of sawdust and wood chips, mainly from hardwood. They can be, for example, oak, alder, etc. In this case, sawdust and wood chips do not ignite, but only smolder. Smoke is formed in smokehouses, or otherwise called sausage chambers. Smoke is created due to temperature changes or using fans. The smoke generator is powered from a household voltage of 220 V.

(Fig. 2 - Approximate structure of any smoke generator)

How does it work?

The scheme of operation is quite simple. The smoke is literally pushed into the smokehouse under the pressure of the incoming air. The pressure is created by a pump or fan, depending on the connected device. This flow of smoke and air is forced out of the generator directly into the cabinet. You can build a thermometer into the cabinet, which will allow you to monitor the process.

How does a smoke generator work - how does it work?

The smoke generator operates on the principle of pyrolysis. Pyrolysis is the process of decomposition of organic natural compounds in the absence of oxygen, in our case wood. The essence of the smoke generator is quite simple. Smoke production occurs due to the simultaneous occurrence of two continuous interrelated processes: heating of sawdust and oxygen-free smoldering.

The smoke generator device itself is a closed compact box, not large in size, each part of which performs specific functions.

- Front end. There is a switch panel here that allows you to control the operation of the device.

- Top part. There is a hopper for supplying chips and a pipe for removing smoke.

- The internal part is equipped with a mechanism that supplies a dosed amount of chips to the heating element, a tray for collecting ash and an electronic controller that is responsible for the temperature regime and frequency of chip supply.

In this case, the controller is always set to the optimal mode, allowing the temperature of the heating element to ensure guaranteed smoldering of the chips and prevent them from igniting. The chip feeding mechanism is adjusted in such a way as to ensure a stable supply of fresh, thick smoke into the smoking chamber.

Condensate and resin container

The vertical section of the pipe through which smoke is supplied to the smoking chamber is a kind of natural reflux condenser. The condensation that accumulates on its cold walls is saturated with harmful resins (which can hopelessly spoil the taste of smoked products), after which it flows down. On the one hand, it is impossible to do without a reflux condenser; on the other hand, the master who has equipped his device with a vertical reflux condenser is faced with the question of recycling harmful products of wood combustion. It can be solved quite simply - by installing a receiving container in a suitable place.

The length of the reflux condenser is, as a rule, slightly less than the length of the combustion chamber.

Smoke generator dimensions

The size of one smoke generator may differ from another; factory models of devices have a passport, which indicates the optimal volume of the cabinet. As for homemade smoke generators, the container to which the smoke generator is connected must correspond to its power, because if you attach a container for several tons of product to a small household smoke generator, there will be no effect. Therefore, it is necessary to correlate the performance of the smoke source with the volume of the cabinet so that it is sufficiently filled with smoke.

A homemade smoke generator, as a rule, is connected to a container that is selected experimentally. Accordingly, it is difficult to accurately correlate the volume of the generator and the cabinet, since it is necessary to take into account the performance, which is different for each device. However, most often a cabinet with a volume of about 0.3 m3 is used. Moreover, everyone can create a device according to their own size.

The combustion chamber

The design of a classic smoke generator is so simple that the device can be manufactured without even having the appropriate drawings. In order not to confuse the dimensions and imagine the future unit, you can use a small sketch drawn by hand. We will tell you about the main dimensions of the device, based on practical recommendations from FORUMHOUSE users.

Before you begin manufacturing the combustion chamber, you need to decide on the material. Ideally, this should be a stainless (food grade) steel pipe.

At the same time, many make the combustion chamber body from an ordinary metal pipe with a diameter of 90-120 mm. A square pipe with a comparable flow area is also suitable.

As for the height of the combustion chamber: the optimal size for a smoke generator with a lower smoke intake is 50 cm. If the smoke intake is from above, the combustion chamber can be made a little lower (to improve draft).

Where is a smoke generator used and its advantages?

A smoke generator can be useful not only for smoked meat lovers, but also for summer residents, fishermen, hunters and even entrepreneurs who can earn income from signature smoked meats.

The smoke generation device will allow you to prepare a variety of food products at home:

The advantage of a “home” smoke generator compared to “purchased” smoked meats from stores and supermarkets:

- Thanks to the device, you can prepare natural homemade delicacies from natural products. All products contain natural fats; no additional spices or ingredients are required during the cooking process. Unlike products from stores, which acquired their taste using chemical flavors.

- In the process of home smoking, you decide for yourself what additives you will use in cooking. Manufacturers always add preservatives and flavor enhancers to smoked products from supermarkets so that the product can be stored for a long time, which negatively affects health.

- The cost is at least 2 times lower, and the quality is 10 times better!

- You are always confident in the high quality of the product and can invent your own original dish.

- The delight of friends when they try homemade smoked fish. Smoked fish from the store is not capable of surprising anyone and is unlikely to become a desirable dish on the holiday table.

(Fig. 4 - Do-it-yourself generator from the author Anatoly Fedorov)

A few words about smoking technology

In order for the smoked meats to be tasty, it is necessary to prepare all the products in advance.

This needs to be done correctly. Be sure to pre-salt all products. After this, you need to dry the meat or fish a little. Only after this can you begin the smoking process. Particular attention should be paid to the choice of wood. You should not use wood chips from coniferous trees, because the resulting smoked meats will be bitter. Using a smoke generator, you can get delicious homemade products, the cost of which is much lower than store-bought ones. Moreover, they will not contain any preservatives or harmful additives.

Source

Is it possible to make a smoke generator with your own hands?

A smoke generator for a smokehouse is a fairly simple but extremely effective device that can be made with your own hands from scrap materials. The whole attractiveness of the smoke generator is that it can operate in automatic mode. The temperature in the smoking cabinet is not too high, so there is no need to worry about the food burning.

The secret to installation is how to ensure consistent, even combustion and how to feed smoke into the smoking cabinet. To assemble a smoke generator for a smokehouse in a home workshop you will not need many elements.

Moreover, all components can be easily purchased in a store or, after searching carefully, found in your own garage or home workshop. Drawings and instructions for assembling a smoke generator for a smokehouse are abundant on the Internet. To build a smoke generator with your own hands, you will also need a welding machine, an angle grinder and some skills in working with them.

Read also: Dimensions of a 50 liter gas cylinder

Smoke generator from fire extinguisher

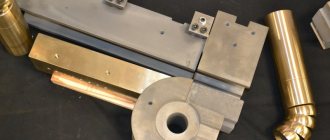

As a practical and affordable source for a smoke generator, you can take a used fire extinguisher. The manufacture of the device does not require significant investment. Items you will need:

- fire extinguisher body;

- smoke exhaust pipe;

- compressor for air supply or fan (cooler);

- nipple 3/4;

- long sweep 3/4 (for smoke removal);

- 3/4 tee;

- union;

- copper tube, diameter 14 mm.

Below is a diagram of the operation of a homemade smoke generator from a fire extinguisher.

(Fig. 5 diagram of the operation of a smoke generator from a fire extinguisher)

The fire extinguisher is taken with a diameter of about 100 mm and a length of 400 - 500 mm. These dimensions will allow you to produce enough smoke for a smoking chamber with a volume of up to 1 m³. At the bottom of the container, two Ø 10 mm holes are drilled for the blower. It is located at a height of 50 mm from the bottom. For the upper part we use a fire extinguisher cap with a ¾ cut internal pipe thread.

(Fig. 6 elements for a smoke generator from a fire extinguisher)

From the fire extinguisher, smoke enters the smoking chamber through an inch pipe 150-250 mm long, screwed into a tee.

Various compressors with low capacity are suitable as a compressor:

- for aquarium;

- in this case, a computer (laptop) cooling fan.

A mobile phone charger is suitable to power a compressor made from cardboard, stationery tape and a computer fan. It is easier to use a factory compressor, provided that it is available, since its purchase will significantly increase the cost of the entire structure.

(Fig. 7 - Air blower from a cooler for a smoke generator)

An old refrigerator can be used as a smoking chamber. The advantages of this solution:

- tight closing of the door thanks to an airtight seal;

- optimal temperature conditions and smoke density in the chamber for cold smoking.

Making a smoke generator with your own hands from a handy cylinder will require the performer to have technical knowledge and the availability of tools.

Types of homemade generators

The circuits of homemade smoke generators may differ slightly, but they are all united by a common device. They include a chamber in which the pyrolysis process occurs, a heating source, a smoke pipeline and a smoke cooling system. The device can be made using available materials. You can make a smoke generator from a fire extinguisher, an electric stove, or an aquarium compressor. Let's look at these and other ideas in more detail.

Electric stove smoke generator

If the idea of homemade smoked sausage has just struck you, and you haven’t prepared for it in advance, you can find a simple and quick way: make it from an electric stove. All other parts can be found in a barn or garage: a barrel without a bottom or a piece of tin pipe, a piece of wire mesh, a sheet of plywood and wood chips.

Almost every country house has an electric stove, and it will become part of the smokehouse

It is better to set up an impromptu smokehouse outside, then at home it will be difficult to get rid of the aromas that will permeate all things. Install the tiles in a place that the extension cord can reach. A barrel is placed on the electric stove and wood chips are poured into it. At 2/3 of the height, the barrel is pierced with two reinforcing pins crosswise, and a mesh is laid on them. This is where your products will be hung. The top of the barrel is covered with a sheet of plywood or iron. The smokehouse is ready. All that remains is to adjust the tile to the minimum temperature so that the wood chips smolder, and from time to time add fresh material for pyrolysis into the barrel.

The smoking process with such a device is not very convenient because you need to constantly monitor the situation, raise the barrel to adjust the temperature, remove food to add wood chips

Such a device cannot be called a proper smoke generator for cold smoking, but for temporary use the idea is quite suitable.

Generator for smokehouse from fire extinguisher

A great idea for a homemade smoke generator is to use an old fire extinguisher. You need to cut off the top of it, it will then be used as a lid. You don’t even have to remove the lever; it will become a handle. Below the cut, two holes are drilled in the body for air access and smoke exit.

Thus, you will get a generator with a top ejector. The advantage of using a fire extinguisher is that it is sealed and durable, and is the right size. This home-made cold-smoked smokehouse with a smoke generator can operate continuously for 10-12 hours.

How to make a smoke generator from a fire extinguisher in the video:

Watch this video on YouTube

How to use an aquarium compressor for a smoke generator

We have already said that you can use a low-power aquarium compressor to operate a small smoke generator. For this purpose, you will need an active compressor, that is, one that is installed outside the aquarium. Submersible aquarium filters are not suitable for smoke generators.

Such a device can easily serve a small smokehouse with a volume of 15-20 liters. This will ensure a sufficient supply of smoke. It is better if the device is equipped with air supply power control. It is not difficult to connect a compressor for a smoke generator with your own hands: if it has two air outlets, you need to combine the supply into one channel and insert the hose into the air supply fitting in the ejector.

Such a system can operate around the clock; the pump consumes little electricity

You can go another way: use a fan for a smoke generator. A computer cooler is suitable for this purpose; it will provide the necessary air injection. Details of the work in this video:

Smoke generator stove for smokehouse

For a large-volume smokehouse, you will need a full-fledged oven. A smoke generator stove for a cold smokehouse is easy to make with your own hands: it is a basic potbelly stove with two levels for fuel: the lower one for firewood and the upper one for wood chips. Pellets, firewood are placed in the lower part, or a portable gas stove is placed, which will heat the upper part with sawdust. From the upper part there is a pipe - a smoke duct, from the lower part - a regular hood, like for a stove.

To lower the smoke temperature, the pipeline is cooled by burying it in the ground or making a water “jacket”. To ensure that smoke enters the smokehouse, the pipe is tilted towards the stove

Drawings of homemade smoke generators

Homemade smoke generators can be made using ready-made drawings already available on the Internet. Here are some of the simplest and most popular ones.

(Fig. 8 - Drawing for smoke generator 1)

(Fig. 9 - Drawing for smoke generator 2)

(Fig. 10 - Drawing for smoke generator 3)

As we can see, drawings and diagrams of smoke generators are completely different in design and complexity.

Factory smoke generators

Nowadays, smoke generators can also be purchased in stores, so those who have financial means and do not have the time or ability to make a smoke generator with their own hands can buy one. The price of devices is completely different and depends on the number of functions, power and brand. Let's look at the most popular ones.

Smoke generator Bravo

(Fig. 11 - Bravo smoke generator)

The Bravo brand smoke generator has several models. Let's study the simplest and inexpensive Bravo Favorit. Ideal option for a beginner smoker. The model is in mass demand.

Model characteristics

(Fig. 12 - smoke generator Dymka)

Smoke generator Dymka is an automated installation for generating smoke for hot and cold smoking in a smoking chamber.

Model characteristics

(Fig. 13 - Hobbi Smoke smoke generator)

Hobbi Smoke is one of the popular models of smoke generators. The brand has several models, consider model 1.0.

Model characteristics

(Fig. 14 - Hanhi smoke generator)

Hanhi smoke generator is ideal for cold smoking. The smoke generator is based on food grade stainless steel AISI430 GOST 5632-72. This steel is most often used in the food industry. The advantage of stainless steel is that it does not oxidize, does not rust, and does not emit toxic substances when heated.

Model characteristics

Since ancient times, smoke treatment has been used to increase the shelf life of products. It is still used today, only for slightly different purposes. For long-term inventories, there are other technologies and equipment. Fumigation with smoke gives food a special taste and aroma. This can be achieved using a smokehouse that has a smoke generator for cold smoking.

Review of several smoke generators on the market

You can find any smoke generator for cold smoking on the market. Each of the presented models has its own pros and cons, which are worth learning about before purchasing this or that smoke generator for cold smoking.

Summer resident

According to users, the Dachnik smoke generator can be considered one of the best devices.

It consumes a minimal amount of fuel. This can be explained by the fact that the design has a special screw mechanism. Due to this, the supply of fuel to the chamber where it will smolder is controlled. Also, the advantages of the Dachnik smoke generator include not only efficiency, but also a high efficiency rate. The device is very easy to operate. The summer resident is small in size and weighs up to six kilograms. The manufacturer provides a five-year warranty. the average cost of the structure is 3,400 rubles.

Pros:

- consumes approximately 313 grams of wood chips per hour;

- there is no need to change the load for three months;

- operating the device is very simple;

- installation does not require any special knowledge;

- has small dimensions;

- installation of the structure does not take much time;

- you can independently adjust all the necessary smoke parameters;

- despite the fact that the device is very simple, it has proven its effectiveness in practice;

- The resulting products are tasty, aromatic and rich in healthy ingredients.

Minuses:

- nondescript appearance of the structure.

Hanhi zmei 7l

Controlling the Hanhi Serpent is incredibly simple and you don’t need any special knowledge to do so.

Power regulators are located on the electrical stand of the device. With their help, you can choose the most suitable mode for smoking. It is imperative to take into account exactly what product will be smoked. The device has a high performance rate and can work on one load for 12 hours. In addition, the design is equipped with a special filter, which not only retains excess moisture, but also cleans the smoke from resin to make the finished product even tastier.

The smoke generator Hanhi zmei 7l has a weight that reaches 12 kilograms. The manufacturer provides a one-year warranty on this model. The average cost of the structure is 11 thousand rubles.

Pros:

- the smoke generator is equipped with a special safe electrical stand for heating wood chips;

- the device can work offline for 12 hours;

- you can manually adjust the smoke power, taking into account the type of semi-finished product;

- the length of the coil reaches six meters, which allows the smoke to cool to the desired temperature - 27 degrees;

- the device is very reliable and has a long service life;

- It is small in size, so it does not take up much space in the room.

Minuses:

- users did not find any significant disadvantages.

Smoke Dymych

The device has very good parameters and is more than affordable.

It is considered one of the most popular models among buyers. The Smoke Dymych smoke generator is very easy to use, has a very spacious chamber and can operate autonomously for up to 15 hours. The weight of the device is 6.75 kilograms. Manufacturer's warranty – one year. The average cost of the Dym Dymych smoke generator is 4,000 rubles.

Pros:

- the design is quite simple, but at the same time has good strength indicators;

- in one smoking session you can load up to 15 kilograms of various products;

- installation of a smoke generator does not take much time; anyone can cope with the task, even those who are completely ignorant of technology;

- the body of the structure is made of stainless steel;

- can work offline for up to 15 hours.

Minuses:

- It’s a little difficult and inconvenient to remove the cover;

- case walls are not thick enough - 0.8 millimeters;

- no special stand.

Basic information

For many years, exclusively natural raw materials were used for such processing. This allowed the products to absorb the aromas characteristic of certain types of trees. However, on an industrial scale, sawdust is used to a minimum. They are mainly replaced by various flavoring additives and substitutes. One of these chemicals was liquid smoke, which is not harmless to the body. However, for personal use, a smoke generator for cold smoking using natural fuel is used, located in the courtyard of a house or cottage.

Features of heat treatment

Smoke treatment of meat or fish occurs in two ways. The first requires heating in the range of 55-110 degrees. With such hot smoking, the products ripen very quickly, but heat treatment decomposes all useful substances. If heating is uneven, part of the loaded raw material burns.

The second method is based on soft processing at low temperatures of 25-30 degrees. This is a long process, but all the vitamins remain in place. The shelf life of cold smoking is longer.

equipment requirements

In order to make a smoke generator for smoking with your own hands, you need to use information about methods and equipment. As a rule, any construction of your own smokehouse comes down to finances and technical capabilities.

Read also: Is it possible to charge a screwdriver with a car charger?

Given these features, the following rules must be observed:

- The design must ensure rapid smoke release.

- Minimal human control.

- At the same time, fire safety rules must be observed.

- Complete combustion of fuel will allow you to add it less often and thereby fluctuate the cooking temperature.

- The simpler the device, the better it works.

Smokehouse device

It is not difficult to describe the circuit of this device. In one part there is smoldering of firewood and sawdust. Open fire should not be allowed due to increased temperature. The condition for this process is a lack of oxygen.

The other part contains products that need to be smoked. A collector is laid between them for the flow of smoke. To speed up the procedure there should be as much of it as possible. In the second compartment you need to make a hole to remove excess smoke and create a vacuum in this chamber.

The disadvantage of the simplest smokehouse is the need to constantly monitor the fuel level and periodically add it. This negative point is minimized by using a smoke generator.

Features of the smoke generator device

The parts of a homemade smoke generator for a cold smoked smokehouse should not be labor-intensive, expensive or heavy. Available materials and existing equipment will be useful in its manufacture . Main components of the device:

- Container for sawdust with a removable lid.

- Hole with hose for air injection from below.

- At the top there is a channel leading to the smokehouse.

- Compressor.

Passive smoke generator. We smoke it slowly.

I became interested in the smoking process in my youth. In those days when buying, for example, smoked mackerel in a country of developed socialism was somewhat problematic. A little later, when almost anything appeared on the shelves, traditional smoking methods were replaced by new technologies: liquid smoke. And although many chefs claim that liquid smoke is ordinary water through which smoke has been passed (at least from good manufacturers of this liquid), the taste of products “smoked” in this way is different. In addition, “echoes of smoke” remain in the body for a long time after consuming them. At the same time when it was easier to find the book you needed in the library, a scanned book about smoking appeared on the FidoNet network. It gave roughly the following diagram:

Not only did I not intend to engage in industrial production (and where can all this be placed?), but it also remained a mystery to me how it was possible to maintain combustion around the clock for three days (which is approximately how long you need to smoke according to the recipes in the book). In general, the idea of preparing delicacies was postponed indefinitely. Later, I welded a smokehouse for hot smoking from a sheet of metal. The fish turned out great.

By the way, such a device can also be used in the kitchen. Water is poured into the groove where the lid fits. It turns out to be a water seal through which smoke does not pass. And the smoke itself can be removed through the tube through ventilation.

Then active smoke generators appeared on sale.

The idea is this: sawdust is poured into the pipe and set on fire. On the side, a small compressor pumps air. The outlet pipe is connected to the container in which smoking will be carried out. One of my friends bought such a device, but it still lies somewhere in his bins. And, unfortunately, I live too far from him to come and smoke something right in his presence.

But in one of the videos I saw a passive smoke generator. Its owner purchased it somewhere on Amazon for very indecent money. And although I found the same one on Chinese sites, its price then also seemed not very affordable to me. Moreover, when you watch a video on YouTube, the authors can do whatever they want. And when you start repeating it yourself, the result is not always satisfactory. Therefore, it was decided to make the device with our own hands. Actually, it's just a cuvette with partitions inside. The only problem was what to make it out of. The original uses a stainless steel mesh. Unfortunately, in my small town there is no company that sells such mesh or makes anything from it. There was no point in ordering a piece of 30x30 cm on the Internet. No one would sell it, and there was no point in buying a roll or a couple of meters. An air filter for large cars caught my eye. As the classic said: what you protect, you have (© Zhvanetsky). And then I remembered a friend who worked at an agricultural warehouse where such filters were available. There were several used and discarded filters from John Deere combines.

I managed to get hold of one of these filters. As a result, in a short time, using only metal scissors and pliers, such a generator was made.

For those interested, size 270x160 mm, height 40 mm. The cuvette is divided into four sections. Sawdust is poured into it and set on fire on one side. But the sawdust doesn't burn. They just slowly smolder. Each section burns for about an hour. As a result, one refill lasts four hours or more. The time depends on the size of the sawdust, humidity, weather and other conditions. By the way, it turned out that the wood chips sold in stores are not suitable for this. She's too big. As a result, a burning chip cannot set fire to the next one, because it does not fit tightly.

The best option is sawdust from a circular or gas/electric saw. But in the second option, the chain is lubricated with oil during operation. Some of this oil ends up on the sawdust. And although I did not notice any foreign taste in the products or smell when burning, it is still better not to use them. In fact, you don’t need very much sawdust for one bookmark. So, with a little patience, you can cut them with a regular hand saw (It’s better to cut raw wood. It’s easier. And then dry the sawdust). Naturally, for smoking you need to use sawdust from non-coniferous trees. Products prepared for smoking are placed in a closed container. Some people use an old refrigerator or a box made from boards for this. You just need to remember that fresh air must flow inside, and there must also be a hole for the smoke to escape. By the way, the size of this hole also affects the burning time of the sawdust. A closed barbecue is perfect.

I usually use cardboard boxes. Firstly, right now I have nowhere to store and use a stationary box. Secondly, I rarely smoke. The cardboard box can be used several times. But it’s impossible to store it at home. There is quite a strong smell of smoke left in it. For the same reason, it is unlikely that you will be able to use a stationary box for any other purposes, for example, to store things there.

One more moment. Since the temperature inside the box during cold smoking should not exceed 30 degrees, I only do this when the weather outside is quite cool. Due to the fact that the sawdust smolders slowly, the temperature inside does not increase much.

During operation, it turned out that the holes in this mesh are quite large. And if you make the partitions dividing the device into sections thinner, then the smoldering sawdust will set fire not only to those in this section, but also to those in the adjacent one.

Surely many have noticed that the mesh of such a filter is made not of stainless steel, but of galvanized iron. I can hear a wave of indignation rising from the back rows about the dangers of this for our health. .

I’ll hide my thoughts on this matter under a spoiler. But I am sure that the debate will be serious.

On the one hand, zinc is a poison for the human body, on the other hand, it is an essential element for life, which is included in almost all vitamins. But the daily norm is only 10-20 mg per day. Zinc poisoning occurs at a dose of about 0.5 g (and less if consumed daily). It is quite possible to get poisoned by zinc if you carry out welding work on galvanized products in an unventilated area. Those who have done welding know what an unpleasant smell there is. Be that as it may, galvanized products are still used in everyday life. Now let's go back to the generator. Let's start with the fact that the temperature at which sawdust burns is much lower than the “burning” of zinc (when welding, for example). If we assume that zinc does evaporate during use, then it will turn out that after the first use it will simply all disappear, and therefore there will be no problems next time. However, if you look at the photo above, you will notice that the coating remains almost everywhere. This is despite the fact that the product is stored outdoors for several years. If the zinc evaporated, it would completely rust. But the photo shows that there is rust in only one place. This is where the sawdust is ignited using a gas burner. And the grate becomes red hot. And then, if there is still some evaporation, then the main amount of zinc goes “down the chimney” along with the smoke. Some of it settles on the surface of the box. And only some minuscule amount possibly settles on the products. Again, no one will eat the entire mass of cooked food in one sitting. I do not advocate using galvanized products everywhere, but I believe that in this case there is nothing to worry about. Again, this is my personal opinion. And be that as it may, so far no one has been poisoned by my smoked meats.

In order not to worry about the damage from galvanizing, you can buy a finished product. Banggood.com just sent it for review. The product arrived in a regular box without identification marks. There's only a generator inside.

Size: 150x150x25mm. Somewhat less than I expected. Weight 170 grams. The frame is made of wire with a diameter of 2.5 mm. There are handles on the sides made of the same wire and legs at the bottom.

A mesh with a cell size of approximately 1.5 mm is welded to the frame

On one side there is a small stand where a candle is placed to set the sawdust on fire.

The width of the turns (tracks) inside is 25 mm. The product is tough. Nothing bends (within reasonable limits). Doesn't magnetize.

But enough talk. We need to cook something. In fact, cooking smoked food is quite a long process. Moreover, the bulk of this time is spent preparing the products. You can smoke almost anything: meat and fish products, vegetables, fruits (prunes), cheese and even vegetable oil, such as olive oil. For meat products there are two options: raw smoked and boiled-smoked. I'm doing the second one. Mainly because the first ones need to be smoked for several days. If earlier products were smoked in order to extend their shelf life, now mainly in order to give them a characteristic smell and taste. This means that often an hour or a little more is enough to smoke a boiled shank, for example. As I wrote, preparing food takes quite a lot of time. On the one hand, I don’t really want to spend a lot of time and cook a couple of legs. On the other hand, several kilograms of the finished product will be consumed by my family for a long time. Firstly, eating the same product over and over, even if it is very tasty, gets boring. Secondly, smoked products are still not very beneficial for the body due to the presence of carcinogens there. Therefore, I smoke several different foods at the same time, for example, chicken legs or bacon, fish, usually mackerel and cheese. Preparation begins with salting. For fish, the wet method is used, for meat - dry (but wet is also possible).

Two tablespoons of salt and a spoonful of sugar dissolve in a liter of water. You can also add bay leaf and black pepper. In order for the salt and sugar to dissolve faster and the spices to give off their taste, the brine can be boiled. The brine is then cooled and the mackerel, usually gutted, is placed in it.

For meat, nitrite salt is taken at 2% of weight (another stumbling block for followers of healthy food). You can use regular salt as the meat will cook. But nitrite gives the finished product a pleasant color and additional taste. I also add various seasonings to taste. The piece is rubbed with the mixture. It is advisable to place it in a bag or closed container. Then everything goes into the refrigerator, and there are three long days of waiting, during which the food will be salted. But doing this is quite boring for them, so you have to pay attention to them every day. Namely, it is necessary to turn over and lightly massage the fish and meat so that the salting occurs evenly. This time there were two pieces of meat: bacon and lard (at least that's what it said on the price tag in the store. I'm guessing it's cheek).

The second stage is cooking the meat. This is where a device called sous vide comes in very handy, which has been reviewed here quite often and is often criticized by site visitors. The problem is that the meat must not only be boiled in boiling water, but brought to an internal temperature of about 70 degrees. If you boil it in the usual way, the outside of the product will cook. Many people say that you can completely use a slow cooker, which is what I do in the absence of sous vide. But, unfortunately, pieces of a rather limited size fit into the multicooker.

Meat is not simply cooked in water. Usually I place it in a baking sleeve or carefully wrap it in cling film (No, during cooking, “harmful substances” from polyethylene do not get inside the product being cooked). Another necessary device is a thermometer, the probe of which is placed inside. All that remains is to select the required temperature in the multicooker (about 80-85 degrees) or sous vide and wait. All this can be done in the oven, if it has temperature control. But the process will take much longer, because the thermal conductivity of air is much less than water. After cooking is finished (and this may take several hours depending on the size of the piece of meat), it is necessary to rinse the meat under water and hang it to ventilate and cool for several hours. This needs to be done. Otherwise, unsightly streaks may appear on the finished product during the smoking process.

It’s also good to dry the fish a little.

In fact, these products are already ready for consumption.

Unless you can dry the fish for another day, then you will get a hanging fish. Do you still have the desire to do such a dreary task as smoking? Then let's continue. Now let's move on to the process. The products are hung in the box (you can’t put them on anything, because one side won’t be smoked. You can use some kind of mesh, but then the finished product will probably end up in a checkered pattern). The pieces should not touch either.

We put sawdust into the generator.

It took me 70 grams or about a half-liter jar.

In the photo above you can see that a candle is placed in a certain place, which will heat the metal until the sawdust burns. I don’t see any point in waiting that long, so I use a gas burner. Naturally, sawdust can catch fire. But they are very easy to put out by gently blowing on the fire.

The generator goes in a box. Periodically I check that the sawdust has not gone out. The density of the smoke again depends on the sawdust. If they are large, there will be less smoke and they will burn longer. And if they are smaller, then there will be a little more smoke, but the sawdust will burn out faster.

It was slightly frosty outside. Perhaps this is why, or because the size of the sawdust was somewhat large, the burning lasted almost six hours and some did not burn out.

As a result, the color of the finished products did not change much. But they acquired the smell and taste of smoked meats.

The effect is especially noticeable on sticks of suluguni cheese (not smoked below).

But everything else turned out delicious.

The photo below shows pieces of bacon: on the left after cooking, on the right after smoking. You can see that the bacon has become drier.

There remains the last, most “difficult and lengthy” stage of preparation. The products should be wrapped in parchment paper and kept in the refrigerator for about a day. This is necessary so that the taste is evenly distributed and the bitterness is removed from the surface. It is not recommended to use immediately after smoking.

Overall, an excellent device for smoking at home. The products are not as dark in color as those sold in the store or, especially, in the market. But the taste is excellent. My old generator produces slightly more smoke due to the volume of sawdust.

There are also round generators like this. They are slightly larger in size.

Until 01/10/2021 there is a discount on products using coupons: BGNNDGK for square - $12.99 BGNNDGK02 for round - $11.99

The product was provided for writing a review by the store. The review was published in accordance with clause 18 of the Site Rules.

Creation of smoking equipment

If you have a welding machine, the skills to work with it, the presence of metal components and the desire, such equipment can be manufactured in a few hours. First you need to find drawings of a smoke generator for cold smoking. Instead of developing them yourself, you can find the best options using the Internet.

Collectively, this unit consists of the following components:

- Thermal module.

- Fuel (coal, gas, firewood, but most often wood chips and sawdust).

- Smoke removal and supply system to the smoking chamber.

For personal use you will not need a large amount of products. Therefore, the body is made from a part of the pipe. A chimney is welded on top. Sawdust is poured inside.

To create thrust, air is pumped from above by a compressor. An old refrigerator or one from an aquarium will do. The second is preferable due to the ability to adjust the air flow. The smoke coming out is of low temperature. As a result of smoldering, there is no open fire, so frequent addition of a new portion of fuel is not required.

Materials for production

Reducing the cost of the generator is possible due to the available scraps of various metal products. You just need a few details:

- The pipe is round. Its length is about 1 meter, diameter 80 - 0 millimeters. The size of this component determines how much fuel will be stored in the device and how long it will take before the next portion is loaded. Here you need to come to a compromise between the weight of the generator and the possibility of convenient maintenance with maximum performance.

- A square pipe with a side length of at least 80 millimeters.

- Three-quarter pipe from 30 centimeters.

- One quarter inch pipe of any size.

- Mesh or plate with a mesh of 2-3 millimeters.

- Leg fittings. Any rod or plate will do. The main thing is that the device stands steadily on the surface.

- Compressor with a capacity of one and a half to two liters. Correction of air outlet is preferred.

- Fittings for joining pipes.

Assembly steps

If you can’t find a round pipe to make a smoke generator with your own hands for a smokehouse, you can replace it with a square pipe of the same size. This option has a slight advantage in the convenience of connecting outgoing channels. In the largest pipe, cuts are made along the diameter at a distance of two centimeters. This will be the bottom of the smoke generator. A piece of mesh cut along the cross-section of the body is inserted into them and fastened to the sides.

A 3/4 inch pipe is welded on the opposite side. Opposite is the fitting with which the compressor is connected. An important condition is the clear location of both components on the same straight line.

The most cunning arrangement is near a thin pipe . Through the fitting, inside the body, it should extend 1 centimeter into the three-quarter outlet. This design will supply air from the compressor and provide draft to support the smoldering of the sawdust. To arrange the circulation of smoke and air in a housing tightly filled with sawdust, you need to put a spring of a larger diameter on it. This is a kind of ripper through the coils of which air flows will pass.

For the lid you need a piece of iron 1.5 - 2 centimeters wider than the cross-section of the body. For convenience, you need to make a handle. It can be welded or made removable. The middle part may be wooden. It will not burn due to the low temperature of the case. To prevent the lid from moving off, at a short distance from the edge, you need to weld a rod or metal strip along its perimeter or radius.

The legs are welded from below, and the smoke generator is ready. It’s a good idea to choose a piece of metal for the stand. This will ensure equipment stability and fire safety.

The principle of operation of a homemade device

The body becomes clogged with shavings, wood chips or sawdust. The whole mass is set on fire. After active smoldering begins, the compressor is turned on and the lid is replaced. If everything is correctly assembled and connected, the fuel is dry, active smoke emission and the smoking process will begin. That's the whole working principle.

Modernization

The design described above is fully functional. But it has many disadvantages and is not very convenient. Based on the results of its use, modifications and improvements were made.

Adjustable traction

One of the main disadvantages of the described design is poor regulation of combustion intensity. It can be slightly changed by adjusting the compressor performance. An adjustable blower can be added to the design. It can be made according to the gate principle:

- In the lower part of the body (above the place where the stack is attached), weld a piece of round pipe 10-15 cm long.

- Drill two holes that are located exactly opposite one another.

- Take a rod that fits into these holes. Its length is 20 cm greater than the diameter of the pipe. Shiber looks like this

- Cut a circle from a sheet of metal (2-3 mm thick). Its diameter is slightly smaller than the internal diameter of the pipe.

- Make a “handle” from the rod (bend it).

- Insert a handle into the holes and weld the cut circle.

That's it, the adjustable damper is ready. Turn it, adjust the intensity of air flow, adjusting the intensity of combustion.

Ash pan

Another drawback is that ash spills through the mesh. You can place the smoke generator on a metal plate, but you can make an ash pan. By the way, the gate can be made in an ash pan. This will be more correct, since the air leak can be almost blocked, which cannot be achieved with a damper in the housing - the air enters through the mesh.

Ash pan - a small container slightly larger in size than the body

The ash pan is made from a piece of pipe with a slightly larger cross-section than the pipe on the body. If you don't have one, you'll have to cook it. The bottom is welded to a piece of pipe, and a thin strip of metal is welded to the body around the perimeter. The body is inserted into the ash pan (the legs are also welded to it).

Condensate collection

When a smoke generator for cold smoking operates, condensation occurs. This makes life difficult, especially if the temperature outside is low. You can solve the problem by making a condensate collector. For this:

- lower the exhaust pipe of the smoke generator downwards,

- at the lowest point we install a container for condensate, welding two pipes to it - one opposite the other;

- on the opposite side the pipe rises again and enters the smoking cabinet.

To collect condensate, I complicate the smoke supply route

With this device, a significant part of the condensate ends up in the container. The problem is not so acute.

Advantages of ready-made units

Self-production of such equipment, although not difficult, requires a welding machine and the ability to use it. Because of this, the option of purchasing a factory device for circulating smoke appears. This step is justified by the following advantages:

- High performance.

- Devices equipped with heating elements do not consume much electricity.

- The installed smoke purification system makes it possible to use the smoke generator indoors. Resins deposited on the walls are cleaned with detergent.

- The fuel burns completely.

- Unpretentious in maintenance.

- Due to their simplicity, these devices rarely break down.

- The small size and weight of household gas generators allow them to be transported in the trunk of a car.

For these reasons, such devices are very popular. The most widely used are the following:

- Bradley Smoker is a smoking device that uses automatic feeding of special briquettes for combustion. Products cooked in it have a natural taste.

- Shawarmaker - in addition to automated fuel loading, has electronic control and high power, which will provide a small cafe with its products.

- The smoke generator from America Weber - Stephen runs on coal and can replace a grill. Due to its size and performance, it is more suitable for catering establishments.

The fuel compartment of these devices is filled with sawdust approximately three-quarters. Semi-finished products are placed in the smoking section. The rate of smoke formation must be monitored periodically. Cooking time depends on the product. The device casing requires cleaning after each use.

There are a few more recommendations:

- The smoking process will speed up if the sawdust is dry. To heat them, you can install a heating element for open installation.

- Each tree has its own smoky aroma.

- Grapevine added to sawdust will add an unusual taste to products.

- When smoking occurs in dry, windless weather, the result will be ready faster.

If you follow these tips, cooking errors will be eliminated.

Troubleshooting and troubleshooting methods

Smoke generators for cold smoking, like any other equipment, can break down or start to work worse. The reasons for this can be very different, ranging from manufacturing defects or inaccuracies to improper operation of the device. Some of the breakdowns can be fixed on your own, others only with the help of specialists.

Why does the smoke generator go out?

Users who already have sufficient experience in operating smoke generators for cold smoking say that the device can go out as a result of insufficient air circulation in the chamber. Experts have figured out how to ignite the device so that this trouble does not happen.

Debris and the remains of burnt wood chips begin to settle in the smoke generator tubes, which clog all the holes. It is necessary to thoroughly clean everything and the device will start working stably again and will stop going out. Another important point is that it is better to supply air through the top of the chamber.

Why do wood chips get stuck in the smoke generator?

Sometimes users encounter problems such as wood chips freezing. Because of this, the smoldering process becomes unstable or the design for cold smoking may even go out.

There may be several reasons for this. For example, incorrectly selected size of chips used for smoking. Also, the bunker from which the wood chips are supplied may have additional elements that retain the fuel and prevent it from falling steadily into the combustion zone.

It is worth choosing smoke generator models that have a sufficient hopper diameter and that do not contain foreign elements that negatively affect the movement of fuel. To prevent chips from hanging due to incorrectly selected sizes, it is worth familiarizing yourself with the recommendations of the manufacturer of a particular device. As a rule, the manufacturer indicates which fraction of wood chips will be most suitable.

How to clean resin from a smoke generator

In order to clean the smoke generator from resin, you can use special products. There are commercially available products that allow you to quickly remove tar and other particularly stubborn deposits resulting from burning wood. It is worth noting that they can be used to treat alkali-resistant surfaces. Otherwise, the structure may be damaged.

During cleaning, you must first remove all remaining wood chips and ash from the bunker. Next, the holes through which air enters the structure and smoke escapes are plugged. For this you can use ordinary pieces of silicone hose, which are pinched at the ends.

Next, the selected cleaning solution is poured into the structure and left for an average of half an hour. The exact time it will take to cleanse will be indicated on the packaging of the purchased product. After this time, the solution is drained from the smoke generator. If there is some resin left on the walls, you can rub them a little.

Important! The process of cleaning the smoke generator from resin must be carried out with rubber gloves so that the skin of your hands is not damaged.

How to light a smoke generator correctly

You need to light the smoke generator very carefully. It is best to use a special lighter for this, not matches.

First you need to turn on the compressor so that draft appears inside the compressor. Then, through a special small hole, which is usually located at the bottom of the device, the smoke generator is ignited. You need to wait a few minutes for the smoke to start coming out.

Security measures

A smoke generator is a device with increased fire hazard. Despite the low temperature of the smoking process, following these rules will help you avoid trouble:

- The device is installed on a flat, non-flammable surface.

- Painting is possible only with heat-resistant paint.

- The device should be placed away from electrical wiring, flammable liquids and combustible materials.

- The factory device must be equipped with an emergency shutdown system.

Following these steps will not only help you prepare delicious food, but also prevent fires and damage to your health.