An angle grinder (grinder) is a tool that can be used to perform various types of work: cutting, cleaning, grinding, polishing, brushing. To do this, use grinder discs and different types of attachments. The main thing is to choose the right consumables. The nozzle must correspond to the operation that will be performed on a specific model of angle grinder. They are produced in a large assortment, each variety is used to solve a specific problem or several operations. You can purchase them in the retail chain from Russian and foreign manufacturers at different prices. Let's consider the main types of nozzles, their purpose and features of choice.

Types of discs for grinders

Grinder circles are replaceable elements. When working with different materials, you need to understand their types. This will help to perform the necessary operation efficiently. Circles are classified according to the following parameters:

- by appointment;

- type of work performed;

- design;

- type of cutting;

- material of manufacture;

- sizes.

Depending on their purpose, there are attachments for working on metal, wood, stone, concrete, marble, etc. Manufacturers indicate the purpose in the marking, which is applied directly to the product itself. Many varieties are universal tools, suitable for processing several types of materials.

Based on the type of work performed, as indicated in the title, manufacturers produce the following attachments for angle grinders:

- stripping (metal brushes, end flap wheels, with mandrel, batch);

- roughing (grinding wheels, twisted cutters, diamond roughing wheels);

- saws The presence of teeth on the cutting edge is a design feature of the product. This allows you to obtain particularly clean cuts on wood, plasterboard, gas silicate, plywood and other similar materials;

- cut-off Cutting and diamond discs are produced with a continuous cutting edge and divided into segments;

- grinding (discs with varying degrees of grain size and hardness);

- polishing (felt, felt, with special Velcro and grinding attachments);

- for cutting joints in asphalt, concrete, etc.;

- milling (for cutting grooves, bowls, edge processing, etc.);

- sharpening A characteristic feature is the ability to perform operations with the side surface.

The disk is a product of a certain diameter and thickness, which has a mounting hole for attachment to an angle grinder with a cutting edge of a solid, segmented or shaped configuration. The choice of a specific type depends on the operation being performed and the material on which it will be performed. Cutting using such attachments can be done dry, wet or combined. The labeling indicates this feature.

Depending on the material used, the discs can be abrasive, carbide, diamond or brush. The basis of the first type of circles is special latex paper or fiber, onto which an abrasive layer with a binder is applied. The nozzle, made of fiber, comes with a rubber or plastic support plate. Carbide disc is a product made of alloy steel. Such consumables can be used for cutting aluminum, stainless steel, high carbon steel and other materials, as indicated in the marking.

Diamond blades are a universal consumable. It is a steel product with diamond coating applied to its surface. This allows you to get the thinnest cut in any material. Popular products, popularly called turtles, are a type of attachment made on a flexible base, have a grooved structure and are attached with Velcro. In addition, they produce diamond blades with a solid edge for cutting in the wet method, segmented and turbo-segmented for cutting in the dry method, and combined ones.

Why is grinding needed?

The top layer of a concrete floor is the point where the concrete base closely interacts with the external aggressive environment. In addition, concrete is more susceptible to mechanical loads. When matured, cement laitance emerges from the concrete, which then hardens on the floor surface and forms an unstable layer. In order for the concrete base to be monolithic and durable, this collapsing layer needs to be cut off; for this purpose, diamond cups are used for grinding concrete.

Other tasks can be solved with the help of a diamond grinding disc:

- After the concrete screed has dried, a concrete grinding cup will give it the required smoothness, evenness and remove minor flaws: dimples, bumps, ripples and similar imperfections.

- If you are grinding concrete that has been in use for a long time, then the remnants of old floor coverings that cannot be removed with other tools and traces of complex contaminants are removed from its surface.

- The water resistance of a concrete floor increases several times.

- The level of dust formation is minimized.

- The concrete floor gains strength and resistance to moisture and chemicals. substances, temperature changes.

- Maintenance costs for the concrete base are reduced.

- Using tools such as a grinder and diamond grinding discs, a nondescript concrete floor can be given an attractive appearance.

Grinding is an indispensable technological process if self-leveling mixtures are poured onto the concrete floor, various impregnating compounds or thin-layer paints are applied. Sanding is used at various construction sites: commercial and administrative buildings, industrial buildings, and is used to create beautiful areas in front of buildings.

DIY concrete surface grinding

Standard disk sizes

The sizes of discs for grinders are standardized. The table shows the main technical characteristics of attachments for grinders:

| Outer diameter, mm | Thickness, mm | Bore diameter, mm |

| 115 | 1,0; 1,6; 2,0; 2,5; 3,0; 3,2 | 22,00; 22,23 |

| 125 | 0,8; 1,0; 1,25; 1,6; 2,0; 2,5; 3,0; 3,2 | 13,20; 22,23 |

| 150 | ||

| 180 | 1,0; 1,25; 1,6; 2,0; 2,5; 3,0; 3,2; 4,0 | 22,23; 32,00 |

| 230 | 1,6; 2,0; 2,5; 3,0; 3,2; 4,0 |

The dimensions of non-standardized circles may differ from those indicated in the table if they are manufactured according to the manufacturer’s specifications.

Cutting discs

Cutting discs, or they are also called abrasive discs, are most often used for grinders. Electrocorundum or silicon carbide of different sizes and hardness are used as abrasive grains. Nozzles are available in bakelite (with and without reinforcing elements) and vulcanite bond, flat and with a recessed center. The latter type cuts metal with an emulsion, since it has a low degree of heat resistance and cannot work under increased loads. Discs differ according to the material they can work with. The marking of such products contains an inscription and color. Explanation of the inscriptions in the table:

| Inscription | Purpose: for cutting |

| Metal | metal |

| Сoncrete | concrete and stone |

| Steel | become |

| Aluminum | aluminum, non-ferrous metals and alloys |

| Inox | stainless and high alloy steel |

| Castiron | castings and cast iron |

If there is a blue stripe on the disk, then the circle is intended for working with metal, and green for working with concrete.

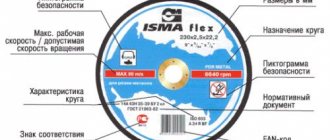

The circle markings are clearly shown in the figure.

Products made with vulcanite binder operate at speeds from 50 to 80 m/sec, with bakelite binder – from 80 to 100 m/sec.

Read also: Dif 101 dekraft connection diagram

The disc itself indicates the date until which it can be used, i.e. the expiration date. If it is on a vulcanite bond, then this period does not exceed 1 year, on a bakelite bond - 6 months.

Grinding wheels

The products belong to the group of abrasive materials and are used before preparing the product for grinding, to clean contaminated surfaces and tarnished colors on metal. They consist of an abrasive substance and a binder. Available in hard and flexible. In the first case, a binder of bakelite, vulcanite or ceramic is used, in the second - based on rubber.

The degree of surface cleaning depends on the grain size. A distinctive feature of the grinding wheels is that they have the same seat diameter, equal to 22 mm. They are available in outer diameters of 115, 125, 150, 180 and 230 mm and thicknesses from 3 to 20 mm.

This group of products includes cord brushes, the working surface of which is metal wire. The products are called twisted cutters and come in cup-shaped and disk-shaped.

Sanding discs

Products in this group allow you to grind with the required degree of roughness on metal and wood. The grain size plays an important role. The finer the grain size, the higher the quality of the sanded surface. Manufacturers produce wheels with the following grain sizes: 50, 100, 200, 400, 600, 800, 1000, 1500, 2000, 3000. Consumables can be made of emery, have a sponge, felt, felt or fabric surface.

The felt wheel is used to perform polishing operations on grinders that are equipped with a speed control device. Products are made from coarse or fine wool of sheep, cows, goats, and camels. The diameter of such circles is from 50 to 150 mm, and they are 25 or 30 mm thick. It is recommended to polish at the speed specified by the consumable manufacturer.

Grinding wheels

Using sharpening discs, the edges of cutting tools are brought into working condition, and weld seams are also cleaned. Available in flat and cup-shaped. A distinctive characteristic of such products is their thickness, which is at least 5 mm.

Rating of grinding wheels for mid-price angle grinders

A24-P-BF (125*6*22.2 mm) Bosch 2608603182 (15455068)

A peeling device is purchased for use with grinders for the purpose of processing metal structures. Users note high performance and reliability, as well as value for money. Belongs to the grinding type. The shape is concave. Universal installation - on a flange. Each circle has individual packaging. Sold at any specialized retail outlet. It is extremely popular among domestic builders.

The average price is 107 rubles.

A24-P-BF (125*6*22.2 mm) Bosch 2608603182 (15455068)

Advantages:

- German quality;

- practicality;

- functionality;

- long service life;

- safety;

- easy to install and operate.

Flaws:

- not found.

X-Lock Bosch (125*6*22.23 mm) 2608619366 (16144676)

The German brand is produced at Chinese production facilities. Reviews about the product are only positive. The manufacturing company controls the quality of products at all stages. Only high-quality materials are used in production. Purchased for cleaning metal structures. Belongs to the class of grinding. Concave shape. Own weight – 190 grams.

The average cost is 107 rubles.

X-Lock Bosch (125*6*22.23 mm) 2608619366 (16144676)

Advantages:

- performance;

- wear resistance;

- versatility;

- durability;

- ease of operation.

Flaws:

- none.

Trigger 7032 tov/157537 (15737808)

The German brand is produced in the Middle Kingdom. Product parameters – 115*6*22.2 mm. Designed for metal manipulation. Grinding type. Available in straight form. Flange mounted. Weighs only 115 grams. It is reliable and practical. It is very popular among amateurs and professionals. Often purchased for household use. An indispensable assistant when carrying out minor repairs.

Purchase price – 126 rubles.

Trigger 7032 tov/157537 (15737808)

Advantages:

- functionality;

- quality factor;

- versatility;

- practicality;

- durability.

Flaws:

- none.

Luga-Abrasiv D-11201802260000 (15854286)

A metal cleaning disc from a Russian manufacturer is very popular among domestic builders due to its good price-quality ratio. Bought to tidy up metal structures. Installed on the flange of hand-held grinding machines. Has a straight shape. It will quickly and efficiently deal with contaminants on various steel surfaces and remove defects resulting from welding seams. Disc diameter – 180 mm, thickness – 6 mm, seat diameter – 22.2 mm. The manufacturer provides personal packaging for each unit of product. There are no problems with the purchase. The product can be found at any specialized retail outlet or ordered online in an online store.

The sellers are asking 138 rubles for the consumables.

Luga-Abrasiv D-11201802260000 (15854286)

Advantages:

- reliability;

- practicality;

- strength;

- safety;

- performance;

- positive results from work.

Flaws:

- not identified.

DeBever NWG-12560228/R (15702603)

The product is purchased in cases where there is a need to tidy up metal products using a manual grinder, freeing them from rust, paintwork or other composition. It will help to quickly and efficiently clean the base before welding work. A distinctive feature of the circle is its strength and wear resistance. The ideal combination of price and quality. Belongs to the grinding group. Parameters – 125*6*22.2 mm. The surface is concave. Attached to the flange. There are no complaints during operation. In a matter of minutes it will make any surface clean and smooth, ready for further manipulation. Own weight – 170 grams. Sold in separate packaging.

The average cost is 158 rubles.

DeBever NWG-12560228/R (15702603)

Advantages:

- wear resistance;

- performance;

- reliability;

- long service life;

- ease of use;

- Innovative technologies are used in production.

Flaws:

- not found.

How to choose the right disc for an angle grinder

Wheels for grinders can be purchased in retail chains in a varied assortment and at reasonable and high prices. With the help of products made from different materials and using different technologies, diverse operations are performed. What are the basic selection rules and what to pay attention to? It is necessary to clearly know what materials you will be working with. You also need to pay attention to the following factors:

- diameter and thickness (indicators should not be greater than indicated in the passport data for the angle grinder or, more simply, the disc must fit into the protective casing);

- seat size (must correspond to the diameter of the grinder spindle);

- rotation speed (it must correspond to the type of grinder, indicated on the disk itself);

- type of cutting (dry, wet or combined).

The rules that must be followed to make products last longer are simple. For hard materials, choose discs with a soft binding, for soft ones – with a hard one. The work area should not overheat during operations. Therefore, it is recommended to periodically remove the disc from the material to allow it to cool. You cannot make deep cuts in one pass. Do not press the product with great force and work at high speeds. Remember: if during operation the disc experiences beating or cracks appear on it, you cannot cut with this consumable. It needs to be replaced.

The video explains in detail and clearly about grinder wheels:

We ask those who have encountered discs for grinders, made their choice and worked with specific models, to share their experience in the comments to the text.

Agree, it is always more convenient to have one universal tool on hand than several specialized ones - the issue of transporting a huge amount of rarely used “junk” is immediately resolved. Instead of carrying a lot of all kinds of tools, craftsmen transport a small set of them. The most versatile tool in this regard can be called a grinder. With its help, using different disks or attachments, you can carry out a fairly wide range of various operations. The grinder is capable of cutting almost any material, regardless of its strength, grinding, polishing, sharpening, peeling - in general, performing all types of work for which rotational movements can be used. It is these attachments that will be discussed in this article, in which, together with the site stroisovety.org, we will study all the available discs for an angle grinder and understand their purpose.

How to choose discs and attachments for an angle grinder

Cutting discs for grinders

Cutting discs are the most common replacement cutting tool for an angle grinder - there are quite a lot of them and they can cut through almost any material. The most used among them are grinder discs for metal, stone, wood and a diamond wheel.

- Disc for cutting metal. It should be understood that cutting discs for grinders may differ in both their outer diameter and thickness. Everything seems to be clear with the diameter of such attachments - in this regard, they are intended for small, medium and large tools. Accordingly, their diameter can be 115, 125, 150, 180 and 230 mm. As for the thickness of these discs, it can vary from 1mm to 3.2mm. Disks of large diameters are made thicker, disks of small diameters can be of any thickness. This approach to the matter is associated both with the speed of rotation of the disk and with the expected loads on them.

Read also: Dimensions of a homemade plow for a walk-behind tractor

Grinder disc for metal

- Stone discs. They differ from their metal-cutting counterparts solely in the abrasives used.

- Wood discs. In principle, the use of such discs is fraught with unpleasant consequences in the form of all kinds of injuries - you need to work with them very carefully. Compliance with safety precautions when working with such replaceable attachments is in your best interests. Firstly, you should not remove the protective casing from the tool and, secondly, for an angle grinder it is better to use a wood disc with a fine tooth. Under no circumstances should you cut wood with a strong feed. And it is better to avoid using such attachments on a large instrument altogether. The ideal option for using such a tool would be to use it in conjunction with special equipment (a device for stationary mounting of an angle grinder).

Wood discs for grinder photo

- Diamond blade for grinder. This attachment can be called universal - it is able to cut almost any material, from soft to durable. Such attachments are most widely used in the field of cutting porcelain stoneware, reinforced concrete, artificial and natural stone and tiles. For each of these materials, there are separate types of discs - some of them have a solid cutting edge, and some have a ragged edge with slots. Also, depending on the purpose of these wheels, they can have a large or small fraction of diamond coating. For example, grinder discs for concrete have a fine coating and special transverse recesses along their entire diameter. In contrast, a diamond blade for a stone grinder has a continuous cutting edge.

Diamond blade for grinder photo

It is difficult to determine the purpose of diamond discs visually, therefore, when purchasing such attachments, carefully read the packaging - everything is written there in detail about its purpose.

Actions when a disk is jammed

This problem occurs quite often, so it should not be ignored. If such a situation arises, professional builders recommend taking the following actions:

- Use gas wrenches. Manipulations must be carried out confidently, but with a certain accuracy. Otherwise, the stopper may be damaged. It is necessary to free yourself from the remnants of the circle in order to get to the lower flange. Just use pliers. Then, using keys, clamp the lower and upper fasteners and turn them in different directions.

- Disassemble the gearbox. This method is used when the latch has become unusable. The disc can also be removed using pliers. The fastener and cover are removed. The shaft is secured using a vice. The fastener is unscrewed using a key.

- The circle is shrinking. Parts of the disk are deleted. A metal sheet is taken with a vice, the angle grinder is turned on and the remaining abrasive is ground off on the end of the sheet.

- The nut is warming up. You can't do without a blowtorch. You can use the services of a hair dryer or a gas burner. The heated flange can be unscrewed using the supplied wrench. It is worth thinking about safety precautions and carrying out manipulations with gloves to avoid touching a hot surface.

- Use WD-40 lubricant. The composition is applied to the junction of the flange and shaft. A five-minute interval is maintained so that the lubricant gets inside. Then try to unscrew the fastener.

- Cut the part using a hacksaw. It is imperative to hold down the stop button.

- Knock on the middle of the nut. You can use a hammer drill with an impact function. In this case, the stopper state must be active. A few movements are enough and the fasteners will be removed.

Grinding and polishing discs for grinders

There are quite a lot of varieties of grinding and polishing wheels - depending on the required surface quality, discs with replaceable sandpaper, felt, sponge, and even fabric discs can be installed on the grinder.

Grinding disc for grinder photo

Most of them require the use of special fine abrasive pastes or even liquids to operate. Fine abrasive grinding wheels are used for rough grinding and cleaning. Grinding discs for grinders allow you to bring almost any material to the required roughness - such attachments are even used in auto repair shops for polishing car bodies.

Petal disc for grinder

Discs for sharpening tools and grinding attachments for grinders

Among this type of devices, in order to expand the functionality of the grinder, three types stand out significantly - twisted cutters, abrasive grinding discs and diamond grinding wheels.

- Twisted cutters are used for peeling metal and stone surfaces - if we are talking about removing old paint or thoroughly dried cement mortar, then a better replacement tool can hardly be found. It is made in the form of steel cups, along the perimeter of which wire brushes are installed. The size of the wire can be different - depending on the roughness of the processing, the cutter can be equipped with either thick or thin wire.

Peeling attachments for grinders photo

- Abrasive grinding discs. Such attachments are designed for rough metal processing - they are used to clean welds and sharpen all kinds of cutting tools. As a rule, such attachments are most widespread on small grinders - this is due to ease of use. Such attachments can be distinguished from cutting wheels by their thickness and shape - their inner part has a recess, which allows the sharpening process to be carried out with the flat part of the circle, and the thickness cannot be less than 5 mm.

Sharpening discs for grinders photo

- Diamond grinding discs. In principle, they are somewhat similar to abrasive grinders. Only in contrast to them, processing with a diamond tool of this type can only be performed by the periphery of the disk on which the cutting edges are located. In contrast to its sharpening counterpart, a grinding diamond is not intended for working with metals; its specialty is grinding concrete, stone and similar materials. If we are talking about removing a small section of cement screed, then you won’t be able to come up with anything better than this diamond.

Wheels for grinder photo

In general, one way or another, grinder discs can significantly increase the functionality of an angle grinder. In modern construction and other areas of life, it is very difficult to find any industry where an angle grinder is not used - together with a huge number of various attachments, it is a truly universal tool.

For high-quality metal grinding, it is not enough to purchase an angle grinder; you must also choose the right disc. Using a variety of angle grinder attachments, you can cut, clean and grind metal and other materials. Among the variety of metal wheels for angle grinders, it can be difficult even for a specialist to make the right choice. This publication will help you navigate the types of consumables and the principles of working with them.

What are metal grinding discs?

Sanding is one of the most common processes for which a grinder is used. Using this device and a set of attachments, you can carry out gentle and rough processing of metal, wood and stone surfaces. Basically, grinding precedes polishing of products. The attachments used in this situation may contain sandpaper or felt material.

Read also: Attachments for polishing machine

For grinding metal, a variety of brushes are used, which are made of wire located on a metal base. Moreover, now you can buy other, more technologically advanced attachments for angle grinders. The tape file is direct proof of this. It is used for grinding, polishing and removing corrosion. Taking into account the required surface quality, wheels with replaceable sandpaper, felt, porous and even fabric can be mounted on an angle grinder.

It is worth noting that an angle grinder must have smooth speed control, which is an indispensable condition for using such an attachment.

Metal grinding wheels are used to perform the following activities:

- tool sharpening;

- final processing of welding seams;

- cleaning the surface from paint and corrosion.

In most cases, the work will require specialized abrasive pastes, and sometimes liquids. For rough grinding and cleaning, grinding discs with fine abrasives are used. Grinding wheels for angle grinders make it possible to refine almost all materials to the required roughness. For example, such attachments are even used in car services for polishing car bodies.

Types of grinding wheels

Grinding attachments belong to the roughing category. They are discs whose edges have iron wire. Cleaning wheels are used to remove corrosion from metal surfaces, as well as to remove other types of heavy contaminants. In most cases, they are used to prepare pipes for painting.

There are 4 types of roughing or grinding discs , but the flap disc is considered the most popular of all types of sanding devices. Emery (flap) wheels for an angle grinder are mainly used when removing old varnish or paint, and sanding wood surfaces. This product is used for sanding metal, wood and plastic parts. The emery circle is a circle along the edges of which not very large pieces of sandpaper are fixed. Taking into account the type of work, the size of the abrasive grains of the working elements is selected.

The use of a disk with a petal structure makes it possible to perform pre-processing of products made from various materials. With its help, finishing processing is also allowed. For final grinding, fine-grit discs are used.

The following types of petal circles can be found on sale:

The grinding disc for an angle grinder with a mandrel is used when high-precision work is required. Many models in this category are used to remove burrs after cutting plastic or metal pipes. Finish grinding of weld seams is carried out using grinding discs. The components of the circles include crumbs of electrocorundum or carborundum. The structure of the circles contains a fiberglass mesh. These wheels are thicker than cutting wheels for metal.

To perform grinding work, there is a variety of iron brushes to choose from: attachments:

- To clean the surface from persistent dirt or corrosion, specialized wire discs are used;

- Diamond cups are used for polishing stones;

- For polishing metal, disc-shaped attachments made of plastic or rubber are ideal, to which a replaceable abrasive mesh or emery cloth is attached.

Rating of quality products from 50 rubles

C 24/R Makita D/25292 (13349299)

Japanese brand, produced in the Middle Kingdom. The equipment is designed for manipulating stone. Purchased for angle grinders. It is in great demand among both professionals and beginners. Suitable for both domestic and commercial use. Breakdowns are rare due to the use of innovative technologies in the production process. It copes well with rough machining of stones, concrete and bricks. Thickness – 6 mm, diameter – 100 mm, weight – 100 grams. Type – grinding. Straight shape. Flange mounted. Sold in convenient packaging.

How much does the product cost? You can buy it for 39 rubles.

C 24/R Makita D/25292 (13349299)

Advantages:

- reliability;

- wear resistance;

- strength;

- long service life;

- practicality.

Flaws:

- not identified.

Professional (125*6.4*22.2 mm) Maxweld KRPR-12564 (16486904)

Cleaning consumables are purchased to bring metal surfaces into proper condition. Thickness – 6.4 mm, diameter – 125 mm. The disc is of the grinding type. Bore diameter – 22.2 mm. Concave shape. Attaches with a clamp. Installation location: flange. The packaging contains one item of the product. The weight of the structure is 140 grams. The Belarusian brand is manufactured at Chinese production facilities, but there have been no complaints about the quality.

The product is sold at a price of 81 rubles.

Professional (125*6.4*22.2 mm) Maxweld KRPR-12564 (16486904)

Advantages:

- quality of materials used;

- ease of operation;

- wear resistance;

- positive reviews;

- can be ordered online in the online store.

Flaws:

- not installed.

SP-Novoflex Metabo 617170000 (15869836)

An inexpensive grinding wheel is produced at a domestic enterprise. Durable steel is used in manufacturing. Installed on hand grinders. Designed for cleaning steel surfaces. A distinctive feature is high productivity and a huge working resource. Belongs to the grinding type. Diameter – 125 mm, thickness – 6 mm. The shape is concave. Flange mounted. The product weighs 0.170 kg.

The average cost is 87 rubles.

SP-Novoflex Metabo 617170000 (15869836)

Advantages:

- practicality;

- functionality;

- versatility;

- performance;

- strength;

- durability;

- safety.

Flaws:

- none.

Tsunami D-16110011562300 (15856003)

A six-millimeter metal cleaning wheel with a diameter of 115 mm is very popular among craftsmen. Straight shape. The seat is a flange. Weighs 150 grams. Sold at any specialized retail outlet. You can use the online store service. There is practically no defect on sale. The domestic manufacturer controls the quality of the product at all stages.

The purchase price is 93 rubles.

Tsunami D-16110011562300 (15856003)

Advantages:

- strength;

- long service life;

- versatility;

- wear resistance;

- absence of marriage;

- achieving a positive result in a short period of time.

Flaws:

- not identified.

A21 R BF 14 A BU80 Luga-Abrasiv D/11201502260000 (15854285)

The sanding attachment is used with hand sanders. Ideal for power grinding of parts and structural elements made of durable steel. Quickly and efficiently puts welded seams in perfect order. The product is produced by a Russian company. The reviews are only positive. There are no complaints about quality and durability. They are purchased by both amateurs and professional builders. Thickness – 6 mm, disc diameter – 150 mm. Flange mounted. The shape is straight. Each circle has its own packaging. To extend service life, the manufacturer's recommended speed must be observed.

Purchase price – 98 rubles.

A21 R BF 14 A BU80 Luga-Abrasiv D/11201502260000 (15854285)

Advantages:

- strength of the materials used;

- application of innovative technologies;

- versatility;

- practicality;

- reliability.

Flaws:

- not installed.

additional characteristics

For grinding wheels of angle grinders, the size of the abrasive grains is of significant importance. The higher its indicator, the smaller the abrasive elements, and, therefore, the more delicate the processing:

- 40-80 – primary grinding;

- 100-120 – leveling;

- 180-240 – final testing.

Abrasive grain sizes of elastic-backed diamond polishing pads: 50, 100, 200, 400, 600, 800, 1000, 1500, 2000 and 3000 (tiniest grit). The size of the abrasive is indicated by the marking on the label.

How to choose?

When purchasing a blade for an angle grinder, you should pay attention to several aspects.

- The diameter of the circle must correspond to the maximum permitted for a particular instrument. Otherwise, the disk may collapse due to exceeding the maximum permitted rotation speed. The resource of an angle grinder may not be enough to work with a large disk.

- Grinding discs have different structures and are rigid, flap and maneuverable. The choice of product is determined by the desired level of plane homogeneity. To give impeccable evenness to the wood, fine-grained flap discs are mainly used in the final sanding. They are available in spindle and flange versions.

- Discs with fine grains have proven themselves well in polishing wood. Medium abrasive discs are often used to remove the top layer of wood. Coarse grain discs are an excellent option for removing old paint. The grain size is certainly indicated on the product. The larger the grain, the faster the grinding will be done. However, we should not forget that the cutting or grinding quality of discs with coarse grains is worse. Additionally, manufacturers indicate the rigidity of the binding agent of the circle base. When sanding soft materials, it is advisable to use discs with a soft bond.

- To clean stone and metal surfaces, specialized wheels for an angle grinder are produced - twisted cutters (cutters). They are implemented in the form of metal cups, along the contour of which wire brushes are fixed. The diameter of the wire varies and is selected based on the desired degree of grinding coarseness.

- Information about the maximum permissible linear speed is printed on the packaging or the side surface of the wheel. The operating regulations of the angle grinder are selected in accordance with this indicator.

When purchasing metal blades, it is recommended that you first consider the scale of work you need to carry out.

Ensuring safe operation

The grinder is considered one of the most dangerous power tools used on construction sites. While working with it, you need to follow a number of rules:

- Use protective equipment - mask or goggles, gloves.

- Do not remove the protective cover during operation.

- Never use blades with a larger diameter than stated on the power tool.

- Do not use grinding discs when cutting parts.

- Check that the clamping ring is securely fastened before starting the electric motor.

- You cannot cut the workpiece closer to the center if it has two support points at the edges. Because of this, the disk can jam and rupture.

- Check the integrity of the equipment before starting work.

- Do not pinch the clamping ring.

- Do not use the grinder near flammable materials or liquids.

- After starting the tool, you need to wait a few seconds for the disk to spin at maximum speed.

- Do not press the tool against the workpiece when cutting.

- If the disk is jammed, you must immediately turn off the tool.

- Metal corners, profiles, and large-diameter pipes are cut in two approaches.

During active work with an angle grinder, you need to use coolant, which is poured over the cut area. The instrument itself should be allowed to rest every 5 minutes.