The grinder is a universal tool with a wide range of capabilities. To implement them, a special attachment for the grinder is required. Among its types is a diamond cup for concrete for a grinder, which is used to clean and polish floors and walls.

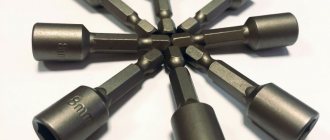

Attachment and discs for an angle grinder for concrete

Each tool used in conjunction with an angle grinder (angle grinder) is designed to perform the operations for which it is designed. The correct choice contributes to efficient and safe work with discs and attachments.

Cutting discs

Diamond cutting wheels are used to work with concrete. These are discs made of durable hardened steel with diamond coating on the cutting part.

These nozzles differ in the following design features:

- Cutting edge. It can be solid or with various slots. Segmentation increases the efficiency of air cooling during operation.

- The grain size of the diamond coating and the spraying method. The most reliable methods using laser welding and thermal bonding. Silver soldering allows operation with water cooling only. The electroplated diamond edge cuts only soft natural stones.

- The outer diameter of the circle. The correct size disks must be installed. Working without a protective cover is not only dangerous: the increased size of the nozzle leads to premature wear of the gearbox.

Diamond cutting can only cut material in a straight line. Curved sawing increases the load on the cutting edge, causing the diamonds to break.

Grinding discs for concrete

Concrete is ground to eliminate coating defects. Diamond wheels are used, which have a high abrasive ability and a long working life. Sometimes hard-alloy coated disks, the characteristics of which are lower, are called diamond. The efficiency of work is determined largely by the grain size of the working surface.

Depending on the concentration of diamonds, discs for grinding concrete are distinguished:

- grain size 40-80 (for pre-treatment);

- indicators 100-120 (for leveling the surface);

- grit 180-240 (for polishing).

The tool is a steel circle with soldered segments. Diamond powder is fixed to them with a special bond. It keeps the diamonds from being destroyed by the centrifugal force that occurs during rotation.

The designations on the discs consist of 2 or 3 numbers. The first number indicates the outer diameter, the second indicates the size of the mounting hole. The third number is not always present; it indicates thickness. For a grinding tool, this parameter does not play a big role.

Cleaning and roughening attachments

These attachments look like cups or circles. There are cutters and diamond discs. Twisted metal brushes are located around the circumference of the rollers. They strip metal and stone. The diameter of the wire varies depending on the purpose (scraping or stripping).

The working part of the diamond grinding disc has cutting edges. It is not used for stripping metal: it is used to clean stone, concrete, and remove hardened cement mortar.

Purpose of an angle grinder

The peculiarity of the machine is its ability to process not only smooth surfaces, but also chamfers. This is achieved thanks to the angular placement of the working disk.

The device is universal and can be used to perform many jobs:

- The main operation for which an angle grinder is intended is grinding. Wide grinding wheels are used. Processing the ends with an eccentric grinder is difficult, but it is accessible for an angle grinder. The surface is ground with or without water cooling.

- Polishing with a grinder is also possible. To do this, use special diamond-coated polishing discs.

- Another operation that is performed with a grinder is res. The unit is not suitable for working with thick materials. Concrete or thick stone should be cut with special machines that have a water-cooled working wheel.

- An angle grinder easily cleans surfaces, removing dirt, paint, mastics, adhesives, and construction mixtures using abrasive attachments.

A grinder can be used instead of a wall chaser. A cutting disc is used to cut grooves for electrical cables and pipelines.

Processing of logs inside the house

Grinding the grooves of logs is always done with a grinder. The grooves are processed with a nozzle smaller than the disk. If the attachment and disc are the same size, this may cause the machine to jam.

To process the ends, use a grinding wheel with 40-grit sandpaper. Usually in these places they limit themselves to rough and medium processing, without grinding the ends to perfect smoothness. Immediately after grinding, the ends are treated with protective impregnations and antiseptics.

All actions are identical. When sanding a frame made of planed logs, if the wall inside will not be lined with anything, add one more pass for finishing: with an eccentric sander with a 120 abrasive disc. This will allow you to achieve a perfectly smooth surface.

The inside of the log house is polished to furniture smoothness.

What is a grinder attachment in the form of a diamond cup?

To prepare for applying the next layer or final finishing of the coating, the screed is ground and polished. At the same time, uneven surfaces are removed and cracks are smoothed out. The ultra-hard working surface of the equipment - a diamond cup for concrete - easily removes the top layer.

Design Features

The nozzle has a round concave base on which a grinding wheel is attached. Its working part is divided into segments with small diamonds attached.

The bowl-like base has holes that help cool the tool during use. Between the segments there are spaces left - slots. They help cool the tool and material with air and water.

There is a hole in the center of the cup through which it is threaded through the grinder spindle and screwed with a nut. Some models have a thread in the hole, so the tool is screwed onto a shaft.

Nozzle for an angle grinder. Main characteristics

The diameter of the cups is standard: 110-180 mm, the most popular is 125 mm. The grinder engine must have a power of at least 1.5 kW. Large nozzles work faster, but they are more expensive - a more powerful machine is required. The mounting hole for use with a standard size grinder is 22.2 mm.

Small diamond fractions are fixed on a steel base. The mixture is pressed, which makes it especially strong. Mills with large grains (200/160 microns, 160/125 microns) are used for stripping and rough processing of surfaces. Finishing is carried out with diamond-coated nozzles of small and medium fractions: 125/100 microns, 100/80 microns.

Diamond grinding cups are valued for benefits such as:

- high strength;

- efficiency;

- good balance, making work easier;

- durability.

An important advantage is the ability to work without water cooling. Hot air is discharged through holes in the bowl, preventing overheating.

Nozzle for an angle grinder. Application area

Diamond cups are superior to other attachments in terms of efficiency. This is achieved by high wear resistance and reliability. They peel and polish various materials: concrete, brick, artificial and natural stone, porcelain stoneware, paving slabs.

Diamond cups perform the following operations:

- peel off the sagging screeds;

- remove irregularities;

- align the seams;

- grind the joints;

- clean surfaces;

- remove unnecessary layers;

- polished.

Sanding cups save time: they simultaneously remove deposits and level the surface.

Machine Applications

All three stages of finishing can be performed on special grinding machines or using other electrical equipment: grinders for smooth or angular surfaces. There are homemade brushing machines. It is difficult and expensive to make a full-fledged machine with your own hands, working like a thickness planer, so they use the same grinder with several metal and nylon attachments.

Full mechanization of work makes sense for large volumes of wood that require brushing. In such a situation, investments in the acquisition and operation of units will be justified. Common types of home repair and construction work can be quite successfully done with an angle grinder, which every craftsman has.

Sources

- https://master-srubov.ru/sovety/nasadka-na-bolgarku-dlya-shlifovki-dereva

- https://moiinstrumentu.ru/diski-po-derevu-na-bolgarku.html

- https://tokar.guru/instrumenty/ushm-bolgarki/polirovochnye-nasadki-dlya-dereva-na-bolgarku.html

- https://intehstroy-spb.ru/osnastka/nasadki-na-bolgarku-dlya-shlifovki-dereva-raznovidnosti-i-sovety-po-vyboru.html

Nozzle for an angle grinder. Types of Diamond Cups

Attachments for grinding concrete using an angle grinder are classified depending on the manufacturing method.

There are types:

- with a single-row working surface;

- double row;

- solid.

Single-row equipment has good performance and low weight. It is used to polish concrete and create a smooth edge. The disadvantage is that the tool is difficult to hold on the surface.

Double-row cups are used to carry out primary processing and eliminate gross defects in the concrete screed. Surfaces are polished using nozzles with continuous coating.

Surface degumming

Conifers are known to contain large amounts of natural resins. On the one hand, this circumstance is an advantage, since the resin content protects the tree from rotting and mold formation. But on the other hand, resin prevents good adhesion of paint to wood, and when sanding it spreads over the surface and spoils the appearance of the wood. Therefore, before processing the needles with a grinder, it is necessary to remove excess resin.

How to remove resin from a log before sanding? Suitable solvents for this are: acetone, white spirit, turpentine, purified gasoline. You just need to apply the selected product to the wooden surface, and rinse off the residue with warm water.

Shape and number of segments

The number and shape of segments vary depending on the conditions and the required quality of work. They are also positioned differently, which affects the working properties of the nozzles.

Double segment

Diamond cups with double-row segments eliminate large defects in concrete. They easily cope with large sagging and protruding seams. They can reduce the thickness of the screed. The surface after processing is rough, finishing grinding is carried out with a different attachment.

Boomerang

The shape of the segments resembles the weapons of the Australian aborigines, which is why the cups got their name. These are diamonds of the finest fraction, which determines the purpose of the attachments - finishing grinding. Thanks to it, the screed acquires a mirror-like evenness. Light weight and balance make it possible to use the Boomerang with an angle grinder. The equipment is stable and soft in operation.

Square

Square incisors of increased thickness are located at a distance from each other. This allows you to remove protrusions on the concrete and level the surface. The weight of the disc is large, which helps in work. Powerful segments cut off unnecessary elements. Rough processing is used to prepare for subsequent operations. It leaves behind a rough surface with good adhesion, which requires coating with different compounds.

Nozzle for grinder Turbo and Typhoon

"Typhoon" is used for peeling and grinding ultra-dense and hard materials. High wear resistance of the segments increases the service life. "Turbo" is used for high quality grinding. Nozzles of this type are used for processing chamfers, edges, bends, and engraving work.

The cutters of both attachments are located perpendicular to the rotation. The slots between them are of minimal size, making the working surface almost continuous.

Sanding by professional craftsmen

By choosing professional services from qualified specialists, you save yourself from many problems. In our work, we use modern equipment and high-quality grinding attachments, which we select in accordance with specific working conditions. Sanding is carried out at the optimal moisture content of the wood with precise adherence to technology. Our craftsmen have extensive grinding experience and know all the intricacies of this work. To leave your request, contact us using the coordinates on the “Contacts” page.

An attachment for an angle grinder in the form of grinding cups. Features of choice

When choosing a tool, consider:

- Type of planned work. For each operation, special attachments are most effective. Using the wrong ones slows down the work or makes the process impossible, and quality suffers.

- The diameter of the cup, which should correspond to the power of the grinder. For accurate sanding of small areas, small attachments are more suitable. It is faster to work with large equipment, but its price is higher.

- Mounting hole, which must correspond to the size of the shaft. If the tool spindle is thinner, an O-ring is used: the fit on the shaft cannot be loose.

- The discs are designed for a rotation speed that the grinder cannot exceed.

The diamond grinding tool is marked with a marking that reflects:

- external diameter;

- cup depth;

- working edge width;

- segment height;

- mounting hole size.

Numbers in millimeters indicate characteristics in the sequence given above. The spraying parameters are indicated separately: diamond content in percentage, grain size in micrometers (µm). Coarse diamond powder is suitable for roughing and rough grinding; fine diamond powder is used for polishing.

Self-grinding mistakes

Most home craftsmen sand a wooden house with a household-grade grinder, which is not easy to use, has little power, and overheats quickly. A household appliance is not capable of sanding wood at a good quality level.

Professional equipment is expensive, so not everyone can afford it. But even if you buy such a model, you need to know how to use it, otherwise, if handled ineptly, high-quality grinding will still not work. Many people make the mistake of working at high speeds, pressing hard on the tool, which leads to damage to the surface.

The wrong choice of nozzles also does not lead to anything good. In the best case, the surface will simply be poorly polished, and in the worst case, cases of injury cannot be ruled out.

Grinding technology

The work is carried out using a dry or wet method. Wet grinding, which is close in quality to polishing, is used for processing concrete and products made from marble chips. The process is accompanied by the formation of sludge from wet dust.

The dry method is used for grinding concrete, which produces a lot of dust. The method is effective if you use high-quality nozzles.

Surface preparation

The quality of grinding and the service life of concrete depend on surface preparation. They start by dismantling the old coating, if any. Milling, shot blasting or diamond grinding discs are used. After this, grooves often form, which are removed by long grinding.

Surface preparation also includes the following work:

- Check the strength of the concrete base by tapping it with a hammer. If voids are found, the areas are opened and filled again.

- Check whether reinforcement elements or mesh are exposed to the surface. When they are discovered, a depression is made around it, which is then sealed, and the metal is cut off.

- Small irregularities, seams, cracks are eliminated with epoxy mastic. It grinds well, but the consumption of nozzles is greater.

- Then they check the plane by applying a 3 m long ruler to the surface. Holes and potholes are marked so that they can be repaired later; low bumps will be cut off with a diamond tool. All irregularities affect the wear of the cup.

- If necessary, concrete drilling and other similar work is carried out.

Large cracks and seams are expanded using a circle to a depth of 10 cm. They are freed from dust, primed, and sealed with mortar. A good filler for the repair mixture is river sand. When the first layer has sagged, apply a second one and level it out. The frozen surface is polished.

Repairing Potholes

On the old coating, due to mechanical wear, depressions form, and raised areas appear nearby. When preparing the surface, these places are found using a ruler. If the differences exceed 5 mm, the screed is leveled. To do this, around the pothole, a “grinder” with a diamond disk is used to cut out the damaged area to a depth of at least 20 mm. The concrete is broken up with a hammer drill and the material is removed.

The cavity is cleaned of dust using a vacuum cleaner or sandblaster. Next, it is treated with a primer and filled with a building compound, which is used to seal irregularities. If the depression is large, the mixture is applied in several stages. The surface is leveled and sanded after hardening. Cracks may form in the area where the pothole has been repaired; these should be repaired.

Surface grinding

Sanding begins after a few weeks, when the screed has dried and the coating has become durable. If work is started earlier, the diamond cutters will tear out the rubble. The surface is primed with a special mixture. It strengthens the top layer, closes the pores, and makes the concrete more resistant to moisture.

At the first stage, discs with a grain size of 40 are used. At the final stage, nozzles with fine spraying (with a grain size of 400) are used. After such grinding, the surface does not require additional care. A glossy shine appears after processing concrete with a tool of the highest grain size - 1500-3000. Sometimes the floor is additionally coated with several layers of polyurethane varnish.

A prerequisite for grinding is a continuous supply of electricity. If there are interruptions, it is difficult to achieve a high-quality surface.

Varieties

Grinding is the basic purpose of an angle grinder. In the case of working with wood, this is a complex process that requires care and skill from the master. Natural wood of varying structure is brought to perfection with high-quality and reliable discs. Regular diamond cutters will not work here. There are special grinding wheels for the woodworking industry.

There are several types of grinding wheels for angle grinders. First of all, the initial cleaning of surfaces is carried out. This work is performed by several disks, differing in shape and size.

- Roughing. They are designed to remove old paint and varnish from wood. Typically, remnants of the previous coating that cannot be cleaned by hand are removed from windows, window sills and floor surfaces. The disc is equipped with steel wire bristles for rough processing. The elastic bristles are placed either around the entire perimeter of the circle, that is, along, or at an angle segmentally, as in a regular brush. It depends on the purpose of the nozzle.

- Cord brushes with wire or spikes. They allow you to level and smooth the surface of any material. A wire brush can be used to easily remove a layer of varnish or old paint or rust from metal. If the boards on the floor are of different heights, they can be compared with each other using a tenon circle. They vary in shape and speed of rotation.

- End fittings. They work in layers, like files, with sides and edges, corners and oblique cuts. The attachments are designed for sanding edges or straightening bevels.

When sanding with a sander, the wood layer remains intact, only the decorative coating is removed. This property of the grinder is indispensable when restoring products. Having removed the previous colorful design, you can apply another one to the fresh and smooth panel. At the same time, the furniture will change its appearance and will look new. A brush is used to brush or artificially age the material. To do this, the soft fibers are removed to reveal the rings and grain of the natural wood. The stain emphasizes the relief transitions.

At the next stage of processing, the surface is smoothed. Here experts advise using polishing wheels. They are made of sponge, felt and coarse fabric, with replaceable sandpaper. Fabric and felt are secured for work using Velcro. The attachments are sold in sets of five for easy replacement. Sandpaper is selected with medium or fine grit. The brand is usually indicated on the packaging.

The design of the nozzle is also important. Lapping or finishing wheels are divided into petal, solid and movable. The use of a petal wheel allows you to achieve an absolutely smooth surface. Several layers of emery are placed on the disc as an abrasive, overlapping like fish scales. This arrangement of the abrasive material reduces wear. The product is brought to an ideal state by such a modern attachment as a cup circle. The bowl provides minor texturing and penetrates joints easily. It has a pile made of synthetic material or corrugated wire reinforced on it.

A nylon wood brush consists of a large number of small bristles. It is used for final polishing. The bowl-shaped attachment allows the craftsman to sand the most difficult to reach areas of the part. The brush removes burrs and minor dirt and polishes the varnish. End brushes are made of polymer abrasive, cylindrical brushes are made of brass and steel wire.

Equipment types

Several types of equipment are used in polishing. Firstly, these are rotary polishers. They come in different types, sizes, capacities, etc. However, by and large, they are all the same. All modern rotary polishers have several speed levels and replaceable polishing plates. They constantly maintain the same speed, the nozzles rotate in a circle.

In addition, eccentric sanders can be found in auto repair shops. This type of grinder has several types. In fact, they differ only in the rotation of the disk.

This equipment is professional. If you decide to polish the car yourself, then a drill, screwdriver or grinder may be enough for you.

When polishing, what matters most is not so much the tool you use, but the polishing attachment and, of course, a certain skill in polishing.

Choosing a car polishing machine

To purchase a reliable and inexpensive grinder for polishing a car, you should pay attention to the following technical parameters of the tool:

- The power of the unit should be about 1200 - 1400 W. In this case, the grinding machine will cope with more tasks.

- Please note that there is a speed control function. If you have them, you will be able to carry out all stages of polishing with the highest quality. In addition, thanks to such modes, it will be possible to process different types of surfaces.

- Availability of a compensator. Thanks to power compensation, you can change the load level while maintaining the speed of the unit. The fact is that jumps in speed (when pressing and releasing the machine) can lead to rapid overheating of the paintwork surface, which is sensitive to high temperatures.

- Smooth engine start. This function will protect you from inrush currents during long-term operation of the tool. Thanks to this mode, the machine can be turned on when it is already installed on the surface of the body. In this case, “burning” will not occur.