The drill is an irreplaceable thing in construction. Using a drill, holes are made for utility pipes, technological niches and openings for cables are created. An experienced builder cannot be surprised by a stuck drill. And yet: what is the reason for such trouble and how to neutralize the consequences? Let's figure it out together.

How to remove a drill from a screwdriver?

To do this, turn on the reverse rotation mode on the screwdriver, hold the outer body of the chuck and press the “start” button. This will allow the drill to come out easily. If you do not have a special key, the drill can be removed using a Phillips screwdriver or a nail.

Interesting materials:

What is Maxim Gorky famous for? What is the Ryazan region famous for? What is good about membrane clothing? How to glue granite slabs? How to glue food utensils? What to feed a blackbird? What to feed Khrushchev? What to feed Rudd? What to feed a bedridden elderly person? What to feed a dog with distemper?

Why is the drill stuck?

- The first and most common reason is improper operation of the hammer drill. What does a hammer drill do? Crumbs the thickness of stone or concrete, creating the necessary hole. During the drilling process, stone chips are formed, which stick to the drill, as a result of which it stops moving in the hole. To prevent this from happening, you need to remove the hammer drill from the hole from time to time.

- The second option is contact with reinforcement. Occurs when there is strong pressure on the punch. To avoid such accidents, you need to hold the hammer straight and gently. He will do all the work for you.

- The third option is similar to the second: it involves getting the drill into a solid fraction: stone or pebbles.

Removing the fragment using two screwdrivers

A more complex case is when the drill breaks below the surface of the part, inside its body. It is impossible to hook the edge with pliers in such a situation. Therefore, you will need a device consisting of two thin screwdrivers:

- both screwdrivers are alternately inserted into the hole along the screw grooves until they stop, as if grasping the fragment on both sides;

- The screwdriver handles are held tightly by hand;

- Using counterclockwise movements, the fragment is removed from the part.

At its core, this is an imitation of the option of removing a fragment with pliers. It is suitable if the drill bit sits loosely enough in the hole and is not jammed in it or bent.

If the fragment is difficult to give in and there is not enough hand strength to fix it well with screwdrivers, you need to press the rods with pliers or pliers with your other hand.

Useful tips

The drilling process is simple, but it requires certain dexterity and skills. It is important to keep the tool level so as not to displace the drill and increase the load.

Some tips will help simplify the work and make the hole in the wall neat:

- You can't skimp on drills. Poor quality attachments break and bend easily.

- You can determine the presence of fittings with a metal detector.

- When installing the dowel, the hole should be several millimeters longer than the fastening. These extra millimeters will be clogged with cement dust when the dowel is inserted.

- If it is necessary to make a through hole, at the end of drilling, when approaching the opposite side, the speed must be reduced. This will help prevent the concrete from chipping.

- When using a low-power drill, it is important to regularly, every 10-15 minutes, stop and cool the motor. This will help prevent damage to the instrument.

- When drilling, it will be dusty, and therefore, before drilling into a concrete wall, it is better to prepare a vacuum cleaner. It is better to use a construction vacuum cleaner, since household models will quickly deteriorate from small crumbs.

How to get a drill that is stuck in a wall or floor?

- The most common and safest option for the tool: turn on a clean blow and little by little, twisting the hammer drill, remove it from the hole. In this case, the tool, as it were, drills a return hole, due to which it comes out of the hole.

- You can try to turn the hammer drill counterclockwise. This method is simpler than the first, but it can break the instrument. Therefore, it is recommended to pull out the drill in this way only if there is a warranty on the tool.

- You can turn off the drill and try to pull it out with a gas wrench, turning it in the opposite direction. This method is much more labor-intensive, but it is safe for both you and the instrument. Gradually tapping the drill with a gas wrench, unscrew it from the wall.

- If you cannot remove the drill using the methods listed above, you will have to take extreme measures - simply cut the drill with a grinder, and then seal the hole. If this is impossible for some reason, then drill several holes around the stuck drill at an angle to the stuck drill and remove a whole cone of concrete along with the stuck drill. The hole is then sealed.

- If you can’t get the drill out using any of the methods, and the cut drill sticks out unsightly from the hole, before sealing it, you should hammer it in with a sledgehammer and go through it a little with a file.

As a conclusion, it is worth saying: it is necessary to follow the rules of working with any construction tool. You just have to work with the hammer drill correctly, following the work procedure and safety precautions, and the drill will never get stuck in the wall. Don't expect to be able to get it easily. This is not always possible. And this results in additional and completely unnecessary reinforcement of the concrete wall.

Sequence of work

To remove the dowel from the surface, you need the following tools:

- screw or corkscrew;

- hammer, punch;

- pliers or pliers, nail puller;

- construction knife, chisel;

- soldering iron;

- Bulgarian.

Depending on the chosen method, you will only need those tools that will be involved in removing the item.

The wooden object is removed in parts. It must be broken into pieces using a hammer and chisel. Then take out the rest.

The plastic dowel is removed using a screw or a corkscrew. If that doesn’t work, you can make holes with a drill or cut off the cap and just leave it in the wall.

Metal rod. The part sticking out above the surface is cut off with a grinder. Or you need to tap milk on the protruding part from different sides. It will loosen and come out easily. The additional hole method is also applicable.

Removing a stuck drill bit

There are several ways to remove a drill bit from a hammer drill. The nozzle must be secured in a workbench vice, and then, shaking the tool from side to side, pull it towards you. There is a second option to solve the problem. Before removing the drill from the hammer drill using a gas wrench, the tool is secured in a vice. Next, the nozzle clamped with a key must be struck several times with a copper hammer. The direction of the impact must coincide with the vector of the drill exiting the chuck.

Since contamination or lack of lubrication is often the cause, special penetrating fluids can be used. They allow you to establish proper operation of the tool and extend its service life.

The drill can also get stuck because it has turned in the chuck. In this case, the elements of the cartridge must be removed, but you can try simply turning the nozzle in the right direction. However, in this case, replacement of parts of the clamping mechanism will be required.

Originally posted 2018-07-04 07:44:52.

How to remove an old dowel from a wall when it is broken?

In any job, defects happen. During installation, the screws may break, the notches on their heads may wear off, and the plastic of the bushing may crack. If the screw is not completely broken, then you can remove its remains using a little trick. To do this, take a reversible drill, clamp the remnants of the screw sticking out of the wall into the chuck instead of the drill, and turn on the reverse motion. If the fragment does not allow this to be done, then pliers with a large lever or pliers will be needed. These tools have a lot of pressure in the working part, which will allow you to grab the most difficult edge.

The same tool will help you remove the plastic part stuck in the wall. You need to carefully pry up the upper skirt of the liner and pull it, trying not to tear it. Since it can be difficult to remove a broken dowel from a tiled wall without damaging it, you can consider the option of partially dismantling it.

Reasons: why the drill stuck

Experienced experts cite three main reasons why the drill cannot be removed from the drill (regardless of the type of chuck):

- Tool diameter too large. During the process, a drill that is too large grinds in and gets stuck, like a dowel.

- Weak steel and, as a result, deformation (most often, the tail wedges like an anchor) of the drill or drill. For the same reason, equipment breaks, especially in rotary hammers and impact drills.

- Mismatch between the shank and the chuck clamping mechanism. This often leads to the equipment falling apart and a part remaining in the chuck, but it also happens that the drill/drill simply gets stuck.

Another, less common reason is rust. People who often do repairs usually don’t encounter this, but if a drill/hammer with accessories collects dust for a long time on a balcony, in a barn, unheated country house, garage, etc., the tool is eaten up by corrosion. In this case, masters say that the sting has “soured.”

I’m announcing a competition of ideas - how to pull out a 12 or 14 drill bit that was driven in there 20 years ago from a brick wall. The shank sticks out about 4-5 centimeters just from it. flood is welcome))))

cut off the tip with a grinder and don’t suffer) Either rake the wall around the perf, or screw on the chuck from the drill and turn the drill.

hit the drill. then unscrew it with a gas wrench.

Everything that is not done remains broken

So you make an offer here, and I’ll run and experiment with 12-gauge drills (the house isn’t mine anyway).

and for a snack... I broke the table I bought for my child))) damn it, I almost killed myself. how to close it)? well, so it wasn’t boring))))) everyone today because everything has already been invented) just interesting to listen to))))

hit the drill. then unscrew it with a gas wrench.

I've done this a hundred times

mm. off topic.. let’s try now)

But what about crazy hands or how to fix everything with tape? ))) At the same time I’ll buy a table to experiment with)))))

hi))) there is hardened steel there and the grinder will not cut it right away and no. Today's tools include a screwdriver, a jigsaw and a hammer drill) and also a metal file)

Take out the euroscrew, tear it apart, remove what is in the way. put the PVA mosaic back together, grab it with a clamp, and screw the screw back the next day

Everything that is not done remains broken

Table of contents

Drilling metal is one of the most common metalworking processes. In order to drill metal, you must have a drill, a suitable cutting tool with the appropriate diameter, as well as a special punch with a hammer, with which you mark a hole. In order for the drilling process to be as efficient as possible, it is necessary to take into account the sharpness of the tool, since the drill has the property of becoming dull very quickly. The speed of dulling depends on several parameters: speed, feed force, cooling force. In order to create the best conditions for this process, it is important to dip the tip of the device in oil or drip machine oil into the punching area; this will help the device cool better and also make cutting metal easier. Each material that is drilled has characteristics of this process. It is imperative to select a suitable separate device - a cutting tool - for drilling each material. For example, a device made of carbide material will be able to drill through ductile iron. The devices require careful care and timely sharpening, otherwise they will break. If a breakdown occurs, you need to know how to drill out a broken drill.

Drilling?

Do not try to drill out the drill

others with

a drill of the same brand

.

This will not give results. As a result, you will simply ruin two drills instead of one.

There is one possibility for drilling - with a carbide drill, but there is a high probability that

the hole in the part will deviate from the required parameters.

If the hole is badly damaged during the process of removing the drill, it can be welded

and repeat the drilling process,

preferably with a carbide drill.

If there is nothing to catch on, then most likely you will have to break the drill inside the hole.

5. Break it into pieces.

If all the previous options do not help, then there is only one thing left to do - break the drill

inside the hole

into small pieces.

This can be done with a broken, sharpened tap of a suitable diameter. You can try it with a nail.

Once you have broken the drill into small pieces by periodically blowing air out of them, the extraction operation is almost complete.

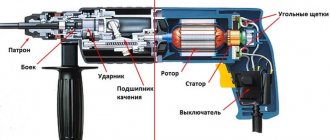

Types of drill heads

Before you figure out how to remove a drill from a drill, you should understand what fastening mechanisms manufacturers use.

There are only two main types:

- Key or toothed

The key type is very reliable, but as the name suggests, a special key is needed to tighten it. It activates special cams that firmly fix the drill. This type is the most reliable, but the drill fastening time leaves much to be desired.

Gear chuck

- Quick-clamping

Quick-release sockets are keyless and are tightened by the user's manual efforts.

Keyless chucks are divided into two more types:

- Double coupling

It consists of two couplings, which means you need two free hands to fix it. One of the advantages is that such couplings are more reliable and require less effort for fastening.

Double coupling quick-release

- Single coupling

Single-coupling ones are much more convenient, since only one hand is used for fastening. This type of chuck ensures no backlash, but more force must be applied to tighten it.

Single coupling quick-release

Cam key chucks

If we are talking about simple rust, then the problem is usually solved quite simply. You just need to treat the tool with a rust converter, or spray it with something like WD-40, wait a little and then pull out the drill or drill.

But it also happens that the hammer drill is seriously stuck in the chuck and it is impossible to pull it out with simple force. The element is deformed, which complicates the solution of the problem.

In such a situation, you can resort to the following actions.

- Prepare a gas wrench, a screwdriver or chisel, a hammer no larger than 700 grams, and some kind of lubricant.

- First, process the chuck with a drill. Here you can get rust converter, WD-40, motor oil or any other similar lubricant.

- Allow the product to penetrate and react properly. Usually it is enough to wait from 5 to 20 minutes. But it's better not to rush.

- Using a gas or plumbing wrench, tighten the chuck so that you are holding the drill with your left hand. For lefties, do the opposite.

- Use your legs to secure the structure. If possible, use clamps or a vice for this. Although usually the efforts of the legs are enough.

- Place the screwdriver on the existing clamping ring, tilting it towards you. The tip should be in the groove between the teeth.

- Use a hammer to hit the handle of the screwdriver with measured force. Thus, the ring should begin to rotate. This will allow you to remove the stuck nozzle.

If you have 2 suitable gas keys at once, then try a different technique. Its essence is to turn two rings simultaneously, but in different directions. This will release the clamp and the drill will come free.

Since the auger or drill bit has become deformed inside the jaw key chuck, be sure to check that the tooling has not damaged the inside of the chuck. If there are dents, grooves or other signs of mechanical damage, then it is better not to use such a cartridge anymore. The correct solution would be to replace it.

Using a vice

Coupling or quick-release elements can be unscrewed using a vice. To do this, firmly secure the vice, then tighten the coupling(s) into it.

If the drill is switchable and it is possible to turn it in the other direction, then start turning it slowly, increasing the power, and with a small probability the chuck may become wedged.

When the drill turns only in one direction, you need to wedge it manually, with your hands or a plumber. keys.

Note! You cannot immediately accelerate the drill to maximum speed, because there is a chance of breaking the vice or breaking the chuck.

Peculiarities

Using a hammer drill you can make a hole in almost any material. This device is most often used when working with concrete, brick and metal, and less often with wood.

The variety of materials requires several operating modes and a large number of attachments:

- Boers;

- drill;

- crowns;

- chisel

The main difference is their purpose.

Drill bits involve performing drilling and punching work with high-strength materials. In this case, the hammer drill performs not only drilling, but also impacts or vibrating actions. Using drills, neat holes of the required depth and diameter are made in the surfaces. Crowns are used for drilling large diameter holes. For example, under a socket. Installing a chisel or blade involves working the tool like a jackhammer.

A significant difference is the type of fastening, which for all attachments, except for drills, is suitable exclusively for a hammer drill, since it has a mounting tail and fastenings in the form of grooves for this tool.

But you can also attach a regular drill bit from a drill to a hammer drill. This requires an adapter called a removable cartridge. This device comes in two types:

- cam;

- quick-clamping

The name of the type itself determines the type of drill clamping mechanism. The cam clamp is operated by a special key, which is inserted into the thread on the outer perimeter and turned. In this case, the collet mechanism installed inside the chuck is compressed or unclenched, depending on the direction of movement of the key.

The quick-release type is operated with a slight hand force. When you press the chuck downwards, a hole for the drill opens.