Any equipment needs maintenance and care. Rotary hammers are no exception. These are powerful power tools capable of performing a wide range of work during repairs, construction and more.

In fact, not only beginners, but also experienced people and professional builders can encounter problems with a hammer drill. One of them is the attachment getting stuck in the punch chuck or in the ceiling or wall when processing the surface.

Objectively, pulling out a whole attachment in the form of a drill or auger is much easier than when a piece of debris remains in the chuck or wall. But such tasks can also be overcome. Here you need to navigate the situation, start from the reasons and act based on what tools and devices for extraction are at your disposal.

Why does the hammer drill attachment jam?

It will be useful to know how to remove a replacement drill bit that is stuck inside the hammer drill or in the wall. There are 3 main reasons.

- Large diameter of the equipment used. When the hammer drill is working, due to the excessively large size of the drill, it begins to grind, as a result of which it can become thoroughly stuck.

- Low quality steel. If the steel is of mediocre quality, then during active work the material may become deformed. What most often happens is that the shank becomes wedged, like an anchor. Due to weak steel, attachments also break. This mainly occurs when working in impact drilling mode.

- Mismatch between chuck and attachment. This situation leads to the fact that the drill or drill begins to fall apart. Some element remains in the cartridge, or gets stuck in a hole in the wall, ceiling, or floor.

Separately, we can highlight such a problem as rust. When a power tool is used quite frequently, such problems may not occur.

And it’s a completely different matter if the nozzle was not removed from the problem hammer drill and left for long-term storage. As a result, the sting sours. Rust forms, which blocks the free exit of the element from the cartridge.

If a drill or drill suddenly gets jammed in your hammer drill or in the wall, then you will definitely need to pull it out. It is highly not recommended to leave pieces of metal fittings in the wall. This will cause rust to develop, which can affect the finish.

Cam key chucks

If we are talking about simple rust, then the problem is usually solved quite simply. You just need to treat the tool with a rust converter, or spray it with something like WD-40, wait a little and then pull out the drill or drill.

But it also happens that the hammer drill is seriously stuck in the chuck and it is impossible to pull it out with simple force. The element is deformed, which complicates the solution of the problem.

In such a situation, you can resort to the following actions.

- Prepare a gas wrench, a screwdriver or chisel, a hammer no larger than 700 grams, and some kind of lubricant.

- First, process the chuck with a drill. Here you can get rust converter, WD-40, motor oil or any other similar lubricant.

- Allow the product to penetrate and react properly. Usually it is enough to wait from 5 to 20 minutes. But it's better not to rush.

- Using a gas or plumbing wrench, tighten the chuck so that you are holding the drill with your left hand. For lefties, do the opposite.

- Use your legs to secure the structure. If possible, use clamps or a vice for this. Although usually the efforts of the legs are enough.

- Place the screwdriver on the existing clamping ring, tilting it towards you. The tip should be in the groove between the teeth.

- Use a hammer to hit the handle of the screwdriver with measured force. Thus, the ring should begin to rotate. This will allow you to remove the stuck nozzle.

If you have 2 suitable gas keys at once, then try a different technique. Its essence is to turn two rings simultaneously, but in different directions. This will release the clamp and the drill will come free.

Since the auger or drill bit has become deformed inside the jaw key chuck, be sure to check that the tooling has not damaged the inside of the chuck. If there are dents, grooves or other signs of mechanical damage, then it is better not to use such a cartridge anymore. The correct solution would be to replace it.

How to remove a drill from a hammer drill

This kind of problem occurs in two cases:

- The drill is jammed in the adapter chuck, which is used for the attachment of a conventional drill

- The part is stuck in the clamping lips of the hammer drill itself

The first problem occurs due to the need to use a conventional drill to operate the drill, which requires a special adapter chuck for manipulation with a hammer drill. It is inserted into the clamp of the device.

After finishing work, it is often impossible to pull out the drill, because the clamping element of the hammer drill holds it tightly. To remove the drill, in this case it is enough to use a special compound, for example, WD-40. It will release the clamp within a few minutes.

If such a product is not available and the store is far away, you can use regular kerosene. After 5–10 minutes, you should try to remove the drill by tapping the chuck and at the same time loosening the attachment.

This should help, and it will be released safely, and the clamp needs to be cleaned and lubricated.

The second reason for the nozzle jamming may be the clamping of the hammer drill. This type of operational interference occurs under other circumstances. The attachment in the drill rotates around an axis, sometimes performing weak movements of a reciprocating nature. This happens due to the transfer of power to the power tool through the lips of the clamping element and the bottom of the chuck.

The hammer drill mechanism transmits energy differently, so the drill in the clamp moves differently. The tool contains rotational-impact and simple impact operating functions. Energy is transferred to the device by a special striker, which hits the tail of the installed nozzle.

The nozzle has special grooves that are firmly fixed in the clamping element, ensuring the transmission of torque. Low-quality attachments are made of a soft alloy that cannot be heat treated, as a result the tails cannot withstand the load and become unusable.

What to do if the drill gets stuck in the hammer drill?

When, in the process of performing a large amount of work, the drill on the opposite side becomes unfastened, it is impossible to pull it out of the hammer drill freely.

To remove a drill from a power tool, there are two methods:

- The stuck drill must be taken in a vice, while holding the tool in your hands, shake it to the sides and pull it towards you.

- The hammer drill is clamped in a large vice, using rubber pads so as not to crush the body. Then the drill is clamped with a small vice and a small hammer is used to easily strike it in the direction directed towards the exit of the equipment from the chuck.

In both cases, penetrating solutions can be used.

If you cannot pull the drill directly out of the chuck while turning, then you need to remove the chuck parts or try turning the drill back 90 degrees. Rotating it usually results in a complete replacement of the clamping element components.

If attempts to remove the drill from the device are unsuccessful, then to prevent the hammer drill from breaking completely, it is better to seek help from a specialist.

What to do if a drill bit gets stuck in a hammer drill and how to remove it correctly?

Construction and repair involve the use of a huge number of devices, a hammer drill occupies a special place among them. Using this tool, they make holes of different sizes in any surface, and also dismantle buildings made of stone, concrete and iron.

Sometimes situations occur in which it is impossible or very difficult to remove the drill (or a piece of it) from the hammer drill. Therefore, any person who does repairs needs to know how to remove the drill without harming the device.

And to do this, you should study in detail the prerequisites for the occurrence of the malfunction.

How to unscrew a regular bolt from a threaded hole

Problems with unscrewing from a threaded hole can occur not only with anchor bolts, but also with ordinary bolts. This situation often occurs when the bolt has an almost completely missing head or its side edges are severely crumpled. To remove such a bolt from the wall, you can use one of the following methods.

- You can rotate a bolt whose head is badly worn using a sharp core placed at an angle to the top of the fastener.

- On the worn head of the bolt, using a grinder, make a slot into which the tip of a screwdriver is inserted and try to use it to pull out the fastener.

- You can remove a bolt that cannot be removed from the wall using a tap with a left-hand thread by screwing it into a pre-made threaded hole. If you do not have such a tap on hand, then instead you can use a screwdriver, the tip of which is sharpened to a “cone”.

- To remove the bolt from the wall, you can also use a tap with a right-hand thread. To do this, the tool must be screwed into a hole previously prepared in the head of the fastener, and then firmly fixed to it by welding.

- The most radical method of removing a bolt from a wall is to drill it out. For this purpose, use a drill whose diameter is closest to the cross-sectional size of the fastening element itself.

Related article: Soda against mold on walls

Methods for removing broken bolts depending on the location of the break

Finally, take a look at the seven best ways to remove broken bolts.

Causes

There are several main reasons why this malfunction can occur.

Among them, the two most common are:

- jamming of the drill in the chuck or in the buffer element (it is used when installing a conventional drill bit);

- the drill bit is stuck in the hammer drill clamp.

In the first situation, the malfunction occurs due to the need to use a drill, which is necessary for the operation of the device. To insert it, a special element is used - an adapter chuck (the same part is used for an electric drill). It is usually placed in the clamping element of the hammer drill, and then begins to work.

Double clutch chuck

Compared to a key jaw chuck, this device does not have teeth or a stop. The rings are quite smooth. In this regard, a removable holder is well suited for removing equipment. Modern drills are increasingly equipped with the appropriate device. That is, the holder is included. Plus, arm yourself with a hammer up to 1 kg.

If the attachment is stuck and firmly held in the hammer drill, which makes it impossible to remove it in the usual way, try the following:

- using the holder, grasp the upper coupling, which is located closer to the drill, and clamp tightly;

- grab the drill itself using your own hands, feet, or a vice or clamps;

- strike the holder handle with force in the direction in which you want the clutch to unwind.

Usually one solid blow is enough to move the ring. After this, the drill is removed from the hammer drill without any problems.

The effect of this method will be even greater if you first add a little grease or oil into the gap between the cams or under the clutch.

This makes it easier to glide. Due to this, the clutch unwinds more easily.

Methods that can help pull out the drill + (Video)

The rotary hammer chuck is designed so that during operation the drilling or drilling equipment moves along the shaft. During riveting, the barrel will not allow the drill to come out easily. You can try to get the drill in the following ways:

- You need to hold the drill in a vice and then slowly loosen the hammer and pull it towards you.

- The hammer drill itself is clamped in large clamps, but in such a way as not to cause damage to the body. Then the drill is clamped with a pipe wrench or in a small vice, and then you need to hit it with a hammer, knocking out the drill.

In any of these cases, a few drops of WD-40 will not be superfluous. Very rarely, a drill jams due to lack of lubrication or a clogged chuck. The fixation ball, in cases where there is a foreign body under it, will prevent the drill from coming out. To avoid this, the shank on the device must always be lubricated.

If the drill is stuck due to the fact that it has turned in the chuck, then you need to remove the chuck itself, while dismantling the cap and rubber ring, or try to turn it back 90°. Because of this, you will most likely have to replace all the clamping parts on the hammer drill.

But do not forget that if the shank is already broken, it will not be possible to free the drill. In this case, you need to completely disassemble the hammer drill and then knock out the stuck device. But again, after such maneuvers it will be necessary to replace the barrel.

Keyless chucks

Sometimes it becomes necessary to pull out a nozzle that is tightly seated in a quick-release chuck. They can be used in the design of not only a rotary hammer, but also a drill and a screwdriver. There is no rotating clutch here. The attachments are held in place by a snap ring.

If we talk about how to get a broken drill out of your hammer drill or other power tool, then there are 2 solutions to solve the problem at home.

- First way. When faced with the fact that the drill bit is stuck and firmly seated in the quick-clamping chuck of your hammer drill, you can try the following. Remove the top o-ring, then pull the chuck back and use a metal wire and a screwdriver to pry the clamp ears off. Then you need to stretch and pull the cartridge in the opposite direction. Next, grab the nozzle using pliers or pliers. Start swinging and turning in different directions, gradually pulling the drill or drill outward

- Second way. Since the nozzle can jam quite tightly, there is another option. Remove the tube that leads to the cartridge (raster). This will give you access to the end of the drill. Using a regular drill with a metal drill bit, drill out the tip. This will allow the drill bit to come out of the keyless chuck easily. This option can be considered almost a non-alternative solution when the tip of the nozzle literally flattens. Otherwise, it is almost impossible to get the nozzle out of the hammer drill.

Tips for avoiding jams

To avoid problems associated with the drill jamming in the hammer drill chuck, it is recommended to use only high-quality attachments that are produced by well-known, popular brands. In addition, when working with different materials, it is necessary to correctly and correctly select the appropriate working attachments. Before long-term use of the attachment for drilling a durable surface, it is recommended to first check its quality.

To do this, using a nozzle, you need to make several holes in the working surface, and then remove it from the chuck. If, after the completed manipulations, it easily passes through the shank and is dismantled, then, most likely, such a nozzle is made of high-quality material and its deformation should not occur during the work.

What to do if the tip of the nozzle in the chuck breaks

It's one thing to clamp a solid cartridge in a chuck. Here you have the opportunity to grab the tip, pull it out with pliers and use other methods of influence.

Another question is if the nozzle breaks and the shank remains inside the chuck. Here you won’t be able to grab the drill or drill with tools. We need to look for another way out of this situation.

As a standard, home craftsmen try to pick out the remains of the drill using an awl or a screwdriver. Some try to get it out using a magnet. Another common solution is to stick it to the drill using superglue and then pull it out. But in practice, all these methods show low efficiency. Of course you can try. But if the fragment is held tightly, then the superglue will not be enough to set. And a powerful magnet won't help.

In fact, if the drill cannot be pulled out of the hammer drill, there are two solutions to what to do: contact a workshop, where experienced specialists will disassemble your cartridge in parts, or install a new one, or still try to solve the problem on your own. Note that the first option is safer, but requires financial costs.

If you decide to take everything into your own hands, then there are 2 ways to solve the problem to choose from. This can be done using a welding machine or by pressing.

When using the welding machine, follow these instructions:

- Using a heavy-duty vice, clamp the hammer drill. The cartridge should face up.

- Remove the seal, retaining ring, washers, and nuts. Depends on the design. Or pull down the cartridge itself.

- When the cartridge is opened to its maximum, insert the insulating sheath into the cartridge. Take a fairly powerful wire, the cross-section of which will be at least 7 mm.

- Connect one terminal from the welding device to the body of the hammer drill. The second terminal should be used to grab a metal rod or welding tip of sufficient length. The cross-section should be smaller than that of the insulation.

- Connect the tip with a fragment of the nozzle. Using the device, give a short, low-power discharge.

- When the welder grabs the fragment, it is enough to pull it along with the rod out of the chuck.

If you have a welding machine and a vice, the procedure takes very little time.

But there are several disadvantages:

- Not everyone has the necessary equipment at home;

- after welding, adhesions may remain inside the cartridge;

- Welding joints form randomly on the chuck and hammer.

The danger of soldering is that they can disrupt the normal operation of the power tool and ultimately permanently damage it. Therefore, there is an alternative solution: extraction with pressure.

The meaning of the idea is as follows:

- remove the boot from the cartridge;

- pull back (down) the cartridge;

- turn on shock mode;

- At the same time, using some suitable device, press on the fragment of the nozzle.

This is a potentially dangerous method, because when pressed, a piece of the drill or auger flies out at high speed and in an unpredictable direction.

To minimize risks, install some kind of shield or panel at a short distance opposite the cartridge that can absorb the force of the impact. It should not be a metal sheet or anything hard. Otherwise, the fragment will ricochet and may hit you. Or something will be damaged in the room. It's not worth the risk.

As a result, you will end up with a broken drill or auger. Check the condition of the cartridge to make sure it can be used again.

Types and causes of drill jamming in a hammer drill

There are two most common variants of this problem:

- the drill jams in the drill chuck or in the buffer element, which is used to install an ordinary attachment in a hammer drill;

- the product gets stuck in the clamp of the hammer drill itself.

In the first case, the problem appears due to the fact that solving the problems requires a drill, which is used for a conventional drill. There is a special product for its installation - an adapter chuck, the same as in a conventional electric drill. It is inserted into the clamping element of the hammer drill, after which you can begin work.

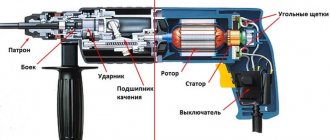

Diagram of a standard hammer drill

After they are completed, in some cases it is not possible to simply remove the drill, since the lips of the clamping device hold it tightly. This problem is quite easy to solve, since its root lies in the incorrect use of the clamping mechanism. Some craftsmen simply forget to lubricate it regularly, which is why the tool jams.

To open the lips of this device, you should treat them with special compounds, for example, WD-40. If such a substance is not at hand, and the hardware store is far away, then kerosene can be used as a working fluid. Then you should wait about a few minutes for the composition to take effect. After this, you should tap the surface of the clamp with a hammer, while simultaneously loosening the product. After such manipulations, the lips of the device will give in and the drill can be removed. Finally, you need to dismantle the cartridge, clean it and lubricate it.

To remove the drill bit from the hammer drill, you can use WD-40 fluid

In the second case, the drill got stuck in the hammer drill. This trouble appears for completely different reasons than getting stuck in a transition node. The nozzle in an electric drill moves around its axis, in some cases making weak reciprocating movements. This is due to the transfer of energy into the tool body through the jaws of the clamping mechanism and the bottom of the chuck.

The hammer drill uses a different technology for transmitting energy, and accordingly, the nozzle in the clamp moves differently. Since the hammer drill provides rotational-impact and simply impact vectors of tool movement. Energy is transmitted to it through a special striker, which is driven by a power unit powered by electricity. This striker exerts a mechanical effect on the shanks of tools installed in the chuck, such as a drill, a drill, a crown or a chisel.

Sometimes a vice is used to remove the drill from the hammer drill.

These elements are equipped with special grooves, with the help of which they are securely fixed in the clamping device. These grooves also serve to provide the tool with energy to perform rotation. Low quality tools are made from soft alloys that are not heat treated. The shanks of such products cannot withstand high and prolonged mechanical loads, and therefore become unusable. In this case, before removing the drill from the hammer drill, you may have to disassemble the tool.

Return to content

Drill or auger stuck in surface

It also happens that during the drilling process the nozzle breaks off and a fragment remains inside the wall, ceiling or floor, or gets stuck entirely, falling out of the chuck.

In this case, you can apply several different solutions.

- Reverse mode. The simplest situation is when the nozzle remains clamped in the socket, does not break, but does not want to come out of the wall. Turn on the reverse mode and begin to gradually pull the hammer drill back.

- Metal chain. This is relevant if part of the drill or auger was outside and you were drilling the ceiling. In this case, you can wrap a chain around the shank, tie on a heavy weight, and let gravity do the work. Just don't stand under the weights so they don't fall on your head.

- Vise. Using a portable vice, you can clamp the protruding part of the drill, and then use a lever to start swinging and turning the attachment. The help of a partner will not hurt here.

- Impact mode. You need to turn off the rotation and leave only the impact mode. At the same time, the hammer drill should be pulled in different directions. This will break up the concrete around the area where the bit is stuck. The drill will then come out easily.

- Gas key. You need to screw the nozzle onto it, and then turn it in the opposite direction with the key. Due to the long lever, you don’t have to put in much effort.

- Additional holes. If there is nothing to grab onto, you should try to drill or gouge the wall from above, below or on the sides of the stuck drill or auger. Although you end up with a large hole, it can easily be filled with mortar.

- Magnet. When a piece of a hammer drill attachment remains in the wall, but dangles freely in the hole, and you cannot grab the edge manually or with tools, try using a magnet. It will attract the metal and the drill will come out.

As a last resort, if the nozzle cannot be removed, you should use a grinder to cut it flush with the wall, and then cover it with mortar. It is also advisable to fill the hole with an anti-corrosion agent for metal so that a rusting drill does not lead to damage to the finish coating.

Have you ever had to pull a drill bit out of a wall or a hammer drill? What method did you use? Have nozzles been left in the walls?

How to remove a stuck drill bit from a hammer drill?

A stuck drill bit in a hammer drill is not uncommon. This happens from the use of low quality attachments. Jamming occurs due to high loads on the drill tail during chiselling mode. It simply crumples, clinging to the insides of the cartridge’s locking mechanism, and gets stuck.

Finding themselves in such a difficult situation, some try to pull it out by holding the drill in a vice and swinging the hammer drill from side to side. It happens that the hammer drill itself is clamped in a vice, trying to swing the attachment. These methods will not lead to good results. There is a high probability of damage to an expensive instrument.

Reasons for drill jamming in a hammer drill

When using a hammer drill, the drill may jam, making it very difficult to remove it from the chuck. Basically, this problem can occur in 2 cases:

- The drill jammed directly in the adapter chuck. As a rule, such an adapter is used during drilling mode, when there is a need to use an ordinary drill.

- The drill becomes jammed directly in the clamping jaws of the power tool.

In the first case, the drill gets jammed in the adapter chuck, which is used together with the hammer drill, due to the need to use the drilling mode without impact. Before use, such an adapter must be inserted into the clamp of the power tool, and only then place the drill in it.

After completing all the work, a situation may arise when removing the drill from the clamping element becomes problematic. Therefore, in this case, it is recommended to use special compounds to safely dismantle the used drill. For example, WD-40 is perfect for these purposes.

After application, this composition, in a short period of time, will be able to relax the clamp to such an extent that the drill can be removed without much effort. As an alternative to WD-40, you can use ordinary kerosene. It needs to be applied to the mechanism, then wait 10 minutes and try to dismantle the drill, loosening it a little and tapping the chuck.

Quite often, when using a drill directly in a power tool chuck (without adapters), jamming can occur, which makes it sometimes very difficult to remove. As a rule, this is due to the fact that the drill is made of low-quality material.

During operation of the hammer drill, a rotational - impact or simply impact mode is used. As a result of this, all the energy is transferred to the drill from a special striker, which delivers successive blows to its shank. The drill, in turn, is equipped with special grooves, which, after installation, are firmly fixed with a clamping element.

As a rule, low-quality shanks are made of soft alloys that are not subject to additional heat treatment. As a result, they are not able to withstand long-term heavy loads and become unusable, after which they jam.

How to Remove the Shank from a Hammer Drill

How to remove a stuck drill bit

from a hammer drill

At the time of construction work, the introduction of a hammer drill becomes very necessary. When using it, various holes are made, in other words, old cement-stone coverings are dismantled.

A situation often arises when drilling accessories cannot be removed from the hammer drill chuck.

How to remove a drill without the help of others and with minimal risk of damage to the tool? For this purpose, you need to understand certain features of the appearance of similar problems when using the tool.

If the drill is stuck in the chuck, you need to drop a few drops of oil into the joint area.

Types and reasons for drill jamming in a hammer drill

There are 4 options for this problem:

- the drill is jammed in the drill chuck or in the adapter chuck for using a regular drill in a hammer drill;

- bit is stuck

in the hammer chuck.

The first option appears due to the need to use an ordinary drill while working with a hammer drill. For this purpose, you have an adapter chuck, like in an ordinary drill, it is inserted into the clamping device of a hammer drill, and the drilling process is carried out.

At the end of the work, from time to time it is not possible to remove the drill freely, since it is impossible to unscrew or unclench the lips of the chuck. This problem does not cause any difficulties in resolving it.

Usually, the drill jams because the clamping device is not lubricated or is very dirty.

Drill chuck diagram.

To release the clamping mechanism, you need to drop a special penetrating liquid there, for example, WD-40; there is an option to use kerosene. After 5-10 minutes, you need to carefully tap the chuck with a copper hammer, and immediately try to loosen the drill with your other hand. After these manipulations, the mechanism can be unscrewed. When the cartridge is free, it needs to be cleaned and lubricated.