Types of hand tools

The tool consists of 3 elements: handle, frame and file. When choosing a jigsaw, the material of the frame and handle, the weight of the product, the quality of fastening of the elements, the type of blade and design features are taken into account.

On wood

For comfortable woodworking, you need to pay attention to the following:

- You need to choose the right frame shape that matches the task at hand. For example, a rectangular or pointed tool shape may be used.

- A jigsaw for wood should be light in weight. When painstakingly sawing, a lightweight tool will reduce stress and hand fatigue. You should choose instruments with an anatomical handle. Such models are more often found in the assortment of foreign manufacturers.

- The strength of the frame plays an important role. It is recommended to give preference to titanium or steel jigsaws. The aluminum sheet does not have high strength and will change position upon contact with the material.

Comfortable use depends on the design of the clamps. When choosing between nuts and drums, it is better to give preference to the latter option. In this case, you will not need to use wrenches to change the blade, because These clamps are easy to unscrew.

For metal

The hand tool can handle metal elements up to 1 cm thick. The cutting speed is lower than when working with wood. You should choose a tool with a blade made of high-strength material. Metal files are made of hardened high-carbon steel. Working with small teeth is most effective.

Jewelry

When making decorative cuts, a jewelry jigsaw is used, which will allow you to make small lines and bends. It differs from standard models in its lightness and small size. In this embodiment, the frame is sliding and has a clamp connection. This design provides strong tension on the canvas.

In jewelry work and decorative wood carving with a jigsaw, thin files are used, which often break. Due to the design features of the tool, a longer piece is inserted into the tool to continue working.

For additional thread tension, some models have the frame positioned in the opposite direction from the handle.

How to make the right choice?

To make the right choice and purchase a manual jigsaw for wood, you need to take a close look at a few things. First, pay attention to the shape of the tool. For example, a rectangular jigsaw is suitable for some purposes, while a pointed jigsaw is suitable for others.

The weight of the tool is also important. Working with a hand jigsaw is a long and tiring task; your hand gets tired quickly. For this reason, it is worth choosing light and comfortable manual jigsaws that have anatomical handles (shaped like a hand). It is noteworthy that lightweight devices are produced by foreign companies, while Russian companies focus on quality, which means they have a significant weight.

Jigsaws have different frames. It can be made of aluminum, iron, steel and titanium. If you need a durable tool, then you should not buy devices with an aluminum frame, because the strength of aluminum is quite low. The steel or titanium option is, of course, more expensive, but you will get a high-strength product, and the saw blade will not “jump” during the cutting process.

Pay attention to the jigsaw clamps as well. They are different:

- drums

- nuts

Drums will be preferable because they guarantee more comfortable work with the instrument. You don't have to take a set of wrenches with you to change the blade. You will only need to unscrew the drum and replace the blade yourself, without using other tools.

The manufacturing company also plays an important role. You should not buy Chinese hand jigsaws - they do not inspire confidence, and their service life is very short. Among the world-famous manufacturers, it is worth highlighting Stanley and Intertool, as well as Mastertool and Topex. Such companies produce not only jigsaws, but also a line of other construction and carpentry tools.

A hand jigsaw is ideal for working with thin boards, as well as for creating small wooden crafts. However, such a device is not suitable for sawing workpieces whose thickness reaches 40-50 mm.

Criterias of choice

The metal must be strong and difficult to bend. Wooden handles are more durable than plastic ones. The latter may fly out of the groove, which can cause injury. Tightening the fasteners should be easy, without the need for additional tools. Lambs with small ears complicate the work, because... It is difficult to grab them and fix them.

An important point is the choice of manufacturer. Products made in China are not durable. It is recommended to choose products from trusted companies. These include Stanley, Intertool, Mastertool and Topex.

The durability of the tool and ease of use depend on the right choice.

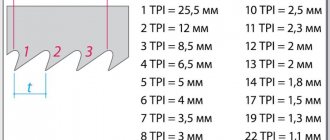

All jigsaw manufacturers specify the TPI parameter “Tooth Pro Inch” (number of teeth per inch). The higher the indicator, the neater and smoother the cut. However, the cutting process takes longer. You should also choose a jigsaw taking into account the tooth spread. This parameter affects the ease of cutting and the movement of the tool in the material.

Choosing a jigsaw

Today there are many manufacturers offering their own models of jigsaws, each of which may differ in a lot of nuances. Therefore, the choice is not as simple as it might seem.

Usually, in order to choose the best option, it is worthwhile to have a good understanding of the internal structure of the jigsaw and the elements of which it consists.

In this example, we will consider a regular jigsaw with a standard set of capabilities:

- cut regulator - almost all modern models have it. It allows you to control the speed and select your own for different materials, so this is one of the most important elements of a modern jigsaw;

- pendulum in several stages - it allows you to increase the service life of the blade, since it directs it after cutting to a different position, and when cutting in this way, sawing is carried out only in one direction;

- fastening the canvas - different models use screws or wings, but today a simpler option is fixation using a clamp lever;

- rotating mechanism - it allows you to cut the material at any angle relative to the vertical, thanks to which you do not have to turn your hand and unscrew the mechanisms themselves, and in almost the same position you can make any image or contour of any complexity;

- angle clamp - this device helps to cut the part at a certain angle when firmly fastened, which perfectly helps furniture makers and other craftsmen to obtain fairly accurate cuts;

- cooler - cools the jigsaw motor, allows it to be used without interruption and remains operational even under prolonged loads.

Also, different models differ in cost. Typically, the cost corresponds to a set of all the characteristics and design elements listed above.

Professional models, like the simplest ones, will help you cope with wood no more than 7 centimeters thick or metal up to 4 millimeters thick, but will cost much more. In turn, they will serve for sawing much longer and wear out less.

The number of vibrations available also affects the cost of the tool. 3000 vibrations per minute is a sufficient indicator, and anything more may not be useful in operation, but it will definitely affect the cost.

Classification and types of files

The average blade length for hand saws is 13 cm. There are options of 15 cm and 16 cm. Sawing blades are classified as follows:

- For roughing or finishing cutting. They differ in cutting speed and quality of the result.

- Flat and twisted files.

The shape of the teeth depends on the thickness of the blade. They are classified from 0 (for cutting thin workpieces) to 12 (cutting material 15-20 mm thick).

The teeth differ in pitch and angle. Blades for hand tools may differ in the arrangement of teeth:

- Standard. Products with equally spaced teeth are used for rough cutting. These saws are used for jigsaws on wood for simple cuts.

- For delicate work that requires high precision, options with double teeth are suitable. The work speed is low, but the cutting quality is high. Leave a small amount of sawdust and heat up slightly.

- Blades with a missing tooth slightly reduce quality, but increase work speed. They practically do not overheat, remove sawdust and rarely get stuck. Used for curved and straight cuts.

- Products with a reverse tooth are necessary for cutting without chipping on the underside. Used in jewelry making.

- Options with a spiral tooth are used for figured cutting. They make it possible to abruptly change the direction of cutting, but are difficult to use.

For hand sawing, you should choose pinless blades with flat ends. They are suitable for mounting in jigsaw clamps. When creating patterns, they can be threaded through thin holes.

What is a wood jigsaw?

The jigsaw appeared during the development of applied carving from thin plates of precious woods, which later became known as intarsia. Bow saws were already known to mankind, and by analogy with them, a jigsaw was created - a file stretched into a wooden frame. Jigsaw files are wood saws, but their dimensions were quickly reduced and the number of teeth increased.

A hand jigsaw is a very popular device. Despite the existing disadvantages, which are associated with a low level of productivity, as well as the inability to solve a large number of tasks assigned to it, for example, sawing thick wood, precise cutting and adjusting edges, straight cuts, this tool is still very popular today. Probably the main reason for its popularity is its low cost. Today, you can buy a good manual jigsaw for about 2-3 dollars, and a professional tool for 6-7 dollars.

The design of all manual jigsaws is similar. The main components are:

- wooden handle

- saw clamp

- metal case

- file

Several photos of a jigsaw for wood are presented below.

There are two main types of blades, which differ in their shape and arrangement of teeth:

- blade with straight double teeth. With this blade you can make a straight cut in a short time. Its length reaches 130 mm, while the working length is approximately 85 mm. Excellent for sawing both wood and plastic

- spiral. Features a twisted shape and is ideal for creating a variety of circles and sinuous lines.

How to insert a file into a manual jigsaw?

Incorrect placement of the blade at the fastening points can complicate the cutting process. The ends of the file should be clamped 1 or 2 mm in front of the screw. Pinching the tails to the edge or behind the screw will not provide good grip. The teeth should be directed towards the handle. The build process looks like this:

- The edge of the blade is fixed at the handle.

- Then, with a little effort, the edges of the arc are compressed, and the opposite edge of the blade is fixed at another fastening. You can press the tool with your chest or rest it against the edge of the work table.

- The file is inserted into the grooves, while the thumb fastening is tightened with the other hand.

- It is recommended to use pliers if manual fixation is not possible due to the size of the fasteners.

For a jigsaw with a tubular arc, the method of tensioning the saw blade looks different. A device that is part of the cutting table is used. These are 2 round grooves on the side of the board. The jigsaw must be installed in the slots, and the file must be tightened with clamps.

Device and characteristics

It should be noted initially that the tool is divided into two large classes: manual and electric jigsaws.

The former are more suitable for fine and precise work with small elements, while the latter are in most cases used where it is necessary to quickly make a shaped hole or make a straight cut.

The design of a manual jigsaw is extremely simple; it consists of the following elements:

• Small arched metal frame.

It is mainly made in the shape of the letter “P” or “C” from steel.

Its main feature is the large gap between the upper part and the stretched fabric.

This allows the frame not to rest against the edges of the workpiece, but to go around them.

If it is necessary to make a cut along a line that should not extend beyond the workpiece, then a hole is drilled in it.

The canvas is then removed from the frame, passed through this hole, and reattached to the frame.

• Blade – the working, sawing part of the tool with small teeth.

It is stretched between the ends of the frame (fixed with its fastenings).

It has one big drawback - low mechanical strength, which, coupled with the small size of the frame, makes sawing at a great distance from the edges of the part impossible.

The canvas itself often simply bursts and breaks off.

• Handle – an element that is installed on one side of the frame and is designed for convenient holding of the tool with one hand.

Made from wood, metal or plastic.

A standard electric jigsaw consists of:

- Housings with a comfortable handle and a start button, in which all electrical elements are hidden.

- Electric motor with gearbox.

- Stock.

- Files.

- Guide support plane fixed in the lower part of the body.

- Various optional additions for ease of operation: backlight, pendulum switch, additional guide mechanism, laser pointer, etc.

The operating principle of an electric jigsaw is the reciprocating movements of the saw at high speed.

It is fixed in a rod, which moves due to the transfer of energy from the engine through a gearbox.

Sawing occurs perpendicular to the surface being processed.

Dimensions and weight

The most common hand jigsaws weigh 285 g with a blade length of 130 mm and a sawing depth of up to 300 mm.

But there is a tool with the following parameters:

- Weight: 120 – 450 g;

- Sawing depth: 100 – 400 mm;

- Blade length: 22 – 300 mm.

Parameters of typical electric jigsaws:

- Weight: 2 – 5 kg;

- Length: 180 – 300 mm;

- Width: 60 – 120 mm;

- Height: 180 – 400 mm;

- Saw blade length: 40 – 250 mm.

Recommendations for working with manual jigsaws

To ensure comfortable work and safety, you must follow the following recommendations:

- It is necessary to ensure the immobility of the workpiece. The material is tightly fixed using a vice.

- When cutting, do not put pressure on the workpiece. If too much pressure is applied, the file will break and the material may burst and become unusable.

- Insufficient pressure on the workpiece will affect the quality of work. It is recommended to increase the pressure gradually from edge to edge and unfold the part.

- It is necessary to determine the direction of the file. When turning more than 15°, there is a risk of damage to the material and the file itself.

- When cutting horizontally, the product warps. If necessary, cutting along and across movements are always directed from top to bottom at a smooth pace.

- If, due to the specific shape of the workpiece, the blade rests and gets stuck at its edges, it is necessary to reduce the pressure and turn the pin vice to the sides.

- If it is necessary to cut inside the workpiece, first drill a hole with a drill. Then the blade removed from the jigsaw is inserted into it. After this, the file is again attached to the tool.

- To prevent the file from jumping out of the clamps, it must be periodically fixed by turning the handle. It is important not to overdo it, otherwise the canvas may break. When tensioned, you should feel the strength of the file fastening, and the handle should not rotate easily.

- For planing the workpiece, a light voltage is sufficient, and for a straight cut, the maximum voltage is set on the handle.

For an accurate result of the work and the creation of a complex pattern, it is recommended to first apply a sketch to the workpiece. This will help to avoid mistakes, damage to the material and will allow you to cut beautiful and even products with your own hands.

Purpose of the jigsaw

Unlike conventional saws intended for rough straight cuts, jigsaws are used to perform figured cutting.

Almost any intricately shaped cutout can be done with this structurally simple tool.

The special shape of the frame, similar to a bow saw, allows you to make precise longitudinal cuts from the end of the workpiece, deeply deepening the blade into the material.

A jigsaw is also convenient for making straight cuts with high precision.

A jigsaw is primarily used to make curved cuts in sheets of plywood, chipboard, fiberboard and similar materials.

This tool is suitable for shaping miniature workpieces, and due to the possibility of a curved path of the blade through the material, it is convenient for them to round corners on the workpiece.

Interesting decorative items for furniture, home, and even clothing can also be made using a jigsaw.

Carving with this tool has already gained popularity among DIY enthusiasts.

Moreover, artistic cutting of plywood products is a task that almost every person can handle.

Jigsaw or saw

You need to understand that although jigsaws are used for the same purpose as saws, the result is still slightly different.

A band jigsaw has a number of advantages compared to a conventional saw:

- it gives a much smoother cut and in most cases you don't even need to sand it. But the cut from the saw turns out to be quite rough;

- Installing a file into a jigsaw is very simple; you don’t have to make a significant effort to do this. And you won’t have to adjust the canvas tension often;

- from a safety point of view, the saw is also inferior to a jigsaw;

- In terms of cost, the comparison is also not in its favor.

On the other hand, these tools solve different problems. A thin, elegant file is simply not able to cope with a thick piece of board or timber. If you try to make such a cut, then you can forget about accuracy - due to overheating, a decrease in the quality of the cut is inevitable. In addition, there is a high risk that the file will simply break, and the load on the engine will be higher than that for which it is designed.

A jigsaw can still handle this thickness

How to choose a jigsaw and files for it

Given the variety of models on the market, choosing the right option can be not so easy. In order not to make a mistake when choosing, you need to at least in general terms imagine the structure of a jigsaw.

The main components of a modern jigsaw

To understand the principle of operation, consider the structure of a regular household jigsaw.

Of course, depending on the manufacturer, the device of different models may differ, but in general the device remains the same:

- cutting regulator - modern models are equipped with it without fail. This is logical, because you can cut not only wood, but also plastic, aluminum and even steel. Instructions for cutting different materials require a different speed setting for each of them;

The device of a modern jigsaw

- multi-stage pendulum mechanism - it is used to ensure that the canvas oscillates not only in the vertical, but also in the horizontal plane. Thanks to this, the material is cut when the saw moves only in one direction; during the reverse stroke, the blade moves slightly back, thereby extending its life;

Pendulum mode can be disabled

- As a rule, in modern devices, files are not attached using screws or wings, but a special system is used to facilitate this process. Simply press the lever, remove the old one and insert the new blade;

- It will also be useful to be able to rotate the canvas around its axis by 360ᵒ. This is useful if you need to cut a round hole or any other closed contour. Instead of twisting your hand, you just need to turn the blade itself. Cutting out various patterns from wood with a jigsaw with a rotating blade is a pleasure;

- Sometimes it becomes necessary to make a cut at an angle. So the ability to fix the angle of inclination will also not be superfluous; the angle lock allows you to rigidly fix the angle in the range of 0-45ᵒ;

Angle lock allows you to make cuts at an angle

- the engine is cooled by a small fan, part of the air flow is directed directly to the cutting line, so that sawdust does not clog the markings and the line to be followed is always visible;

- The addition of a laser can significantly improve cutting accuracy. The laser beam is directed at the material being processed and when working, you just need to combine it with the markings; this is convenient if the view is partially blocked.

Laser beam improves the cutting accuracy of the workpiece

As for choosing a specific model, the main criterion can be considered cost. The fact is that household jigsaws can quite cope with lumber with a thickness of about 50-70 mm, as well as steel sheets up to 2-4 mm thick.

In most cases, this is more than a solution to all problems that arise during home renovation or construction, but such jigsaws cost 3 times less than professional models. The disadvantages include a shorter service life and a simpler design.

The number of blade vibrations per minute is also important. Most often, this indicator is in the range of up to 3000 vibrations/min; there are also more productive models, but their cost also increases.

Selection of files and operating rules

Jigsaw blades differ in many ways, including the material from which they are made, the type of fastening, the quality of the cut, etc. It can be difficult for a non-specialist to choose the appropriate option for their needs, so let’s look at the main types of files and their area of use.

Depending on the material being processed, the following files can be distinguished:

- for metal;

- wood;

- metal and wood;

- any other materials (in addition to plastic and foam plastic, steel, aluminum, tiles, etc. can also be cut).

Comparison of the design of a file for wood and metal (A and B) and a universal blade (C)

The design of the teeth greatly affects the quality of the cut:

- files for high-speed cutting have set, ground teeth. Due to this, the cutting speed is maximum;

- if the teeth are not set apart, the speed will decrease somewhat, but the edges of the cut will be without chips and perfectly smooth;

- Jigsaw blades for wood with wavy milled teeth are suitable only when the quality of the cut does not matter.

The shape of the tooth is of great importance. The fact is that blades with straight teeth are sawed in a top-to-bottom motion, but with reverse teeth, it’s the other way around. Therefore, when working with saws with reverse teeth, you need to fix the part, otherwise it may rise when the blade moves from bottom to top.

You also need to pay attention to the shape of the fastening; options with fastening in the form of the letter T or U are possible.

Types of shanks

In order to be guaranteed not to get confused, you just need to understand the markings of the canvases. Most questions will disappear on their own.

You need to pay attention to:

- color marker on the shank (white indicates that the blade is suitable for wood and metal, gray for wood, red for plastic, blue for metal, black for other materials);

- letter designation T or U, characterizing the method of fastening the canvas;

- the following number indicates the length of the blade (1 – no more than 75 mm, 2 – from 75 to 90 mm, 3 – from 90 to 150 mm, 7 – over 150 mm);

- the letters ABCD can be used to indicate tooth size;

- other letters are used to show the purpose of the file. F means that the file is bimetallic, O – intended for curved cutting, R – with a reverse tooth, P – blade of increased thickness (for cutting at an angle), X – the file is considered universal, HM – a high-strength alloy is used.

Examples of markings of some files

For example, the marking T101BIF means that a T-shaped fastening is used, the length of the blade is up to 75 mm, the tooth is small, the blade is bimetallic. Such a canvas can be used to very cleanly cut laminated chipboard and other capricious materials with your own hands.