What is a bow saw used for?

It is convenient to use a jigsaw to make short, mainly transverse cuts, and a hacksaw to make long, longitudinal cuts. And only with the help of a bow saw can you make a variety of dividing cuts, both with dry and wet wood. In addition, for a bow saw for wood, it does not matter how the wood is cut - along or across the grain. If we add to this the ability to work with one hand (the first “bows” were exclusively two-handed), it turns out that the tool in question can be used for cutting wood:

- in longitudinal;

- in transverse;

- in figured;

- in an angular direction.

The only insurmountable obstacle for bow saws is the transverse dimensions of the workpieces - for thick logs it is still better to use a power tool. However, you have to work much less often with thick logs...

Three circumstances give versatility to bow saws for wood:

- Adjustable tension of the saw blade (in some ways this process is similar to pulling the string of a bow, hence the name of the tool). Testing shows that bow saws can create tension forces of up to 100...120 kg without destroying the saw blade.

- The special shape of the teeth allows for both roughing and finishing cuts.

- The size of the saw is compact, which ensures its use even in cramped environments.

Modern manufacturers of bow saws and accessories for them - trademarks Bahco, Stanley, Intertool, Fiskars and others - complete their products with different types and designs of saw blades, which increases the ease of use of the tool.

WORKING WITH CURVED SAWS

With the exception of the circular saw, which is used like a regular hacksaw, curve saws are difficult for a beginner to use. It is necessary to master specific techniques for working with them in order to adapt to their curved frames.

Working with a bow saw

The bow saw is clumsy unless you use the correct two-handed grip to operate the tool. Grasp the handle with one hand, extending your index finger towards the blade. Place your other hand next to it like this. so that the index and middle fingers cover the stand on opposite sides of the canvas.

Working with an openwork saw

It is difficult to force a thin canvas to move in the desired direction. It will be easier if you hold the handle with a double grip or put your index finger on the frame if you have to saw with one hand. To make a closed cut away from the edge, first drill a hole in the workpiece within the offset. Pass the blade through it and reinstall the blade in the frame mounting pin.

Working with a jigsaw

When working with a jigsaw, you should use a low chair and position the workpiece so that its edge protrudes beyond the edge of the workbench. The canvas is so narrow that it can make even very sharp bends without turning it in the frame. If the workpiece bends and jerks, cut a V-shaped notch in a piece of scrap board or plywood to support the workpiece on either side of the blade. Attach this board with a clamp or screws to the workbench.

The device of a bow saw for wood

The modern “onion” includes:

- Frame made of rolled profiles. Depending on the size of the saw blade - and they are usually standard: 350 mm, 530 mm or 760 mm, the frame can be made in the form of an oval trapezoid (for longer blades) or an oval triangle (for shorter ones).

- A handle whose profile prevents sudden injury to the worker’s fingers.

- Saw blade.

- Devices for tensioning saw blades.

- Fastening the canvas to the frame.

The frame of a bow saw for wood has special requirements - it must be rigid and at the same time light, so as not to increase physical stress during sawing. A special tubular profile with a very small width satisfies the task. This makes it easy to bend it during the manufacturing process to the required frame configuration without losing the strength of the part, providing the saw with the necessary mobility.

One of the main differences in the design of modern bow saws for wood is the principle of saw blade tension. For example, the Gardena or Proline brands use a handle with an eccentric for tensioning: by using it, changing the angle of inclination of the handle relative to the longitudinal axis of sawing, you can thus adjust the tension force.

Manufacturers of saws from Bahco Stanley have taken a different path: there a special screw mechanism for tensioning the saw blade is mounted in the handle. The choice is determined by ease of use, however, the presence of a screw mechanism provides increased tension accuracy, and does not depend on random movements of the user, when the position of the handle during sawing can randomly change. Therefore, it is recommended to use a rotary tension mechanism if you have some experience working with a bow saw.

To fasten the saw blade to the opposite part of the “string” (frame), removable cotter pins or wing screws are used. The latter are more reliable, since the cotter pin, usually made of mild steel, wears out over time and can spontaneously come out of the mounting hole.

How to use a saw

After all the faults have been eliminated, you should grab the front handle with your left hand, and the back handle with your right hand, and install the cutting part of the saw on the material previously fixed on the workbench. The saw must be directed strictly along the intended line, without sharp jolts, smoothly, since the tool disk during sudden and fast movements can jam, causing breakdown of the electric motor.

If, however, the disk jams and it stops, the electric saw is pulled back a little, helping to free the disk and set the required rotation speed, and then continue sawing. If the disk does not reach the required rotation speed, work with the saw is stopped. Upon completion of sawing, turn off the saw, wipe it with a rag soaked in kerosene and put it away for storage.

There are hacksaw hand saws (hacksaws), transverse and bow saws. The former are used for cutting small rods.

An ordinary hand hacksaw has two (right and left half-frames), joined by a clip. The handle is located on the side of the right half-frame. The hacksaw blade is placed in the gap between the rod and the tension screw, and then secured with a pin. Then the tool blade is tensioned with a thumb.

Hacksaw blades can have a length of 320 and 370 mm. The width of the hacksaw is 15 mm, and the thickness is a maximum of 0.75 mm. The height of the hacksaw tooth profile is 55-60 mm. The choice of the number of teeth on a hacksaw blade is determined by the work with a particular metal. In particular, blades with 16 teeth are suitable only for working with soft metals, blades with 19 teeth are used for work on hard metals, and blades with 22 teeth are intended for working with super-hard metals.

To cut a bar with a hacksaw, it should be placed in a vice and clamped so that the cutting line is located next to the jaws of the vice. When cutting a part that has a large width, the position of the hacksaw is horizontal. In the event that parts are cut from strip or angle steel, the position of the hacksaw is inclined.

To achieve optimal results, you need to perform 40-50 movements with a hacksaw per minute. When the tool moves forward, pressure is applied; when moving backward, there is no pressure. The pressure force is determined by the properties of the metal with which you are working. In particular, the pressure force when cutting soft metals should be significantly less than when cutting hard metal products. When working with a hand hacksaw, in order to prevent the tool blade from cracking and injuring your hands, sudden movements accompanied by significant pressure should be avoided. In addition to hand saws, electric ones are also used. When working with such a hacksaw, you must periodically moisten the tool blade with liquid emulsion to avoid overheating.

Crosscut saws are designed for crosscutting and carpentry work. The saw teeth resemble isosceles triangles and have an oblique sharpening. The angle at the top of the tooth is usually 42-45°. Saw blades can have a thickness of 1.1 and 1.4 mm.

Bow saws consist of a bow made of hardwood, a blade having a length of 785-800 mm, and a bowstring made of twisted hemp or flax cord having a thickness of 3-4 mm. They can be longitudinal and transverse. For transverse bow saws, the width of the blade is 22-25 mm, the sharpening angle is 70-79°, and the distance between the teeth is 4.5-5 mm. For longitudinal bow saws, the blade is 50-55 mm wide, 0.5-0.7 mm thick, the distance between the teeth is 5 mm, and the sharpening angle is 45-50°.

Circular saws are used to cut material along a curve. The blade of these saws is 500 mm long, 5-15 mm wide, the distance between the teeth is 5 mm, and the sharpening angle is 55-60°. The saw teeth are sharpened straight.

In order to reduce the friction force, which can lead to the tool blade getting stuck in the cut, the teeth are set apart. To do this, the canvas should be placed in a vice and clamped. Then you need to take a universal setting and bend the tops of the teeth from the base by at least 2/3 of their height. Even teeth deflect in one direction, and odd teeth in the other.

To perform work with hardwood, the saw teeth are set apart by 0.25-0.5 mm. If it is necessary to cut soft wood materials, the saw teeth are set apart by 1 mm. To check the correctness of the divorce, a template is used.

To prevent the bowstring from stretching for a long time, after finishing work with the saw, the twist should be slightly released.

Apartment renovation on your own.

Bow saw blade

The versatility of this tool also determines changes in the design of the saw blade, in particular its teeth. Most often used:

- Saw blades with uniform tooth pitch. They are designed for smooth cutting of wood with a relatively short length.

- Canvases with the so-called “American” tooth, when after 3..4 ordinary teeth there is a double or “Kremlin” tooth. This configuration of the cutting part of the saw blade allows for longer and more complex cuts. The frequency of alternation determines the accuracy of the result: the closer the double teeth are located to each other, the less clean the cutting line will be.

- Spatial teeth with wide spacing. A blade with such teeth is useful for maximum cross-sectional sizes of wood being cut. The cutting force and the amount of waste increase, but sawing productivity becomes the highest possible.

Main settings

The effectiveness of using a hacksaw for wood largely depends on its technical characteristics. The main ones are:

- the material from which the saw blade is made;

- length of the canvas and its shape;

- tooth size and shape;

- type of handle.

When choosing a tool, you need to pay attention to each element of the characteristics. Only in this case you won’t have to regret the purchase.

Canvas material

The blade of modern hacksaws for wood is made from high-quality tool (alloy) steel with a high content of carbon and silicon (65G, 8HF, U7...U10). The hardness must be at least HRC 45. There are also models that use a combined, more wear-resistant blade with a cutting part (teeth) that has increased hardness (HRC55...60).

Length and shape of the canvas

On the domestic market you can find hacksaws for wood with a length of 250 to 650 mm in increments of 25 mm. This parameter is specified by GOST 2615-84 and depends on the distance between the teeth.

Note! It is necessary to choose a saw, guided by the rule: “The length of the blade should be 2 times the thickness (diameter) of the workpiece.”

Otherwise, working with a hacksaw will be uncomfortable, since the short blade will jam inside the solid wood.

As a rule, hacksaws with a narrow blade are no more than 350 mm long and are equipped with a large number of small teeth. Tools for universal use are equipped with blades about 500 mm long with medium-sized teeth. Hacksaws with a wide blade are made with large teeth located at a large distance from each other (large pitch); their length can reach 650 mm.

Traditionally, a wood saw has the shape of a triangle narrowed on one side. This tool can work with any type of wood. In addition, there are hacksaws adapted for working, for example, with tree branches or other objects located at some distance from the sawyer. They have a rounded shape and are lightweight.

Tooth size and shape

The size of the teeth (pitch) of the hacksaw blade directly affects the performance and accuracy of the tool. The larger the teeth, the higher the speed, but the accuracy and quality of the cut deteriorates. Using a saw with fine teeth, on the contrary, guarantees a clean and even cut, but at the same time the speed decreases.

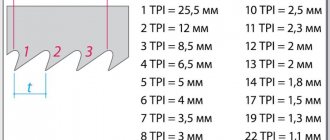

The cutting accuracy is determined by the number of teeth per 1 inch of blade length (TPI coefficient), that is, their density. Its value is marked on the side surface of the canvas (for example, 7x1″ or 7TPI). The higher the TPI, the smaller the pitch. So, 2TPI=12 mm, and 12TPI=2 mm.

When choosing a hacksaw for wood, you must take into account that the minimum thickness of the workpiece must be greater than a pitch of three teeth.

The appearance of sharpened teeth is essential when working with a hacksaw on wood. In this case, teeth that are sharpened on both sides and have the form of an acute-angled or isosceles triangle are considered standard.

Important! The latest generation of saws are equipped with hardened teeth of non-standard shape. They have the shape of a trapezoid and are distinguished by the presence of three sharpened edges and increased wear resistance. Blades with such teeth cannot be resharpened.

Handle type

The type of handle and the material from which it is made largely determine the ease of working with a hacksaw on wood. It is best to work with a saw equipped with a solid plastic handle with rubberized finger inserts. The handle, made of two parts, is less comfortable, as it does not have sufficient rigidity.

There are also hacksaws with reversible handles. They are usually equipped with universal and bow saws, in which blades can be changed during operation.

What is it and what is it for?

A bow saw can easily be defined as an outdated device. But even if you have the entire necessary set of power tools stored at home, there may be many situations when you cannot do without a hand-held bow saw. If we consider the main purpose of this tool, it is worth noting that this kind of device is intended for accurate sawing of metal parts, as well as for working with wooden surfaces.

A bow saw can be used to make various parting cuts with any type of wood. We must not forget that for a product intended for cutting wood, the method of cutting it – lengthwise or crosswise – does not matter. There is also the ability to work with only one hand. This tool can be easily selected for cutting wood: in the longitudinal direction, as well as in the transverse and figured, even in the angular direction. True, for thick logs it is better to choose a more serious tool.

If we compare a standard saw with two handles with a bow saw, we should highlight the following positive features over the classic product:

- a bow tool will allow you to make a much more beautiful cut;

- you will spend much less effort - sometimes you can work with a bow and a pair, which will not work when working with a hacksaw saw;

- easy care.

Design features

This kind of saw is called a bow saw for the reason that its structure will be as elastic as that of a combat bow. At its core is a machine made of high-quality racks. There are 3 racks in total - 2 on the sides and 1 placed horizontally. Racks are most often made of hardwood. At the bottom of the vertical posts there are similar holes for attaching handles to them. The horizontal stand is called the mullion.

The working handle can be called a real piece of carpentry art, since the convenience of working and the percentage of its productivity will directly depend on its quality. The handles are most often round in shape; at the end there are cuts and special holes for installing the working blade.

There are several original varieties of bow saws.

- Folding bow saw , which is simply an indispensable accessory on hikes, which involve independently constructing a resting place using trees adjacent to the camp. Most often it is called hiking or tourist. Some manufacturers develop this kind of tool specifically in order to use it in difficult conditions. The main feature of this saw is its folding design. The product will actually quickly fold and unfold, and will not require additional tools or serious effort.

- Hand-held bow saw for wood. Before you start working, you will need to carefully examine the product itself and find out for yourself that there are no defects on those parts of the racks that are made of durable wood, and that the canvas is intact.

- Bow saw for metal. Before purchasing a specific tool, find out exactly what material you will need to process. After this, it will be possible to choose the most convenient shape for the work, as well as the length and width of the teeth, and the speed of movement of the device.

Important! The best option would be to purchase a product made of hardened steel - this is a 100% guarantee of its strength and long service life.

Classification

There are several varieties designed to perform individual tasks. They are divided into groups according to different characteristics.

By type of canvas:

- Narrow . Used for cutting out various shapes with a relatively large radius of curvature of cutting lines.

- Regular . This is the most common type of saw, has a standard blade width and is designed to perform different jobs.

- Obushkovaya . These tools have a wide blade with fine teeth. Capable of performing clean cuts with high precision. Used for precise, critical work using a template or pre-applied markings. A special feature of backed hacksaws is the need to process material that is obviously thinner than the blade - the presence of a backing will prevent it from being passed through the cut.

- Luchkovaya . A narrow sheet with a small tooth is stretched between two support bars. This design combines several capabilities - clean, neat cuts, cutting accuracy and high productivity.

By type of tasks performed:

- Classic . It is used in most situations when it is necessary to saw off a piece of board, saw through timber or solve other issues of a common nature.

- Trimming . Used to adjust elements protruding above the plane. The handle of such a saw is placed in such a way as not to interfere with the blade coming into contact with the material along its entire length. A special case of a scoring saw is the abutment construction. This group also includes tenoning and edging saws.

- Circular . The narrow blade allows you to make figured cuts. You can cut a closed contour by starting work from a pre-drilled hole. The free end of the blade is not secured, which requires caution during operation—it is easy to bend or deform the saw with a careless movement.

- Plywood saw . It has a wide blade that allows you to hold a straight cut without the danger of taking it to the side. The teeth at the beginning of the blade allow you to start cutting from the middle of the plane.

- Award . This saw is capable of performing specific tasks - cutting grooves and other structural elements. It has several handles, and the method of operation is closer to the method of processing with a plane. Requires skills and experience from the master.

- Folding saw . Typically, such a tool has a handle that is detached or rotated, making the overall length of the hacksaw noticeably shorter. Convenient for a hike, trip or other field conditions.

There is a separate group of tools - Japanese saws.

The traditions of carpentry in this country require virtuoso mastery of the instrument, the quality of which has been elevated to the level of art. The technique of working with Japanese saws cannot be repeated with a conventional hacksaw, since the elasticity of the blade and the ability to maintain shape and plane are used.

The names of the tools are little familiar not only to beginners, but also to experienced specialists:

1-Kataba 2-Ryoba 3-Dozuki

- Kataba . A saw with teeth on one side of the blade. It has a universal sharpening that allows you to perform both longitudinal and cross cuts.

- Rioba . The blade of these tools is equipped with teeth on both sides of the blade, and on one edge there is a notch for longitudinal cutting, and on the other - for cross cutting.

- Dozuki . The flexible blade is designed for precise and accurate cutting. in the area of the handle, the teeth become smaller, which is convenient for performing critical work.

- Mawashibiki . A narrow blade with fine teeth, capable of producing fine and clean work.

Rating of the best models

Although they are similar in appearance, bow saws will differ significantly from different brands. For example, there will be differences in almost the entire structure of this instrument - from different bow designs or comfortable handles, to different fixation techniques, as well as different string tension.

- Bow saw from the Proline brand. It is useful for different types of cuts, including figured ones. It has a durable beam with a tightly stretched fabric. The bow will have 2 strong stands, special spacers, and there will also be a tension type bowstring. The length of this product is 760 mm, which will allow it to cut medium-sized logs.

- Product from Stanley Raker Tooth. It is perfect for working with not very large pieces of wood. The oval-shaped cross-section of the steel frame guarantees this product increased durability. There is a lever here with which you can properly tension the fabric and quickly change it if necessary. The saw is made of a special type of steel – hardened. The teeth here will have a shape that is commonly referred to as American - they do not require sharpening or constant care. This tool copes well with dry wood and completely fresh materials.

Subtleties of choice

It is worth paying attention to the main features of choosing a saw blade.

- When selecting or purchasing a bow saw, you need to take a special look at its main parameters - whether you have chosen the right blade size, whether its stability, thickness, and fastening method satisfy you.

- Choosing the most suitable length of the product canvas is quite simple - you just need to know the length of its frame. The parameters of the frame may differ - it can be 350 mm long, and can also have a length of 500 mm or 700 mm or more. The length measurement system that will be used is also important - it can be in inches or centimeters. If the size of your saw is calculated in inches, then you need to select a blade for it, whose length is calculated in the same parameters.

- It is important what material the product is made of. Several types of steel can be selected here. Saw teeth are often coated with a special Teflon coating to prevent corrosion or other negative processes that appear due to the influence of the environment surrounding the tool.

- The shape of the blade teeth is a special characteristic when selecting a product blade. It can have different shapes - trapezoid or triangle, “Kremlin” shape. An important feature of blades for archery woodworking can be considered the fact that it will have a different number of teeth per 1 inch (or centimeter) of blade. This indicator will allow you to get a more accurate cut. The greater the number of teeth per 1 inch of blade, the more beautiful the cut will be, and if there are few teeth, then the cut will be rough.

Varieties of hand saw

To obtain maximum results, you need to make 40-50 saw movements per minute. When it moves forward, pressure is applied; when moving backward, it is absent. The pressure force is determined by the properties of the material on which the work is being carried out. For example, the pressure force when working with soft metals should be significantly less than when cutting hard metal.

When working with a hand hacksaw, so that the tool blade does not injure your hands by cracking, it is necessary to avoid sudden movements accompanied by great pressure. In addition to hand saws, electric ones are also used. When using such a hacksaw, from time to time it is necessary to moisten the tool blade with a watery emulsion in order to avoid overheating.

Hand saws are divided into several types according to their intended purpose:

Read also: What is a bass guitar for?

- transverse;

- archery;

- round (for cutting holes);

- classic hacksaws (longitudinal or transverse cutting);

- tenon hacksaws (for cutting connecting tenons).

Crosscut saws are designed for carpentry work and crosscutting. The saw teeth have an oblique sharpening and look like isosceles triangles. The angle at the top of the teeth is almost always 42-45 degrees. The blades of the cutting blade itself can be 1.1 or 1.4 mm thick.

Bow saws are made from:

- from wood pulp of onion hardwoods,

- blades 785-800 mm long,

- bowstring, which is made of linen or twisted hemp cord having a thickness of 3-4 mm.

They can be transverse and longitudinal. For bow and cross saws, the width of the blade is 22-25 mm, the sharpening angle is within 70-79 degrees, the distance between the teeth is 4.5-5 mm. For bow rip saws, the cutting blade is 50-55 mm wide, 0.5-0.7 mm thick, the distance between their teeth is 5 mm, and the sharpening angle is 45-50 degrees.

Circular saws are used for sawing material along a curved path. The cutting part of these saws is 500 mm long, 5-15 mm wide, the distance between its teeth reaches 5 mm, and the sharpening degree is 55-60. Their sharpening is usually straight.

When selecting a hand hacksaw, not only the shape, but also the volume of the teeth plays a significant role.

There are 3 types of incisors:

- fine tooth - 2.0−2.5 mm (for cutting small products and high-precision sawing);

- medium tooth - 3.0−3.5 mm (for processing medium-sized parts);

- large tooth - 4.0−6.0 mm (for hard cutting of logs and beams).

There is also an international classification, it also classifies hacksaws, but not by the height of the teeth, but by their number, which falls on 1 inch of the cutting layer. This standard has also taken root among domestic manufacturers, so you should not be surprised if the instrument label contains foreign designations PPI or TPI. The number indicated behind these letters will indicate the number of teeth per 1 inch of length. The higher the number, the smaller the tooth (for example, PPI 8 or TPI 14).

Safety precautions at work

To make working with a bow product as comfortable and safe as possible, you need to consider the following tips:

- place the blade only in separate slots located in the handle, and secure it in the required holes with special dowels;

- place the product near your chest so that the bowstring practically touches the body itself, and visually inspect the location of the canvas in the most careful way - so that it becomes perpendicular to your line of sight;

- by accurately turning the handle, you can easily achieve an even position of the blade with teeth in special holes;

- after the canvas is adjusted, you should, carefully turning the arrow, tighten the string and stretch the racks in order to secure the canvas more firmly;

- You should not sharpen or straighten blades for this type of product without the help of a specialist if you do not have professional skills; It is best to immediately purchase sharp factory blades;

You should not be distracted when working with such a saw; you should not leave the saw sticking out in the material while resting, so as not to spoil the blade, and it will be extremely difficult to start working again from this position.

To learn how to choose the right bow saw and how to use it, watch the following video.

Manufacturing

To get started you will need:

- Wooden stick (suitable from under furniture)

- Board

- Twine

- Saw blade

- Bolts and nuts

- Tools

Before you start work, please read the drawing:

Source twimg.com

The first step is to cut your stick in half on a pendulum saw. Next, we measure 1.5-2 centimeters from the end of the sawn piece and process it with a rasp under the twine for the tie.

We do the same with the second segment. To do this, clamp two pieces in a vice at once to save time.

Make a groove in the side edge of the board for the piece of stick you worked with.

Repeat on the opposite side of the board. This is what you should end up with:

Next, start cutting the sections to install the cutting blade. To do this, clamp the segments that will serve as the handles of the saw in a vice, measure the center of one and the second segment with a ruler, and then connect these points with a straight line.

Using a regular saw, carefully cut along this center line. Insert the blade into the cuts and check how it fits, correct anything if necessary.

Afterwards, you need to make holes in the handles for bolts to fasten the blade. Insert the canvas, mark the locations for the holes, and then remove the canvas.

Next, use a drill or drill press to make holes on the first and second handles.

We continue to work on the handles. Mark on them how it will be more convenient for you to hold the saw, then use a rasp to process the indentations for your fingers in these places.

The grooves from the rasp turn out to be uneven and rough, so take a rounded metal file and process the grooves with it.

In the back of the handle it is also necessary to make indentations for the palms with a rasp, which are then also processed with a file.

As a result, you should end up with two handles like this:

Source yandex.net

Having measured 1-1.5 centimeters from the recess for the fingers on the handles, start making grooves for the board.

Place it evenly between the handles and mark its width on the handles themselves with lines.

Then work on the grooves for the board.

Use a rasp or file to cut a recess of a few millimeters, then round it so that the board and handles fit perfectly into each other's grooves.

If desired, you can decorate the bar and handles. You can do it in your own style, or like me:

Source pinimg.com

Then it's a matter of little things.

Lay out the structure on the table, put on the canvas and tighten it with bolts and nuts.

Next, take the twine, wrap it around the indentation at the end of one handle and tie it, then twist the ends of the twine, insert a small piece of wood into the central loop and continue twisting the twine, wrap the indentation at the end of the second handle and tie it.

Afterwards we go to test a homemade bow saw.

Source yandex.net

Do-it-yourself bow saw at home is ready.

I recommend the following video, where the author makes a bow saw with his own hands: