Caring for a gun or carbine consists not only of its thorough and competent cleaning, but also of timely bluing. This procedure not only extends the life of the weapon and protects it from corrosion, but also gives the metal an excellent appearance. For competent bluing, it is necessary to have specific knowledge about the interactions of various substances, as well as to have on hand an arsenal of the necessary reagents for oxidation. Below in the article we will tell you in detail about everything you need to know, about the types of bluing and what to purchase for this procedure.

Gun bluing agent 40ml Brush 520 for 1 pc. Bruning agent Brun 18 ml 385 per 1 piece. Burnishing agent 50ml 2363/23611 1,490 per 1 piece. Pencil for bluing, black gloss 10ml. 15101 Super Black BIRCHWOOD CASEY for 1 piece. Means for bluing copper, brass, bronze Nerofor 50ml 25890 Ballistol 1,195 per 1 piece.

Corrosion protection

This is the most important goal. This is especially true when a metal structure is used outdoors, that is, the steel is constantly exposed to oxygen and moisture. With such actively reacting substances, an oxidative process - rusting - is possible. As a result, red rust is formed. It greatly affects the strength, reducing it, and also shortens the service life. In this regard, many car enthusiasts are actively interested in how to make the surface of the metal black, and how to blue the steel elements of the car, since corrosion spoils automobile spare parts.

Criteria for choosing a bluing method

Before carrying out the procedure and its preparation, you should decide on a more effective bluing method that is suitable in this particular case. Typically several criteria are considered:

- Age of the weapon. Rare samples were always subjected to thermal bluing. However, there were some nuances here: if the weapon had silver soldering, then heat treatment was contraindicated for it, since the salts contained in the solution dissolve the silver. Thermal bluing is a lengthy process, so it is in little demand, although the necessary preparations are not difficult to obtain.

- Worn existing bluing. If the percentage of wear is small, the coating is renewed using a cold or alkaline method. If there is a large degree of wear, it is better to remove the old layer and apply a new one. Again, you can use the cold method, or you can use the hot method.

- Rationality. The thermal method is expensive, so it seems unreasonable to use it to burnish a cheap barrel.

- Budgeting. Here the method of foresight is better than stinginess. If you save on a good barrel at the beginning, giving preference to the cheap method, then a situation may arise that ends in an expensive restoration. On the other hand, cheap bluing can be repeated more than once as needed. Then how much the cost of such a regular event will cost is not difficult to calculate.

The choice depends on the shooter’s preference and capabilities. Regardless of the choice of processing, products are pre-prepared:

- Clean the surface to be treated;

- Sand thoroughly;

- Complete degreasing is carried out.

Give the product a presentable look

A dark matte shade can give a stylish design to an ordinary knife. The blade, coated with an oxide film, looks very unusual and attractive. The same can be said for a number of other items. This need is especially relevant when the item is already old.

The technology is also used for artistic purposes, when a creative approach is taken to decorative elements of the interior.

Acid oxidation

Regardless of what reagents are used, cold bluing involves oxidizing the metal surface without the use of high temperatures. This type of treatment is used in cases where they want to get a light bronze shade. Let's look at the most popular types of cold bluing.

In this case, the so-called rusty varnish is used for processing. It is a saline solution of iron. The essence of the process is to accelerate the corrosion process; treatment with rusty varnish falls into the category of cold bluing of weapons.

To work you will need:

- distilled water - 1 liter;

- steel filings - 30 g;

- metal scale - 20-30 g;

- nitric acid - 54 ml;

- hydrochloric acid - 50 ml.

The entire process must be carried out in the fresh air, away from residential premises, since evaporation has toxic properties.

Pour 50 ml of hydrochloric acid into a glass container, place steel filings, scale and nitric acid in equal parts. The chemical process will begin. When the components interact, the solution will acquire a greenish tint and a brown gas will begin to evolve. We add another portion of the components in the same proportions. In total, the initial components need to be divided into 3-4 parts, they need to be added gradually. When the reaction is complete, you should end up with a rust-colored mass, reminiscent of sour cream in consistency. Close the container tightly and leave the composition to infuse for 24 hours.

After 24 hours, add 1 liter of distilled water to the infused composition. The mass is ready for use. We apply the resulting varnish to the metal surface of the gun in a thin layer, carefully process all parts and leave the elements to dry at a temperature of +30-60 °C. Over time, the metal will acquire a light red color.

Popular methods

Before we move on to specific techniques that are used in production or at home, we will talk about the stages. They almost always remain the same:

- Preparatory. It is necessary to carefully prepare the part, remove any contamination from the surface and from the holes, before blueing the metal at home. If there are scales or other raised parts, they can be smoothed out using sanding paper. If you use liquid media, be sure to dry the workpiece at the preliminary stage.

- Degreasing. This especially applies to car parts. As a rule, they have a thin oil layer on them, which must first be removed. If there is an oily layer between the steel and the active substance, the chemical solution, the reaction will not occur at all or will be incomplete, with disturbances. Even the slightest traces of oily media should be removed. For example, fingerprints on the handle of a knife, which remain due to the work of the sebaceous glands. Therefore, you should always work with gloves.

- Application of the composition. Below we will tell you more about how you can apply the mass. There are also ways to completely immerse a part.

- Finishing processing. It includes washing the workpiece, drying, and light cleaning if any errors appear.

At home, you can carry out cold and hot bluing of metal: how to blued steel at home, we will present videos that show the three most common options.

Alkaline

The process will produce gas. It has an unpleasant odor and is also dangerous if inhaled in excess. Therefore, it is very important to provide yourself with a suitable workplace - an open space with good ventilation. A garage will do if the doors and windows are open and you are wearing a construction respirator that will protect you from inhaling toxic fumes.

Once you've prepared the area, it's time to find the container. It must be spacious so that the object prepared for the procedure fits completely inside and does not touch the walls of the vessel. Manufacturing material – stainless steel. Let's say it's a large saucepan or metal bucket.

After preliminary degreasing of the surface, we recommend hanging the workpiece by thin threads or wire so that you can move it without touching it with your hands.

Now we apply the solution for bluing. We suggest a small experiment with 100 ml of water (suddenly you need to blacken, say, a nail), but for larger products you should prepare a similar composition, only adhering to the proportions. So, pour 0.1 liter of liquid (bottled, without impurities), dissolve caustic soda in it (caustic soda, sodium hydroxide, NaOH - there are many names, you can buy it at any hardware store) in the amount of 120 grams. Plus we add literally 30 g of sodium nitrate. It is very important to mix well so that when mixing the consistency is homogeneous and without sediment.

When the liquid is ready, place the container on the stove. We heat it to 130–150 degrees. We note right away that you will also need a thermometer adapted to such high temperatures. The mixture will begin to boil, and it will be possible to place an object into it in a pre-specified manner (so that it is completely immersed and does not touch the walls). Wait 20 minutes.

During this period of time, a black oxide film is formed. Now you can rinse the product removed from the solution in ordinary water for quick cooling.

After drying, we recommend taking machine oil and a clean piece of cloth. They should wipe the surface and make it dry. Because of this, you get a top layer that has increased wear resistance and smoothness. If everything was done correctly, polishing will not be required.

Let us note once again the important rules:

- the workpiece must be completely immersed in the vessel;

- When working, use gloves and a respirator.

In case of uneven immersion, you may not get the result you expect: the color will not be the same, but with transitions from lighter to darker.

Acid oxidation of metal at home

The use of acids is a dangerous process that can cause chemical burns on the skin and mucous membranes, so you need to protect yourself reliably. Be sure to wear safety glasses. The second important rule when using this blackening technology is careful adherence to the preparatory stage. Any traces of corrosion should be removed. Rust can be easily cleaned with sandpaper (first coarse-grained, then fine-grained). If the corrosion damage or contamination is very deep and has a large area, then it would be appropriate to use an angle grinder with an attachment (metal brush).

Then cleaners, for example, based on sodium triphosphate and ethyl alcohol, help well. Kerosene is also a good way to deal with greasy stains. You can soak it in it for about 10–15 minutes, then rinse it with running water and dry it at room temperature in a room where dust will not actively settle. While drying, prepare a solution for blackening the metal. For one liter of water you will need only 2 grams of tannic and tartaric acid.

Mix the ingredients thoroughly, place the container on the heating element and wait until the temperature reaches 150 degrees. Now you can place the workpiece into the boiling liquid. The rest of the rules are the same - complete immersion, should not touch the walls, do not touch with your hands. 15 minutes of boiling is enough.

Unlike alkaline, acidic is not easily washed off with cold water. It is best to first place the part in a container with ordinary cool liquid, rinse, and then pour over boiling water - this will wash off all the remaining substances. To consolidate the result, place the product in machine oil for 1 hour. After the time has passed, remove and dry the metal with a clean cloth, which was blued using a chemical method at home. Now you can use the tool.

Thermal

It is also called hot bluing. This is an older and more reliable, proven method. The advantages are that the top coating lasts much longer, and less harmful fumes are produced during the process. But precautions are still necessary.

The technology is simple, it consists in the fact that when heated, the steel acquires a tarnished color. An interesting point - this way you can achieve not only black, but also interesting tints, it all depends on the temperature and the duration of hardening.

First you need to carry out classic cleaning. Then preheat the workpiece a little so that the oil composition can better adhere to the warm material. Now cover the entire surface with oil, linseed or olive works well. How exactly to completely lubricate the part is up to you. It seems to us that it is best to immerse it in a container with liquid.

It is very important to wait a while after immersion so that no oil traces remain; otherwise, unsightly stains, stains, and drips will remain. After this, you can take it outside and heat it evenly. Most often, a blowtorch is used for this. At the same time, watch for changes in shade. Stop firing when it turns black.

Sometimes an oil product is not used at all. That is, they simply heat and process iron in the open air. Due to interaction with oxygen, steel changes its color.

Hot bluing in oil

This is the most common method of home bluing, as it does not involve the use of expensive chemicals and hazardous substances. The only danger is the possibility of an accidental burn, so be as careful as possible and protect your hands with clothing with tight sleeves. Most hunters sincerely believe that this is the only correct method of bluing and they are right in their own way. After all, the protective film obtained by this method is many times stronger and more durable than the coating obtained using cold bluing.

First you need to heat the part. This can be done in a wood-burning oven or in a barrel. Thick gloves, clothing with thick sleeves and good grippy tongs are required. After this, you need to immerse the part in a container with machine or linseed oil. Wait for a maximum of 10 seconds and carefully remove. After this, we observe the surface - dark spots that have begun to appear indicate that the metal is ready for further processing.

Next, we burn the barrel with a blowtorch. To do this, after removing it from the oil, you need to hang it by the fly and process it with a soldering iron. Bake the surface evenly until the metal completely turns from brown to black.

Allow the barrel to cool at room temperature, do not cool further, then wipe with a dry cloth to absorb any remaining oil.

How to bury metal at home using rusty varnish

This is a simple and fast way to blacken steel. You need to prepare the container in advance. Porcelain is ideal. Then the surface should be prepared - mechanical processing and degreasing are carried out according to the standards described above. Now let's move on to preparing the composition. It contains hydrochloric acid as a base, additionally metal shavings, nitric acid and iron rust.

Stir the mixture until as smooth as possible. During the preparation of the solution, a reaction will occur with the release of gas. After this, add alcohol or ordinary vodka in a 1:1 ratio. It will settle along with the cloudy sediment; you need to drain it along with the steel filings and the cloudy liquid.

Place the product in the container and wait for it to change color. If a red coating appears, medium-hard bristles will help clean it off. Using this method, you can coat bladed weapons or interior items made of steel, or blacken metal at home in the shortest possible time.

Bluening process

Oxidation of ferrous metals in professional terminology is called bluing.

When we talk about steel blueing, for example, oxidation, blackening or blueing, we can say that this is a process during which a layer of iron oxide is formed on cast iron or low-alloy steel. As a rule, the thickness of such a film ranges from one to ten microns. The thickness of the layer also determines the presence of a certain tarnish color. Depending on the increasing thickness of the film layer, the colors can be: yellow, brown, cherry, purple, blue and gray.

Currently, there are several types of bluing:

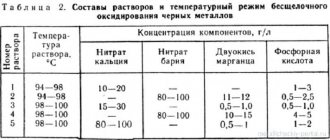

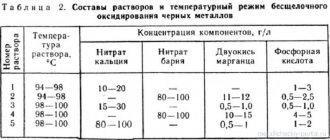

- The alkaline type is characterized by the use of appropriate solutions, with the addition of oxidizing agents, at temperatures ranging from 135 to 150 degrees Celsius.

- The acid type of bluing uses acidic solutions and chemical or electrochemical methods.

- The thermal form of processing is characterized by the use of fairly high temperatures (from 200 to 400 °C). The process takes place in the atmosphere of superheated water vapor. If an ammonia-alcohol mixture is used, then the temperature requirements increase to 880 °C, and in molten salts - from 400 to 600 °C. The use of an air atmosphere requires preliminary coating of the surface of the spare part with a thin layer of varnish, which must be asphalt or oil-based.

How to oxidize metals at home?

In practice, bluing is performed according to various schemes:

- Heat treatment of parts followed by oil coating.

- Heating to boiling temperatures in chemical solutions.

- Painting with special compounds that penetrate the surface layer. Diffusion of the coating layer with the base occurs.

At home, you can implement any of the methods, you just need to familiarize yourself with the features of the technology, as well as prepare the necessary equipment.

Selection of technology for bluing parts

To choose the right bluing method, it is advisable to decide on a number of specific parameters and recommendations:

- In the case of restoration of damaged coating, the extent of existing damage should be determined. If you need to revive limited areas where there are scratches or small abrasions, the choice is made on the alkaline method of producing an oxide film on the metal surface.

- If the surface of the part is significantly damaged and there is corrosion on it, the existing coating will have to be completely removed.

- Each product has a certain value. Based on this, it is worth estimating how long subsequent operation is expected. If the item will spend most of its time on the wall as an exhibit, simple chemical processing methods are possible.

- For products actively used on hikes or in the open air (knives, utensils or firearms), thermal methods using oil are used.

- When performing work to order, much depends on the price that the customer can pay. Cheap orders are carried out using simple methods, expensive ones involve the use of more expensive bluing techniques. When performing work for third-party customers, the question is: “How much does it cost?” – will be very relevant.

- At the training stage you will have to pay for everything yourself. Any professional training is expensive, but self-learning the basics of the profession has the advantage: knowledge is acquired without additional payment to the mentor.

All that remains is to study the basic methods of applying an oxide film, and then practice the techniques through real experience and gain the necessary skills.

When carrying out bluing work using chemicals, you will have to use tools to clean the surface from dirt and various types of grease.

You can do the work manually or use a power tool. The work must be done on a desktop (workbench or cover the table in the apartment with a removable tabletop).

In the room itself you need to have equipment and certain protective items:

- You need a working container for bluing. It should ensure that the part is completely immersed in the solution.

- Create good exhaust ventilation and fresh air flow. It is advisable to install a probe above the place where processes are carried out, then harmful fumes will not affect humans.

- When working, you need a container made of material that is neutral to alkalis and acids. It should contain water or a solution that can quickly neutralize the drugs used. The container is made of plastic, glass, porcelain or earthenware.

- The work must be done with gloves. Here you will need rubber and other types of gloves to prevent solutions from getting on your hands. They must also protect against possible thermal effects.

- Respiratory protection is achieved by using respirators. When using strong acids, activated carbon filters will be needed.

- Vision protection is achieved by using safety glasses. There are special glasses for working with chemical reagents; they are sold in work clothing stores.

- Aprons and jackets made of tarpaulin will protect the body from drops of solutions.

Using machine oil

It is not necessary to prepare a complex composition for chemical bluing of steel at home. Sometimes an ordinary oil substance that is poured into a car engine is enough. The procedure is similar to the thermal method, but in reverse order. First, heat the steel element red-hot, then place it in a tank completely filled with oil (machine or linseed oil will do). The part itself should be held using pliers or pre-prepared hooks. It must be maintained for at least 15 minutes. After this, place it on a paper napkin, which will absorb the liquid. Then similar steps are repeated 4-5 times until a rich color is formed. It will likely be dark gray rather than black, but the surface will be good against rust.

Preparation

Do not neglect thorough preparation, as this will help ensure both your safety and the quality of the procedure.

- We clean off leaded deposits using a copper or plastic brush.

- We carefully treat the inner surface of the barrel with a rag soaked in kerosene.

- We wash the barrel channel with a soapy solution (water + any non-abrasive detergent).

- We put the barrel in a warm place and wait for it to dry completely.

- We grind the outer surface of the barrel in any convenient way to an ideal state - this can be done with sandpaper or fine sand.

- Degrease using citric acid solution or alcohol.

- After the preparatory cycle, you can proceed directly to the bluing itself.

Bluening and rust remover 40ml Ballistik 341 for 1 pc.

Set of brushes in blister, 3 brushes, 9k. Blister9 260 for 1 piece. Cleaning agent and canned food. weapons plastic cylinder 90 ml (2-014) RUNIS 41 for 1 pc. Brass brush k.20 65a/20 95 for 1 piece. Set of brushes in blister, 3 brushes, 410 k. Voenokhot 230 for 1 piece. Gun degreaser 40ml. Kalashnikov 155 for 1 piece. Spiral brass brush k.16 Voenokhot 130 for 1 pc. Foam for cleaning barrels Forrest 500 ml 503003 Milfoam 3,765 for 1 pc. Cleaner and degreaser for weapons 200 ml WC356428 810 for 1 piece. Composition for removing old bluing and rust Blue & Rust Remover. Weight 90ml. 16125 BIRCHWOOD CASEY 800 for 1 piece. Choose a care product for any type of weapon Safety precautions

Even a schoolchild will understand that oxidation at home is a rather dangerous process, especially if it involves aggressive chemicals. Therefore, strictly follow all rules for storing and using chemicals.

- Reagents may only be stored in clean containers, out of reach of unauthorized persons.

- During the bluing process, you must wear protective clothing, gloves, goggles and a mask.

- It is best to work with hazardous substances outside or in a well-ventilated room.

- It is extremely important to comply with the proportions and time frames indicated in our article.

- If you suspect poisoning with a chemical substance, you should immediately consult a doctor.

Pay attention to the other equipment you will be using. For example, if the reagent is supposed to be heated on a gas stove, then the stove, like the cylinder and the gas pipe, must be in good working order. The same applies to the sander and other tools.

Cold bluing

If you know that the steel of your gun barrel has not been cold hardened, then it may not withstand heat well. In this case, it is better to choose a cold bluing method. It is usually preferred by owners of small-caliber and pneumatic weapons. The essence of cold oxidation is the step-by-step processing of a steel part with oxidizing agents. These reagents are available in specialized stores, where you can purchase ready-made kits. The most popular among hunters is the mixture of “Voron-3” (domestic product) and “Parisian oxide” (foreign production).

The process can also be carried out in two ways - applying the solution to the metal surface with a brush or using complete immersion. Let's take a closer look at each.

Brush and solution

This method is perfect for those who are doing bluing at home for the first time, since all the reagents needed for the procedure are usually non-toxic and the standard safety requirement is to avoid getting the liquid in your eyes, just like with regular household chemicals.

But this method also has a drawback - when treating the surface with a special brush, the solution cannot get into all hard-to-reach places. The layer also turns out uneven due to this method of application, so polishing must be carried out after processing. The most unpleasant moment is that if, when processing the surface, an uneven mark is left on the metal, and this happens when using low-quality solutions, then you will have to do everything again. This is already a significant expense, so when bluing with a brush you should be extremely careful and attentive and not skimp on the quality of the reagents.

Immersion method

This oxidation method is more preferable, since in this case the liquid penetrates into all gaps and provides much more reliable protection of the metal. Also, when using a brush, splashes are inevitable, which are completely eliminated in this method, so immersion bluing is also safer. There is, perhaps, only one drawback - the high cost of the concentrate required for the procedure.

For the first recipe we will need the following reagents:

- nitric acid (HNO3) - 20 grams;

- ferric chloride (FeCl3) - 75 grams;

- medical alcohol (C2H5OH) - 30 grams.

Reagents for the second recipe:

- ferric chloride (FeCl3) - 170 grams;

- nitric acid (HNO3) - 13.5 grams;

- hydrochloric acid (HCl) - 4 grams;

- copper sulfate (CuSO4) - 4 grams.

Remember that this method is completely unsuitable for bluing blades, since the cold coating is very unstable to mechanical stress and will quickly wear off. The hunter also runs the risk of getting scratches on the film covering the trunk during his first hunt by catching it on a branch.

Recommendations

You yourself can choose a way to blacken metal at home, each of them can lead to a very high-quality result. A container is almost always needed. Best suited: porcelain, durable glass (if heating is not needed), galvanized stainless steel. Attach hooks to the edges of the tank: you will need them to secure the part.

Another tip: degrease not only the workpiece itself, but also the container for the procedure. This can be acetone, gasoline, kerosene or a special composition. The main thing is that they are inert towards steel, that is, they do not enter into a chemical reaction with it.

Be sure to be responsible when choosing a location; it should be a room with excellent ventilation. Otherwise, you may be exposed to dangerous, toxic fumes. Additional protection - a respirator, goggles to protect the mucous membrane of the eyes, gloves.

An important preliminary step when using any method is to remove rust and dirt before applying the metal blackening agent. It can be done using sandpaper or a grinder with a special attachment. In extreme cases, etching can be used.

We recommend carefully choosing which product can be used for a particular type of material. If you follow our tips correctly, you can get excellent results at home.

What can you achieve with bluing?

As a result of this work, a film of iron oxide will appear on the surface. The dimensions of its thickness completely depend on the technology used. It can be 1-10 micrometers. Using the metal bluing method, you can solve the following problems:

Read also: Gold and blue... (Alexey Goncharov)

- protect the coating from corrosion, since rust does not appear on blued surfaces;

- give the product a more presentable appearance.

You can obtain the required coverage in many ways. But the most popular of them are alkaline, thermal or acid bluing. Alkaline treatment is ideal for DIY work. To do this you will need water, a digital scale, sodium nitrate and sodium hydroxide. You will also need a protective mask and gloves for personal safety.

For work, use only stainless steel utensils. Steel bluing is carried out under a certain temperature regime. The solution is kept in a boiling state, which is why you need to work with it extremely carefully.

Blackening

We will present another option on how to burnish steel with your own hands. This option is as simple as possible to use. It is suitable even for those who live in an apartment or simply do not want to carry out such a procedure with heating an alkaline or acidic liquid composition. This is bluing with a brush. Special products are sold, for example, the domestic “Raven 3” or the foreign “Prague Oxide”.

The technology is very simple to apply - you first need to remove the top fatty layer, that is, degrease the surface. But there are some disadvantages:

- It is difficult to provide a good film in areas where access is difficult. Therefore, it is better to immerse crafts with complex configurations completely in containers.

- The layer is not very durable and is not resistant to mechanical damage.

Safety precautions and preparation for bluing

If you look at the root, then bluing is a common chemical reaction. And for the same reason, certain rules should be followed and the action should be carried out in a designated and equipped safe place.

Ventilation must be excellent, since caustic fumes from chemicals can easily harm the respiratory tract. All containers are allowed only from glass, porcelain or earthenware. It is mandatory to unload the weapon and dismantle the wooden parts.

Whatever bluing method is chosen, the following auxiliary materials will be needed:

- Latex gloves;

- Steel wool;

- Sandpaper of various grain sizes;

- Cleaner;

- Protective glasses;

- Powdered pumice;

- Fine sand;

- Gun oil for cleaning and lubrication;

- Cotton pads and swabs, rags, a pair of toothpicks, a shoe brush (new) and a toothbrush.

Blueing a Damascus steel gun

Damascus steel is not a specific type of metal. An alloy is a mixture of steel elements and wrought iron. In the process of sour weed, a unique ornament or pattern is obtained. Different types of bluing are used for such guns; let’s look at the most popular ones.

The first method will achieve brown steel. To prepare the solution you will need:

- copper sulfate - 8 g;

- nitric acid - 30 g;

- hydrochloric acid - 2 g;

- ethyl alcohol - 30 g;

- water - 1 l.

Dissolve copper sulfate in water, then add the remaining ingredients. Let the solution sit for several days, after which we process the metal in several approaches until a rich brown tint is obtained.

To obtain black Damascus steel we use the following technology:

- carefully polish the steel;

- treat the surface with wood oil;

- sprinkle the elements with ash;

- Place the metal on hot charcoal and make sure the temperature is maintained.

After completing the procedure, let the parts cool and wash them with water and a small amount of sulfuric acid. We wash the parts in clean water and dry them, rub them with oil. After these procedures, Damascus steel will look unusual: the steel elements will remain light, but the iron inclusions will darken.