What can be achieved by bluing

As a result of chemical or thermal treatment, a layer of iron oxide with a thickness of 1 to 10 microns appears on the surface of a steel part. The thickness of the layer is determined by the selected processing technology.

Blueing of metal allows you to achieve two main goals:

- Increasing the corrosion resistance of the product. Treated parts do not rust.

- Improved appearance. It is especially important for those parts that, due to operating conditions, cannot be painted.

Temperature conditions for bluing

The treatment does not affect other properties of the steel.

Blueing of steel is possible not only in production conditions, but also at home. There are many methods and compositions, almost all of them involve the use of chemically active substances that can cause serious harm to health. To successfully and safely use these substances at home, you must follow the following safety rules:

- Use a protective mask and gloves.

- Ensure ventilation of the room in which work is carried out.

- Use stainless steel utensils.

- Do not exceed the recommended processing temperature.

Selection of technology for bluing parts

To choose the right bluing method, it is advisable to decide on a number of specific parameters and recommendations:

- In the case of restoration of damaged coating, the extent of existing damage should be determined. If you need to revive limited areas where there are scratches or small abrasions, the choice is made on the alkaline method of producing an oxide film on the metal surface.

- If the surface of the part is significantly damaged and there is corrosion on it, the existing coating will have to be completely removed.

- Each product has a certain value. Based on this, it is worth estimating how long subsequent operation is expected. If the item will spend most of its time on the wall as an exhibit, simple chemical processing methods are possible.

- For products actively used on hikes or in the open air (knives, utensils or firearms), thermal methods using oil are used.

- When performing work to order, much depends on the price that the customer can pay. Cheap orders are carried out using simple methods, expensive ones involve the use of more expensive bluing techniques. When performing work for third-party customers, the question is: “How much does it cost?” – will be very relevant.

- At the training stage you will have to pay for everything yourself. Any professional training is expensive, but self-learning the basics of the profession has the advantage: knowledge is acquired without additional payment to the mentor.

All that remains is to study the basic methods of applying an oxide film, and then practice the techniques through real experience and gain the necessary skills.

Methods for bluing metals at home and requirements for their implementation

Popular methods of bluing metal at home are:

- Boiling in self-prepared or purchased chemical compositions.

- Coating the steel with special oil and subsequent heat treatment.

- Coating the surface with the prepared composition at room temperature.

Burnishing steel at home

Chemical bluing of iron also involves preparatory operations of etching and cleaning, as well as grinding and polishing.

When carrying out blueing of steel, it is important to select a container for the solution so that it completely covers the object being treated.

Using machine oil

Knife bluing can be done at home with oil. You will need the following:

- 500 ml machine oil;

- equipment for holding the part, such as special hooks, pliers or pliers;

- metal container for bluing in oil;

- rags or paper napkins;

- gas burner, hair dryer or gas stove.

How to do the procedure if you have a hair dryer? To do this, the part is laid out on a non-combustible surface, such as a brick. Then the hair dryer is set to high heat. The part is heated as much as possible. Then, using pincers or pliers, it is placed in the bath, completely covering the surface with oil. This will ensure an even color upon completion of the procedure. Then the part is placed on a paper napkin to absorb the oil.

When processing metal using this method, you can use linseed oil. The procedure stops as soon as the desired color is obtained. The process must be repeated 3 or 4 times. At the end of each cycle, the product becomes darker.

If you are deciding how to blue your steel, this method will not turn it black. And the surface will not be too durable. This bluing product is suitable if you need to protect a steel product from rust.

Popular bluing methods

The most common methods of bluing at home are:

- alkaline;

- thermal;

- acidic.

The alkaline method is well suited for self-use at home. It will require

- water;

- precision scales;

- sodium nitrate and hydroxide.

For the coating to become durable, the process must last at least an hour and a half.

Alkaline

The technology for bluing steel using the alkaline method at home is divided into the following operations

- Degrease the surface with a solvent or special degreaser.

- Pour 100 g of water into a stainless steel container with a capacity of at least a liter.

- Add 120 g of caustic soda and 30 g of sodium nitrate, stir thoroughly until completely dissolved.

- Heat the solution to 130-145 °C.

- Place the product in the dish, avoiding touching the walls.

- After 20 minutes, after the part has turned black, rinse it in distilled water.

- After drying, generously lubricate the product with machine oil and wipe thoroughly.

Steel bluing with alkali

Careful adherence to proportions and parameters will allow you to obtain a smooth and abrasion-resistant coating that does not require polishing.

Important! The product must be completely covered with the solution throughout the treatment. Otherwise, coating inhomogeneities, color transitions, etc. are possible.

Acid

This method involves the use of acidic solutions.

Before starting processing, you should carefully remove all rust from the surface of the object. To do this, use ordinary sandpaper, and in hard-to-reach places and with severe rust, use a grinder or a screwdriver with a wire brush.

Means for degreasing steel before processing

Next, chemical cleaning is carried out. It is used for

- sodium triphosphate;

- ethanol mixed with kerosene;

- or pure kerosene.

The product is placed in a container with the solution so that it completely covers it and kept for at least a quarter of an hour. After cleaning, the product is washed with plenty of water and dried.

The composition for acid bluing consists of:

- water: 1 l;

- tannic acid: 2g;

- tartaric acid: 2g.

After thorough mixing and complete dissolution, the composition is heated to 150 ° C and the workpiece is completely immersed in it. Leave for 15 minutes, then rinse with running water and briefly dip in boiling water for complete and high-quality rinsing.

Components of the solution for bluing

The last stage of the process is soaking in machine oil for an hour. After drying, the product is ready for use.

Thermal

Thermal bluing is the oldest and simplest method for home use. The whole process boils down to heating the steel in the open air. It lasts until the upper layers of steel react with oxygen in the air and result in an oxide film. The more a part is heated, the darker it becomes.

Thermal bluing

It should be remembered that heat treatment also changes the physical properties of the steel of the entire product.

Blackening

We will present another option on how to burnish steel with your own hands. This option is as simple as possible to use. It is suitable even for those who live in an apartment or simply do not want to carry out such a procedure with heating an alkaline or acidic liquid composition. This is bluing with a brush. Special products are sold, for example, the domestic “Raven 3” or the foreign “Prague Oxide”.

The technology is very simple to apply - you first need to remove the top fatty layer, that is, degrease the surface. But there are some disadvantages:

- It is difficult to provide a good film in areas where access is difficult. Therefore, it is better to immerse crafts with complex configurations completely in containers.

- The layer is not very durable and is not resistant to mechanical damage.

Features of chemical bluing and recipes for some compositions

Before applying a new coating at home, you must remove the old one. This is done by combining mechanical and chemical cleaning methods.

To obtain a durable and beautiful coating, the part must be boiled for 30 to 90 minutes, during which time part of the solution boils away. The workpiece must be completely covered with the composition at all times, so the composition must be prepared with a reserve and periodically topped up during boiling.

At the end of the chemical bluing procedure, the product should be washed in a soapy solution, dried and generously lubricated with oil.

There are many options for chemical bluing. In some, the composition is made by the master himself, while others involve the use of ready-made factory-made products, such as Parisian oxide, Voron3M, Clover and others.

Safety rules and regulations

Any manipulation with weapons requires compliance with safety precautions, especially for manipulations at home. Failure to comply with the rules of conduct is dangerous to the health and life of not only you, but also those around you.

- Before bluing your firearm, be sure to unload it and remove any woodwork.

- Solutions with chemical components can emit harmful fumes, so the entire process should take place in a well-ventilated area.

- Select special utensils and tools for bluing, keep them separate from household equipment and wash them well after use.

- Working with chemicals requires full protection to avoid burns.

Whichever bluing method is chosen, it requires preliminary preparation:

- cleaning the surface of the workpiece;

- thorough surface grinding;

- degreasing, after which you need to continue working only with rubber gloves;

- using only those products that are suitable for bluing weapons at home;

- final processing of the product.

When starting bluing, you should strictly follow the order and sequence of actions to prevent damage to the weapon.

To ensure that the product can serve for a long time without painting, metal bluing is used at home to protect against corrosion. This processing method creates a thin oxide film on the surface of the parts. It does not allow moisture (H₂O) and gases (CO and O₂) to pass through to the open metal (in real conditions, a chemical reaction occurs to reduce the carbon content with a decrease in hardness).

Oxidation proceeds in such a way that iron exhibits divalent properties. Oxides form on the surface or a layer of insoluble salts forms. Only in the presence of strong acids can the resulting film be dissolved.

Means for bluing metals

Relatively simple methods of bluing, available for doing it yourself, include surface application of oil, saltpeter and the purchased composition “Clover”

Sapphire for bluing

Oil coating

This is one of the most popular home methods. The technology is divided into the following operations:

- The part is sanded and degreased with a solvent.

- Cover with oil.

- In a muffle furnace it is heated to 350-400 °C. It is permissible to use an oven.

- The cooled part takes on a black or brown tint.

- To saturate the color, the procedure is repeated.

The oil is applied with a brush or by dipping the product into a container of oil. Different types of oil are used, such as

- weapons;

- olive;

- flaxseed

Use of saltpeter

Home craftsmen achieve excellent results using saltpeter solution. You can purchase a ready-made solution, or you can make it yourself:

- water-1000 ml;

- sodium nitrate - 0.5 kg;

- caustic soda - 0.5 kg.

After boiling for an hour, a smooth surface of a deep blue-black color is obtained that does not require further processing.

Means "Clover"

The gel-like product can be purchased in 50 ml jars and is used for alloys with a chromium content of no more than 3 percent

Means "Clover"

It is designed to restore localized corrosion. To obtain a bright shade, the product will have to be applied several times. The product should first be sanded and wiped with a degreaser.

Apply clover with a brush and leave for two minutes. The white-yellow coating that appears is washed off with water and the part is wiped with a rag.

Thermal bluing of parts

In industrial conditions, they prefer to perform bluing using a thermal method. Usually this operation is combined with low tempering, which relieves internal stresses inside steel products:

- The part is heated in a muffle furnace for 20...30 minutes to a temperature of 180...220 ⁰C.

- The removed part is wiped with machine oil using a swab. It is advisable to treat all surfaces.

- If necessary, the treatments are repeated.

- Usually, a double heat treatment is sufficient to obtain a high-quality blued surface.

Information: weapons factories producing firearms and bladed weapons use thermal bluing. The coating on many products lasts more than 100 years. Example, Mosin rifles manufactured in 1891 and Nagan revolvers released at the end of 1888.

Republished by Blog Post Promoter

Cold bluing at home

“Clover” does not require heat treatment of the part, so this method is considered cold bluing. Cold bluing can be carried out by other means.

- "Voron-3M". The drug forms a dense film of deep black color on the surface.

- "Paris Oxide" An imported selenium-based preparation is supplied in three containers: 1- for surface preparation, 2- the main composition and 3- a fixative that gives the coating additional protection.

Liquid for cold bluing is applied to the parts with a brush, and after painting it is washed off with warm soapy water. The method is popular for processing barrels and other parts of firearms that do not require boiling.

Alkaline steel bluing

The simplest way to apply an oxide film to products is alkaline bluing. The operating principle is based on the use of caustic soda and sodium nitrate (used as a fertilizer). Both components have a pronounced alkaline reaction.

To process a part weighing about 900...1000 g you need to have:

- 100 g caustic soda (NaOH);

- 30 g of sodium nitrate (sodium nitrate NaNO₃).

Process:

- Dissolve the components in 100 ml of water. If this amount of working solution is not enough, then increase the amount of liquid, as well as caustic soda and nitrate in proportion.

- The solution is heated to 135...145 ⁰С (salt solutions boil at a temperature higher than pure water boils).

- The part is washed with soap or weak alkali to remove possible greasy stains.

- Place in the working solution for 30…35 minutes and maintain a high temperature. In a hot state, the rate of film formation on the surface of a steel object will be high.

- After completing the procedure, it is necessary to wash off the remaining working solution.

- Wipe the product with vegetable or technical oil.

- Then thoroughly wipe the item with a rag; only a thin layer of oil film will remain, which will further protect the finished product.

As a result, the metal surface will receive a black coating with a bluish tint. It is quite durable and can withstand minor mechanical stress.

Other alkaline treatments are possible in NaOH and KOH solutions. Prepare a solution in which 300...400 g of each component is dissolved. The minimum concentration of alkalis is 700 g per 1 liter of solution.

The processing procedure takes place according to the technology described above. In this case, the result is a film with slightly more blue.

Attention! During alkaline processing, the liquid level should be maintained so that the part is always completely in the solution. Then the entire coating will be uniform.

Burnishing steel at home

If you are bluing steel at home, you need to wisely choose the components of the boiling solution. Heating hardened parts can lead to them losing their strength properties.

Alkaline solutions have a less harmful effect on steel, and experienced craftsmen advise choosing them. Treatment with acidic solutions is preferably carried out at low temperatures

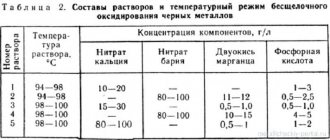

So, for example, when using an acid composition for bluing steel from:

- calcium nitrate – 94%;

- orthophosphoric acid – 3%;

- manganese dioxide – 3%.

processing is carried out from half an hour to 45 minutes at 100 ° C

Other bluing methods

It is easy to achieve a noble blue tint by heating the part for a long time. During processing, the steel surface turns white, then turns yellow and acquires a purple tint. But at the end of the procedure, a blue coating is formed.

For work you need a forge and a metal box.

- Birch coals are placed in the box, leaving space for the product. The box itself is placed in the forge and heated until the coals begin to smolder.

- The part is lubricated with ordinary vinegar and placed in a box.

- When the steel surface turns blue, the product is removed, cooled and placed back in the box.

If necessary, you can do without heat treatment.

- Iron sesquichloride and 3 gamma “red salt” (hexacyanoferrate) are added to 0.5 liters of water using separate containers.

- Then combine and stir.

- The part is immersed in the working solution and held until the desired shade of the surface film is obtained.

Use of saltpeter

Excellent results can be achieved by using saltpeter. To do this, the product is boiled in sodium nitrate at 130-150 degrees.

Required:

- liter of water (distilled);

- 500 grams of caustic soda;

- 500 grams of sodium nitrate.

It is noteworthy that it is not difficult to find ready-made preparations with saltpeter for specialized purposes.

Preparation "Clover"

The finished solution resembles a gel and is sold in 50 ml bottles.

It is convenient to use to protect areas affected by rust. The surface is first cleaned and degreased with a solvent.

Apply the product using a small soft brush and leave for a couple of minutes until a whitish coating appears. Wash off with warm water and dry the area with a cloth. To improve the quality of the coating, the procedure is repeated 2-4 times.

There are other ready-made preparations for oxidizing steel on the market.

If you want to do the bluing yourself, it is wise to resort to the most convenient option for yourself.

Metal blackening

Depending on the acidity of the environment in which the workpiece is processed, the color of the resulting coating changes, from yellow to black. Therefore, bluing and blackening of metal are not the same thing. The required shade is selected by varying the intensity and duration of heat treatment and the percentage of solution components.

Metal blackening

If you take a mixture of 7 parts copper nitrate and 3 parts alcohol denatured alcohol, apply it to the product and heat it over a fire, then as it heats up the coating begins to change its color. When the desired shade is achieved, stop heating.

It is also possible to blacken steel by coating it with oil and calcining it in an open flame. The result is a durable film of deep black color. There are other compositions for blackening.

What is bluing?

Steel bluing is a treatment during which steel is coated with an oxide film. In this case, the product is exposed to chemical or thermal effects. The thickness of the surface coating with an oxide layer can reach 10 mm.

Burnishing is considered an effective method of combating rusty metal and the spread of corrosion. If the stages of the selected bluing technology are carried out correctly, complete elimination of rust can be achieved. Burnishing is applied to those blanks that will not be painted in the future.

At the same time, the process of increasing corrosion resistance and changing the appearance does not in any way affect other parameters of metal products. When carrying out processing, the features of bluing should be taken into account:

- observe safety precautions;

- adhere to the specified temperature regime for heating the workpiece;

- When working, use utensils made of galvanized metal.

This way you can protect the body from harmful fumes and increase the effectiveness of your actions.

Application of rust varnish

The method using the so-called “rusty varnish” is distinguished by its cost-effectiveness against the backdrop of quite acceptable quality of the coating.

The product is immersed in a chemically active corrosive liquid based on hydrochloric acid, which forms red and black oxides on its surface.

To remove rusty deposits, you will have to use a stiff wire brush. A black oxide film will remain on the product.

Ready rusty varnish

The method is long and labor intensive, but provides excellent results at home.

Before starting processing, as with all other methods, you should thoroughly clean the object with sandpaper and degrease it with a solvent.

The active liquid is prepared in special porcelain vessels; the use of protective gloves, an apron, acid-resistant shoes and thick work clothes is mandatory. A respirator and clear face shield should also be used.

A small amount of hydrochloric acid is poured into the vessel, adding rust scraped off the iron, sawdust and nitric acid. The mixture should be stirred carefully with a porcelain stirrer until bubbles stop appearing.

Next, carefully add water and vodka in equal parts. The solution is allowed to settle and drained from the sediment.

The result of using rusty varnish

The part is placed in the solution for a time sufficient to acquire a deep black color. At the end of the process, the part should be rinsed with plenty of water.

Attention! The solution used in this method is one of the strongest solvents. Beware of even the smallest splashes - they can cause very serious injury and property damage.

If splashes get on clothes, they should be removed immediately. If, despite all precautions, drops get on the skin, the affected area should be washed generously with a soda solution and immediately seek medical help.

Bluening methods

Various steel bluing technologies are used in production. Surface treatment is carried out using purchased chemical compounds or improvised means. It is important to know the stages of the work so as not to damage the metal workpiece.

Alkaline

The alkaline method can be used at home. The process consists of several main stages:

- Degrease the surface to be treated.

- Prepare a stainless steel container with 100 ml of clean water.

- Pour 30 grams of sodium nitrate and 120 grams of caustic soda into the liquid. Mix the ingredients thoroughly with water.

- Slowly heat the mixture to 130°.

- Transfer the workpiece to the chemical composition.

When the surface of the product takes on a dark shade, you need to remove it from the chemical and wipe it with distilled water. The last step is to lubricate the workpiece with machine oil.

When carrying out work, it is strictly forbidden to change the amount of chemicals used. Otherwise, the metal surface may be damaged. When the product is in a container with a solution, you need to control that it touches each of its sides. There will be stains in the empty spaces.

Chemicals for bluing

Acid

When using this method of bluing metal, you need to use an acid solution. Processing process:

- Remove debris, dirt, paint, and rust from the surface of the workpiece.

- Immerse the workpiece in a metal basin with clean kerosene. There it should be kept for 25–30 minutes. After cleaning, rinse the workpiece in clean water. Dry in a ventilated area.

- Make a composition for bluing. To do this, mix 2 grams of tartaric acid, 2 grams of tannic acid and a liter of clean water. Mix the ingredients thoroughly and heat slowly to 150 degrees.

- Dip the workpiece in the chemical composition and leave for 15 minutes.

- Wash the product with distilled water and immerse it in a container with machine oil for 60 minutes.

Thermal

This is one of the oldest methods of coating metal surfaces with an oxide film. Thermal bluing is performed outdoors. The workpiece heats up slowly. Heating must be stopped at the moment when the top metal layer reacts with oxygen. As a result, an oxide film should form.

Burnishing with citric acid

This method is good for high carbon steel. Oxidation reliably protects against rust, oxide films, and corrosion.

The bluing does not have long-term durability, so it is suitable for weapons that the shooter uses extremely rarely.

For hunters living in big cities, who rarely go out to shoot, this method of bluing is more than suitable: it is budget-friendly, and the procedure can be carried out in apartment conditions. All you need is machine oil, water and a pack of citric acid.

The acid is poured into a container, poured with boiling water and stirred. The product is immersed for 1 hour, periodically moving it to knock down bubbles. Having removed the part, it is rinsed and lubricated with oil.

The simplest ways

Most housewives have vinegar, tea and citric acid at home. And Coca-Cola lovers can not only wash off tar from their cars with it, but also use it to blue metal.

We will not describe each method, since they are almost the same and are most often used for blackening knives and other kitchen utensils. Let us describe the method of bluing a knife.

So, we will need any of these ingredients:

- Table vinegar.

- Citric acid – 1 sachet.

- Coca-Cola (you need to release the gas in advance).

- Black tea (infusion).

Now about the technology of metal blackening.

- The knife needs to be degreased and poured boiling water over it to keep it hot.

- Any of the listed liquids is filled into a plastic bottle with the neck cut off so that only the handle remains outside.

- The knife must be shaken frequently to ensure that there are no air bubbles on the blade.

- Periodically, the knife should be removed from the liquid and the blade should be wiped, removing oxides in this way.

- When the metal becomes the desired color, the bluing process stops.

The coating is not very durable. If desired, it can be removed and reapplied.

In your comments, you can talk about your method of bluing at home, sharing your opinion and impressions of the work performed.

Blue without heat treatment

You can achieve the desired shade of blue without heat treatment - using a special solution.

To complete the work you need 2 reagents and water:

- Potassium hexacyanoferrate (red blood salt) - 2.5 g.

- Iron sesquichloride - 2.5 g.

- Water – 1 l.

Take 2 0.5 liter jars and dissolve each ingredient in them separately. There will be no problems with this, since water is an ideal solvent for them. After this, the solutions are mixed, and a steel part is placed into the resulting mixture. It is necessary to carefully monitor the oxidation process. When the desired shade of blue is achieved, the part is removed from the solution and dried.

2 more ways

- In order to make a part dark blue, you can melt the sulfur by mixing a small amount of soot into it. The part is placed in this composition, and the process of color change is controlled.

- By heating the saltpeter to more than 320°C, we will bring it to a liquid state. Further, as in the previous method.

There are many more ways to blue metal, thanks to which you can achieve a beautiful and durable color of the part, but not all of them are suitable for use at home. We tried to describe the simplest and, if possible, safe ones.

Any of the methods described above for bluing metal can cause harm to human health! You need to take safety precautions in advance, remembering that hot metal can cause thermal burns, and reagents can cause chemical burns. In addition, reagents can cause fumes poisoning. Many reagents are flammable and should not be heated, so be extremely careful and follow the instructions carefully.