We cut plexiglass at home - is it possible to cut it at all? What is the best way to cut plexiglass? cutting plexiglass

Vhomeconditions

is required extremely rarely. This issue is often dealt with by specialists in workshops that cut synthetic plastic, glass and other building materials. However, sometimes the skills of cutting polymethyl methacrylate can be useful in everyday life. A hacksaw is included in each

home

, therefore this method of cutting organic glass is considered the simplest and most accessible

We cut plexiglass - features

It is important to consider that the physical properties of the polymer influence the power tool when cutting plexiglass. Because of them, problems often arise on how to cut plexiglass at home.

It begins to melt as soon as the temperature reaches 160 degrees. You can bend it when it reaches only 100 or even 90 degrees. As a result, thick slabs cannot be processed using a simple circular saw. We have to resort to other options.

This material has plenty of pros and cons. The benefits include:

- high light transmittance;

- low thermal conductivity;

- resistance is five times higher than that of glass;

- environmental cleanliness;

- resistance to bacteria, moisture, microorganisms;

- electrical insulating properties.

The bad thing is that acrylic is prone to surface damage, catches fire easily, and microcracks often occur at the bend points.

There are many tools on the market that allow you to make an even cut.

Cutter

Polymethyl methacrylate of slight thickness can be cut with a stationery or mounting knife, or a homemade cutter.

In order for the cutting line to be smooth, it is necessary to make markings. You need to place a metal ruler along the intended cutting line and press it firmly with your hand. Using gentle but firm movements, move the cutter along the ruler several times. When the fabric is cut by more than 50%, carefully break the material along the line of the formed fold. Irregularities and roughness must be treated with sandpaper or a grinding machine.

As for the disadvantages, this method of cutting plexiglass requires certain dexterity and skills. Lack of experience and careless movements can cause damage to the building material.

The main advantages of plexiglass are

The main advantages of artificial glass are its ease of processing. Polymer glass does not break into small pieces; it can be given the desired shape. You just need to know the basic processing and cutting techniques, and have a special machine and tools available. Only polymer glass combines the external beauty, transparency of glass and the strength and lightness of modern plastic. Sometimes polymer glass can successfully replace glass and plastic. Artificial glass can be processed using several techniques: sawing, planing, turning. Polymer glass will be cut differently at home and on industrial machines, the main thing is not to scratch the glass and so that the material does not become covered with microcracks.

Our equipment

- The machine is designed for fast feed up to 190 mm/sec.

- The working field of the machine is 2000x4000 mm, which allows the use of large sheets entirely.

- Ball screw guides.

- Detailed settings of cutting modes and accelerations on the control panel.

- Working sensors for axes and spindle shaft voltage.

Cutting plexiglass - suitable tools

There are many options for cutting plexiglass 2 mm and thicker at home. We will analyze in detail the most effective and easily accessible ones.

Cutting plexiglass - hand cutter

Another option for cutting plexiglass at home is to make a handy tool from a hacksaw blade. Take a blade (even if it's used) and a file.

On the forums they advise making a sharp nose on a grinding wheel. To make it easier to work, you should wrap the handle with something. For example, electrical tape. The whole job will take a few minutes.

You can also buy a ready-made cutter for plexiglass in the store. A convenient tool for home craftsmen. True, it is effective only for one-time work, when you have to cut sheets with a thickness of no more than two to three mm.

If you are looking for how to cut plexiglass in half, then it is enough to make only a few cuts and then break the material. There is no need to cut all the way through.

Cutting plexiglass - three-pronged disc

When it becomes necessary to process large numbers of sheets, more efficient tools are needed. To mechanize this process at home, use a three-pronged disk for plexiglass and wood. This is an effective tool to figure out how to cut plexiglass evenly.

In essence, this is an improved grinder. Among the materials with which it is recommended to work with a three-pronged disc, not only plexiglass is mentioned, but also wood. This is a great way to cut plexiglass at home in a straight line.

It is important that the temperature of the acrylic does not increase, it does not begin to melt and stick to the disk. With its help you can cut sheets up to 10 mm. When deciding how to cut plexiglass, use a three-prong blade.

Cutting plexiglass - jigsaw

New ways to cut plexiglass at home are constantly appearing on the Internet. Experts advise using a jigsaw. The main condition is the presence of a speed control function.

For sawing, files designed specifically for this material are used. If you don’t have them on hand, you can take wood saws. They will also cope with the task of cutting plexiglass at home.

Plexiglas cutting is carried out at minimum speed. Take the files themselves with the smallest teeth. If you increase the speed, the plexiglass will begin to melt in the cutting area, and the color of the seams will turn white. In some workpieces this is unacceptable.

We cut plexiglass - laser

The most convenient method for cutting acrylic is called laser. However, this method cannot be used at home; it is used exclusively in industrial production.

A thin laser allows you to make precise cuts and cut out even the smallest details of a future design or product. If necessary, you can contact a specialized workshop or enterprise that produces organic glass and products made from it. It is recommended to make drawings in advance and apply markings to the polymethyl methacrylate sheet.

The laser allows you to accurately cut even small parts of plexiglass; it is used only in industrial production

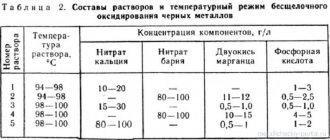

Specifications

The variety of existing manufacturers and the emergence of new ones have led to the emergence of a wide range of devices for cutting polymers. The range of main parameters of laser machines intended for large-scale use is as follows:

- laser lens diameter – 12-25 mm;

- emitter type – carbon dioxide powered;

- lens material – zinc selenide or gallium arsenide;

- power consumption - up to 2 kW;

- beam power – 80-120 W. With increasing radiation power, the maximum possible thickness of the processed material increases;

- MTBF – from 2000 to 10,000 hours;

other methods

Organic glass, as a type of modern building material, is in great demand among builders, designers and even farmers. Sometimes it is not possible to seek help from a specialist who cuts polymer, so you need to know what other methods of cutting plexiglass exist.

In some cases, the use of a circular or band saw is allowed. A circular saw helps to make an even and neat straight cut, a band saw is used for making workpieces and small parts.

Nichrome thread, which must first be heated well, accurately and accurately cuts fabric with a thickness of 4, 6 and 8 mm. This method is not suitable for cutting thicker polymethyl methacrylate sheets.

Hot nichrome thread is widely used for cutting plexiglass

To cut a single piece of plexiglass into parts, some craftsmen use a slotted screwdriver. The blade of the tool must be heated with a 25 W soldering iron, pressed against the acrylic and drawn a line. After the polymethyl methacrylate begins to melt at the site where the cut is formed, the canvas is broken manually. The cut area should be sanded or sanded.

Plexiglass is characterized by low fire resistance; for this reason, it is not recommended to work with this material near an open fire.

Working with organic glass requires precision, care and caution. Failure to follow simple safety rules can lead to dire consequences. Thus, when working with polymethyl methacrylate, it is necessary to wear protective clothing and glasses that reduce the risk of injury or burns.

Compliance with a number of safety rules, the correct choice of tools and a responsible approach to business are a guarantee of high-quality cutting of polymethyl methacrylate.

We cut plexiglass at home - cutting rules

To quickly and accurately cut a workpiece, you need to follow several rules. They “work” for most synthetic materials: organic glass, polycarbonate and others. Let us list the basic rules on how to cut 4 mm plexiglass and other sizes at home.

- It is much easier to make a straight or curved cut if the part is heated. To do this, it is warmed up a little before processing. A hair dryer or gas burner is used as a heat source. Important point. In order not to melt the acrylic, it is kept at a distance from the heating device.

- For work, it is best to choose a canvas marked MP.S. This is high strength hardened steel.

- Sawing with any power tool should only be done at low speeds. Otherwise, the acrylic glass will heat up from the blade and melt. The speed for each device is selected individually.

- Do not cut material without eye protection. You must wear a mask or special glasses. During operation, many very sharp small fragments are formed, which fly away from under the cutting unit.

Jigsaw

To cut polymethyl methacrylate, an electric jigsaw with special files for organic glass is used. Plexiglas files have a special marking - the letters of the Latin alphabet MP.S.

To cut plexiglass at home, a jigsaw with saws marked MP.S is often used.

When cutting the blade, you need to control the speed of the tool. The higher the number of revolutions, the higher the speed of the jigsaw. At high cutting speeds, the synthetic polymer begins to melt. The cut area becomes white and sealed - such material is unsuitable for use.

The feed speed and number of revolutions of the file are selected experimentally. Before you start cutting the working blade, it is recommended to practice on unnecessary fragments of polymethyl methacrylate.

An electric jigsaw is used to create straight and curved cutting lines.

How and with what to cut plexiglass at home

Plexiglas is a synthetic material created from an ester of methacrylic acid. The correct name is polymethyl methacrylate, but due to the difficulty of pronunciation, several names have been assigned to it: acrylic, acrylic glass, plexiglass.

Plexiglas happens:

High molecular weight molded plexiglass is more durable.

It is quite difficult to distinguish it from glass at a great distance. When cutting organic glass with modern power tools, problems arise due to small particles of organic material sticking to the saw blade.

Transparent plexiglass

Before cutting plexiglass, you need to familiarize yourself with some of its properties that affect the operation of the power tool.

This plastic melts at a temperature of 160 degrees; sheet material can be bent at 90-100 °C.

Therefore, it will not be possible to process thick plexiglass slabs with an ordinary circular saw at high speeds. We will look at what tool to use and what to pay attention to in this article.

Cutting plexiglass - preparation and marking

This step-by-step instructions for preparing the workplace are common for all types of tools used, except for the industrial laser and milling machine.

Step 1. Clear the work area of debris and unnecessary objects. This is necessary not just for reasons of cleanliness, but so that they do not interfere with the process and do not leave dents, scratches or other marks on the back of the sheet.

Preparation of the workplace

Step 2. Lay a sheet of plywood, chipboard or fiberboard on the site. Now the cutting area is as level as possible.

Step 3. Transfer and place the polycarbonate sheet on the work area. If it has a laminated, mirror or UV coating, then it should “look” up. Do not remove the protective film from the sheet until you have finished cutting the material.

Step 4. Make preliminary markings in the form of a diagram on paper, observing the scale.

Cutting drawing for polycarbonate sheet

Step 5. Transfer the markings from paper to polycarbonate. For measurements, use a tape measure, a metal ruler, and a rule; to draw cutting lines, use a black marker.

Marking a polycarbonate sheet

When working with large-area sheets, place a board on top (at least 100 mm wide) and walk only on it so as not to damage the surface of the polycarbonate. Examples of cutting material for the gable of greenhouses are shown in the image below.

Cutting a polycarbonate sheet for the greenhouse gable

Step 6. Not far from the cutting line, on the left and right, place boards at least 4 cm high and at least 10-15 wide under the polycarbonate. Their ends should “peek out” from under the sheet on both sides. The boards act as supports, necessary to ensure that the tool does not cut directly into the substrate material. Read a detailed article about polycarbonate and greenhouses.

Step 7. As when applying markings, when cutting polycarbonate, do not move along the surface of the sheet itself, but along a wide board lying on it. Working as a kind of “ski,” it reduces the risk of damage and deformation of the material under the weight of the cutter.

An example of using a board base

When working with pieces of polycarbonate or sheets of small sizes, a workbench or a fairly large table is used instead of a working platform.

Manual processing, materials and tools

How to cut plexiglass if you need to use a sheet of acrylic for work, but you don’t have a power tool at hand? To begin with, you can try to cut it with an ordinary hacksaw.

In terms of hardness, plexiglass can be compared with beech, and sawing beech with a metal hacksaw is quite a long task. To keep it from heating up, you need to cut slowly. The mark of the felt-tip pen is clearly visible on the surface of the acrylic. Draw a cutting line with any sharp object: a nail, knife, etc.

This blade cuts metal, and organic glass even more so

A hacksaw can only cut straight lines. It is difficult to cut curved surfaces with this tool.

Tips: To prevent the blade from sticking, pour a little water onto the cutting line to cool.

For one-time jobs, make a cutter from a hacksaw blade.

Processing acrylic by hand

You can actually make a hand cutter in the shape of a tooth yourself at home. To do this you need to have at least:

- old hacksaw blade;

How to make a homemade hand cutter, watch this video:

All of the above methods are labor-intensive and are only suitable for one-time small jobs on thin sheets of acrylic 2-3 mm thick.

For home handymen, the industry produces ready-made knives for acrylic. They are easy to buy in the online store.

This knife can easily cut plexiglass

To saw a workpiece in half, you do not need to cut it all the way through. It is enough to make a few cuts and break off the required piece.

If a home craftsman needs to process many sheets, he will have to mechanize the cutting process. Meet the three-pronged disc for wood and plexiglass.

Cutting plexiglass with a three-prong blade

How to cut plexiglass in large volumes? Technical improvement of hand tools does not stand still. For more efficient use of the grinder, the industry has released a three-tooth saw blade for wood.

Three-tooth saw blade

In its technical characteristics, organic glass is also mentioned along with wood. It excels at cutting acrylic for straight cuts. The material does not heat up, melt or stick to the saw blade. This disc is tough enough, with a thickness of 5 to 10 mm.

How to use an angle grinder with a three-tooth saw blade, watch this video:

In addition to the grinder, craftsmen use a jigsaw with special saws for plexiglass.

Cutting polycarbonate with a knife

A knife is the most affordable of the tools suitable for cutting monolithic or cellular polycarbonate. For such work, stationery or construction knives with retractable and replaceable blades are used. It is better to take a construction one, as it has a comfortable handle and a more reliable blade locking mechanism. It’s also a good idea to cut polycarbonate using a shoemaker’s knife.

Shoe knife

Regardless of the type of tool, it must be well sharpened - a dull knife will not only significantly slow down the process, but will also leave a lot of burrs on the material. A construction knife is best suited for working with small sheets, cutting them and adjusting them to size.

Construction knife with replaceable blade

But, compared to an electric jigsaw or grinder, cutting polycarbonate with a knife with a retractable blade will require more time. It is not very convenient for them to work with sheets of large area. It is also worth considering that stationery and construction knives are suitable for cutting polycarbonate with a thickness of up to 6-8 millimeters, but no more.

It is advisable to use a stationery, construction or shoe knife exclusively for cellular polycarbonate. Monolithic sheets of similar thickness are too hard to cut with such a tool.

Step 1. Prepare the work area. Detailed instructions on how to do this are outlined in the section above. Mark the polycarbonate with a black marker.

First you need to prepare everything

Step 2. Test the knife on scraps of material or that part of the polycarbonate that will not be used - you need to check the sharpness of the tool. If it is insufficient, replace the blade (for stationery and construction knives) or sharpen it (for a shoe knife).

Polycarbonate can be fixed with electrical tape

Step 3. Apply a rule or thick metal ruler to the cut line. If they are not available, use a flat board or building level. When working with large-area sheets, your assistants should follow the rule and the sheet itself - this will increase the accuracy and quality of cutting.

Alternatively, you can mark the cut lines with the same electrical tape

Step 4. Place the knife blade near the end of the cut line. When working with thick polycarbonate, hold the tool perpendicular (or almost perpendicular) to the plane of the sheet. If the polycarbonate is thin, then it is permissible to hold the knife at an angle of 30-45°. Slowly insert the knife into the end of the sheet to leave an initial notch there.

Cut with a knife

Step 5. Guide the knife from the notch along the cut line. A rule or ruler will help you follow the cutting pattern.

When cutting with a knife, it is convenient to use a long ruler or rule

The cutting speed should be low; accuracy is more important here. When working with rounded elements, be careful not to allow burrs or cut-ins beyond the line drawn with a marker. Don’t be afraid to leave excess – you can trim it later.

When cutting polycarbonate with a knife, use a ruler or rule

Step 6. If the cut polycarbonate sheet does not separate from the rest of the material, run the blade again along the cutting line. It is prohibited to break or bend the material - there is a risk of cracks and other defects.

Step 7: Trim any burrs, if any. Trim the excess to fit the sheet to size. If you were cutting cellular polycarbonate, then glue the ends with construction tape or electrical tape to prevent dust and debris from getting into the cells.

If the thickness of the polycarbonate (monolithic only!) is less than 30 mm, it can be cut with large scissors

Job is done

Cutting plexiglass with a jigsaw

The use of an electric jigsaw is quite justified, but it must have a speed control. For cutting, special nail files for organic glass are used.

If you can’t buy them or need to cut them, then use wood saws. There is a main rule here: the teeth should be small and the cutting speed should be low. At high speeds, the cut begins to melt and turns white. For some products such white seams are not suitable.

Advice: in order to remove burrs and make the cut clean, it must be heated with a gas burner flame. In extreme cases, you can use a lighter.

A jigsaw also allows you to make curved cuts. For this purpose, you need to choose narrow saw blades.

Tip: When purchasing nail files for organic glass, pay attention to the markings. It must have the Latin letters MP.S.

Cutting curved parts with MP.S files

While cutting, pay attention to the feed speed of the tool. The higher the rpm, the higher the feed speed can be. The feed speed and revolutions are selected experimentally so that the acrylic does not melt. When cutting, it is necessary to use a protective mask over the entire face from fragments flying at high speed.

If the parts have a complex curved shape, then it is permissible to use a nichrome spiral for cutting organic glass.

Cutting plexiglass - hacksaw

Plexiglas, also known as acrylic, polymethyl methacrylate, and metaplex, is a hard, transparent synthetic polymer. Unlike ordinary glass, polymethyl methacrylate is characterized by high strength, water resistance and resistance to various physical and chemical influences.

The material is widely used in industry, construction, national economy, outdoor advertising, landscape and interior design.

To cut plexiglass at home, you can use a regular hacksaw

Cutting plexiglass at home is extremely rarely required. This issue is often dealt with by specialists in workshops that cut synthetic plastic, glass and other building materials. However, sometimes the skills of cutting polymethyl methacrylate can be useful in everyday life.

A hacksaw is available in every home, so this method of cutting organic glass is considered the simplest and most accessible:

- Clear the work surface of construction debris, broken branches, small stones and dust.

- Place a sheet of polymethyl methacrylate on your workbench. Use a marker pen to mark the cutting lines.

- In the process of cutting the blade, control the evenness of the hacksaw stroke and the pressing force. To prevent the material from starting to melt, try not to rush. Otherwise, the cut line will turn out uneven and slightly melted.

This method of cutting organic glass has one significant drawback - the roughness of the cut site. Sand the edges of the plexiglass with sandpaper or a file.

Nichrome spiral cutting

When using a nichrome spiral, you must remember that the melting point of acrylic glass is about 160 °C. The nichrome spiral heats up to 1,000 °C. Therefore, to regulate the temperature you need to have a rheostat or a set of resistances.

Adviсe:

- remember acrylic glass burns. When processing using a nichrome spiral, it is necessary to give an allowance of 0.2-0.5 mm and then bring the parts to the required dimensions manually;

- Acrylic glass can be sanded perfectly with all sizes of sanding paper.

There are two options for using a nichrome spiral:

- horizontal straight cut;

- vertical curved cut.

Straight-line cutting of organic glass with a nichrome spiral

Any DC or AC step-down transformer is suitable for these purposes.

Acrylic curved cutting device

Even a welding machine at minimum currents will give the required heating temperature. The main thing is to adapt to the speed of penetration of the spiral into the acrylic. A wood burning device is also suitable for these purposes.

How to cut plexiglass into shapes

In some cases, it may be necessary to perform figure cutting. This is done in the following ways:

- With a caliper. Plexiglass is cut using sharp sponges for marking.

- Nichrome thread. A template is made from cardboard and glued to the workpiece. For convenience, the wire can be secured in a simple jigsaw instead of a blade. Then you need to carefully cut out the plexiglass part according to the template.

- You can use a glass cutter to cut a circle. The suction cup is attached to the center of the intended circle, then a strip or ruler is attached to it. The glass cutter is rigidly attached to the rail with self-tapping screws. By turning the cutting tool around the suction cup, a groove is cut in the plexiglass. Excess parts are broken off.

Gluing, bending and polishing plexiglass

The gluing technology is quite simple; it is only important to immediately wipe off the remaining glue on the surface and place the plexiglass in a dry and ventilated room.

You can bend small glass using a soldering iron. First, clean the surface and mark the plexiglass fold strip. After this, use a heated soldering iron (to about 90 degrees) over the intended location. Having heard a characteristic crack, manually and very carefully bend the glass towards you to the desired angle. The movement should be smooth and fast enough.

Large glasses can be bent with a metal pipe heated to 100 degrees, but in this case you will need special safety equipment (grips). This will allow you to be as far away from the glass itself as possible when melting.

Treat the surface with soda solution and mark the bend location. The diameter of the pipe must correspond to the angle of the desired bend. After this, the technology repeats the bending process using a soldering iron: apply the pipe until you hear a crack, then bend the glass.

If a crack appears, it can be repaired with chilled vinegar. Pour vinegar into the crack, then slightly move the edges. Polish after a while and the crack will become invisible.

Before polishing, you need to protect the edges of the product. This can be done with tape, which does not leave marks, and then wash the glass. You need to polish the glass with 800-grit sandpaper evenly and carefully, without jerking, constantly wetting the plexiglass with water. Polishing occurs until the glass is transparent and smooth. After this, you need to take 2000 sandpaper and sand it until completely transparent.

The places where there was tape can be polished and the corners smoothed if desired. It is quite possible to process organic glass manually, saving time and money. The main thing is to familiarize yourself in detail with the features of the required processing method, as well as follow the basic rules.

How can you cut glass if you don’t have a glass cutter?

How to cut glass without a glass cutter

- Burning thread

- Soldering iron

- Scissors in water

- Diamond blade

- File

- Pobedit drill

Interesting materials:

How is ammonia produced in industry and in the laboratory? How are metals obtained? How do you get meal? How is beeswax obtained? How to receive more applications in Yandex Taxi? How to get 300 Robux? How to get a free domain and hosting? How to get Burden of Izanagi in Destiny 2? How to get money to open a small business? How to receive money from a current account?

Some features of using industrial equipment

Before cutting plexiglass with a circular saw or using a router, there are some precautions you should take. The material quickly heats up and begins not only to melt, but also to smoke. Constant cooling is required. To do this, use a strong air flow or ordinary water. One liter of water is enough to work quietly for an hour.

The container is installed on one side, and water flows through a plastic hose with a diameter of about 2.5 millimeters. This allows you to make a straight and even cut without melted edges.

Cutting plexiglass at home using a milling machine or a laser machine is in most cases impossible, since this complex technical equipment costs a lot of money and takes up a lot of space. At the same time, workshops with such machines are appearing in many cities in ever larger numbers, which makes it possible to use the services of professionals.

How to cut a circle with a jigsaw

If you don’t think about it and take up this matter, then it’s unlikely that anything will come of it.

After all, plexiglass is a very unique material:

- it heats up quickly and contributes to tool breakage;

- if you handle it roughly, it may crack;

- in order not to break the strings of the jigsaw, you must not apply force;

All these properties indicate that cutting a circle from this plexiglass is not so easy. Before you begin the cutting process, you need to process the material.

These processing methods are suitable for plexiglass, whose thickness is about four millimeters, but no more. There are also ready-made knives for acrylic. They will help a person with marks and in difficult areas they will help solve various problems.

With this device you can cut up to one centimeter of plastic. This method will also save a lot of time and allow cutting in fairly large quantities.

Using an electric jigsaw you can also do a large amount of work, only in this case it will be more convenient. You can use wood saws. Just don’t need to develop high speed, otherwise the device may fail.

Currently reading: Manual jigsaw for wood: description, photos and prices

But you need to remember that if the teeth are large, then such files will not work. Very fine teeth are required and the cutting speed must be kept as low as possible.

To cut a circle, you need to draw a circle shape on the fake. Then start cutting into the desired shape.

You should select the cutting option you are interested in and begin the process.

Cutting plexiglass on an industrial scale

In production, the most common method is cutting plexiglass with a laser beam. Of course, it is faster and more convenient than other methods. The laser cuts the sheet along a perfectly smooth cutting line, the cuts remain slightly rough and require little effort for polishing, and there is practically no waste. There are a couple of disadvantages to this method - not everyone has acquired a laser machine yet. This is the main disadvantage. And when cutting with a laser, internal stress appears in the material at the level of atoms and molecules - this is the second drawback. It’s just that it is not recommended to connect plexiglass sheets after laser processing with glue - the connection will not be strong.

How to bend plexiglass

Step-by-step instructions for bending plexiglass. Our experts reveal the secrets of this technology and...

Cutting plexiglass - entangling saws

Band saws, which are typically used for metal and wood work, are often used for trimming the edges of molded plexiglass products and contour cutting plexiglass. As a result of using band saws, the cutting line turns out to be quite rough, so additional processing is required in the future. Depending on the cutting contour, the saw width is selected in the range of 3 – 13mm. Number of teeth – from 3 to 8 pcs. per centimeter of canvas length.

How does the process of processing organic glass take place at Laser365?

The order fulfillment process in our workshop occurs in three stages:

1. Development of a prototype.

In one of the computer programs (AutoCAD, Compas, CorelDraw, Adobe Illustrator) a layout is created on which contour cutting will be performed.

2. Selection of material.

At this stage, you select the appropriate type of acrylic glass, based on the properties of the source material, as well as the task at hand.

3. Carrying out cutting.

Moving according to a CNC program, the laser emitter performs artistic cutting, melting a sheet of organic glass.

Cutting plexiglass - useful tips

There are several tips on how to saw plexiglass without chipping. To achieve a clean cut, leave the acrylic over a gas burner for a while.

Another option: you can use the simplest lighter. True, you will have to spend a lot more time.

You can cut plexiglass using a jigsaw. Use narrow saw blades.

When you purchase them, look for ones that have the MP.S designation on them. These are the most effective devices to solve the problem than cutting off plexiglass.

While working, monitor the speed of the tool. The number of revolutions depends on this. In practice, the speed is selected experimentally. The most important thing is that the plexiglass does not start to melt.

Be sure to wear a protective mask on your face. This will protect you from fragments that will fly at great speed during cutting.

Video “Cutting plexiglass at home”

From this video you will learn how to cut plexiglass at home.

When turning a plexiglass part on a lathe, cutters with carbide plates are used for roughing, and the maximum cutting depth of plexiglass in size should not be more than 6 mm. Fine processing is performed with tool steel cutters. For cooling, drilling emulsions or emulsion oils compatible with organic glass are used.

Turning is the most optimal way to produce disk-shaped parts from sheet blanks. They are clamped with a bag between the tailstock of the machine and the chuck and ground down to the desired size. In a few passes.

Milling cutting

The milling method is used to process edges after previous mechanical operations: drilling, guillotine shearing or cutting. The design of roundings and curved contours is also performed using milling. Any milling machines are used as equipment. The cutters are chosen to be end cutters, single- or double-edged, of small diameters.

To perform artistic engraving work, engraving, top or reverse cutters are used. They can be controlled either manually or electronically.

Video: “Plexiglas milling”

As a result

Working with plexiglass at home in most cases is not particularly difficult and requires the use of a simple set of tools. Despite its simplicity, when choosing a certain cutting method, you should first test it on a small part of the material, and after a kind of “training”, begin finishing work.

It is better to entrust the use of a circular saw, milling or laser machine to specialists, especially since the number of workshops that offer these services is constantly growing. Often you can choose the right type of plexiglass there.

Sources

- https://pressadv.ru/teoriya/kak-rezat-orgsteklo-v-domashnih.html

- https://math-nttt.ru/instrument/kak-rezat-akrilovoe-steklo.html

- https://www.ivd.ru/stroitelstvo-i-remont/otdelocnye-materialy/kak-i-chem-rezat-orgsteklo-6-podhodyashchih-instrumentov-71851

- https://jusof.com/kak-rezat-orgsteklo-v-domashnih-uslovijah/

- https://BurForum.ru/tehprocessy/chem-raspilit-orgsteklo.html

- https://polikarbonat.guru/orgsteklo/rezka-orgstekla.html

- https://paes250.ru/delaj-sam/chem-porezat-orgsteklo.html

- https://MetizTorg72.ru/oborudovanie/kak-vyrezat-orgsteklo.html

- https://ctln.ru/kak-akkuratno-razrezat-orgsteklo-v-domashnih-uslovijah/

- https://spk-kovka.ru/proizvodstvo/kak-razrezat-orgsteklo-v-domashnih-usloviyah.html

316