Physics is not always akin to straightforward logic. If a person places an empty metal container on the stove, it will heat up in 1 minute.

Assuming that when a container is filled with water, its heating rate should be equal to the heating rate of the vessel walls, but this is not the case. Housewives know that regardless of the speed of heating the pan, the water in it will gradually increase its temperature.

This dependence is due to the specific heat capacity of steel and other substances. In today’s article this issue will be examined through the prism of physical processes and industrial applications.

Heat capacity of stainless steel

› Steel

20.03.2020

Inexpensive corrosion-resistant nickel-free chromium steel grades AISI 409 and 430 (400 series) are among the most in demand on the rolled metal market today.

According to the ASTM A240 standard, nickel-free chromium steel grades AISI 409 and 430 (AISI 400 series) are classified as general use and can be adapted to various operating conditions in any industry. In addition, this is the optimal choice of material for solving a whole range of technical problems.

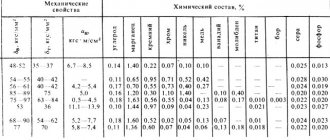

The mechanical properties of rolled sheets of various stainless steels in accordance with ASTM A240 and A 176-99 standards are given in Table. 1.

It should be noted that the actual values of the tensile strength, yield strength and relative elongation of rolled sheets made of steels 409, 430 and 439 significantly exceed the values regulated by the A240 standard (B = 500-550 MPa; 0.2 = 250-350 MPa; 5 = 25- thirty%).

Mechanical properties of rolled sheets according to ASTM A240 standard

*) Martensitic stainless steel (analogous to domestic steels 20-40Х13), which is strengthened by heat treatment and has high wear resistance.

This steel has good ductility (as supplied), high impact strength, good corrosion resistance and heat resistance. In the annealed (softened) delivery state, the steel structure is a mixture of ferrite and carbide phases.

When heated to a temperature of 1000-1060 ° C and subsequent quenching (in air or in oil), martensite is formed, the hardness of which is directly proportional to the carbon content.

The resulting chromium carbides further dispersely strengthen the steel structure, increasing its hardness (up to 55 HRC) and wear resistance after quenching and tempering.

400 series steels retain fairly high mechanical properties at elevated operating temperatures, ensuring the structural strength of the equipment.

If stainless steel structures are operated for a long time at high temperatures, then temperature-time factors that can negatively affect the strength characteristics should be taken into account.

For example, domestic nickel-containing stainless steels and steels of the 300 series (with the exception of grades 321 and 347), in contrast to steels of the AISI 400 series, when operated for just a few hours in the temperature range of 450-750 ° C, can be susceptible to a very dangerous type of corrosion destruction - intergranular corrosion (ICC). And chromium ferritic steels of the 400 series are not prone to high-temperature MCC at temperatures up to 1000 °C.

One of the main reasons for the destruction of stainless steel structures is often corrosion caused by the electrochemical heterogeneity of the heat-affected zones of welds and the base metal. Therefore, reducing the carbon content in steels is an important factor in preventing crevice and knife corrosion in welded joints.

The low carbon content in ferritic steels of the AISI 400 series (actually up to 0.03%) and the low value of strain hardening compared to nickel-containing steels determine not only high resistance to MCC, but also the ability to weld well and be relatively easy to machine mechanically without the hardening inherent in austenitic steels. steels.

Sometimes, during high-temperature heating, the time factor can affect the strength properties of chromium stainless steels.

430 steel, containing 16-18% chromium, can lose strength properties when cooled, but only after very long continuous operation (more than 100 hours) in the temperature range of 425-530 ° C due to the so-called 475-degree embrittlement.

Chromium-sparing 409 steel is not susceptible to this type of failure and is therefore preferred for use in structures subject to such very long periods of heat (for example, continuous cycle convection ovens operating in the temperature range up to 500°C).

Technological properties of various groups of steels are given in table. 2.

Technological properties of steels of the 300th and 400th series

Mechanical processing (milling, turning) Satisfactory Good Heat hardening Not hardened Not hardened Drawing Excellent Excellent Perforation Satisfactory Good Guillotine cutting Satisfactory Good Sheet separation stamping Satisfactory Good Stamping Good Good Grinding Satisfactory Satisfactory

https://www.youtube.com/watch?v=ZyK3nd4Ndks

Weldability Excellent Excellent*

*) When using austenitic filler materials that provide high strength properties and increased ductility of the weld.

Chromium stainless steel, compared to nickel-containing austenitic stainless steel, has a low coefficient of thermal expansion (CTE) and increased thermal conductivity. This predetermines its predominant use (including rolled pipe) in various heat exchange structures.

Welded structures and pipelines made of chromium steels change dimensions significantly less during temperature fluctuations, which reduces destructive fatigue loads due to temperature changes and prevents possible leaks from hydraulic connections.

In addition, having a relatively low thermal inertia (specific heat capacity), structural elements made of ferritic chromium steels warm up faster (and, accordingly, cool down) with lower energy consumption. This allows you to avoid possible inertial overheating, which is very important for a wide range of food industries.

These steels can withstand high peak temperature loads (up to 950°C) and can be continuously operated at temperatures up to at least 700°C.

The physical properties of various groups of steels are given in table. 3.

Food and processing industries

Chromium stainless steels, which have high corrosion resistance in many food environments, can be used for the manufacture of technological equipment used at various stages of food production (washing or hygienic processing of raw materials, products and equipment, grinding, separating and sorting products, mixing, heat treatment, packaging and packing, transportation, etc.). According to the conclusion of the All-Russian Scientific Research Institute of Steel Corrosion, the AISI 400 series, in accordance with GOST 13819, are “very resistant” or “resistant” in boiling drinking water, superheated water steam, cheese grains, boiling vegetable and animal fat, meat products, wine, ethyl alcohol, beer, beer wort, etc. These steels can be used, for example, for the manufacture of malthouse equipment (malt preparation, malting, tanks for washing and soaking barley for malting, dryers for green malt, malt cleaning equipment, sprouting machines, devices for removing sprouts and dust, etc.). P.).

Heat capacity of stainless steel – Metalworker's Handbook

The summary table shows the specific heat capacity of steel of common grades: carbon, low- and high-alloy steels, as well as cast iron at different temperatures.

The values of the average specific heat capacity of low-alloy steels and carbon steels at various temperatures are given, and the heat capacity of high-alloy steels with special properties depending on temperature is indicated.

The table shows that the specific heat capacity of steel increases with increasing temperature. It should be noted that the heat capacity of steel at room temperature ranges from 440 to 550 J/(kg deg); The specific heat capacity of steel in the table is presented in the temperature range from 20 to 1000°C.

Specific heat capacity of steel at different temperatures Steel grade Temperature, °Steel heat capacity, J/(kg deg)

| 02Х17Н11М2 | 20…400…600…800 | 470…560…610…650 |

| 02X22N5AM3 | 20…100…200…300…400 | 480…500…530…550…590 |

| 03X24N6AM3 (ZI130) | 20…100…200…300…400 | 480…500…530…550…570 |

| 05ХН46МВБЧ (DI65) | 100…200…300…400…500…600…700…800 | 445…465…480…490…500…510…515…520 |

| 06Х12Н3Д | 100…200…300…400 | 523…544…577…594 |

| 07Х16Н6 (Х16Н6, EP288) | 100…200…300…400…500…600…700 | 440…500…550…590…630…670…710 |

| 08 | 100…200…400…600 | 465…477…510…565 |

| 08kp | 100…200…300…400…500…600…700…800…900 | 482…498…514…533…555…584…626…695…695 |

| 08Х13 (0Х13, EI496) | 20 | 462 |

| 08Х14МФ | 20…100…200…300…400…500…600 | 460…473…502…540…574…682…754 |

| 08Х17Т (0Х17Т, EI645) | 20 | 462 |

| 08Х17Н13М2Т (0Х17Н13М2Т) | 20 | 504 |

| 08Х18Н10 (0Х18Н10) | 20 | 504 |

| 08Х18Н10Т (0Х18Н10Т, EI914) | 20…100…200…300…400…500…600…700 | 461…494…515…536…549…561…574…595 |

| 08GDNFL | 100…200…300…400…500…600…700…800…900 | 483…500…517…529…554…571…613…697…693 |

| 09X14N19V2BR1 (EI726) | 20 | 502 |

| 015Х18М2Б-VI (EP882-VI) | 100…200…300…400 | 473…519…578…636 |

| 1Х14Н14В2М (ЭИ257) | 20…100…200…300…400…500…600…700 | 461…486…515…536…544…557…590…624 |

| 4Х5МФ1С (EP572) | 20…100…200…300…400…500…600…700…800 | 431…477…519…565…620…703…888…766…749 |

| 10 | 100…200…400…600 | 465…477…510…565 |

| 10kp | 100…200…400…600 | 466…479…512…567 |

| 10Kh12N3M2FA(Sh) (10Kh12N3M2FA-A(Sh)) | 100…200…300…400…500 | 510…538…562…588…627 |

| 10Х13Н3М1Л | 20 | 495 |

| 10Х17Н13М2Т (Х17Н13М2Т, EI448) | 20 | 504 |

| 10Х17Н13М3Т (Х17Н13М3Т, EI432) | 20 | 504 |

| 10Х18Н9Л | 100 | 504 |

| 10GN2MFA, 10GN2MFA-VD, 10GN2MFA-Sh | 100…200…300…400 | 469…553…599…628 |

| 12MH | 20…200…300…400…500…600…700 | 498…519…569…595…653…733…888 |

| 12X1MF (EI575) | 100…200…300…400…500…600…700…800 | 507…597…607…643…695…783…934…1025 |

| 12Х13 (1Х13) | 20…100…200…300…400…500…600…700…800 | 473…487…506…527…554…586…636…657…666 |

| 12X13G12AS2N2 (DI50) | 100…200…300…400…500…600…700 | 523…559…602…613…648…668…690 |

| 12Х18Н9 (Х18Н9) | 20 | 504 |

| 12Х18Н9Т (Х18Н9Т) | 20…100…200…300…400…500…600…700…800 | 469…486…498…511…519…528…532…544…548 |

| 12Х18Н12Т (Х18Н12Т) | 20…100…200…300…400…500…600…700 | 461…494…515…540…548…561…574…595 |

| 14Х17Н2 (1Х17Н2, EI268) | 20 | 462 |

| 15 | 100…200…400…500 | 469…481…523…569 |

| 15G | 100…300…500 | 496…538…592 |

| 15K | 100…200…400…500 | 469…482…524…570 |

| 15kp | 100…200…300…400…500…600…700…800 | 465…486…515…532…565…586…620…691 |

| 15L | 100…200…400…600 | 469…477…515…570 |

| 15Kh2NMFA-A, 15Kh2NMFA-A class 1 | 100…200…300…400 | 490…515…540…569 |

| 15X11MFBL (1X11MFBL, X11LA) | 100…200…300…400…500…600 | 494…528…574…641…741…867 |

| 15Х25Т (Х25Т, EI439) | 20 | 462 |

| 15ХМ | 100 | 486 |

| 17Х18Н9 | 20 | 504 |

| 18Kh11MNFB (2Kh11MNFB, EP291) | 100…200…300…400…500…600 | 490…540…590…666…766…900 |

| 18ХГТ | 100…200…300…400…500…600…700…800 | 495…508…525…537…567…588…626…705 |

| 20 | 100…200…400…500 | 469…481…536…569 |

| 20G | 100…200…400…500 | 469…481…536…569 |

| 20GSL | 100…200…400…500 | 469…482…536…569 |

| 20K | 100…200…400…500 | 469…482…524…570 |

| 20L | 100…200…400…600 | 469…481…536…570 |

| 20kp | 100…200…300…400…500…600…700…800…900 | 486…498…514…533…555…584…636…703…695 |

| 20HML | 100…200…300…400…500 | 498…572…588…612…660 |

| 20ХМФЛ | 100…200…300…400…500…600 | 498…574…590…615…666…741 |

| 20Х3МВФ (EI415, EI579) | 100…200…300…400…500…600 | 502…561…611…657…716…754 |

| 20Х23Н13 (Х23Н13, EI319) | 20 | 538 |

| 20Х23Н18 (Х23Н18, EI417) | 20 | 538 |

| 20ХН3А | 100…200…300…400…500…600…700…800 | 494…507…523…536…565…586…624…703 |

| 22K | 100…200…400…500 | 469…481…519…569 |

| 25 | 100…200…400…500 | 469…482…524…570 |

| 25L | 100…200…400…600 | 469…481…519…570 |

| 25Х1МФ | 20 | 461 |

| 25Х2М1Ф (EI723) | 100…200…300…400…500…600 | 536…574…607…632…674…733 |

| 25ХГСА | 20…100…200…300…400…500…600…700 | 496…504…512…533…554…584…622…693 |

| 30 | 100…200…300…400…500 | 469…481…544…523…762 |

| 30G | 100…200…300…400…500 | 469…481…544…599…762 |

| 30L | 100…200…400…600 | 469…481…523…570 |

| 30Х13 (3Х13) | 20…100…200…300…400…500…600…700…800 | 473…486…504…525…532…586…641…679…691 |

| 30ХГТ | 100…200…300…400…500…600…700…800 | 495…508…525…537…567…588…626…705 |

| 30X | 20…100…200…300…400…500…600…700…800…900 | 482…496…513…532…555…583…620…703…687…678 |

| 30ХН2МВА (30ХН2МВА) | 20…100…200…300…400 | 466…508…529…567…588 |

| 30ХН3А | 100…200…300…400…500…600… 700…800…900…1000 | 494…504…518…536…558…587… 657…703…695…687 |

| 33ХС | 20…100…200…300…400…500…600…700 | 466…508…529…563…599…622…634…664 |

| 35 | 100…200…400…500 | 469…482…524…570 |

| 35L | 100…200…400…600 | 469…481…523…574 |

| 35ХГСЛ | 100…200…300…400…500…600…700…800…900 | 496…504…512…533…554…584…622…693…689 |

| 35HML | 100…200…300…400…500…600…700…800…900 | 479…500…512…529…550…580…617…689…685 |

| 36Х18Н25С2 (4Х18Н25С2, ЭЯ3С) | 20 | 515 |

| 40 | 100…200…300…400…600 | 469…481…519…523…574 |

| 40G | 100…200…400…600 | 486…481…490…574 |

| 40L | 100…200…400…600 | 469…481…523…574 |

| 40Х10С2М (4Х10С2М, EI107) | 300…400…500 | 532…561…586 |

| 40Х13 (4Х13) | 20…100…200…300…400…500…600…700…800 | 452…477…502…528…553…578…620…666…691 |

| 40HL | 100…200…300…400…500…600…700…800…900 | 491…508…525…538…569…588…626…701…689 |

| 45 | 100…200…400…500 | 469…482…524…574 |

| 45G2 | 100…200 | 444…427 |

| 45L | 100…200…400…600 | 469…481…523…569 |

| 45Х14Н14В2М (ЭИ69) | 300…400…500…600 | 507…511…523…528 |

| 50 | 300…400…500 | 561…641…787 |

| 50G | 20…100…200…300…400…500…600…700 | 487…500…517…533…559…584…609…676 |

| 50L | 100…200…400…600 | 478…511…511…569 |

| 55 | 100…200…400…500 | 477…486…523…569 |

| 60 | 100…200…400…600 | 481…486…528…565 |

| ХН35ВТ (ЭИ612) | 100…200…300…400…500…600 | 511…544…569…590…595…595 |

| KHN64VMKYUTL (ZMI3) | 20…100…200…300…400…500…600… 700…800…900…1000 | 430…450…470…490…515…540…565… 590…625…650…1008 |

| KHN65VKMBYUTL (EI539LMU) | 20…100…200…300…400…500…600… 700…800…900…1000 | 424…436…480…493…505…518…548… 596…650…692…710 |

| KHN65VMTYUL (EI893L) | 20…100…200…300…400…500…600…700…800 | 425…430…440…470…500…510…550…615…650 |

| KHN65KMVYUTL (ZhS6K) | 20…100…200…300…400…500…600…700…800…900 | 380…400…420…445…470…485…515…560…610…660 |

| ХН70БDT (EK59) | 100…200…300…400 | 450…475…500…505 |

| KHN70KVMYUTL (TsNK17P) | 20 | 440 |

| KhN80TBYuA (EI607A) | 100…200…300…400…500…600 | 494…547…607…678…749…829 |

| Х15Н60-Н | 20 | 460 |

| Х20Н80-Н | 20 | 460 |

| Х23У5Т | 20…800 | 480…750 |

| Х27У5Т | 20…800 | 500…690 |

| A12 | 100…300…400…600 | 469…477…515…569 |

| R6M5 | 100…200…300…400…500…600…700 | 440…470…500…550…580…670…900 |

| P18 | 100…200…300…400…500…600…700 | 420…450…470…510…550…610…690 |

| U8, U8A | 20…100…200…300…400…500…600…700…800…900 | 477…511…528…548…565…594…624…724…724…703 |

| U12, U12A | 20…100…200…300…400…500…600…700…800…900 | 469…503…519…536…553…720…611…712…703…699 |

Average specific heat capacity of high alloy steels

The table shows the mass specific heat capacity of high-alloy steels with special properties, such as G13 steel and R18 steel. The heat capacity of G13 and R18 steels is given in kJ/(kg deg) at temperatures of 50...1300°C.

Average specific heat capacity of low-alloy steels

The table shows the mass specific heat capacity of low-alloy steels. The heat capacity values are given for the following steel grades: steel 30Х, 30Н3, 30ХН3, 30Г2, 50С2Г. The specific heat capacity of steels in the table is expressed in kJ/(kg deg) and is indicated depending on the temperature - in the range from 50 to 1300°C.

Specific heat capacity of carbon steels and cast iron at different temperatures

The table shows the values of the specific (mass) heat capacity of the following carbon steels and cast iron: steel 08, art. 20, art. 35, art. U8, electrical sheet steel, white cast iron, SCh10 cast iron. The heat capacity is presented in the table in the temperature range from 80 to 1573 K in the dimension kJ/(kg deg).

Specific heat capacity of alloy steels at different temperatures

The table shows the values of the mass specific heat capacity of steel of the following grades: steel 15L, 25L, 45L, 55L, 13N2ХА, R18, 11R3AM3F2, R6M5, 4Х13, 1Х12В2МФ, Х5М, 30ХМ, 30ХМА, 30ХГС, 30ХГСА, 1Х11МФ, 1Х12В IMF, 25Х2МФА, ХН35ВТ ( EI612, EI612K), Kh17N13M2T (EI448), Kh16N25M6 (EI395), Kh22N26, VZh100, ShH15. The mass heat capacity of alloy steels in the table is expressed in kJ/(kg deg) depending on temperature - in the range from 300 to 1400K.

Average specific heat capacity of carbon steels

The table shows the values of the mass heat capacity of iron and the following carbon steels: steel 08KP, st. 08, steel 20, 40, steel U8, U8′, u12. The mass specific heat capacity of carbon steels in the table is given in the dimension kJ/(kg deg) in the temperature range from 50 to 1300°C.

Sources:

- Chirkin V.S. Thermophysical properties of nuclear technology materials.

- Industrial ovens. Reference manual for calculations and design. 2nd edition, expanded and revised, Kazantsev E.I. M., “Metallurgy”, 1975. - 368 p.

- Brand of steels and alloys. 2nd ed., add. and correction/A.S. Zubchenko, M.M. Koloskov, Yu.V. Kashirsky and others. Under the general editorship. A.S. Zubchenko - M.: Mechanical Engineering, 2003. 784 p. ill.

Specific gravity of steel. Specific heat capacity of steel

Steel is considered an alloy of iron with other chemical compounds. Among the components included in the composition, carbon is present in an amount of 2.14%.

Thanks to its presence, iron alloys acquire their strength. The specific gravity of steel is 75500–77500 N/m³. The alloy may sometimes contain alloying elements.

The specific heat capacity of steel at 20 °C is measured at 460 J/(kg*°C), or 110 cal/(kg*°C).

Classification

There are various parameters according to which the material in question is characterized. For example, steel can be used for instrumental or structural purposes. High-speed alloy is considered one of the types of tooling.

There are also differences according to the chemical composition. Depending on what elements are present in the alloy, they are divided into alloyed and carbon. A classification based on the level of carbon concentration has also been adopted.

So, there are three types of alloys:

1. Low carbon. It contains carbon content up to 0.25%.

2. Medium carbon steel. This alloy contains about 0.25-0.6% carbon.

Designation according to international standards

International standard American ASTM A240European EN 10088-2Russian GOST 5632-72

| Brand designation | AISI 304 | 1.4301 | 08Х18Н10 |

| 12Х18Н9 |

Application

- Household items

- Sinks

- Frames for metal structures in the construction industry

- Kitchen utensils and catering equipment

- Dairy equipment, brewing

- Welded structures

- Tanks on ships and land tankers for food, beverages and some chemicals

Typically, steel manufacturers divide the grade into three main classes (grades) according to their drawing ability:

- AISI 304 – Basic grade

- AISI 304 DDQ (Normal and deep drawing) – Deep drawing grade

- AISI 304 DDS (Extra deep drawing) – Extra deep drawing grade

Main characteristics

- good overall corrosion resistance

- good ductility

- excellent weldability

Chemical composition (% by weight)

standard brandCSiMnPSCrNi

| ASTM A240 | AISI 304 | ≤0.080 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.030 | 18.00 – 20.00 | 8.00 – 10.50 |

Mechanical properties

AISI 304 Tensile strength (σв), N/mm²Yield strength(σ0.2), N/mm²Yield strength(σ1.0), N/mm²Elongation (σ), %Brinell hardness (HB)Rockwell hardness (HRB)

| According to EN 10088-2 | ≥520 | ≥210 | ≥250 | ≥45 | – | – |

| According to ASTM A 240 | ≥515 | ≥205 | – | ≥40 | 202 | 85 |

Mechanical properties at high temperatures

All these values refer only to AISI 304

.

Physical properties

Physical properties Symbols Unit of measurement Temperature Value

| Density | d | – | 4°C | 7.93 |

| Melting temperature | °C | 1450 | ||

| Specific heat | c | J/kg.K | 20°C | 500 |

| Thermal expansion | k | W/mK | 20°C | 15 |

| Average coefficient of thermal expansion | α | 10 -6 .K -1 | 0-100°C 0-200°C | 17.5 18 |

| Electrical resistivity | ρ | Ωmm 2 /m | 20°C | 0.80 |

| Magnetic permeability | μ | at 0.80 kA/m DC or h/h AC | 20°C μ μ discharge air | 1.02 |

| Elastic modulus | E | MPa x 10 3 | 20°C | 200 |

Corrosion resistance

304 steels have good resistance to general corrosive environments, but are not recommended where there is a risk of intergranular corrosion. They are well suited for use in fresh water and urban and rural environments. In all cases, regular cleaning of external surfaces is necessary to maintain their original condition.

304 steels have good resistance to various acids:

- phosphoric acid in all concentrations at ambient temperature,

- nitric acid up to 65% at temperatures 20°C – 50°C,

- formic and lactic acid at room temperature,

- acetic acid at a temperature of 20°C – 50°C.

They are recommended for the production of equipment in contact with cold or hot food products: wine, beer, milk (fermented milk products), alcohol, natural fruit juices, syrups, molasses, etc.

Acidic environments

Temperature, °C2080

| Concentration, % by weight | 10 | 20 | 40 | 60 | 80 | 100 | 10 | 20 | 40 | 60 | 80 | 100 |

| Sulfuric acid | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Nitric acid | 2 | 1 | 2 | |||||||||

| Phosphoric acid | 2 | 1 | 2 | |||||||||

| Formic acid | 1 | 2 | 2 | 1 |

Code: 0 = high degree of protection – Corrosion rate less than 100 µm/year 1 = partial protection – Corrosion rate from 100 to 1000 µm/year

2 = no protection – Corrosion rate more than 1000 µm/year

Atmospheric influences

Comparison of 304

grades with other metals in various environments (Corrosion rate calculated for 10-year exposure).

Environment Corrosion rate (µm/year) AISI 304 Aluminum-3S Carbon steel

| Rural | 0.0025 | 0.025 | 5.8 |

| Marine | 0.0076 | 0.432 | 34.0 |

| Industrial Marine | 0.0076 | 0.686 | 46.2 |

Resistant to corrosion in boiling chemicals

Boiling environmentMetal conditionCorrosion rate (mm/year)

| 20% acetic acid | Regular metal Welded | * (With a sample thickness of 0.8 mm and a press diameter of 20 mm) |

| AISI 430 | 2.05 mm | |

| AISI 304 | 2.0 mm |

*Limiting drawing ratio – limiting drawing ratio

Whether specific or general thermal capacity, in the generally accepted physical sense, is the ability of a substance to heat up. At least this is what any textbook on thermophysics tells us - this is the classic definition of heat capacity (correct formulation). In fact, this is an interesting physical feature. The “side of the coin” is little familiar to us from everyday life.

It turns out that when heat is supplied from the outside (heating, warming up), not all substances react equally to heat (thermal energy) and are heated differently. The ability of steel 20 of a metal alloy to receive, accept, retain and accumulate (accumulate) thermal energy is called the heat capacity of steel 20 .

And the heat capacity itself is a physical characteristic that describes the thermophysical properties of the metal. Moreover, in various applied aspects, depending on the specific practical case, one thing may be important for us. For example: the ability of iron to accept heat or the ability to accumulate thermal energy or “talent” ” metal and alloy contain it.

However, despite some differences in the physical sense, the properties we need will be described by the heat capacity of steel.

Classification and types

Steel is classified according to its chemical composition, the content of additives, the manufacturing method, the level of deoxidation and other groups.

According to the chemical composition, it can be carbon and alloyed. In carbonaceous, in addition to carbon and iron, there is silicon (up to 0.3%) and manganese (up to 1.1%).

To impart special qualities, alloying additions (usually metals) are introduced into the alloy: chromium, aluminum, titanium, nitrogen, phosphorus, silicon, carbon, boron, etc.

Low-carbon high-quality structural steels, by definition, have low strength and high ductility.

Medium-carbon high-quality (St 30−55) are used after surface hardening and normalization to create parts with high core strength. St 60 - St 85 have greater strength, wear resistance, and elasticity properties.

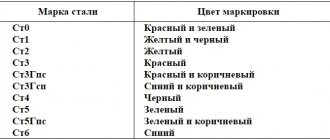

High-quality has a complex chemical composition with a reduced proportion of phosphorus and sulfur. Steel of ordinary quality (carbon fraction less than 0.6%) is designated St 1−6. The symbols “St” indicate a material of normal quality, and the numbers indicate the marking number based on the properties.

In high-quality steel, the proportion of carbon is given in hundredths of a percent; in addition, the nature of hardening and the level of deoxidation can be indicated. It is characterized by a high level of weldability and great ductility.

Based on the level of deoxidation, it is divided into the following types:

- Calm (St3sp) - complete deoxidation with a minimum of impurities and slags contained in it.

- Semi-quiet (St3ps) - obtained by deoxidation of liquid metal, less complete than when smelting calm, but more than when making boiling.

- Boiling (08kp) - unoxidized with a high content of non-metal inclusions.

According to the area of application, steel can be construction, tool, structural and alloyed.

Construction grade has excellent weldability. The number shows the conditional number of the composition according to GOST. The higher it is, the stronger the alloy (for example, cast iron) and the less its ductility.

Alloyed - universal , which contains special impurities. It contains more than 0.6% silicon and 0.9% manganese. If the content of the alloying component is above 1.5%, then it is written with a number following a certain letter:

- Low alloy - alloying components up to 2.4% (09G2S, 18HGT, 10HSND). It is distinguished by great strength due to the increased viscosity limit, which is extremely necessary for structures of great responsibility.

- Medium alloyed (from 2.4 to 10%).

- Highly alloyed (from 10 to 50%).

Steel 09G2S is used for steam equipment operating at temperatures from -70 to +450°C and pressure, as well as for critical welded sheet structures in oil and chemical engineering, and shipbuilding.

Steel 10HSND is used for welded structures in chemical engineering, profiles in car building, and ship building. 18ХГТ is used for elements that operate at high speeds, loads and pressure.

Special purpose steel is an alloy with special physical properties. Used in the electrical industry and precision shipbuilding.

According to standardized parameters, it is divided into categories: from 1 to 5. They denote the chemical composition, ultimate viscosity, and tensile mechanical properties. For example, category 1 - we do not standardize the chemical composition, category 3 - has a standardized maximum viscosity at t = +20°C. For St0, neither the chemical composition nor the impact fluidity are standardized.

Nickel-free corrosion-resistant steel grades

Inexpensive corrosion-resistant nickel-free chromium steel grades AISI 409 and 430 (400 series) are among the most in demand on the rolled metal market today.

According to the ASTM A240 standard, nickel-free chromium steel grades AISI 409 and 430 (AISI 400 series) are classified as general use and can be adapted to various operating conditions in any industry. In addition, this is the optimal choice of material for solving a whole range of technical problems.

The mechanical properties of rolled sheets of various stainless steels in accordance with ASTM A240 and A 176-99 standards are given in Table. 1.

It should be noted that the actual values of the tensile strength, yield strength and relative elongation of rolled sheets made of steels 409, 430 and 439 significantly exceed the values regulated by the A240 standard (B = 500-550 MPa; 0.2 = 250-350 MPa; 5 = 25- thirty%).

Comparative characteristics of the heat capacity of basic building materials

In order to compare the heat capacity of the most popular building materials, such as wood, brick and concrete, it is necessary to calculate the heat capacity for each of them.

First of all, you need to decide on the specific gravity of wood, brick and concrete. It is known that 1 m3 of wood weighs 500 kg, brick - 1700 kg, and concrete - 2300 kg. If we take a wall whose thickness is 35 cm, then through simple calculations we find that the specific gravity of 1 square meter of wood will be 175 kg, brick - 595 kg, and concrete - 805 kg. Next, we will select the temperature value at which thermal energy will accumulate in the walls. For example, this will happen on a hot summer day with an air temperature of 270C. For the selected conditions, we calculate the heat capacity of the selected materials:

- Wall made of wood: C=SudhmuddhΔT; Sder=2.3x175x27=10867.5 (kJ);

- Concrete wall: C=SudhmuddhΔT; Cbet = 0.84x805x27 = 18257.4 (kJ);

- Brick wall: C=SudhmuddhΔT; Skirp = 0.88x595x27 = 14137.2 (kJ).

Specific heat capacity of steel

The summary table shows the specific heat capacity of steel of common grades: carbon, low- and high-alloy steels, as well as cast iron at different temperatures.

The values of the average specific heat capacity of low-alloy steels and carbon steels at various temperatures are given, and the heat capacity of high-alloy steels with special properties depending on temperature is indicated.

The table shows that the specific heat capacity of steel increases with increasing temperature. It should be noted that the heat capacity of steel at room temperature ranges from 440 to 550 J/(kg deg); The specific heat capacity of steel in the table is presented in the temperature range from 20 to 1000°C.

Specific heat capacity of steel at different temperatures Steel grade Temperature, °Steel heat capacity, J/(kg deg)

| 02Х17Н11М2 | 20…400…600…800 | 470…560…610…650 |

| 02X22N5AM3 | 20…100…200…300…400 | 480…500…530…550…590 |

| 03X24N6AM3 (ZI130) | 20…100…200…300…400 | 480…500…530…550…570 |

| 05ХН46МВБЧ (DI65) | 100…200…300…400…500…600…700…800 | 445…465…480…490…500…510…515…520 |

| 06Х12Н3Д | 100…200…300…400 | 523…544…577…594 |

| 07Х16Н6 (Х16Н6, EP288) | 100…200…300…400…500…600…700 | 440…500…550…590…630…670…710 |

| 08 | 100…200…400…600 | 465…477…510…565 |

| 08kp | 100…200…300…400…500…600…700…800…900 | 482…498…514…533…555…584…626…695…695 |

| 08Х13 (0Х13, EI496) | 20 | 462 |

| 08Х14МФ | 20…100…200…300…400…500…600 | 460…473…502…540…574…682…754 |

| 08Х17Т (0Х17Т, EI645) | 20 | 462 |

| 08Х17Н13М2Т (0Х17Н13М2Т) | 20 | 504 |

| 08Х18Н10 (0Х18Н10) | 20 | 504 |

| 08Х18Н10Т (0Х18Н10Т, EI914) | 20…100…200…300…400…500…600…700 | 461…494…515…536…549…561…574…595 |

| 08GDNFL | 100…200…300…400…500…600…700…800…900 | 483…500…517…529…554…571…613…697…693 |

| 09X14N19V2BR1 (EI726) | 20 | 502 |

| 015Х18М2Б-VI (EP882-VI) | 100…200…300…400 | 473…519…578…636 |

| 1Х14Н14В2М (ЭИ257) | 20…100…200…300…400…500…600…700 | 461…486…515…536…544…557…590…624 |

| 4Х5МФ1С (EP572) | 20…100…200…300…400…500…600…700…800 | 431…477…519…565…620…703…888…766…749 |

| 10 | 100…200…400…600 | 465…477…510…565 |

| 10kp | 100…200…400…600 | 466…479…512…567 |

| 10Kh12N3M2FA(Sh) (10Kh12N3M2FA-A(Sh)) | 100…200…300…400…500 | 510…538…562…588…627 |

| 10Х13Н3М1Л | 20 | 495 |

| 10Х17Н13М2Т (Х17Н13М2Т, EI448) | 20 | 504 |

| 10Х17Н13М3Т (Х17Н13М3Т, EI432) | 20 | 504 |

| 10Х18Н9Л | 100 | 504 |

| 10GN2MFA, 10GN2MFA-VD, 10GN2MFA-Sh | 100…200…300…400 | 469…553…599…628 |

| 12MH | 20…200…300…400…500…600…700 | 498…519…569…595…653…733…888 |

| 12X1MF (EI575) | 100…200…300…400…500…600…700…800 | 507…597…607…643…695…783…934…1025 |

| 12Х13 (1Х13) | 20…100…200…300…400…500…600…700…800 | 473…487…506…527…554…586…636…657…666 |

| 12X13G12AS2N2 (DI50) | 100…200…300…400…500…600…700 | 523…559…602…613…648…668…690 |

| 12Х18Н9 (Х18Н9) | 20 | 504 |

| 12Х18Н9Т (Х18Н9Т) | 20…100…200…300…400…500…600…700…800 | 469…486…498…511…519…528…532…544…548 |

| 12Х18Н12Т (Х18Н12Т) | 20…100…200…300…400…500…600…700 | 461…494…515…540…548…561…574…595 |

| 14Х17Н2 (1Х17Н2, EI268) | 20 | 462 |

| 15 | 100…200…400…500 | 469…481…523…569 |

| 15G | 100…300…500 | 496…538…592 |

| 15K | 100…200…400…500 | 469…482…524…570 |

| 15kp | 100…200…300…400…500…600…700…800 | 465…486…515…532…565…586…620…691 |

| 15L | 100…200…400…600 | 469…477…515…570 |

| 15Kh2NMFA-A, 15Kh2NMFA-A class 1 | 100…200…300…400 | 490…515…540…569 |

| 15X11MFBL (1X11MFBL, X11LA) | 100…200…300…400…500…600 | 494…528…574…641…741…867 |

| 15Х25Т (Х25Т, EI439) | 20 | 462 |

| 15ХМ | 100 | 486 |

| 17Х18Н9 | 20 | 504 |

| 18Kh11MNFB (2Kh11MNFB, EP291) | 100…200…300…400…500…600 | 490…540…590…666…766…900 |

| 18ХГТ | 100…200…300…400…500…600…700…800 | 495…508…525…537…567…588…626…705 |

| 20 | 100…200…400…500 | 469…481…536…569 |

| 20G | 100…200…400…500 | 469…481…536…569 |

| 20GSL | 100…200…400…500 | 469…482…536…569 |

| 20K | 100…200…400…500 | 469…482…524…570 |

| 20L | 100…200…400…600 | 469…481…536…570 |

| 20kp | 100…200…300…400…500…600…700…800…900 | 486…498…514…533…555…584…636…703…695 |

| 20HML | 100…200…300…400…500 | 498…572…588…612…660 |

| 20ХМФЛ | 100…200…300…400…500…600 | 498…574…590…615…666…741 |

| 20Х3МВФ (EI415, EI579) | 100…200…300…400…500…600 | 502…561…611…657…716…754 |

| 20Х23Н13 (Х23Н13, EI319) | 20 | 538 |

| 20Х23Н18 (Х23Н18, EI417) | 20 | 538 |

| 20ХН3А | 100…200…300…400…500…600…700…800 | 494…507…523…536…565…586…624…703 |

| 22K | 100…200…400…500 | 469…481…519…569 |

| 25 | 100…200…400…500 | 469…482…524…570 |

| 25L | 100…200…400…600 | 469…481…519…570 |

| 25Х1МФ | 20 | 461 |

| 25Х2М1Ф (EI723) | 100…200…300…400…500…600 | 536…574…607…632…674…733 |

| 25ХГСА | 20…100…200…300…400…500…600…700 | 496…504…512…533…554…584…622…693 |

| 30 | 100…200…300…400…500 | 469…481…544…523…762 |

| 30G | 100…200…300…400…500 | 469…481…544…599…762 |

| 30L | 100…200…400…600 | 469…481…523…570 |

| 30Х13 (3Х13) | 20…100…200…300…400…500…600…700…800 | 473…486…504…525…532…586…641…679…691 |

| 30ХГТ | 100…200…300…400…500…600…700…800 | 495…508…525…537…567…588…626…705 |

| 30X | 20…100…200…300…400…500…600…700…800…900 | 482…496…513…532…555…583…620…703…687…678 |

| 30ХН2МВА (30ХН2МВА) | 20…100…200…300…400 | 466…508…529…567…588 |

| 30ХН3А | 100…200…300…400…500…600… 700…800…900…1000 | 494…504…518…536…558…587… 657…703…695…687 |

| 33ХС | 20…100…200…300…400…500…600…700 | 466…508…529…563…599…622…634…664 |

| 35 | 100…200…400…500 | 469…482…524…570 |

| 35L | 100…200…400…600 | 469…481…523…574 |

| 35ХГСЛ | 100…200…300…400…500…600…700…800…900 | 496…504…512…533…554…584…622…693…689 |

| 35HML | 100…200…300…400…500…600…700…800…900 | 479…500…512…529…550…580…617…689…685 |

| 36Х18Н25С2 (4Х18Н25С2, ЭЯ3С) | 20 | 515 |

| 40 | 100…200…300…400…600 | 469…481…519…523…574 |

| 40G | 100…200…400…600 | 486…481…490…574 |

| 40L | 100…200…400…600 | 469…481…523…574 |

| 40Х10С2М (4Х10С2М, EI107) | 300…400…500 | 532…561…586 |

| 40Х13 (4Х13) | 20…100…200…300…400…500…600…700…800 | 452…477…502…528…553…578…620…666…691 |

| 40HL | 100…200…300…400…500…600…700…800…900 | 491…508…525…538…569…588…626…701…689 |

| 45 | 100…200…400…500 | 469…482…524…574 |

| 45G2 | 100…200 | 444…427 |

| 45L | 100…200…400…600 | 469…481…523…569 |

| 45Х14Н14В2М (ЭИ69) | 300…400…500…600 | 507…511…523…528 |

| 50 | 300…400…500 | 561…641…787 |

| 50G | 20…100…200…300…400…500…600…700 | 487…500…517…533…559…584…609…676 |

| 50L | 100…200…400…600 | 478…511…511…569 |

| 55 | 100…200…400…500 | 477…486…523…569 |

| 60 | 100…200…400…600 | 481…486…528…565 |

| ХН35ВТ (ЭИ612) | 100…200…300…400…500…600 | 511…544…569…590…595…595 |

| KHN64VMKYUTL (ZMI3) | 20…100…200…300…400…500…600… 700…800…900…1000 | 430…450…470…490…515…540…565… 590…625…650…1008 |

| KHN65VKMBYUTL (EI539LMU) | 20…100…200…300…400…500…600… 700…800…900…1000 | 424…436…480…493…505…518…548… 596…650…692…710 |

| KHN65VMTYUL (EI893L) | 20…100…200…300…400…500…600…700…800 | 425…430…440…470…500…510…550…615…650 |

| KHN65KMVYUTL (ZhS6K) | 20…100…200…300…400…500…600…700…800…900 | 380…400…420…445…470…485…515…560…610…660 |

| ХН70БDT (EK59) | 100…200…300…400 | 450…475…500…505 |

| KHN70KVMYUTL (TsNK17P) | 20 | 440 |

| KhN80TBYuA (EI607A) | 100…200…300…400…500…600 | 494…547…607…678…749…829 |

| Х15Н60-Н | 20 | 460 |

| Х20Н80-Н | 20 | 460 |

| Х23У5Т | 20…800 | 480…750 |

| Х27У5Т | 20…800 | 500…690 |

| A12 | 100…300…400…600 | 469…477…515…569 |

| R6M5 | 100…200…300…400…500…600…700 | 440…470…500…550…580…670…900 |

| P18 | 100…200…300…400…500…600…700 | 420…450…470…510…550…610…690 |

| U8, U8A | 20…100…200…300…400…500…600…700…800…900 | 477…511…528…548…565…594…624…724…724…703 |

| U12, U12A | 20…100…200…300…400…500…600…700…800…900 | 469…503…519…536…553…720…611…712…703…699 |

Properties of metals

Density.

This is one of the most important characteristics of metals and alloys. According to their density, metals are divided into the following groups:

lungs

(density not more than 5 g/cm 3 ) - magnesium, aluminum, titanium, etc.:

heavy

- (density from 5 to 10 g/cm 3 ) - iron, nickel, copper, zinc, tin, etc. (this is the most extensive group);

very heavy

(density more than 10 g/cm 3 ) - molybdenum, tungsten, gold, lead, etc.

Table 2 shows the density values of metals. (This and the following tables characterize the properties of those metals that form the basis of alloys for artistic casting).