There are a large number of varieties of sanding belts available for sale. This material is in demand not only among workers in factories and workshops, but also among home craftsmen. When choosing a belt, it is worth considering that each model of grinding machine requires a certain size of abrasive. Below you can familiarize yourself with the rules for choosing a product and markings by grain size.

A coarse sanding belt should be used to level the surface.

What is a sanding belt?

Sanding belt ( sanding belt ) is a flexible material on a fabric or paper basis, on which a thin layer of abrasive is applied. Used for machine or manual processing of various materials:

- metal;

- glass;

- fiberglass;

- wood;

- plastic.

Belt sanding is used to eliminate roughness, process seams, remove paint, etc. Thanks to the large selection of materials from which belts are made, they can be used to solve many problems. Manufacturers of power tools and components make several types of sanding belts for:

- hand grinders;

- grinding machines;

- pneumatic tools;

- angle grinder;

- eccentric sanders.

Surface treatment using special machines and hand tools helps prepare materials for painting and varnishing. Depending on the type of abrasive belt , it is possible to grind and polish products with complex geometries.

Makita 9403

Main characteristics:

- Power - 1200 W;

- Belt speed - 500 m/min;

- Tape - 610×100 mm;

- Weight - 5.9 kg.

Housing and ergonomics. Despite its small dimensions, this grinding machine, due to the manufacturer’s reasonable preferences for the use of metal parts, has an impressive weight of 5.9 kg. This causes some difficulties when working with weight, but does not require additional pressure when processing horizontal surfaces. The product is equipped with two handles, equally convenient for gripping on both the right and left sides.

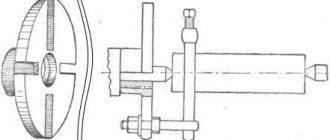

Design features. This model has a steel platform with linings made of cork and graphite, which facilitates the sliding of the skin and dampens vibration and sound waves.

Makita 9403 platform.

The labyrinth-type shaft seal reliably protects the bearings from contamination. The connection pipe for connecting a vacuum cleaner or securing a dust collector can easily be turned in any direction. The cable length of 5 meters is enough for free movement inside the workshop.

Functionality and capabilities. The machine has a high power of 1200 W and develops an optimal linear speed of pelt movement of 500 m/min. It uses a tape with a width of 100 mm and a length of 610 mm. There is no adjustment of the rotation speed, so this model is more suitable for grinding homogeneous surfaces of a large area.

Equipment. The product is delivered in a cardboard box with a sanding belt installed and is completely ready for use.

Pros of Makita 9403

- High power.

- Ergonomic handles.

- Start lock button for long-term operation.

- Low vibration and noise levels.

- Double insulation of current-carrying elements.

- Reliability.

Cons of Makita 9403

- One speed without soft start and speed stabilization system.

- Heavy weight.

- High price.

Types of sanding belts

Abrasive belt grinding is carried out using various consumables, which differ from each other in several parameters. Some are used for rough cutting of metal or wood, while others are used for finishing.

According to the degree of hardness, sanding belts can be divided into three types:

- soft;

- hard;

- superhard.

The first two types of abrasive tapes are used for rough grinding and leveling of surfaces. Soft grain materials process parts with complex geometries, allowing for smooth polishing .

Most belt sanders (BSMs) use endless abrasive belts, the ends of which are connected to each other. Depending on the connection method, the following types of tapes are distinguished:

- Seam A – overlapping tape connection without compensation of abrasive in the place where the ends are glued;

- Seam B - joining the ends of the tape with an overlap with compensation for the abrasive at the junction;

- Seam T – connecting the edges of the tape butt to butt with a vertical cut;

- Seam TS – wave-shaped connection of the sanding belt butt to butt;

- TT seam - joining the ends of the tape end-to-end from the side of the applied abrasive layer on the substrate.

Cleaning and sanding

After assembling a wooden product, its surface must be leveled and sanded. The processing is subject to end cuts, places where grooves were cut with a plane, traces of wood glue, places where small chips have broken off, protruding fibers in places where there is a longitudinal cut or an angle cut.

When preparing the surface for treatment with staining liquids or coating with varnish for sanding, the use of the finest sandpaper will be required. It is also recommended to sand plywood products with fine-grained grades, despite the apparent evenness of their surface. The smallest irregularities, invisible to the eye, after varnishing will acquire relief and excellent visibility.

Abrasive grain materials for belts

The quality of belt grinding is determined by the degree of wear resistance of the abrasive layer, which can consist of powder of various materials. Most often, sanding belts come with the following types of coating:

- Aluminum oxide is a brittle material most often used in the woodworking industry;

- Silicon carbide is a durable and wear-resistant material designed for grinding metal, fiberglass, hard plastic and painted surfaces;

- garnet is a high-strength abrasive that is often used for processing wooden workpieces;

- zirconate is a wear-resistant and coarse-grained abrasive intended for rough belt grinding of metal, wood, and plastic;

- compact grain - a granular material that is used for grinding products made of stainless or black steel;

- ceramic abrasive is a hard material used for sanding and smoothing wood.

In heavy industry, sanding belts made using micro-replication technology are widely used. The abrasive layer of the tapes consists of structured grains. When used on belt machines, it is possible to achieve high-quality finishing grinding of metal surfaces.

Rules for manual grinding

You should start your DIY sanding with the coarsest-grained sandpaper available to remove obvious defects from the surface of the wood. But here we must still take into account the nature of the damage that needs to be eliminated.

You need to act on the surface correctly: it is best to move the block or just sandpaper in a straight line along the fibers in a back and forth direction. And sanding, for example, in a circular motion can lead to unnecessary scratches.

Having reached the edge of the surface to be treated, be sure to grind off the sharp corners. Soon, as a result of exposure to coarse abrasives, dust mounds will begin to appear on the wood. They should be carefully removed with a vacuum cleaner. Then you can proceed to processing with the next medium-grit sandpaper.

This processing is carried out according to the same principles as described above. The final stage is grinding with an abrasive with the finest grain. After this, the wooden product should become completely smooth, there should be no flaws left on it.

Sanding belt sizes

When choosing a suitable sanding belt for a tool , two parameters need to be taken into account - length and width. For manual blade grinders and machines, belts with a length of 350 to 600 mm are most often produced. To select the appropriate size, you need to measure the working length using a machine or hand grinder.

The width of the sanding belt varies from 30 to 150 mm. Most often, abrasive blades with a width of 76 mm are chosen for power tools. This size fits most stationary machines and hand tools.

Sandpaper markings

For different types of work, they produce brands of abrasive paper that differ greatly in their properties and cost. To choose the right brand and not overpay, you should understand its labeling.

There are two main systems for marking sandpaper - European and according to GOST. GOST used the principle of decreasing values as the grain size decreased, and the finest skin was called “nulevka”.

In the European system, on the contrary, the smallest grains correspond to large values - from P2500 to P1200, and coarse-grained skins will have the indices P36 or P22.

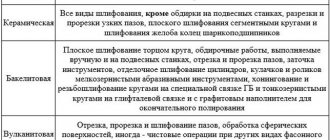

Marking table

In addition, marking by type of backfill is important. Solid backfill is used in household, manual use, and backfill with a density of about 50% of the surface is more suitable for industrial use and use in grinding machines.

Sanding belt grit

size of the sanding belt affects the quality of surface finishing of various materials. Sanding belts are classified according to grain size: the higher the grain , the softer the processing.

Coarse grain belts

- Extra coarse grain size. Sanding belts with very coarse grains (P22-P36) are used for rough sanding and leveling surfaces. The sizes of granules in such tapes range from 500 to 1000 microns;

- Coarse grain. If the grain size of the sanding belt is P40–P60, such a tool will be used for initial processing of wood. Due to the fairly large size of the granules (250-500 microns), such tapes do not become clogged with dust for a long time;

- Sanding belts for primary processing. Abrasive materials (P70–P120) are used for cleaning surfaces when it is necessary to remove old paint, rust, etc. The grain size in the tape does not exceed 100-250 microns;

- Sanding belts for final cleaning. Sufficiently fine grit belts are used for the final abrasive treatment of surfaces before polishing. The granule sizes for P150–P220 do not exceed 63-100 microns.

Fine Grain Belts

- Sanding belts for final sanding. Used for final processing of hardwood products. The sizes of abrasive granules P240–P280 are 40-63 microns;

- Sanding belts for polishing. Used to impart smoothness to painted surfaces. Often used before wet polishing. The grains of sanding belts P400–P600 are small (20-40 microns), so they quickly become clogged with dust and paint residues;

- Sanding belts for fine polishing. These belts are designed for finishing metal, ceramics or varnished wood. P1000 sanding belt granules have a size of up to 14 microns;

There are also tapes for delicate polishing, with the help of which finished products are given shine and smoothness. They can be used to sand down uneven surfaces after painting.

Type of abrasive application

The abrasive grain size can be created using the open/semi-open method or the continuous/closed method of pouring. If the manufacturer uses the first method, the grains will cover up to 60% of the surface. This abrasive is ideal for processing soft materials with low densities. Lumps do not form on such a surface, and the spaces between the grains do not become clogged.

An abrasive whose grain size was created using a closed method can be used in the process of grinding a metal surface.

Preface

- 1 DEVELOPED by the Federal State Unitary Enterprise “Russian Scientific* Technical Center for Information on Standardization, Metrology and Conformity Assessment” (FSUE “STAN* DARTINFORM”)

- 2 INTRODUCED by the Technical Committee for Standardization TC 095 “Tool”

- 3 APPROVED AND ENTERED INTO EFFECT by Order of the Federal Agency for Technical Regulation and Metrology dated May 22, 2022 No. 213-st

- 4 This standard has been developed taking into account the main regulatory provisions of the international standard ISO 2976:2005 “Abrasive cloths. Endless sanding belts. Selection of width and length combinations" (ISO 2976:2005 "Coated abrasives - Abrasive belts - Selection of width/length combinations". NEQ)

- 5 INTRODUCED FOR THE FIRST TIME

- 6 This standard implements the requirements of the Technical Regulations of the Customs Union TR CU 010/2011 “On the safety of machinery and equipment” in relation to endless sanding belts: tensile strength of the connecting seam. marking

The rules for applying this standard are established in Article 26 of the Federal Law of June 29, 2015 N9 162-FZ “On Standardization in the Russian Federation”. Information about changes to this standard is published in the annual (but as of January 1 of the current year) information index “National Standards”, and the official text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the next issue of the monthly information index “National Standards”. Relevant information, notices and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet (www.gost.ru)

© Standardinform. decor. 2020

This standard cannot be fully or partially reproduced, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology

II