What is indicated in the labeling

The main characteristics taken into account when choosing wheels are their type, type of abrasive, bond, hardness and grain size. In this case, hardness and structure for many types of processing play a more important role than the abrasive material.

Product labeling contains the following information:

- circle type;

- product size;

- abrasive material;

- graininess of the circle;

- product hardness;

- structure;

- binding material;

- permissible rotation speed;

- circle accuracy class;

- imbalance of the circle.

When choosing a wheel, it is necessary to take into account that the markings made in accordance with various GOSTs differ in the designations of grain size, hardness and other parameters. In addition, manufacturers use different markings for their wheels, excluding some parameters and using old and new designations. Let's give an example of decoding

1 – 25A – white electrocorundum is used as an abrasive; 2 – average abrasive grain size 370 µm (F46); 3 – medium-soft hardness, type L; 4 - middle structure (6); 5 – ceramic binder (V); 6 – maximum rotation speed 35 m/s; 7 — accuracy category B; 8 – 3rd class of imbalance.

This is interesting: How and with what to solder stainless steel at home: tips, videos, photos

Types and characteristics of grinding wheels

The grinding wheels used today have a fundamentally identical design: in general, it is a body of rotation with a different profile, formed from an array of abrasive grains with a binder, and having a mounting hole in the center for mounting on the spindle (shaft) of the machine/machine. The wheel is made by gluing abrasive grains of a certain size using bonds, which provide the necessary strength to the product and prevent it from breaking under the influence of centrifugal forces during rotation.

Wheels are classified according to their profile (section), type and grain size of the abrasives used, type of binding material and some characteristics.

The following types of grinding powders are used as abrasive materials:

- Electrocorundum (marking “A”) - normal (grades 12A – 16A), white (grades 22A – 25A), chromium (grades 32A – 34A), titanium (grades 37A) and zirconium (grades 38A, can be marked with the letter “Z”) ;

- Silicon carbide (marked “C”) - black (grades 52С – 55С) and green (grades 62 – 64С).

There are grinding wheels that use diamond, CBN and other materials as an abrasive, but they have a different design (metal base on which a layer of abrasive is applied) and characteristics, and are not discussed in this article.

The grain size of the abrasives used for the manufacture of wheels lies within the range of F36 - F220 according to GOST R 52381-2005 (corresponds to the international specification FEPA - Federation of European Producers of Abrasives, European Federation of Abrasives Manufacturers) and M63 - M10 according to GOST 3647-80 (currently time partially cancelled). In wheels with abrasives F36 - F220, the average grain size ranges from 58 - 525 microns, and with abrasives M63 - M10 - from 7 to 63 microns.

When forming a grinding wheel, the following types of bonds can be used:

- Ceramic (marking V, obsolete - K);

- Bakelite (marking B, B4, BF, obsolete - B, B4, BU);

- Vulcanite (marked R, obsolete - B).

Types of Abrasive Wheel Bonds

Ceramic bonds are inorganic components based on various types of clays with the addition of feldspar, quartz and other substances. After firing, the ceramic binder provides the wheel with the necessary rigidity, wear resistance and strength (including temperature), but it has increased fragility. These types of wheels are not used in machines and machines that process shock loads.

Bakelite binder is a resin (bakelite) that can be used in its pure form, with reinforcing additives (marked BF/BU) or with graphite (marked B4/B4). Due to its elasticity, the bakelite bond is resistant to shock loads, but does not withstand high temperatures and aggressive environments (including some types of cutting fluids, coolants). Also, wheels on a bakelite bond have good self-sharpening properties - worn grain is relatively easily torn off from the bond, exposing new grain, which ensures stable abrasive properties.

Vulcanite bond is a vulcanized rubber (actually high-density rubber or ebonite) that can have various additives to increase strength and chemical resistance. Currently, this type of grinding wheel is the least used.

Grinding wheels can be molded with different ratios of abrasive grain and binder, which characterizes their structure, which can be of the following types:

- Dense (marking from 1 to 4);

- Medium (marking 5 - 7);

- Open (marking 8 - 10);

- Highly porous (marking 11, 12).

The higher the number, the less dense the structure of the circle, and the greater the distance between the grains.

Depending on the type of bond and density, the wheels can have different hardness - a characteristic indicating the strength of the bond's holding of abrasive grains. The higher the hardness, the stronger the grain is held in the bond, and the more difficult it is to break out when grinding the surface of the product. In terms of hardness, the circle can be of the following types:

- Very soft (BM1, BM2; F, G);

- Soft (M1 – M3; H, I, J);

- Medium soft (SM1, SM2; K, L);

- Middle (C1, C2; M, N);

- Medium-hard (ST1 – ST3; O, P, Q);

- Solid (T1, T2; R, S);

- Very hard (VT; T, U);

- Extremely hard (HH; V–Z).

The alphanumeric hardness marking corresponds to the old standard GOST 19202-80 (not used today), in Latin letters - to the standard GOST R 52587-2006.

Finally, grinding wheels can have accuracy classes “AA”, “A” and “B”, and unbalance classes from 1 to 4.

Grinding wheels are divided into several types according to their profile (section):

Grinding wheel profiles

- Type 1 - straight profile (PP);

- Type 2 - ring (K);

- Type 3 - with one-sided conical profile (3P);

- Type 4 - with double-sided conical profile (2P);

- Type 5 - with one-sided groove (PV);

- Type 6 - cylindrical cup (CC);

- Type 7 - with double-sided undercut (DVD);

- Type 10 - with double-sided groove and hub (PVDS);

- Type 11 - conical cup (CC);

- Type 12, 14 - disc-shaped (T, 1T);

- Type 20 - with sampling;

- Type 21 - with double-sided sampling;

- Type 22 - with recess and undercut;

- Type 23 - with recess and recess on one side (PVK);

- Type 24 - with recess and recess on one side and with a recess on the opposite side;

- Type 25 - with recess and recess on one side and recess on the opposite side;

- Type 26 - with recess and recess on both sides (PVDK);

- Type 35 - straight profile end;

- Type 36 - straight profile with pressed-in fasteners (PN);

- Type 37 - ring profile with pressed-in fasteners;

- Type 38 - with one-sided hub;

- Type 39 - with double-sided hub.

All characteristics, geometric shape and dimensions of grinding wheels for stationary electrical machines and machine tools in Russia are regulated by the GOST R 52781-2007 standard. Previously, the GOST 23182-78 standard for wheels for hand-held machines was in force, but it has now been cancelled.

A separate group includes wheels for hand-held grinding machines, made of non-woven materials with abrasive grain applied to them. These tools are manufactured according to the enterprises’ own standards; today they are presented in large quantities to perform a wide range of operations.

TOP 5 best diamond blades for grinders

A selection of the best diamond blades based on customer reviews and ratings.

Makita D-50980, 125 mm 1 pc.

For small volumes of work, the D-50980 disk is well suited. Will cope with concrete, slate, brickwork and other similar materials.

Installs on a standard angle grinder.

The model was manufactured using high-tech equipment and meets all modern quality standards.

Dry cutting: you can work with or without coolant if necessary (but the first option is preferable - the equipment will last much longer).

Type - segmented with narrow U-shaped grooves.

Not only the composition, but also the slots in the form of keyholes give versatility: they allow air to pass through well.

Specifications:

- type: segmented;

- bore diameter: 22.23 mm;

- highest number of revolutions: 12250 rpm;

- thickness: 2 mm.

Advantages

- behaves well with reinforced concrete;

- suitable for wall chaser;

- inexpensive;

- long service life;

- does not require mandatory water.

Flaws

- exception - abrasive materials;

- Chips appear on ceramic tiles.

BOSCH Standard for Ceramic 2608602202, 125 mm 1 pc.

One of the striking examples of German quality is the Standard for Ceramic 2608602202 diamond disc from the giant BOSCH.

Designed for dry cutting with brick, marble, porcelain stoneware and all types of ceramic tiles, i.e. where there is a high risk of chipping.

It is a solid circle, the diamond cutting edge of which is continuous.

Due to this, there are no chips left even on the most capricious material.

Uninterrupted water cooling is required. Since there is no silicon carbide in the diamond blade, it is safe to work with: the risk of silicosis or lung cancer is reduced to zero.

Specifications:

- bore diameter: 22.23 mm;

- thickness: 1.6 mm;

- maximum number of revolutions: 12250 in 1 minute;

- gross weight: 0.15 kg.

Advantages

- smooth saw;

- the glaze on the tile does not chip;

- ideal price/quality ratio;

- increased wear resistance;

- good cutting depth.

Flaws

- works slowly;

- rather weak for porcelain tiles.

Metabo Promotion 624307000, 125 mm 1 pc.

The diamond blade should be selected based on the materials you will be working with. Promotion 624307000 from Metabo is a universal option for standard angle grinders.

Suitable for working with the following materials: calcareous tuff, adobe, hard sandstone, wet and regular concrete.

Disk type - segmented, i.e. it has a segmented diamond cutting edge, divided into equal-sized slots (they cool the tool during operation.

Thanks to this design, the disk can be restored for repeated use. Can be used for both dry and wet cutting.

Cost-effective to use, which means high wear resistance and long service life. The highest speed is 12200 per minute.

Specifications:

- maximum operating speed - 80 m/s;

- diameter: 125 mm;

- number of segments: 9 pcs.;

- bore diameter: 22.2 mm;

- thickness: 2.15 mm.

- diamond layer height: 7 mm.

Advantages

- heat resistant;

- high resistance;

- high performance;

- good speed;

- lasting.

Flaws

- the price tag is above average;

- may tear the edge of the material.

Di-Star 1A1R Esthete 11115421010, 125 mm 1 pc.

At first glance, it seems that finding a disk that would be ideal for dry assembly is very difficult. Disc Di-Star 1A1R Esthete 11115421010 is exactly the optimal option you need for finishing and repair work.

So whether to use coolant or not is up to you. Designed for angle grinders.

You can easily obtain a neat and precise cut when processing both ceramic tiles with decorative coating and stone.

The height of the diamond layer is 8 mm, the thickness of the disc is 1.1 mm, the body is reinforced with flanges.

Specifications:

- Diamond blade type: solid

- bore diameter: 22.23 mm

- maximum speed: 12250 rpm.

Advantages

- no chips;

- cutting speed is good;

- durability;

- thin high-quality cut;

- price.

Flaws

- when cutting frost-resistant porcelain stoneware, the disc bends;

- not on abrasive materials;

- accuracy in work is required.

Makita B-28058, 125 mm 1 pc.

This disc can be successfully used for working on brick, asphalt, concrete and marble.

The kit includes an adapter ring: it can be used with a tool with a mounting hole diameter of at least 20 mm.

Type of cut - dry: the use of liquid is not required, nor is the involvement of a second master in the process (but you should remember the high degree of dust, which requires the use of a vacuum cleaner, and the lower quality of the work).

Diamond blade type: turbo. An excellent solution for grooves and slate. Country of origin: China.

Specifications:

- disc diameter: 125 mm;

- bore diameter: 22.23 mm;

- maximum speed: 12250 rpm

- weight: 500 g.

Advantages

- price/quality ratio is at the proper level;

- cuts well;

- takes a long time to wash;

- light weight;

- easy to replace with a similar one.

Flaws

- increased noise level;

- Vibrations are felt during the process.

Abrasives and grit

The abrasive material is indicated by alphanumeric markings. Thus, electrocorundum is marked with the letter A. White electrocorundum - from 22A to 25A, normal from 12A to 16A, chromium from 32A to 34A. There are also titanium electrocorundum (37A), zirconium (38A) and other varieties. The higher the number, the higher the quality of the material. Silicon carbide is designated by the letter C and is divided into black (from 52C to 55C) and green (62C – 64C).

Diamond wheels are marked as follows:

- AC2 – circle of normal strength.

- AC4 – increased strength.

- AC6 is a high-strength abrasive.

- AC32 is a monocrystalline abrasive.

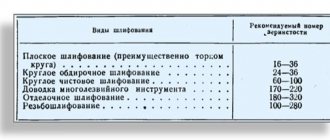

The grain size determines the cleanliness of the resulting surface. The marking indicates the size (width) of the grain. In accordance with the old GOST 3647-80, this parameter is indicated in units equal to micrometers divided by 10 (10 = 100 microns). Micropowders are marked with the letter M. According to the new GOST R 52381-2005, the grain size is indicated by the letter F and a numerical designation. Moreover, unlike the old standard, the larger the number, the smaller the abrasive grain size.

Abrasive compositions used

The initial requirements according to GOST are resistance to frictional wear (and under the combined action of high pressures and sliding speeds), low thermal conductivity and increased surface hardness.

Depending on the intensity of use, GOST 28818 allows the use of the following materials:

- Electrocorundum with a bauxite component, the basis of which is high-percentage aluminum oxide Al2O3 with the addition of calcium oxide. This chemical compound is characterized by increased hardness, which is also maintained at high temperatures occurring in the grinding or straightening zone. Marking of electrocorundum circles - from 12A...15A for normal, to 22A...25A for white. As the index increases, the strength of the wheel increases due to an increase in the hardness of the base substance.

- Electrocorundum on a carbide basis. Most often it contains carbides of chromium, titanium, zirconium and silicon. Marking starts from 38A (for zirconium) and ends at 95A (for chromium and titanium). Carbides of these metals have increased resistance to shear shear stresses, and therefore are suitable for removing surface layers of parts that have undergone heat treatment, or for straightening them. The presence of silicon carbide (marked 52C...65C) increases resistance to temperature changes.

- Spherocorundum is a material that is obtained by blowing molten aluminum oxide, resulting in the final spherical shape of the grains (in electrocorundum the grains are predominantly flat). This composition is labeled ES, and it is characterized by extremely high hardness. This circumstance allows the use of spherocorundum for grinding materials of increased hardness, including even hard alloys.

- Monocorundum (marking - 43A...45A), where the grinding grain, unlike other types, has a monocrystalline structure. This increases the durability of the abrasive composition, but at the same time increases its cost, since the technology for growing single crystals is very complex. A more accessible variety is aggregated monocorundum, which combines poly and monocrystalline sections in a certain way.

The degree of grain size is established in accordance with GOST 3647, and is also noted in the marking.

The abrasive component is fastened to the base using rings, flanges, fiberglass discs, etc.

Hardness and other parameters

Hardness is the ability of the binder to keep the grains from being pulled out, which affects the ability to self-sharpen. There are a total of 8 hardness groups according to the table below.

The next parameter is the structure of the wheel, which implies the percentage of abrasive per unit volume. The dense structure is designated by numbers from 1 to 4, medium 5 – 7, open 8 – 10 and highly porous 11 and 12.

Next comes the link designation. Ceramic is designated by the letter V or K according to the old GOST, bakelite - V (B) and vulcanite R (B). Bakelite bond with hardener is designated BF (BU), with graphite filling B4 (B4). Accuracy class AA, A and B. The most accurate is AA, wheels of this class are used in automatic lines. And the last value is the class of tool mass imbalance. Indicated by numbers from 1 to 4. This parameter does not affect the balancing of the tool assembled with flanges.

The role of ligaments

In addition to the cutting substance itself, the method by which it forms the abrasive mass is also important. GOST allows the use of bakelite or ceramics as binders. The bakelite version is good for its higher density, so the wheel has a higher mass and is suitable for working on metal, but with a limited peripheral rotation speed (especially if a hand grinder is used). The use of ceramics makes the grinding wheel lighter, and the permissible speed of its rotation on the machine increases accordingly. However, the abrasive resistance, as well as the hardness of the wheel with ceramics, are reduced.

The connection also determines the method of attachment to the base of the body. For example, film fastening is suitable for ceramic bonds, but not for bakelite bonds.

A special type of ligament is fiber. This base is used in the so-called “cold” grinding of metal on a machine or machine, when the stainless steel surface or weld area is cleaned. In this case, the material being processed practically does not heat up, since the depth of the grinding zone is insignificant (the process is actually closer to polishing). Marking is carried out in accordance with the standards of GOST R 51967.

Other types of bonds are also used to a limited extent - from various epoxy compositions, magnesite, porcelain.

Abrasive disc size

The marking of abrasive wheels by size is written as follows: DхТхН (where D is the outer diameter, T is the height, H is the diameter of the hole). The D parameter can reach a maximum size of 1100 mm, the H value can be up to 305 mm, and the T parameter varies from 0.18 mm to 250 mm.

The types of CBN and diamond discs are described in more detail in GOST 24747-90. The marking of the shape of such grinding wheels consists of three or four symbols indicating the cross-sectional shape of the body and layer, its location on the wheel, and also provides information about the design features of the body.

For example, 150x16x32 is the size of a 25A white electrocorundum abrasive wheel.

Reminder when choosing abrasive wheels:

- When choosing the diameter of the circle, you should take into account the number of spindle revolutions and the ability to provide optimal speed.

- The larger the diameter, the less specific wear of the circle. There are fewer grains on the working surface of small circles. So, during operation they wear out unevenly.

- When choosing a diamond wheel, you should take into account the width of the diamond-bearing layer. If used incorrectly, ledges may appear on the surface of the wheel.

This is interesting: Cold metal stamping: technology, types, equipment

TOP 5 best grinding discs for grinders

Rating of the TOP 5 best grinding discs in terms of price and quality ratio.

Grinding abrasive disc PRACTICA 773-590

Universal abrasive disc for angle grinders of standard assembly.

Suitable for grinding many types of materials: animal hooves and horns, soft and hard wood, particle boards, stone, brick, rubber, cork, concrete.

The grain in the abrasive mass is large (8). Weighty but easy to use disc.

The main thing: good rotations in the angle grinder (at 12,000 rpm it works perfectly, at 7,500 it slows down noticeably).

When working with soft wood (linden and others), it leaves insignificant marks if the master does not have the skill.

Don't be alarmed if the circle is clogged with tree sap; it's easy to clean out. It grips the material perfectly and can withstand both light pressure and pressure from the entire body.

In a matter of seconds, it strips off paint to putty (of any composition and number of layers), as well as the putty itself.

Specifications:

- outer diameter: 125 mm;

- landing diameter: 22 mm;

- cup type: carbide;

- gross weight: 0.32 kg.

Advantages

- when milling wood, the teeth do not fly off;

- affordable price;

- ergonomics;

- practically does not heat up during the process;

- good grain diameter.

Flaws

- severely wears out the bearings of the grinding machine;

- the coating wears off;

- Not suitable for finishing.

Diamond cup Sparta 729905

This bowl was released by a German hand tool brand. The motto is, so this small but very important detail is distinguished by excellent quality and ease of use.

Whether you need to sand granite tiles, stone, marble or concrete, she's here to help.

It easily and quickly removes a thick layer of material, so it is indispensable for roughing. It copes with sanding foundations and brick walls without any complaints.

There is no vibration during the process, so the master’s hands do not get tired ahead of time. The cup type is double-row, its base is stamped.

The number of segments is optimal (20 pcs.), the height of each does not exceed 4.5 millimeters.

Specifications:

- outer diameter: 125 mm;

- landing diameter: 22 mm;

- gross weight: 0.4 kg.

Advantages

- for intensive cleaning work;

- compact;

- strong;

- ergonomic;

- easy to find in the store.

Flaws

- for household use only;

- costs more than analogues.

Grinding abrasive disc PRACTICA 773-606

Another consumable from a domestic brand. You need to adapt to it: if you turn on the grinder at full speed, the result is unlikely to please you, but leisurely and systematic actions will lead you to an ideal result and a clean and smooth surface.

According to the properties catalog, it is suitable for working with products made of stone, concrete, rubber, cork, and fiberglass.

It can be used on different types of wood: it does not get stuck on soft wood and does not come off on hard wood.

It is also possible to remove bitumen mastic and multi-layer oil paint from floors. The grain size corresponds to the grain size of sandpaper.

The standard bore diameter is 22 mm. Flange mounted. Has all the necessary quality certificates. Country of origin: China.

Specifications:

- diameter: 125 mm;

- grain size: 24 R;

- weight: 0.33 kg;

- length: 188 mm;

- width: 153 mm;

- height: 30 mm.

Advantages

- affordable price;

- serve for a long time;

- available for free sale;

- Can process different materials.

Flaws

- working too quickly worsens the result;

- is not going to the Russian Federation.

Diamond cup Sibrtech 72955

Cup 72955 belongs to the classes of household and professional consumables, ideal for both small household and large professional work.

) knows how to keep his finger on the pulse and release a product that most consumers need on time.

With its help, you can remove sagging after formwork and welding seams, remove a thick layer of concrete, clean granite or marble slabs, stone and brick products.

Need to create a rough surface for applying construction adhesive or plaster? Perform rough processing? No problem: you can always buy this inexpensive, but ergonomic and reliable part at your nearest hardware store.

The cutting edge material is synthetic diamonds. Light weight - less than 470 g. Can be used without water cooling. The segment size is 5 mm, there are 14 of them in total. Country of origin: China.

Specifications:

- landing diameter: 22.2 mm;

- outer diameter: 125 mm;

- dimensions of the packaged goods: 130x30x170 mm;

- maximum speed: 12250 per minute.

Advantages

- convenient to grind down uneven surfaces on concrete;

- no big vibrations;

- high number of revolutions;

- sits down firmly;

- inexpensive.

Flaws

- processing dense material requires several approaches;

- you need a powerful grinder;

- Dust extraction is required.

Grinding abrasive disc AlphaDisk 770-069

An innovative product of domestic development: a roughing and grinding abrasive disc with improved performance characteristics.

Made using a unique technology: due to the fact that the disk body is connected to a tungsten carbide mass (pulse crushing crumbs), the service life is doubled compared to similar disks.

Tungsten carbide is non-toxic to people and strong. Grains with a diameter of 4 mm instantly remove the top layers from the treated surface.

Suitable for sanding wooden buildings, making grooves on logs, leveling crown grooves, leveling floors and removing old paint.

The case is metal, the holes protect it from overheating. Easy to clean with a brush.

Specifications:

- diameter: 125 mm;

- bore diameter: 22.2 mm;

- quantity per package: 1 pc.

Advantages

- does not tear on knots;

- sharp grains;

- heavy-duty soldering of abrasive to the body;

- victorious crumb.

Flaws

- cannot be used for processing metal surfaces and hard rocks;

- the price is above average.

Structure and hardness index

The density of the structure of grinding wheels is indicated by the percentage of the volume of abrasive grains per unit volume of the wheel. The more abrasive, the denser the structure of the grinding wheel will be.

When sharpening a tool, a wheel with a less dense structure is better able to clean the surface of material particles, poses less risk of deformation and cools faster.

Often, specialists use disks of medium hardness, but it all depends on the type of work being performed, the coating being processed and the tool itself.

What are the structure numbers and volumes of abrasive in the grinding wheel:

- dense structures include units of measurement from 1 to 4;

- Average density includes numbers 5-8;

- to open – from 9 to 12;

- a highly porous structure is observed in circles with indicators 13, 14>.

However, do not confuse wheel hardness with abrasive hardness. According to GOST 2424, the hardness of a grinding wheel is distinguished by a capital letter.

According to GOST R 52587-2006, there are the following designations:

- very soft - letters F and G;

- to soft circles – H, I, J;

- medium softness includes markings K, L;

- averages are M, N;

- circles of medium hardness are designated by the letters O, P, Q;

- solids are designated as R and S;

- very hard – T, U;

- Extremely hard ones include V, W, X, Y, Z.

What grinding wheel hardness should I choose? This depends on many parameters - the characteristics of the material or surface being processed, physical properties, and, of course, the power of the grinding machine. If you need to maintain the exact shape of the material being processed, you should purchase a wheel with a high degree of hardness. Soft ones are used to prevent cracks and burns, also when grinding without additional liquid-lubricant cooling of the surface.

For example, let's take the same 25A grinding wheel, which has a hardness class of K and a structure of 7. This means that this disc is medium-soft and has a medium abrasive structure.

Types of grinding wheels

According to the non-professional classification of grinding wheels, the following types are distinguished:

- Velcro discs

are made of sanding paper on a Velcro base, which is attached to the support using a self-adhesive backing. This material is considered consumable and is used in woodworking, metalworking, repair and construction. The Velcro sanding wheel is installed on a grinder or eccentric sander, as well as on a handmade drill. It is marked with a different color indicating the grain size. For example, brown is suitable for wood and metal, blue is suitable for stainless steel, and black can be used to process minerals. - The flap wheel

is fan-shaped, has good elasticity and easily adapts to any surface. It is mainly used for grinding pipes, fittings, and wood products. - A fiber grinding wheel

is a grinder equipment for processing surfaces made of ferrous and non-ferrous metals and steel. Used for cleaning weld seams and removing spatter. The fiber base for such discs is made by processing cellulose. - The diamond grinding wheel

is used for fine grinding of carbide materials, glass, ceramics, precious and semi-precious stones. The diamond blade has an optimal balance of fragility and strength and has a large working reserve.

Application of abrasive wheels

The main area of application of abrasive wheels is cleaning surfaces made of carbon steel, cast iron, plastic, non-ferrous metals, glass, iron. The tool is also used for cutting brick, tile, slate, drywall, and concrete. Products are actively used for cutting grooves and slits of various shapes and depths.

The circles that are installed on the drill deserve special attention. Such nozzles are used during repair and finishing work to clean walls before laying tiles and applying plaster. Removing paint stains, rust and other coatings is another area where abrasives can be used.