Homemade grinder attachment for chainsaw

To make a homemade device, you need appropriate pulleys, a bearing assembly with a shaft, a tire, and a belt.

According to reviews from the owners, it is quite difficult to create such a device with your own hands; you should prepare drawings and diagrams and make the appropriate calculations. If you opt out of the tire option, you can use an adapter to mount the cutting wheel directly on the clutch. At the same time, chainsaw manufacturers warn against using various adapters. This is because the saw is capable of delivering torque up to 14,000 rpm, and the sanding disc is designed to operate at 7,000 rpm. With such intensive use, disk destruction is inevitable, as mentioned above. The only way out is to significantly reduce the speed of the chainsaw by installing a gearbox.

This installation method, which is not entirely safe, is presented in the video review:

In fact, the main advantages of a chainsaw grinder are rational mobility, low cost and high power. It is very convenient to use the grinder attachment in non-electrified places. If you choose between a homemade device and a factory device, then it is wiser to give preference to the latter option, which fully complies with safety requirements.

Before converting a chainsaw into an angle grinder, you need to responsibly weigh the pros and cons, realistically evaluate your technical training and the real need to implement such a project.

– Hitachi GDSL

Price: 5200 rubles

An excellent power tool from Hitachi, with which you can cut or grind metal away from the electrical network. The model boasts extremely fast battery charging - only 45 minutes, as well as fairly compact dimensions - the length of the device does not exceed 30 centimeters, which is incredibly convenient in limited space.

The equipment of the device can hardly be called rich, but everything you need is in place - two 3Ah batteries, a charger, a key, a second handle and the grinding disc itself. The lack of keyless replacement of the attachment is unlikely to please professionals who have to quickly perform a large volume of varied work, but for household needs such a cordless angle grinder is perfect.

Hitachi G14DSL

Features of the grinder attachment for chainsaws

With the help of such a mechanism, you can combine as many as two in one device - the gasoline power of the main unit - the saw itself, and many advantages of an angle grinder, better known as an angle grinder. This combination can be extremely beneficial if there is a need to carry out cutting work with various materials and structures (not wood), and there are no power sources nearby to which a regular mains angle grinder could be connected.

A gas cutter made from a saw with an attachment can be used to cut the following materials:

- metal;

- natural stone;

- brick;

- concrete and reinforced concrete structures.

In addition, they are often used for cleaning weld seams. With most of the attachments available today, cutting wheels - reinforced or diamond - and circular saws are used.

This is interesting: Technical characteristics of popular models of alko chainsaws (al-ko)

Generator

screwdriver models

Perfect for creating a homemade generator. By rotating its handle, the device will be able to supply electrical energy. Such a generator can be used during a camping trip or when there is a power outage in a country house. A homemade generator can be used to recharge batteries (6-12V).

A screwdriver with an operating voltage of 18 V or more is suitable for the job. Craftsmen advise following the following sequence of actions:

- Disassemble the screwdriver

. - Unsolder its electrical board.

- In place of the battery, install a diode bridge that is suitable in terms of technical parameters and characteristics.

- Make an easy-to-use handle by securing it in the screwdriver chuck.

Once these simple modifications are completed, all that remains is to assemble the body. The homemade generator is ready to work.

Pros and cons of the solution

Various types of hand-held electric and gasoline tools are suitable for making grinders. The simplest and most convenient option is a device assembled on the basis of a saw with a chain. Advantages of homemade devices:

- Great power. If we compare a homemade nozzle with factory models, then its power is 2 times greater.

- Independence. The tool does not require electricity, so it can be used anywhere.

- Easy assembly. All the necessary tools and materials can be purchased at the store or searched on your farm.

- Affordable price. If you compare it with a ready-made tool, then you will need 2 times less money to assemble an angle grinder.

Despite all its advantages, the tool has a number of disadvantages. The air filters of the grinder become clogged with metal dust. Because of this, the engine gradually stalls and fails. A person can also get injured from using an angle grinder. Sometimes during operation the disks cannot withstand the load and burst. Under the influence of traction they fly apart. To protect yourself from injury, you need to choose discs up to 115 mm in diameter and use a protective cover.

Wind generator

Old battery

A screwdriver is suitable for creating a simple model of a wind generator that will look like a weather vane. It is necessary to disassemble the tool and disconnect its contacts, dismantle the mechanical elements.

Insert the electric motor shaft into the chuck, clamping it securely. Attach a metal plate no more than 1 mm thick to the gearbox with bolts, which will subsequently serve as the basis for mounting the wind generator blades.

A plastic pipe cut lengthwise into 2 parts is ideal for making blades. Place a clamp on the shaft located between the gear and the chuck. The motor and cartridge are securely attached to the base made of plywood.

You can protect the wind generator from precipitation by placing the working elements of the device in an empty aluminum container.

After making the weather vane, attach the generator to its end and connect the wiring to the engine. To check the power of a wind generator, use a multimeter by rotating the blades.

Advantages and disadvantages

An angle grinder attachment can be made from a variety of hand-held gasoline and electric tools. But the simplest and most convenient method is using a chain saw.

Advantages of the device:

- they are autonomous, that is, a gasoline device will not depend on electrical power, like electric angle grinders, which, on the contrary, need electrical sockets and extension cords;

- the nozzle can have very high power;

- it is easy to design and assemble, the main thing is to have the necessary drawings and tools, which can be purchased inexpensively at a hardware store;

- the price of homemade equipment will be cheaper than the cost of the original.

The disadvantages of homemade nozzles include the following:

- they are too sensitive to metal dust: chainsaw filters begin to become clogged and fail, and the engine may deteriorate: first it stalls, and then it will not be able to maintain speed and will wear out;

- grinding discs can constantly break and fly around, and this is very dangerous for the worker himself and the people around him.

To make your device more secure, you need to follow some rules:

- limit the engine speed of a gasoline saw;

- you need to use disks that are designed for increased rotation speed;

- work must be carried out only using a protected casing;

- the design must have an inertial brake;

- You need to use models that have a kickback protection function.

The angle grinder attachment has:

- a pulley that can wear out or break, so you need to monitor the device and, if necessary, change the pulleys on it;

- In order for the nozzle to work, it must have an adaptive key, consisting of a metal plate, having a hole and 2 steel pins;

- a special V-belt can transmit torque from the engine to the cutting wheel (the belt is a consumable material);

- For attachments such as angle grinder 1 and NK - 100, spare bearings are needed, because the bearings themselves are a consumable item.

Batteries without “memory effect”

Cordless angle grinders are equipped with the most energy-intensive batteries available at the moment - lithium-ion (Li-Ion). The latest models of lithium-ion batteries are also compact in size and light in weight.

Read also: Acetone was found in a child’s urine

In a number of modern models, full charging occurs within 30 minutes, and the presence of an additional battery allows you to avoid downtime. The conditions for recharging Li-Ion batteries do not affect their capacity and service life.

That is, the “memory effect” is completely eliminated, and they can be recharged regardless of the degree of discharge and not necessarily to the end. The self-discharge level does not exceed 5%.

Among the disadvantages is strong heating during charging, which requires certain protective measures that increase the cost. Lithium-ion batteries do not like any kind of shocks, falls, or freezing temperatures. Protective measures affect their price.

When choosing a cordless angle grinder, pay attention to the following facts. The wider the options for customizing operating parameters, the more economically you can use battery power. Multi-pin mounting reduces the likelihood of battery disconnection due to strong vibration. The brushless motor provides a long service life and high efficiency with minimal maintenance. Mechanisms for quick fixation of discs provide ease of changing equipment.

Rules for using a homemade grinder

When using a homemade tool, you need to follow a number of important rules.

Their list includes:

- When operating the device, the operator's hands and eyes must be protected. In addition, to work with the tool you will need to wear a suit made of thick fabric. It must be remembered that the cutting disc of the grinder is quite fragile to break, so at any moment a part of it can break off and cause harm to the operator;

- before using the homemade product, it will need to be equipped with a protective casing;

- You cannot install a large cutting disc on an angle grinder made from a low-power chainsaw. This will increase the load on the engine of the garden tool and lead to an increase in the amount of fuel consumed.

The tension belt plays an important role in the overall operation of the homemade device. Not only the effectiveness of the tool, but also the safety of the operator depends on its tension. To adjust the tension level of the element, you need to grab its central part and try to rotate the belt around its axis. A correctly tensioned belt will turn no more than 900. If this value is greater or less when turning the belt, then it will need to be adjusted.

Tags

cutting disc on the cutting disc cordless grinder from the cordless grinder from the cordless grinder. that the grinder is simply a cordless grinder for the grinder with your own cordless grinder from the cordless grinder with your own cordless grinder with your cordless grinder. let's make a handle. Attach the handle with the end of the handle. in the handle is a switch .to the handle with your own hands with your own hands with your own hands with your own hands cordless grinder and cordless grinder and cordless grinder. cordless grinder and cordless grinder

volt wires homemade electric motor drill devices necessary source installation

How to make an angle grinder from a chainsaw

The combination of an attachment with a saw not only allows you to effectively cut various materials, but also carry out work regardless of the availability of an electrical outlet. After all, an ordinary angle grinder, angle grinder, or grinder, as the tool is simply called, is equipped with an electric motor, and therefore is completely dependent on the power supply source.

Demand creates supply, and grinder attachments for chainsaws of various modifications have appeared on sale. And folk craftsmen mastered this niche of transformation much earlier. The most common tools used for alterations are Druzhba, Shtil, and Ural.

Finished nozzle - grinder

Creating an angle grinder from a chainsaw is one of the first places in the popularity of such transformations. However, before installing it on the saw, you should understand the features of the transformations and possible failures. As a rule, a ready-made device can be purchased without any problems at the appropriate store.

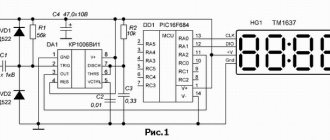

It should be taken into account that the attachment is not a universal device; it is chosen for a specific modification of the saw. Often, manufacturers do not indicate in the instructions which models the nozzle is suitable for or provide an incomplete list. To ensure compatibility, compare the diameter of the saw crankshaft with the diameter of the attachment pulley, after first removing the clutch from the saw.

To avoid injury

An angle grinder is considered one of the most dangerous tools. Indeed, if a disk breaks during operation, its fragments fly away at high speed and can cause serious damage not only to the operator, but to people nearby.

Metal and other dust generated as a result of cutting or scraping materials is dangerous. In order to minimize possible harm, it is recommended to use personal protective equipment: goggles, a respirator, gloves and thick clothing that covers the entire body.

It is extremely important to use equipment that matches the maximum speed specified for a particular model, as well as the mounting diameter and thickness. Should

carefully secure the disk, as well as the workpiece, and while working, hold the tool with both hands.

Additional Information

Compared to a regular saw, an angle grinder:

- works faster;

- takes up less space;

- increases work productivity;

- noticeably lighter;

- lasts longer (if the tool is used correctly).

To cut wood, you can use special cutting discs with a chain. However, it is very difficult to find the type of nozzle suitable for a particular model. A sawing wheel that combines the features of a disc and a special chain, suitable for processing boards no thicker than 4 cm

Extreme caution must be used when using it. It will not be possible to run the angle grinder at higher speeds than the disk allows

There is also a serious limitation on the size of the processed workpieces. To increase it, you have to use larger disks. However, their use is limited by the size of the insulating casing. And if it does not allow you to install a 125 mm nozzle, problems will arise. But peeling wheels connected to chainsaw chains allow you to remove bark and branches from the trunk.

This device will also help prepare a log house no worse than a high-quality ax. But you should not use such a disk instead of a cutting wheel. The cut line will be jagged and too much wood will be wasted. Another type of attachment - a disk with large abrasive grains - is no longer intended for primary processing, but for rough milling. This accessory is safer than a hand rasp.

For more information about chain saw attachments for an angle grinder, see the video below.

Choosing a portable angle grinder

The design features of any tool are the main parameters that characterize the product. When choosing a portable angle grinder, you need to pay attention to the following details:

- Device power. The power determines whether the tool can cope with the task at hand. The optimal power value of the unit is in the range from 0.8 to 1.2 kW. High motor power of the product will lead to rapid battery discharge

- Accumulator battery. The optimal battery option is lithium-ion filling. When purchasing products with lithium-ion batteries, you will have to overpay, but the service life of such UCBs is tens of times higher than that of nickel-cadmium ones. You can check the battery level on the battery or from the seller. The presence of two batteries in the kit will only be a big plus, but usually two nickel-cadmium batteries are included in the kit

- Unit weight. The lighter the product, the easier it is to operate, especially if you have to work with it frequently

- Number of revolutions. The lower the speed, the longer the battery will hold its charge, but the speed of work also depends on this parameter. If for grinding, then a product with a small number of revolutions is suitable, but for cutting concrete or metal, a low value of the parameter will negatively affect the speed of work.

- Product brand. It depends on the manufacturer how long the unit will operate. The modern tool market is overflowing with cheap Chinese products that are not worth purchasing for everyday use. Indeed, in addition to poor workmanship, such units can break down at the most inopportune moment.

- Price is an important parameter on which the decision to purchase an instrument depends. An angle grinder from the Einhell brand costs about 3 thousand rubles, while a similar model from the Bosch brand will cost 15 thousand rubles

Any item purchased must necessarily pay for itself, especially if it concerns tools for work. If the manufacturer gives a 1-year warranty for some models, and no more than three months for others, then you shouldn’t tempt fate, unless you need the product for one-time use. If you adhere to the above recommendations, you can purchase a tool of decent quality and at an objective cost.

Ready-made attachment - grinder for chainsaw

Today, an attachment for a chainsaw, including the “grinder” type, can be bought without any problems at any petrol tool store. There are no problems with installation either, since detailed instructions are supplied with it, after studying which you can install the grinder on the chainsaw yourself, except in cases where the attachment is chosen incorrectly.

Important: the grinder attachment is not universal; it must be selected for a specific chainsaw model. Manufacturers of attachments do not indicate in their documents a complete list of chainsaw models for which they are intended, which makes it difficult to make the right choice

How to choose a grinder for a chainsaw

When choosing an attachment for your tool, first of all, you need to read its technical documentation. If your model is not listed in the list of chainsaws for which it is intended, this does not mean that an angle grinder attachment cannot be installed on it.

To check compatibility, you need to compare the diameter of the chainsaw crankshaft with the diameter of the mounting hole on the pulley from the attachment kit (you will need to remove the clutch from the chainsaw).

The drive pulley of the nozzle can have several types; we’ll talk more about the types a little later. When choosing, it is necessary that the type of the chainsaw drive sprocket and the attachment pulley match, otherwise it is not possible to install the pulley instead of the clutch.

Types of attachment pulleys - grinders

There is no official classification of chainsaw pulleys and clutches by type, but it would be more convenient if there was one. We will try to explain the differences between the pulleys in clear language and show photographs.

Pulley type “Shtil 180” is a closed cup for installation in a regular place, instead of a clutch, combined with a pulley. The pulley is non-separable, the diameter of the mounting hole corresponds to the diameter of the crankshaft with a needle bearing installed on it. Used in Shtil MS 180, 170, 250 chainsaws.

A pulley without a cup, installed on the chainsaw drive sprocket, without removing the clutch. May have several options, depending on the sprocket pitch. The advantage of this type is ease of installation (for Shtil MS 180 with a closed clutch cup, in those chainsaws where the clutch is open, you will need to remove it for installation) and low cost (can be sold separately as spare parts). This pulley is more universal and can be used in chainsaws Husqvarna, Partner, Taiga and other Chinese analogues.

For clutches in which it is possible to replace the drive sprocket, these are most often installed on professional chainsaws; manufacturers make special pulleys. Unfortunately, we did not find a photo of a pulley with such a landing, but there is a photo of the clutch and replacement link, by looking at which you can understand what it looks like.

We looked at the most popular pulley models, but this is not all that can be found on sale.

Now we invite you to watch a video in which the master shows and explains how to make an angle grinder from a chainsaw using a purchased attachment. By the way, this video uses a rarely used and expensive pulley; it could have been replaced with a pulley without a cup, which we talked about above.

DIY installation on a chainsaw

Not everyone knows how to install a grinder attachment on a chainsaw, so we will tell you more about this.

Installation work should begin, oddly enough, with cleaning the chainsaw. It is necessary to remove the side cover, bar, chain and blow out the chainsaw with compressed air; small particles of wood are compressed and accumulated under the side cover, which can get into the bearing when disassembling the clutch.

Next, you need to unscrew the spark plug and limit the piston stroke using a piece of thin and dense rope with knots tied to it. To do this, you need to insert the rope into the cylinder through the spark plug hole. These manipulations are necessary in order to block the stroke of the piston and, accordingly, the crankshaft as safely as possible and unscrew the clutch.

Next, the clutch cup is removed from the crankshaft and, depending on the type of pulley attachment, it is either changed or a pulley is installed on it instead of the drive sprocket. Assembly is carried out in reverse order.

Now let's move on to installing the attachment itself - the grinder. It is mounted in place of the standard tire, nothing complicated, you just need to install the attachment on the two mounting screws, close the side cover and tighten it with the screws.

At the final stage, the belt is tensioned. We described above how to check the tension.

What else should you pay attention to?

Despite the fact that DIY equipment is increasingly becoming an integral part of our everyday life, leading manufacturers of both grinders and saws still strongly advise against such modernizations completely.

And the point here is not at all a matter of competition between production technologies and handicraft production. This warning is based on the fact that modern chainsaws have a very huge torque, several times higher than the same parameter for an angle grinder. What could this threaten? Firstly, the grinding disc may not withstand such a load and fall apart right in the middle of work. Accordingly, the tool itself will lose its functionality and may fail.

But this is not the worst thing that awaits lovers of homemade products. The worst case scenario is associated not only with damage to health, but also with a threat to the lives of both the operator himself and those nearby.

Therefore, before deciding on such an improvement, it is worth weighing all the pros and cons, and only then making rational conclusions and actions.

An alternative to lithium-ion batteries

The consumer knows two more types of batteries - nickel-cadmium (Ni-Cd) and nickel-metal hydride (NiMH).

The “advantages” of nickel-cadmium batteries include: resistance to low temperatures, low cost and a huge resource (up to 1500 discharge/charge cycles). But the disadvantages outweigh the advantages.

First of all, literally - Ni-Cd batteries are heavy. Secondly, they are charged only after complete discharge and always to the end, otherwise the “memory effect” kicks in and the service life decreases. (Yes, even a completely “dead” nickel-cadmium battery can be restored by service departments, but it costs money!) Finally, for reasons of high toxicity and problems with disposal, this type of battery is no longer produced in the European Union.

nickel-metal hydride (NiMH) that replaced nickel -cadmium are recyclable and are also about a third lighter and more compact. But they are also much inferior to lithium-ion ones in the number of cycles and recharge speed, and their self-discharge is still high.

Video reviews

Below is a video review demonstrating the chainsaw attachment

Alexander Mikhailovich:

Getting two tools in one is a great idea. A friend who is well versed in repairing such equipment helped me implement it. We used all the necessary parts from the angle grinder and got a multifunctional device. It works great, but I realized that it is better to install a small 115 mm disk, the work will be more efficient.

Advantages: not expensive, multifunctional device.

Disadvantages: Must be used with caution as this is a homemade device

Let's cut everything around or grinder on a chainsaw

The cutting disc is used in a large size, this is taken taking into account the maximum speed that the chainsaw can produce.

List of materials:

- plywood; - wood screws; — bolts with nuts; - thin sheet metal; - Sheet steel; - a piece of leather or thick rope; — square steel pipe; - cutting wheel.

List of tools:

- rivet gun; — drill and drilling machine; - jigsaw; - lathe; - wrenches, pliers, clutch release wrench, spark plug wrench; — belt grinder; - Bulgarian; — semi-automatic welding machine or inverter; - wood glue; - pencil, ruler, tape measure, paper.

Homemade manufacturing process:

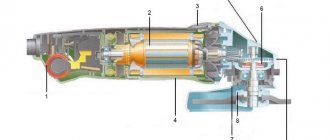

Step one. Preparing the grinder

First of all, remove the tire from the angle grinder, then you will need to remove the clutch along with the sprocket. This task can be quite difficult, since often the clutch is tightly stuck to the shaft and cannot be unscrewed without a service center. To try to unscrew the clutch, you will need a special wrench, it is similar to the one used to unscrew the nut on an angle grinder. Remove the top cover from the angle grinder and remove the spark plug.

Stick as much rope or a piece of leather into the candle hole as you can pull out. This will allow you to block the piston and try to unscrew the clutch. If it works, great!

Step two.

Thrust sleeve Step three.

Making the drive pulley Step four.

Cut out the fastener Step five.

Making a driven pulley Step six. How is the cutting disc attached?

Step seven.

Bearing platform Step eight.

Protective casing Delivery of new homemade products by mail Receive a selection of new homemade products by mail. No spam, only useful ideas!

*By filling out the form you agree to the processing of personal data

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

How to convert a chainsaw into an angle grinder?

Before you make a grinder from a chainsaw, you need to prepare the components required for the job.

To assemble a homemade product, the manufacturer will need:

engine from a chainsaw - it is important that the internal combustion engine has a reserve of power, which will be sufficient for sawing hard metal products. It is best to use a motor with a power of more than 4 liters

With.; working mechanism - a unit from any old household grinder will do. It must be fully operational, otherwise it will not withstand the load from the engine; 4 guide rails, length from 40 to 50 cm; belt; 2 reels.

The work algorithm looks like this:

- First, the belt used must be installed parallel to the standard chainsaw bar;

- After this, you will need to install a pulley on the utility saw. You can attach the element to the standard drive sprocket of a garden tool;

- Then, from the working mechanism of the old grinder, you need to remove the gear built into it and carefully grind it;

- After this you will need to assemble the pulley. It must be attached to the general structure of a homemade grinder by welding;

- The 2 guide bars remaining from the manufacturer must be shortened. As a result, they should fit tightly into the seats and not interfere with the operation of the belt while it is moving. It is best to sharpen one of the used tires for installing the working mechanism from an old grinder;

- Next, all remaining parts of the structure will need to be welded together. After this, the manufacturer will only have to buy cutting wheels and start using the grinder.

When using homemade products, you need to constantly monitor the condition of the air filter from the chainsaw. It must be kept clean, otherwise the homemade device will quickly fail.

Bench Drilling Machine

No less important in a home workshop is a drilling machine. An old screwdriver is also perfect for doing it yourself.

First you need to disassemble the tool, removing the engine, gearbox and cartridge from it. You can secure the head of the future machine using clamps made of textolite. To avoid distortions, it is recommended to process the clamps simultaneously. Restrictive posts are made of bushings with threads located in the inner part. The bushings must be the same size.

After this, you should start making 2 bosses from caprolon. A hole is drilled in their central part. The result is 2 eccentric bushings.

Install a clamp on the rod and adjust the backlash. An eccentric is used for this. To ensure the possibility of returning the drilling head to its initial position, the wooden lever is attached to a metal rod with a spring.

Electric current is supplied through the use of a transformer whose power does not exceed 150 W. Now all that remains is to install the capacitor with a diode bridge and the drilling head on the frame. The lathe is ready for use.