Peculiarities

A grinding wheel is an abrasive replaceable element used in combination with machine tools and power tools.

The classic disk shape is not always used. Grinding wheels also include diamond cups, discs and other types of hard grinding materials. Classic abrasives are presented in the form of circles containing diamond particles. High hardness makes it easy to process surfaces made of high-speed steels, as well as other alloys. To perform high-quality work and obtain the most correct sharpening, wheels with different grain sizes are used. Their production is carried out from natural or artificially obtained raw materials. Grinding wheels are produced by bonding abrasive material with binding elements and subsequent shaping.

Important point

An important point when working with equipment such as a machine paired with a grinding wheel is safety precautions. The first thing to do is to provide the person working at the machine with equipment, the minimum set of which should consist of a protective casing and safety glasses. It is worth using the tool rest as a support for the cutter, and it (the tool rest) should be fixed closer to the circle.

Watch the force with which you press the cutter; excessive pressure can lead to rapid wear of the sharpening discs, as well as the appearance of cracks on the cutter itself. If the circle makes specific sounds, such as crackling or beating, you should stop working. Take care of the ventilation of the work area to avoid excessive entry of sawed particles into the respiratory tract.

Peculiarities

Diamond blades are not only highly efficient and long lasting, but also self-sharpening, combined with a perfect balance between strength and brittleness. The tool is used not only in industry, but also in everyday life.

The discs themselves are made of aluminum alloys or steel. A thin layer of a special composition of bakelite resin with the addition of diamond chips of various fractions is applied to the surface of the workpieces. It should be noted that so far the industry has not invented anything that is superior in hardness to the diamond version of the abrasive. The closest value is only cubic boron nitride - borazone, elboron. The remaining abrasive substances are not at all competitors in the processing of ferrites, metal-ceramic composite and other hard-alloy materials.

Semi-automatic sharpening machine Wood-Mizer BMS250 and its characteristics

In the BMS250 sharpening machine, the band saw blade is sharpened with a CBN harrow sharpening disc, which is shaped to match the Wood-Mizer tooth profile. This disc does not need to be edited. Its use allows it to perfectly maintain the established tooth profile and the cutting edge of the tooth. Wood-Mizer supplies CBN harrow blades in five tooth profiles: 10/30, 9/29, 13/29, 4/34, 7/34.

The BMS250 semi-automatic band saw sharpening machine is equipped with a 0.18 kW electric motor with a rated speed of 2800 rpm. This motor rotates the CBN boron grinding wheel. The engine is firmly fixed, and the position of the saw in the clamping mechanism is height adjustable. The engine is highly resistant to oil, metal dust and abrasive material.

When installing the band saw, the head of the sharpening machine rises up.

The second saw feed motor is securely sealed with a sealed casing to prevent the entry of sharpening waste, which increases the service life of the motor. The sharpening process is stopped under the influence of a magnetic sensor that the operator attaches to the saw.

The sharpening machine is equipped with an exhaust port to remove gaseous waste; an aspiration system is connected to the hole.

During the sharpening process, a special coolant, also supplied by Wood-Mizer, is used to cool the CBN harrow disc and remove metal filings from its surface.

The Wood-Mizer company offers a proprietary set of equipment for sharpening and setting band saws, which, in addition to the BMS250 sharpening machine, includes a BMT100 manual setting device.

Main characteristics of the tool

The equipment consists of a base on which a layer of powder is applied. The requirement for the selection of products for surface treatment is that the hardness of the tool should be higher compared to the workpiece.

If the difference is significant, overheating and thermal defects are possible. A small difference leads to tool failure or reduced productivity.

Features of the diamond-containing layer

The weight of a solid mineral is measured in carats. One carat is equal to 0.2 g. The grains are intergrown diamond crystals. The main characteristics of products include the size and density of particles. To hold diamonds in the working layer, binders are used, of which there are three main types.

Organic components emit little heat and are practically not salted. The advantages of the binder include strong retention of grains, including the fine fraction, which is why the equipment is used for finishing operations. The disadvantage is increased wear resistance.

Metal particles give the working layer strength; upon contact with the part, the powder heats up. Equipment with a bond made of bronze, aluminum, copper and other metals is prone to clogging and requires frequent editing.

The peculiarity of using tools with ceramic powder is for finishing viscous materials. Abrasive products are used for simultaneous processing of steel and hard alloys.

Uniformity and grain concentration

When producing powders, the compositions are divided into fractions. For this purpose, sieves with special cells are used. Product labeling is a fraction. The numerator is the size of the sides of the holes in the upper sieve, the denominator is the parameter of the lower cells.

When processing round parts, the contact point with the tool is minimal. In this case, choose abrasive products in which the working layer contains a high concentration of solid inclusions.

The uniformity and mass fraction of the abrasive affect labor productivity, the cutting ability of the tool and the surface cleanliness of the part.

Types of work: with and without cooling

Water-cooled grinding is preferable because stronger machining conditions can be applied and the wheel wears less. This also reduces the possibility of burns and other thermal damage to the treated surface. Not water, but 1-5% emulsion is used as a coolant for grinding wheels.

For wheels with a metal binder, it is recommended to use BV lubricant, a 1.5-3% emulsion obtained from the NGL-205 emulsion, or from the “Akvol 10” emulsion. For wheels with an organic binder, use a 3% emulsion from industrial oil, soda ash in the form of a 0.5:1.0% solution, 0.1% wetting agent OP10 or OP7, or an emulsion obtained from borax, sodium nitrate, triethanolamine and trisodium phosphate.

Main characteristics

One of the main characteristics is the hardness index. The next important indicator is the concentration of diamonds per cubic centimeter, measured in carats. Standard-type indicators for these values according to the current GOST: K25 (1.1 ct/cm3), K50 (2.2 ct/cm3), K75 (3.3 ct/cm3), K100 (4.4 ct/ccm3), K125 (5.5 ct/cm3) and 150 (6.6 ct/cm3). However, the concentration may change up or down.

The importance of this value is that it has a significant impact on some technical indicators of the disk and its cost. Designs with a hard bond and a low diamond layer are designated K125

The distribution and fixation of carbon grains on the working layer is helped by a binding composition, the so-called binder. In production technology, three basic types of bonds are used.

- Metal. A working layer of this type is most suitable for pre-processing, sharpening parts made of cermets and hard alloys, and cutting off large layers of allowance.

- Galvanic. Metal body with one or more layers of nickel, coated with carbon abrasive. Designed for cutting, grinding mineral materials. In demand in the production of diamond drilling units, final finishing of punches, etc.

- Organic. When creating an organic composition, bakelite is used using formaldehyde resins. Its characteristic feature is low thermal conductivity; such devices are used in operation without coolant supply. As a rule, this is finishing grinding and finishing.

Another parameter that affects the performance characteristics of the device is the type of diamond layer and its width. The abrasive is applied to the peripheral or end part of the diamond wheel. It is the geometry that affects the amount of abrasive and the cost of the model. Height is a value that determines the durability of the structure, while the width determines the size of the area in contact with the workpiece, and therefore the temperature of the working elements and other components. The narrow width allows for increased cutting speed and depth. Large widths mean high precision and clean work.

Diamonds for emery can be 125 mm in size. The marking 150x10x3x32 means a disk with a diameter of 150 mm, a width of 10 mm, a height of 3 mm and a mounting hole size of 32 mm. The same approach is required to decipher the characteristics of grinding diamonds 150x20x5x42x32; 150x20x3x40x32.

Shallow plate. Marking 12A220

In appearance, the plate differs noticeably from the cup in depth; as a rule, the height is only 18 mm. In the other everything is standard, diamond grinding wheel 12A220 150*10*2*18*32 160/125 - plate with a diameter of 150 mm, width of the diamond layer 10 mm, thickness 2 mm, depth - 18 mm (shallow), fit 32 mm. Grain 165/100 is quite coarse compared to others.

Plates come in 150 mm and 125 mm diameters.

They are excellent for sharpening tools; moreover, they can be used to sharpen carbide tips on circular saws. In order to sharpen such tips, you will need a thin plate so that the edge can fit between the teeth.

Grinding wheel grit

Certain numerical values are also used to indicate the grit size of the grinding wheel; they are presented in the following table:

| GOST | 12 | 16 | 25 | 40 |

| FERA | 100 | 80 | 60 | 40 |

As the number according to GOST increases, the size of the grains used in the manufacture of the wheel also increases, as well as the degree of penetration and feed when sharpening a band saw. However, the quality of the treated surface will be better when using fine-grained abrasive wheels.

Grinding wheel hardness

This indicator affects the self-sharpening ability of the abrasive wheel. When sharpening a band saw, the edges of the dull grains are chipped off and removed, thereby revealing new working layers of the wheel.

During the turning process, a harder wheel will hold its shape better, but its chamois will already become dull. To maintain high quality work, you will have to use more power and less feed. However, this may result in burns and risks. In addition, the relatively soft saw material will clog the pores of the wheel, which will affect the quality of sharpening.

If you use a sharpening wheel that is too soft, the bond may hold the grains very weakly, so they will begin to crumble from the body of the wheel. Soft circles will quickly lose their shape and wear out.

When working, the main thing is to choose the right level of hardness of the grinding wheel, and for this you should use the data in the table:

| GOST | M1, M2, M3 | SM1, SM2 | C1, C2 | ST1, ST2, ST3 | T1, T2 |

| FERA | Y, I, J | K, L | M, N | O, P, Q | R, S |

| Hardness | Soft | Medium soft | Average | Medium-hard | Solid |

Our main profiles for narrow band saw blades:

| Saw manufacturer | Disk profile | |

| Step 22 | ||

| Wood -Mizer (WM) summer, Cayman Silver, Ro-Ma, Armoth, Horns, Fenes, Krupp, Lynx, Alligator, Morse | 10/30-6.5 | 1 |

| Wood-Mizer (WM) summer reinforced | 13/29-6.5 | 16 |

| Wood-Mizer (WM) summer reinforced deep | 13/28-7.4 | 21 |

| Wood-Mizer (WM) winter | 9/29-5.5 | 19 |

| Wood-Mizer (WM) winter special | 7/29-5.5 | 25 |

| Carl Rontgen CR-400 | 13/27-6.0 | 26 |

| Wood-Mizer (WM) winter for frozen wood | 4/32-5.5 | 39 |

| Lenox, Nook | 10/30-6.8 | 2 |

| Carl Rontgen CR-300, HWSM, Banholzer (old profile until 2020! New - No. 128) | 10/28-5.8 | 3 |

| Banholzer (Banso) (new, from 2022! Previously No. 3) | 10/30-6.5 | 128 |

| Simonds (old profile until 2022! New - No. 119) | 10/29-5.3 | 8 |

| Simonds (new profile from 2022! Previously No. 8) | 9/30-6.3 | 119 |

| Hakansson | 10/31-7.3 | 9 |

| Diamond | 10/30-5.5 | 14 |

| MFS (Uddeholm) summer | 10/30-6.1 | 18 |

| MFS (Uddeholm) winter | 8/30-6.1 | 28 |

| MFS (Uddeholm) summer | 12/30-6.1 | 29 |

| MFS (Uddeholm) winter for frozen wood | 4/32-6.1 | 30 |

| MFS (Uddeholm) winter for frozen wood | 7/29-6.1 | 31 |

| Bimetal Lenz | 10/30-6.5 | 33 |

| Bimetal Bahco (old profile until 2022! New - No. 108) | 10/30-6.3 | 34 |

| Bahco winter bimetal (old profile until 2022! New - No. 121) | 9/29-6.3 | 35 |

| Bahco winter bimetal for frozen wood (old profile until 2022! New - No. 122) | 4/32-6.3 | 36 |

| Bimetal Bahco (new profile from 2022! Previously No. 34) | 10/30-6.5 | 108 |

| Bahco winter bimetal (new winter profile from 2022! Previously No. 35) | 9/29-6.5 | 121 |

| Bahco winter bimetal for frozen wood (new winter profile from 2022! Previously No. 36) | 4/32-6.5 | 122 |

| Step 19 | ||

| Lenox, Simonds | 10/30 5.8 | 10 |

| Hakansson | 10/30-6.2 | 11 |

| Step 25 | ||

| Hakansson, HWSM, Simonds | 10/30-8.4 | 12 |

| Lenox | 10/30-7.7 | 15 |

| MFS (Uddeholm) | 10/30-6.7 | 32 |

| MFS (Uddeholm) | 9/29-7.7 | 116 |

| Explanation of the value 9/29-5.5 : 9-front corner, 29-back corner, 5.5-depth. | ||

Types of grain size depending on the type of processing

According to the international standardization standards FEPA, the marking of a diamond sharpening tool must contain a grit code: a combination of the letter F and a certain number following it. An increasing number indicates the presence of finer grains in the abrasive. To choose the right wheel for sharpening, you need to know the grade of material, what roughness you need to achieve in the end, and the allowable allowance.

There is an inversely proportional relationship between the grain size in the abrasive and the cleanliness of the metal surface after processing. Therefore, for finishing work, grinding wheels with the smallest diamond grains are used.

Based on the size of the grain fraction, it can be classified as one or another type of grain size:

- 100/80 – fine diamond grains. They are used to perform final finishing of thin blades, sharpening of metalworking cutters, and finishing grinding operations.

- 125/100 – medium diamond grains. Sharpening products to the required sharpness.

- 160/125 – large.

- 200/160 – very large diamond grains. Abrasives are suitable for smoothing the surface of a cutting tool.

Proper processing

After processing, the part should have a convex edge; unnecessary irregularities should also be avoided, as they can easily ruin the part. To achieve a smooth edge, you should keep the tool in constant motion.

This processing technique will extend the life of the discs. The sharpening disc can be used in two ways when processing cutters, both dry and with water. In the latter case, make sure that the stream is large enough and the water will flow continuously.

Upon completion of processing, finishing touches may be required. For it, copper circles or a fine-grained whetstone are used. In addition to tools, technical oil and carbide paste are used.

Design of diamond wheels for tool sharpening

The disc brand is characterized by:

- the configuration of the body and the type of material from which it is made;

- circumference size;

- the concentration of abrasive grains;

- diamond fraction;

- the type of substance used as a binder;

- degree of accuracy;

- class of imbalance.

One of the important parameters is the wear resistance of the disc.

The bodies of diamond grinding wheels can be made of steel blanks, grades St-25, 30, 20 or 3, or aluminum alloys AK-6 or D-16, or polymer materials. For some grinding wheels of type A1PP, AGC, shanks are also made from steel grades U7 and U8.

As for the binders used, which hold the diamond grains together into a single form, discs are produced based on:

- Metallic bonds based on aluminum, copper, zinc or tin. The marking of such products indicates the letter M.

- Ceramic bundles based on fireclay or glass, to which an aluminum component is added. The marking here will contain the letter K.

- Organic-based binders are pulverbakelite and carbolite substances. The presence of such a link is indicated in the marking code by the letters KB.

Electrocorundum, graphite powder, copper, boron carbide and alumina are used as fillers.

Safety at work

Operations involving grinding and cutting equipment have several hazards. This is the rotation of the device, the possibility of destruction of the disk while moving, the threat of touching rotating equipment. To maintain health, you need to fulfill the following requirements:

All work on electrical grinding equipment begins after checking the cable insulation, the presence of grounding, and the serviceability of the emergency shutdown button. Make sure that the wheels are in good condition: there are no cracks, chips, wear. Check the operation of the supply and exhaust ventilation. Overalls must be tucked in, long hair must be hidden under a cap. Before starting grinding, wait 2-3 minutes while the machine is running idle.

This will help identify hidden defects. While working, pay full attention to the operation being performed. Do not work without protective glasses or masks. Replacing abrasive wheels is only possible when the equipment is switched off. All rotating mechanisms are protected by casings, and the circles themselves are protected by transparent screens. When lifting these guards, the operation of the machine must be blocked by switches. When not working, the shields must be raised.

Modern grinding tools and machines greatly facilitate human work. And the correct choice of equipment will allow you to perform cleaning operations with the maximum level of cleanliness.

WATCH THIS USEFUL VIDEO:

Emery wheels for sharpening machines (emery).

Grinding sanding wheels tend to wear out, so they have to be replaced from time to time.

There are two main types of grinding wheels: - white (electrocorundum white), marked 25A. -green (silicon carbide green), marked 64C.

The white circle is intended for household work, sharpening such household products - axes, kitchen knives, shovels, etc.

Read also: Homemade pressure switch for a compressor

The most commonly used diameter of the sanding wheel is 200mm and thickness is 20mm.

The green wheel sharpener is intended for sharpening tips on cutters, on circular saws, sharpening drills for metal, etc. PP wheels with a diameter of 300-350 mm are mainly used, as well as cup and disc wheels.

Sharpening sandpapers have different grains: 8N, 12N, 16N, 25N, 40N. The higher the number, the larger the grain and, accordingly, the rougher the processing.

The coarser the grain of the grinding wheel, the faster the metal layer is ground off; the finer, the slower, but the edge will be smoother and sharper.

There are special emery grinding wheels for saws, their edges are made at an angle for easy sharpening of teeth.

Owners who prefer to make something instead of staring uselessly at the TV screen manage to set up micro-workshops even in apartments. God himself ordered people who have a private home or live in rural areas to acquire a solid set of tools and the simplest devices.

The sharpening machine, popularly called a sharpener, is so versatile that it is one of the first to appear in the workshop. Indeed, a sharpener will help to fit a handle to a shovel for a gardener, cut a groove in a printed circuit board for a radio amateur, make a punch from a piece of wire or fittings for a car owner, as well as many other operations. Its working body is an emery wheel, the characteristics of which will be the subject of discussion in this publication. Here you will also find tips on choosing the optimal abrasive for sandpaper in accordance with the purposes of their use.

Let's sum it up

Let's summarize. What should you pay attention to when choosing a diamond wheel for sharpening a tool or for other work in general? There are two main parameters that should never be overlooked: the type of material to be worked with and the cutting machine. The device on which the disc will be used should be taken into account so that its diameter matches the diameter of the machine and the disc can be used safely. It is worth taking into account the material, because it is this that determines the desired shape of the teeth of the sharpening disc. By choosing the wrong teeth, you can significantly reduce the speed and cleanliness of machining.

When installing the wheel on the equipment with which it will be used, it is worth making sure that the disk rotates in the same direction as the machine shaft, and they must also have the same rotation speed. The arrow located on its body or information sticker will tell you how the disk should rotate correctly.

If there are no markings on the diamond blade itself, carefully read the instructions or other documentation that comes with it. By following these simple rules, you can ensure efficient and safe work. Don't forget about safety precautions too!

Photos of good grinding wheels

What is a grinding wheel

It is an abrasive tool for processing products both on stationary machines and using hand tools. There are several parameters by which grinding wheels can be classified.

For their manufacture the following can be used:

- silicon carbide;

- diamond of artificial or natural origin;

- electrocorundum;

- elbor.

Depending on the grain size, the discs differ in their purpose. Between the grains there is an adhesive and filling composition - a binder, which gives it abrasive properties due to the pores. The abrasive removes particles from the material being processed.

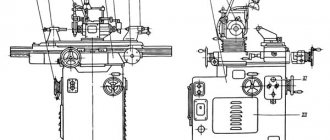

Vertical or horizontal type, what to use

There are several types of boring machines: vertical, diamond, horizontal and coordinate. The equipment is selected taking into account the material that will have to be worked with, as well as based on the needs that the worker pursues. When processing a cutter at home, it is possible to use a grinder, but this method carries a high level of possibility of injury. Sharpening a lathe cutter should be carried out following a certain algorithm.

The first thing to do is to go over the main and auxiliary rear surfaces with the disk, then move to the front surface and only after that start processing the rounding of the ring.

Application of grinding wheels depending on grain size

The choice of grain size is determined by the task at hand. There is a marking on the back or front side indicating the size of the abrasive grain.

The smaller the number on the marking before the letter P, the rougher the grinding wheel is intended for work. Below are the purposes of the discs depending on the grain size:

- grain from 16 to 36 – flat grinding with the end part of the disc;

- 24-36 – circular peeling with the plane of the disk;

- 60-120 – fine circular grinding;

- 170-220 – sharpening of knives, drills, cutters;

- 180-320 – final grinding and finishing.

Discs with coarse grains are used primarily on powerful stationary machines, while fine-grained ones are often used on hand-held angle grinders for painstaking and precise work on finishing and polishing products.

When carrying out work, you should adhere to safety rules - use safety glasses and a respirator to protect your respiratory system from dust particles.

Purpose of abrasives

Depending on the type of abrasive from which the grinding wheel is made, the scope of its application changes.

Normal electrocorundum has good viscosity, adhesion to the binder, and is heat-resistant and is well suited for working with steel, cast iron, bronze and brass due to its physical properties.

White electrocorundum has a more uniform structure, sharp edges, is harder than ordinary corundum and has less surface roughness. Designed for processing the same materials as conventional electrocorundum, but due to less heating and wear, it is also used for alloy and tool steels, sharpening saw teeth, cutting edges of milling cutters, knives, drills. Well suited for polishing products.

Silicon carbide is harder, but more brittle than electrocorundum. It has a higher abrasive ability, but the adhesion of the grain to the binder is weaker than that of corundum.

Diamond has great mechanical strength, but is sensitive to high temperatures, reacts with iron, is brittle, and has very good self-sharpening properties, which gives the blade durability.

Diamond grinding wheels are used for processing materials such as cast iron, glass, ceramics, and hard alloys. Well suited for finishing products, sharpening drills, cutters, saws, knives.

Elbor is second only to diamond in hardness, does not react with iron, is heat-resistant, fragile, and has good abrasive ability.

Used for grinding and processing of hard steels, tool sharpening, finishing, the scope of application of CBN includes areas where other abrasives are not used due to high operating temperatures.

What to consider when choosing

The first difference is the type or shape of the disk. There are 3 shapes: cup, plate shape or flat. The shape of the cup is deep, well suited for working with cutters, knife blades, soldering and other similar devices, suitable for surface grinding. It is the cup shape that is used when working with hard non-metals such as ceramics, stone and even glass.

Plate - has less depth, but otherwise can have the same characteristics as the first type of circle. Well suited for carbide-tipped saws, meat grinder elements, and also, if the disc is thin enough, for sharpening chainsaw chains. The plate removes remaining paint or varnish; it works well when working with art glass, mosaics, and can be used as a polishing tool.

Accuracy and imbalance classes

According to GOST, the marking of grinding wheels with traditional abrasives must include the designation of accuracy and imbalance classes (the last two positions of the marking line). For diamond wheels, GOST does not provide for these parameters. Firstly, this is a tool with a small (in relation to the total volume of the body) layer of abrasive composite, and secondly, according to the requirements of state standards, it is manufactured with standardized high accuracy. For example, the face and radial runout of diamond wheels, according to the requirements of GOST 16181-82, must correspond to 7 ÷ 8 degrees of accuracy.

What to look for when choosing a diamond blade

Diamond wheels, in turn, also differ in several points that you should pay attention to when choosing the device you need. The circles may differ in width, thickness and diameter of the diamond layer, and other aspects. Note that the greater the thickness and width of the diamond layer, the more expensive the disc will be, but the slower it will wear out and become dull.

In order to choose the right disc, you should pay attention to the information label, which is often located on the outside of the disc. On it you can find information on all points of the device’s characteristics: size, structure, grain size, maximum allowed speed, hardness, accuracy and others. There are two main differences: the type of wheel and its grit level.