High molecular weight compounds. Polymerization and polycondensation reactions. Polymers. Plastics, fibers, rubbers.

| High-molecular substances consisting of large molecules of a chain structure are called polymers (from the Greek “poly” - many, “meros” - part). |

For example , polyethylene obtained by polymerization of ethylene CH2=CH2 :

…-CH2-CH2-CH2-CH2-CH2-CH2-CH2-… or (- CH 2 - CH 2 -) n

A polymer molecule is called a macromolecule (from the Greek “macro” - large, long). The molecular mass of macromolecules reaches tens - hundreds of thousands (and even millions) of atomic units.

The compounds from which polymers are formed are called monomers .

For example , propylene (propene) CH2=CH–CH3 is a monomer of polypropylene

A group of atoms repeated many times in a chain macromolecule is called its structural unit .

| Monomers are low molecular weight substances from which polymers are formed. |

The degree of polymerization is a number indicating the number of elementary units in a polymer molecule.

The degree of polymerization is usually indicated by the index “n” behind brackets that include the structural (monomer) unit: (– CH2–CH2–)n.

Polymers whose macromolecules are built in a strictly defined way are called regular .

A polymer is called stereoregular if the R substituents in the main chain of macromolecules (–CH2–CHR–)n are arranged in an orderly manner.

Stereoregular polymers have much better properties - plasticity, strength and heat resistance; they are capable of crystallizing, unlike irregular ones.

Classification by structure

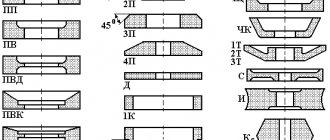

Based on their structure, polymers are divided into: linear, branched and spatial.

| Linear | Branched | Spatial |

| They consist of a sequence of repeating units with a large ratio of the length of the molecule to its transverse size. Cellulose, low-density polyethylene, nylon | Branched macromolecules have side branches from a chain called the main or main starch | There are also chemical bonds between the chains, forming a spatial structure Rubber, |

Linear - macromolecules consist of a sequence of repeating units with a large ratio of the length of the molecule to its transverse size (cellulose, low-density polyethylene, nylon).

Branched - macromolecules of which have side branches from the chain, called the main or main one (starch).

Network (spatial) - chemical bonds are also present between chains (rubber, phenol-formaldehyde resins).

Organoelement compounds

Organoelement IUDs, whose macromolecules include, in addition to atoms of inorganic elements - silicon, titanium, aluminum - and organic hydrocarbon radicals, are created artificially and do not exist in nature. The classification of polymers divides them, in turn, into three groups.

- The first group is substances in which the main chain is composed of atoms of some elements surrounded by organic radicals.

- The second group includes substances with a main chain containing alternating atoms of carbon and elements such as sulfur, nitrogen and others.

- The third group includes substances with organic main chains surrounded by various organoelement groups.

An example is organosilicon compounds, in particular silicone, which has high wear resistance.

Inorganic high-molecular compounds in the main chain contain oxides of silicon and metals - magnesium, aluminum or calcium. They do not have side organic atomic groups. The bonds in the main chains are covalent and ionic-covalent, which determines their high strength and heat resistance. These include asbestos, ceramics, silicate glass, quartz.

Classification by origin

Based on the method of production, polymers are divided into: natural, synthetic and artificial.

| Natural fibers | Synthetic fibers | Artificial |

Directly exist in nature

| Obtained entirely chemically in polymerization and polycondensation reactions

| Obtained by modification of natural polymers

|

Natural polymers directly exist in nature (starch, cellulose, etc.).

Synthetic polymers are obtained entirely chemically through polymerization and polycondensation reactions (polyethylene, polyvinyl chloride, phenol-formaldehyde resins, methyl methacrylate, etc.). They have no analogues in nature.

Artificial - obtained by modifying natural polymers (viscose - modified cellulose, rubber - modification of natural rubber).

Synthetic production

Humanity uses different methods for producing artificial polymers:

- a peculiar extraction of them from organic low-molecular compounds;

- processing of natural organics into unnatural materials.

As the initial product for the formation of synthetic chains, various materials are taken, which are the end results from the processing of gas elements, petroleum products and coal (phenols, acetylenes, benzenes and ethylenes). The result generally depends on the appearance of the starting substances. Their designation gives the name to the polymer.

Synthetic polymers are formed by a synthesis reaction. Fibers are produced from a melt, as well as from a solution using the dry or wet method.

The use of synthetic fibers is gaining significant momentum in contrast to the production of artificial fibers. This is explained by the availability of primary raw materials and the vastness of their properties and useful qualities. This makes it possible to obtain products with different properties, while the ability to modify the properties of artificial fibers is extremely small and sometimes even non-existent.

Classification by chemical character

According to the chemical nature and composition, polymers and chemical fibers are : polyester, polyamide, organoelement (for example, organosilicon polymers).

| Polyester polymers | Polyamide polymers | Organoelement |

| Contains the -COO- Lavsan group (polyethylene terephthalate) | Contains the group -СО-NH2— Nylon, nylon | Contain atoms of other chemicals. elements (silicon, etc.). Organosilicon polymers |

Polyester polymers - contain the group of esters -COO-.

Polyamide polymers - contain a peptide bond -CO-NH2-.

Organoelement polymers contain atoms of other chemical elements (in addition to C, H, O, N).

Organic high molecular weight compounds

Thanks to their unique properties, high-molecular compounds successfully replace natural materials such as wood, metal, stone in various spheres of life, conquering new areas of application. To systematize such a large group of substances, a classification of polymers according to various criteria has been adopted. These include composition, method of preparation, spatial configuration, and so on.

The classification of polymers according to their chemical composition divides them into three groups:

- Organic high molecular weight substances.

- Organoelement compounds.

- Inorganic high molecular weight compounds.

The largest group is represented by organic IUDs - resins, rubbers, vegetable oils, that is, products of animal as well as plant origin.

The macromolecules of these substances in the main chain, along with carbon atoms, contain atoms of oxygen, nitrogen and other elements. Their properties:

- have the ability to reverse deformation, that is, elasticity under low loads;

- at low concentrations they can form viscous solutions;

- change physical and mechanical characteristics under the influence of a minimum amount of reagent;

- under mechanical action, directional orientation of their macromolecules is possible.

Classification by method of production

Polymers are produced either by polymerization or by polycondensation.

| Polymerization | Polycondensation |

| This is the joining of some molecules to others due to the breaking of multiple bonds. By-products, as a rule, are not formed. Polyethylene, polypropylene, etc. | Polymer formation occurs due to a substitution reaction. This produces a low molecular weight by-product. Phenol-formaldehyde resin, nylon |

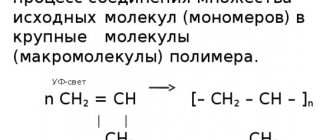

| Polymerization is the process of formation of a high-molecular substance (polymer) by repeated addition of monomer molecules to active centers in a growing polymer molecule. |

For example , the formation of polyethylene occurs according to the polymerization mechanism:

| Polycondensation is the process of formation of high-molecular compounds, which occurs through the substitution mechanism and is accompanied by the release of low-molecular-weight by-products (usually water). |

For example , the formation of nylon proceeds through the polycondensation mechanism:

Combustion of synthetic fibers

In order to have a good understanding of various types of synthetic fabrics, it is useful to know the characteristics of their combustion in a flame.

| Nylon, nylon | Melts to form a resin, a melted brown ball is formed at the end, the smell of sealing wax is felt |

| Polyester, lavsan | Burns with a yellow, smoky flame, black acrid smoke is released, and a dense, non-fragmentable ball is formed at the end |

| Spandex | Burns like lavsan |

| Nitron, acrylic | Burns with a yellow, smoky flame with flashes, forming a hard ball at the end, partially rubbed with fingers |

| Chlorine | Does not burn; when placed in a flame, the fiber shrinks, becomes charred, and smells of chlorine. |

| Vinol | When added to the fire, it shrinks, then burns with a yellow flame with slight soot, after extinction, a solid light brown residue remains |

| Polypropylene | Poor combustion support, inactive flame, no soot formation |

Properties of polymers

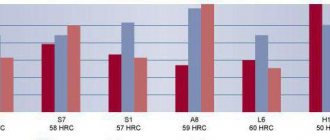

Based on their properties, polymers can be divided into : thermosets, thermoplastics and elastomers.

| Thermoset | Thermoplastic | Elastomers |

| Infusible and inelastic materials. Phenol-formaldehyde resins, polyurethane | They change shape when heated and retain it. Polyethylene, polystyrene, polyvinyl chloride | Elastic substances at different temperatures. Natural rubber, polychloroprene |

Thermosetting polymers are plastics, the processing of which into products is accompanied by an irreversible chemical reaction, leading to the formation of an infusible and insoluble material.

For example , phenol-formaldehyde resins, polyurethane.

Thermoplastic polymers change shape when heated and retain it after cooling.

For example , polyethylene, polystyrene, polyvinyl chloride, etc.

Elastomers – have highly elastic properties over a wide temperature range.

For example , natural rubber.

Thermoplastics

The classification of plastics distinguishes another type - thermoplastics. Their peculiarity is that these materials melt under the influence of high temperatures, but when cooled they quickly return to their original state. The molecular chains of this type of plastic are either slightly branched or linear. When a product is exposed to low temperatures, it is brittle and hard. This is due to the fact that the molecules are placed extremely tightly to each other, which almost completely limits their movement. As soon as the temperature rises slightly, the molecules are able to move, which significantly weakens the bond between them. During the described process, the material becomes more plastic. If the temperature continues to increase, then the intermolecular bonds finally weaken, and now they slide past each other. At this time, the plastic becomes viscous and incredibly elastic. If the temperature is lowered, then all these processes will reverse.

If the temperature is controlled in such a way as to prevent overheating, which provokes the breakdown of the molecular chain, then the processes described above can be repeated an infinite number of times. Using these properties of plastics in this category, they are repeatedly processed into a variety of products. This allows for less environmental pollution, because plastic waste in the soil takes one to four hundred years to decompose.

Moreover, thanks to the features described above, thermoplastics can be easily soldered or welded. Any mechanical damage can be corrected by proper temperature exposure.

The use of plastics of this type is widespread in the automotive industry (manufacture of wheel covers, bumpers, panels, lamp housings, frames, exterior mirrors, bumper grilles, and so on).

Main thermoplastics:

- polyvinyl chloride;

- polyvinyl acetate;

- polyoxymethylene;

- polypropylene;

- polyamide;

- copolymers of butadiene, styrene and acrylonitrile;

- polycarbonate;

- polystyrene;

- polyethylene;

- polyvinyl acetate.

Polymerization

The degree of polymerization is a number showing how many monomer molecules are combined into a macromolecule.

The degree of polymerization is usually indicated by the index “n” outside the brackets, which include the structural (monomeric) unit: (– CH 2 – CH 2 –) n

Characteristic signs of polymerization.

|

Polymerization catalysts can be: sodium metal, peroxides, oxygen, organometallic compounds, complex compounds.

The process of formation of high molecular weight compounds by the joint polymerization of two or more different monomers is called copolymerization .

For example , a scheme for the copolymerization of ethylene with propylene:

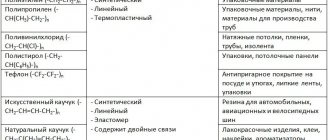

The most important synthetic polymers

Image from the portal orgchem.ru

The most important synthetic polymers obtained by the polymerization reaction and their areas of application:

| Polymer | Monomer | Polymer characteristics | Application of polymer |

| Polyethylene (–CH2–CH2–)n | Ethylene CH2=CH2 | Synthetic, linear, thermoplastic, chemical resistant | Packaging, container |

| Polypropylene | Propylene CH2=CH–CH3 | Synthetic, linear, thermoplastic, chemical resistant | Pipes, packaging, fabric (non-woven material) |

| Polyvinyl chloride | Vinyl chloride CH2=CH–Cl | Synthetic linear polymer, thermoplastic | Stretch ceilings, windows, film, pipes, floors, electrical tape, etc. |

| Polystyrene | Styrene | Synthetic linear polymer, thermoplastic | Packaging, dishes, ceiling panels |

| Polymethyl methacrylate Methacrylic acid methyl ester | Synthetic linear polymer, thermoplastic | Glasses, headlight and lamp housings, shower cabins, furniture, etc. | |

| Teflon (polytetrafluoroethylene) | Tetrafluoroethylene | Synthetic linear polymer. Thermoplastic (t = 260-3200C) Has very high chemical resistance | Dishes, iron plates, tapes and tape, packaging, insulation |

| Artificial rubber Monomer: butadiene-1,3 (divinyl) | Synthetic, linear, elastomer, contains double bonds | Rubber, insulation, various materials, rocket fuel | |

| Natural rubber Monomer: 2-methylbutadiene-1,3 | Natural, linear, elastomer, contains double bonds | Rubber, insulation, various materials, rocket fuel | |

| Chloroprene rubber Monomer: 2-chlorobutadiene-1,3 | Synthetic, linear, elastomer, contains double bonds | Rubber, insulation, various materials, rocket fuel | |

| Styrene-butadiene rubber Monomers: 1,3-butadiene and styrene | Synthetic, elastomer | Rubber, insulation, various materials, rocket fuel | |

| Polyacrylonitrile | Acrylonitrile | Synthetic, linear | Fibers, plastics |

Application

Without exaggeration, we can say that polymers have found application in absolutely all areas of human activity and life. Synthetic polymers are used in everyday life and industry as independent products, as a replacement for traditional materials, or in combination with them to obtain unique characteristics.

Artificial polymers found their first application. The most striking example is rubber. Currently, the majority of rubber products are made from synthetic rubber, but there are several applications where natural rubber rubber is still used.

Synthetic rubber

Polymers have a whole range of unique qualities that traditional materials do not have, or the use of the latter is technologically and economically inappropriate. Resistance to chemical reactions over a wide temperature range and in relation to a large group of active chemical compounds contributes to the widespread use of polymer materials in chemistry and the chemical industry.

Low toxicity, chemical stability, and the absence of allergic reactions have allowed synthetic polymers to find wide application in medicine. These are artificial organs, the production of medicines - from packaging to the shells of medical drugs (tablets, capsules), suture materials, adhesives.

Food packaging made of polymer materials

The same qualities are used in the food industry for the manufacture of tableware, packaging containers for finished products and in the process of their production. The cost of packaging synthetic containers is several times less than that of cardboard, paper or other natural materials.

In industry, high-molecular polymer compounds are used for the production of structural materials, friction units, load-bearing structures, varnishes and paints.

Due to their excellent electrical insulating properties, plastics have almost completely replaced natural materials in the electrical industry. Wire insulation, device housings, and printed circuit boards are made from polymer materials. Rigid winding wires are coated with a layer of synthetic varnishes, which have high resistance and strength at a low thickness, and flexible installation conductors have a sheath made of polyvinyl chloride or polyethylene, painted in different colors for ease of maintenance and repair.

Textile materials of most well-known names are made on the basis of synthetic polymers. Fabrics and clothing contain yarn based on polyamide, polyester, and polypropylene. An alternative to natural wool is acrylic, products from which are difficult to distinguish from natural ones.

The same polyamide, which serves as a replacement for silk, in a monolithic state has strength comparable to many metals. If we consider that polyamide, otherwise called nylon or nylon, is chemically inert, which means it is not subject to corrosion and has a low coefficient of friction, then the replacement of metals with synthetic substances is quite obvious.

Industrial polymers such as fluoroplastics - organofluorine compounds - have even higher qualities. These synthetic polymer materials have one of the lowest coefficients of friction and the highest chemical resistance. These qualities are used in the production of friction units, especially in devices operating in aggressive environments.

When it is impossible to completely replace metal structures with artificial materials, the metal base is coated with a layer of plastic. The technological process of coating metal with a layer of plastic is carried out in such a way that there is a connection between the base and the coating at the molecular level. This achieves high joint strength.

Industrial polymers can come in many different forms. Both thermoplastic materials and thermosetting plastics are used. In the first case, for the manufacture of parts and structures, the method of casting or pressing is used at the softening temperature of the polymer, and in the second, the plastic is formed directly in the form of a finished product or semi-finished product with minimal subsequent processing.

Among industrial synthetic polymers, one can distinguish composite materials, in which a variety of materials can serve as a filler or reinforcing component, and the polymer acts as a binder.

The most famous composite materials are:

- Fiberglass is fiberglass or glass-based fabric impregnated with epoxy polymer resin. This composite has high strength, excellent electrical insulating properties, resistance to adverse factors, and high fire resistance.

- Carbon fiber – the reinforcing element here is carbon fiber. The strength and elasticity of carbon fiber structures, along with their lightness (much lighter than metals), have given rise to their use in the aerospace industry. The complex of useful qualities in this area has a higher priority than the high cost associated with the labor intensity of producing carbon fibers.

- Textolite is a fabric layered material in which layers of fabric are impregnated with a polymer material. The fabric used is natural or artificial. The most durable and reliable option is fiberglass, using glass fiber fabric;

- Powder composites filled with powdered materials of natural or artificial origin;

- Gas-filled materials – foamed polymers. This is the well-known foam rubber, polystyrene foam, polyurethane foam. Gas-filled materials have extremely low thermal conductivity and are used as thermal insulation materials. Softness, plasticity, along with strength, have led to the widespread use of foam packaging materials for lightweight equipment that requires careful handling.

Carbon-chain and heterochain IUDs

Classification of polymers according to the chemical composition of the main polymer chain involves dividing these substances into two large groups.

- Carbon-chain, in which the main chain of the BMC macromolecule consists only of carbon atoms.

- Heterochain, in which in the main chain there are other atoms along with carbon atoms that give the substance additional properties.

Each of these large groups consists of the following subgroups, differing in the structure of the chain, the number of substituents, their composition, and the number of side branches:

- compounds with saturated bonds in chains, examples of which are polyethylene or polypropylene;

- polymers with unsaturated bonds in the main chain, for example polybutadiene;

- halogen-substituted high-molecular compounds – Teflon;

- polymer alcohols, an example of which is polyvinyl alcohol;

- IUDs obtained on the basis of alcohol derivatives, an example is polyvinyl acetate;

- compounds derived from aldehydes and ketones, such as polyacrolein;

- polymers obtained from carboxylic acids, of which polyacrylic acid is a representative;

- substances derived from nitriles (PAN);

- high molecular weight substances derived from aromatic hydrocarbons, for example polystyrene.