You can place an order by phone

Our specialists will be happy to help you

+7

A comparison of AISI 430 and AISI 304 is required by many buyers to determine the optimal grade of steel for a specific purpose. According to the Russian classification, both of them should be classified as “heat-resistant, corrosion-resistant” and their chemical composition has certain similarities. However, there is a difference in cost and prevalence.

What is the difference between stainless steel and regular steel?

All grades of stainless steel contain chromium (Cr). Chromium changes the structure of the alloy crystal lattice. It becomes cubic. Increases strength and corrosion resistance. A protective film of Cr2O3 oxide forms on the surface.

Stainless steel products are durable. They last longer than galvanized iron containers. They do not rust like regular carbon steel. Their properties:

- Chemical resistance

- Strength, wear resistance

- Good weldability, easy cold processing

- Aesthetic appearance

Fact: Stainless steel was patented in 1913 in England. Equipment for chemical production was made from stainless steel. It has become the best material for food containers. Today, many household items are made from stainless steel. These are kitchen sinks, dishes, knives, countertops, cutlery.

In Russia and the CIS countries, stainless steels are marked according to GOST.

Properties of alloys AISI 304 and 430 depending on the chemical composition

AISI 304 has excellent weldability and is easy to process (welding and forging). But the hardness index is less. Although this option is more expensive for use (due to the presence of nickel), AISI 304 is indispensable for the production of structures that have high requirements for manufacturability.

AISI 430 is subject to more complex types of welding and is not subject to hardening.

To understand how AISI 304 differs from AISI 430, you must also pay attention to their magnetic properties. Thus, AISI 304 belongs to non-magnetic alloys - austhenic class, and AISI 430 represents the ferrite class.

In addition to their basic qualities, alloys also differ in other properties.

- High strength and durability, the ability to manufacture parts and structures for use in aggressive environments.

- AISI 430 is more resistant to acidic and alkaline environments.

- Both metals are characterized by a low coefficient of thermal expansion.

- Externally, they differ in surface shades - AISI 304 is yellowish, and AISI 430 is white-blue.

GOST and AISI

GOST means "state standard". In steel “according to GOST”, the content of iron and alloying additives corresponds to the table. Physical characteristics during laboratory tests remain within the specified values.

The AISI standard was developed by the American Steel and Alloy Institute.

Principles of marking according to GOST and AISI standard

Marking according to GOST:

The first numbers in the labeling indicate the carbon content. The first two digits show the carbon content in fractions of a percent. The numbers after the designation of a chemical element indicate its content in the alloy.

Next come the letters of the Russian alphabet. These are symbols for chemical elements. For example, B is tungsten (W). Depending on the place of the letter in the marking, the meaning changes. For example: And at the beginning of the marking there is sulfur, and in the middle there is nitrogen.

If the content of a chemical element is within 1-1.5%, there is no digital designation behind the letter. The number shows the percentage of the element in the steel grade. The last letters are the designation of the steel class depending on the melting method.

AISI marking

Standard stainless steels are designated by three numbers. The first number is the class.

Austenitic – 2ХХ; 3XX;

Ferritic and martensitic – 4ХХ

The last two digits are the serial number of the steel in the group. Only a metallurgist can compare the properties of alloys marked in different systems. The Russian analogue is selected using reference tables:

| Steel | Analogue GOST |

| AISI 304 | 12Х18Н10Т |

| AISI 430 | 12Х17 |

When selecting an analogue, take into account:

- chemical composition of steel

- recommended scope of application.

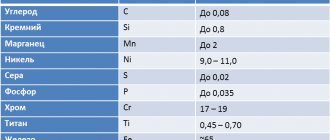

Chemical composition of AISI 304 and its analogue according to GOST:

| C | Mn | P | S | Si | Cr | Ni | Ti | Fe | |

| AISI 304 | 0,08 | 2,0 | 0,045 | 0,03 | 1,0 | 18,0-20,0 | 8,0-10,5 | Rest | |

| 12Х18Н10Т | 0,12 | 2,0 | 0,035 | 0,02 | 0,8 | 17,0-19,0 | 9,0-11,0 | 0,4-1 | Rest |

Recommendations for use

| Steel | Characteristic | Application |

| AISI 304 | Low carbon anti-corrosion austenitic steel | For all types of welded structures. Containers for food liquids, equipment for the food industry. |

| 12Х18Н10Т | Heat resistant austenitic steel | Food, chemical, fuel industries. Heat exchange equipment. Exhaust system manifolds. |

In companies that manufacture bath tubs, mechanics and welders prefer to work with AISI 304 steel. 12Х18Н10Т contains titanium. Steel is heat-resistant. It is more difficult to weld.

When welding AISI 304, an even seam is obtained. It is easy to sand and polish. Roughness and burrs are unacceptable in sauna vats. Seams on a smooth surface should not darken over time.

Magnetic properties

When considering this characteristic, there are clear differences between AISI 430 and AISI 304. The first is magnetic (ferritic class), and the second is non-magnetic (austenitic class). The difference in the chemical composition of the alloys plays a role here; however, this does not in any way change the oxidation resistance of the steel grades in question, nor does it affect other important characteristics.

By the way, using magnets to check 430 steel is not entirely correct, since derivatives of 304 steel also differ in magnetization. Knives, hospital instruments, elements for meat grinders, and pumps that work with aggressive chemicals are made from this material.

Why is AISI 430 steel grade offered for the vat and furnace?

Chemical composition of AISI 430:

| C | Si | Mn | S | P | Cr | Fe | |

| AISI 430 | 0,12 | 0,8 | 0,8 | 0,025 | 0,035 | 0,16-0,10 | Rest |

Stainless steel sheet AISI 304 3x1000x2000 – from 9300 rub.

Stainless steel sheet AISI 430 3x1000x2000 – from 6650 rub.

For many customers this is a powerful argument. Manufacturers are ready to meet halfway.

Let's compare the properties of steels:

| Options | AISI 430 | AISI 304 |

| Color | White-blue | yellowish |

| Mechanical qualities | high (does not deform during processing) | high |

| Heat resistance | high high | high |

| Harmful impurities | No | No |

| Sensitivity to low temperatures | Brittleness at low temperatures | Not sensitive |

| Corrosion resistance | Gradual destruction under the influence of acids | high |

| Manufacturability | high | high |

| Life time | long | long |

| Price | The price is lower | The price is higher |

The weldability of AISI430 is considered good. But when gas welding, the seam can be brittle (when heated, the structure of the metal changes). Fatigue of steel along the seam is low. Not recommended for use under tensile loads. Weld with nickel-containing electrodes.

Experts rate the weldability of steel 340 as excellent. Other areas of application include the manufacture of tanks and tankers for liquid food products.

Domestic analogues

Both brands are common and produced by various factories, both domestic and foreign. A wide range of applications allows them to be used for a variety of purposes. It’s easy for a non-specialist to get confused in the differentiating aspects, and first you need to decide on a theory.

It is more convenient to make comparisons using the corresponding GOST alloys, which are more familiar, reveal the chemical composition and are well described in the standards. AISI 430 approximately corresponds to 17X18 with its composition:

- 0.17% Carbon.

- 18% Chromium.

- Titanium is present in small quantities, but it is enough to have a qualitative effect on the properties. More precisely, AISI 430 allows comparison with both 17X18 and 17X18T.

AISI 304 is identical to 08Х18Н10:

Their silicon and magnesium content is approximately the same - they are rather auxiliary elements. Comparison of undesirable components gives comparable results: there should be a minimum of them. First of all, it is sulfur - which increases the risk of cracking during high heat. Often, the degree of purification of the alloy affects its cost - therefore, the cheapest version may not be the best.

Such differences in chemical composition give rise to the following differences in properties:

- AISI 304 has unlimited weldability, can be hardened and forged. At the same time, its hardness is lower, and the permissible heating is within six hundred degrees (with short exposure - up to eight hundred).

- AISI 430 is more difficult to weld and it is not recommended to strengthen it by heat treatment - this leads to cracks in unpredictable places. Among the advantages, it is worth noting the ability to withstand high temperatures and superior strength and hardness.

Accordingly, when higher technology is required, it makes sense to choose the first option. The second one stands for hardness and lower cost. In certain cases, both are allowed, and it’s worth choosing the more accessible and inexpensive one. Both brands are produced in various rolled products, which allows you to select the optimal blank for a specific product.

Stainless steel grade for chimney

Steel 430 is a heat-resistant budget grade. Household hoods, casings, and protective screens made of 430 steel are used everywhere. Some articles recommend 430 steel as an inexpensive stainless steel for chimneys. But 430 differs from other brands in its relatively low corrosion resistance.

In the chimney of an outdoor stove, moisture and combustion products form acids. Stainless steel for the chimney must be resistant to nitric, carbon and sulfuric acid. In metallurgists' reference books, AISI 430 is recommended for gas boilers with low intensity of operation. The chimney of an outdoor stove made of steel of this brand gradually rusts.

304 steel is considered universal. Stoves and chimneys are made from this stainless steel for baths. They can withstand temperature changes and high humidity. Surfaces retain their shine for a long time. This is what the owners of commercial bathhouses with high traffic were convinced of.

Important. It is easy to distinguish between AISI 304 and AISI 430. 304 steel is not magnetic. Steel 430 belongs to the ferromagnetic class. A magnet sticks to its surface.

AISI 304 steel is more suitable for the manufacture of sauna vats and stoves. It is more expensive due to chromium and nickel. It is used wherever reliable welds are needed. This is its main advantage.

Scope of application

Practice shows priority products:

- AISI 304: furnace equipment, pipes for transporting solutions of acids and steam, heat exchangers and collectors, electrodes of automotive spark plugs, parts of welding and thermal power systems, chemical industry vessels. Permissible operating temperature is up to six hundred degrees. The chemical aggressiveness of the environment should be within average values; for maximum values, there are other solutions.

- AISI 430: fasteners and auxiliary parts for various devices and devices used in combination with moderate solutions of acids and salts. It can also often be found in everyday life: kitchen utensils and parts of kitchen and bathroom appliances.

Comparison of AISI 430 and AISI 304 allows you to choose the most suitable material. Some sources do not distinguish much difference between these materials, which is incorrect. Arbitrary replacement can have unpleasant consequences, expressed in design defects - up to fatal non-compliance.

Stainless steel standards

There are state standards for different types of stainless steel in our country. They determine the quality of products made from this material. Stainless steel has different GOST standards. Certain quality standards are developed for thin sheets, for wire, for thick sheets and for stainless steel pipes.

Stainless steel has different characteristics. Thanks to its chemical and physical parameters, it easily resists the formation of corrosion plaque. This material was developed for use in places where there are different environmental conditions. Due to its heat resistance and strength, steel does not react with substances in the environment.

Percentage of chemical compounds in combustion products

| SO3 (sulfur oxide) | CO2 (carbon dioxide) | W (humidity) | ||

| Wood | 0.5% | — | 90% | 6% |

| Natural gas | — | — | 90% | 10% |

| Diesel fuel | — | 3% | 90% | 10% |

| Coal | 1% | 3% | 90% | 6% |

Stainless steel chimney? Which one should we choose?

We represent three brands of chimneys: Feringer, Ferrum, Craft.

Let's start with Feringer chimneys

The Feringer plant produces various heating units for baths, saunas, rooms and chimneys made of black steel.

Their main use for chimneys made of black steel is sauna and heating stoves. These chimneys are made of 3mm thick black steel. In terms of service life, they approximately correspond to stainless steel chimneys made of AISI 439 steel 0.8 mm thick. We recommend installing them inside the steam room. The main advantage of these chimneys is that, unlike stainless chimneys, they do not darken due to high temperature.

Well, another big plus is that there is less hard radiation from this chimney.

These advantages are worth putting these chimneys inside the steam room. It will look like this... These chimneys do not come in a sandwich version, so running them through the ceilings will be less fire safe. They are covered with heat-resistant light paint. There are limitations when using these chimneys - their standard diameter is 110 mm.

They can be used for chimney diameters Ф115 and Ф120mm, but only through adapters from this diameter to Ф110mm from the same manufacturer. This manufacturer's product range includes chimneys of various lengths, dampers, convectors, and chimneys with mesh.

Chimneys Ferrum

This plant is specialized only in the production of stainless steel chimneys. The assortment of the plant is simply huge. Ferrum produces all the elements that allow you to assemble a chimney. Today the plant uses two types of steel: stainless steel and galvanized steel.

Stainless steel comes in two thicknesses: 0.8mm AISI 430 (only for the inner wall of a double-circuit chimney and for a single-circuit chimney), 0.5mm AISI 430 - for the outer wall of a double-circuit chimney, for gas chimneys for the inner wall and for single-wall stainless steel chimneys for gas.

Brief information on 430 and 439 steel

ASTM standard: 430 Ti AISI, 439 AISI - ferritic steels. 430 AISI is a low-carbon iron-chromium stainless steel.

The steel has good corrosion resistance in mildly corrosive environments and good oxidation resistance at high temperatures. In the annealed state, steel is malleable, does not harden excessively during cold working, and can be easily formed.

Steel has limited weldability and should not be used in welded objects subject to stress. Having a ferritic structure, 430 AISI is brittle at sub-zero temperatures, and cannot be used in cryogenic applications.

Since the steel does not contain nickel or molybdenum, it is cheaper than any of the 300 series steels. The Russian equivalent of 430 AISI according to GOST is 12X17. AISI 439 steel - comes with the addition of titanium.

400 series steels retain fairly high mechanical properties at elevated operating temperatures (see figure), ensuring structural strength of the structure.

Chimneys made of this steel are recommended primarily for use in sauna stoves, boilers, fireplaces that burn wood in domestic conditions, and low-power boiler houses. In such conditions, these chimneys will work for a very long time.

Chimneys Craft

The plant is also designed to produce chimneys only from stainless steel.

Uses 300 series steels AISI-304,321,316,309 and 310 - austenitic steels. These steels are more resistant to external, aggressive, high-temperature operating conditions; these steels contain molybdenum, nickel, and titanium. These elements increase the service life of the chimney by an order of magnitude compared to the 400 series. These chimneys will work for a long time in enterprises and organizations using high-power boiler rooms.

Why are these steels interesting individually?

Stainless steel AISI 304 (08Х18Н10 – GOST CIS) is used mainly for decorative purposes. It can be welded without restrictions (manual, resistance, electroslag, arc welding). This grade of steel polishes well, is not magnetic, has high strength at low temperatures, and is considered universal. Also used in the dairy/chemical/textile/paper/pharmaceutical/petroleum industries, mechanical engineering and consumer goods manufacturing. Recommended working

temperature – up to 300 C. This is austenitic stainless steel with a low carbon content.

Stainless steel 316 AISI (10Х17Н13М2) is an improved version of 304, as molybdenum is added to the composition. It is characterized by increased resistance to corrosion. At high temperatures it shows better performance compared to those stainless steels that do not contain molybdenum. The presence of molybdenum helps protect against pitting corrosion in sea water, chloride environments and acetic acid vapors.

AISI 316 - Recommended for use when heating the unit with gas, diesel, wood

AISI 310 stainless steel is an austenitic refractory heat-resistant steel. Used at temperatures up to 1000 C in a reducing environment. This stainless steel is used in units with high combustion temperatures, even in which coal is burned.