In order to work productively with various materials, the master must be aware of all their physical properties and characteristics, which will help determine the nuances of the work process. This is a very important aspect regarding any workflow related to material handling in various industries.

The properties of almost all materials known to mankind have long been studied and any indicators can be recognized by the user, thanks to the huge amount of theoretical materials that are available in special books and reference books, and on the Internet.

Metals are a whole group of materials that are very widely used in various industrial fields. Their processing is not the easiest process, since physical or thermal intervention . Therefore, it is very important to know many of the physical properties of such materials.

The specific gravity of metals is one of the very important characteristics that you need to know when processing them. This article will discuss some indicators of the specific gravity of different metals, which may later be useful to the user.

History of the production of alloys with changes in their density

Iron was used as a tool material back in the times of Sumer and Ancient Egypt. Archaeological artifacts (jewelry, dagger) were made from a meteorite alloy containing nickel and iron.

The celestial origin of the ore material is reflected in Latin and Greek, where its name means “stellar” (“sider”).

The method of producing steel from black concentrate was described by Aristotle.

Sands containing magnetite were used as raw materials. The steel produced was distinguished by excellent qualities due to its titanium content. With the development of civilizations in the world, the need for raw materials has increased. The industrial scale of ore processing required new smelting technologies.

The first step in metallurgical production was to obtain raw materials by reducing them from oxide. As a result of the process of burning out the ore, a lump of porous metal remained in a specially equipped furnace, which was processed by melting.

As a result of repeated doubling of the workpiece and subsequent forging, it was possible to obtain excellent steel, called Damascus.

But the chemical element was first obtained in a liquid state several centuries ago. This fact made it possible to saturate the molten material with carbon in order to give it new properties.

Through continuous experiments and searches for new technologies for extracting valuable components from ore, a new composition of the material used in the modern production of rolled metal, household items and equipment was formed.

The development was based on improving the technical parameters of the material, changing its density and melting point.

Jewelry area

More than 50 tons of platinum are used annually to make jewelry. Most of the products sold contain 95% pure mineral. Since there are few impurities in the accessories, they do not fade, do not lose their beautiful silver color and retain their shine for a long time. Platinum is used to create beautiful necklaces, chains, bracelets, earrings, and rings.

Jewelry with a pure composition does not irritate the skin, as is often the case with accessories containing allergenic metals. The bright shine resembles a diamond shine. Platinum serves as an excellent setting for precious stones. It is often combined with natural yellow tones of gold.

Platinum jewelry is often chosen due to its high durability. Jewelry accessories made of gold and silver wear out after some time, and they have to be sent in for repairs to replace the deteriorated layer with a new one. This does not happen with platinum items, so they serve their owners for a lifetime.

Specific gravity of metals

All bodies that have the same volume, but are made from different substances, have different masses, which are directly dependent on its volume. The ratio of the volume of an alloy to its mass—density—is a constant value that will be characteristic of a given substance. And specific gravity is the force of gravity of the volume of a given substance directly taken as a basis. In other words, the specific gravity of a metal is the weight per unit volume of an unconditionally dense (non-porous) material. To indicate the specific gravity, the mass of the dry material should be divided by its volume in a completely dense state. All metals known and used in industry have certain physical and mechanical properties, which, in fact, determine their specific gravity. Metals have characteristic properties, including high strength, thermal and electrical conductivity, ductility. Chemical properties and specific gravity of non-ferrous metals

| Name of non-ferrous metal | Chemical designation | Atomic weight | Melting point, °C | Specific gravity, g/cc |

| Zinc | Zn | 65,37 | 419,5 | 7,13 |

| Aluminum | Al | 26,9815 | 659 | 2,69808 |

| Lead | Pb | 207,19 | 327,4 | 11,337 |

| Tin (Tin) | Sn | 118,69 | 231,9 | 7,29 |

| Copper | Cu | 63,54 | 1083 | 8,93 |

| Titanium | Ti | 47,90 | 1668 | 4,505 |

| Nickel | Ni | 58,71 | 1455 | 8,91 |

| Magnesium (Magnesium) | Mg | 24 | 650 | 1,74 |

| Vanadium | V | 6 | 1900 | 6,11 |

| Tungsten (Wolframium) | W | 184 | 3422 | 19,3 |

| Chrome (Chromium) | Cr | 51,996 | 1765 | 7,19 |

| Molybdenum | Mo | 92 | 2622 | 10,22 |

| Silver (Argentum) | Ag | 107,9 | 1000 | 10,5 |

| Tantalum | Ta | 180 | 3269 | 16,65 |

| Gold (Aurum) | Au | 197 | 1095 | 19,32 |

| Platinum | Pt | 194,8 | 1760 | 21,45 |

Specific gravity of the most common steel grades

| Name (steel type) | Brand or designation | Specific gravity (g/cm3) |

| Stainless steel structural cryogenic | 12Х18Н10Т | 7,9 |

| Stainless steel, corrosion-resistant, heat-resistant | 08Х18Н10Т | 7,9 |

| Low alloy structural steel | 09G2S | 7,85 |

| Quality carbon structural steel | 10,20,30,40 | 7,85 |

| Carbon structural steel | St3sp, St3ps | 7,87 |

| Die tool steel | X12MF | 7,7 |

| Structural spring steel | 65G | 7,85 |

| Die tool steel | 5ХНМ | 7,8 |

| Alloy structural steel | 30ХГСА | 7,85 |

Specific gravity of steel of various grades

| Name (steel type) | Brand or designation | Specific gravity (g/cm3) |

| nickel chrome steel | EI 418 | 8,51 |

| chromium-manganese-nickel steel | Х13Н4Г9 (ЭИ100) | 8,5 |

| chrome steel | 1X13 (EZh1) | 7,75 |

| 2X13 (EZh2) | 7,70 | |

| 3X13 (EZh3) | 7,70 | |

| 4X14 (EZh4) | 7,70 | |

| X17 (EZh17) | 7,70 | |

| X18 (EI229) | 7,75 | |

| X25 (EI181) | 7,55 | |

| X27 (Zh27) | 7,55 | |

| X28 (EZh27) | 7,85 | |

| chromium-nickel steel | 0Х18Н9 (ЭЯ0) | 7,85 |

| 1Х18Н9 (ЭЯ1) | 7,85 | |

| 2Х18Н9 (ЭЯ2) | 7,85 | |

| X17N2 (EI268) | 7,75 | |

| EI307 | 7,7 | |

| EI334 | 8,4 | |

| Х23Н18 (EI417) | 7,9 | |

| chromium-silicon-molybdenum steel | EI107 | 7,62 |

| chromium-nickel-tungsten steel | EI69 | 8,0 |

| chromium-nickel-tungsten with silicon steel | Х25Н20С2 (ЭИ283) | 8,0 |

| chromium-nickel-silicon steel | EI72 | 7,7 |

| other special steel | EI401 | 7,9 |

| EI418 | 8,51 | |

| EI434 | 8,13 | |

| EI435 | 8,51 | |

| EI437 | 8,20 | |

| EI415 | 7,85 |

Determination of metal specific gravity

First you need to define what specific gravity is. This will make it easier to subsequently understand all the indicators, as well as use the acquired knowledge when processing workpieces made from this durable material.

Specific gravity is the ratio of a homogeneous body of this substance to the volume of this material. An interesting point that can be immediately highlighted from this is that, in essence, the specific gravity of a metal is its density .

This value, that is, the specific gravity of the metal, is measured in kg/cubic meter. m. This is the unit of measurement most often indicated in various technical reference books. Sometimes other units of measurement may be indicated, but in domestic sources they are much less common.

If a reference book containing the necessary data about a particular metal is not at hand, then the specific gravity can be calculated using the well-known formula:

In this formula, y denotes the specific gravity, which will later have to be calculated, P is the weight, and V is the volume . Using this formula, you can already perform a calculation with known data on weight and volume.

Healing and magical properties

Platinum nanoparticles can easily penetrate into the cells of the human body and have a beneficial effect on metabolic processes occurring in the body. One of the main functions of the mineral is the destruction of free radicals and inhibition of premature aging. Some drugs used in the treatment of cancer contain platinum.

The metal has also found other uses in medicine:

- The mineral is used in the production of surgical instruments, which are sterilized in the flame of an alcohol burner. Platinum alloys containing silver, palladium, copper, zinc or nickel are excellent materials for the manufacture of dentures.

- The metal, due to its inertness to various compounds, electrical conductivity and hypoallergenicity, is actively used as a component of electrical stimulators, catheters and other types of medical equipment.

It is also worth noting the magical properties of the noble mineral. He is considered light, pure and devoid of evil. Platinum does not retain negative memories like gold. She is closely connected with the cosmos and brings wisdom and goodness to people. The material helps to illuminate the soul and enlighten the mind. Medical workers are recommended to wear a talisman made from this metal. Silver metal is also suitable for those whose activities are related to people who need help.

Platinum products are able to neutralize negative emotions and awaken positive thoughts in a person, sharpen intuition, and show their owner the right path or decision. A metal amulet will protect a person from negative influences that destroy the energy shell.

Platinum can soften the effect of precious stones. It is often used as a setting for those gems that can greatly affect their owners and cause them harm. Metal is recommended for people who want to take the path of spiritual enlightenment and turn to religious or occult teachings. When praying or meditating, it is recommended to wear a platinum ring on your index or ring finger.

The strength of the metal is also considered a magical property. Some believe that if newlyweds exchange platinum rings at a wedding, then they will be together for the rest of their lives. Durable amulets will not allow anyone or anything to separate a couple in love.

The mineral should be purchased only by calm natures prone to contemplation. Metal does not like gossipers and envious people, and it can severely punish thieves and traitors.

Platinum is associated with the planet Neptune. This metal is indicated for Pisces and Cancer. Some ancient Indian tribes worshiped platinum bars. People believed that Neptune himself heard them through the mineral.

Indicators of the specific gravity of other metals

Specific gravity is an indicator that is an integral characteristic of other metals.

The specific gravity of silver is affected by the fineness of the alloy. When other metals (copper, nickel) are added to it, the specific gravity and density are lost. Thus, the density of copper is 8.93 g/cm3, nickel – 8.91 g/cm3. All values are calculated using formulas.

Silver is the same noble metal as gold. Its specific gravity is 10.5 g/cm3. It melts at a temperature of 960 degrees. The main physical characteristics of silver are:

- corrosion resistance;

- low resistance;

- increased light reflectivity.

Despite its natural softness, silver has a high density and specific gravity.

Titanium is a non-ferrous metal of a white-silver hue. It has high strength, although it is light in weight. So, it is 12 times stronger than aluminum and 4 times stronger than copper and iron. In terms of the degree of presence in the earth's crust, titanium is given fourth place among the rest.

The low specific gravity of titanium - 4.505 g/cm3 is more consistent with alkali metals. An oxide film forms on its surface, which prevents the formation of corrosion.

Zinc is also a non-ferrous metal with a white-bluish tint. It has medium hardness and an initial melting point of 419 degrees. Under the influence of a temperature of 913 degrees, this metal acquires a vaporous state. Zinc has a specific gravity of 7.13 g/cm3.

Normal temperature makes zinc brittle, but increasing it to 100 degrees makes the metal flexible and ductile. When interacting with air, an oxide film forms on the surface of zinc.

The color of lead is dirty gray, but this does not affect the natural shine of the metal. However, the glow stops quite quickly due to the formation of an oxide film on the surface of the lead. The lead alloy has a high specific gravity - 11.337 g/cm3. In this indicator, it exceeds zinc, aluminum, iron and some other metals. Despite its high density, lead is a very soft metal.

The table shows the specific gravity and melting points of other metals.

| Name of metal | Melting point, °C | Specific gravity, g/cc |

| Zinc | 419.5 | 7.13 |

| Aluminum | 659 | 2.69808 |

| Lead | 327.4 | 11.337 |

| Tin | 231.9 | 7.29 |

| Copper | 1083 | 8.96 |

| Titanium | 1668 | 4.505 |

| Nickel | 1455 | 8.91 |

| Magnesium | 650 | 1.74 |

| Vanadium | 1900 | 6.11 |

| Tungsten | 3422 | 19.3 |

| Chromium | 1765 | 7.19 |

| Molybdenum | 2622 | 10.22 |

| Silver | 1000 | 10.5 |

| Tantalum | 3269 | 16.65 |

| Iron | 1535 | 7.85 |

| Gold | 1095 | 19.32 |

| Platinum | 1760 | 21.45 |

History of platinum

Platinum was known even before our era. The ancient Egyptians used the mineral to create various jewelry. For some time it was common among the Incas. In the middle of the 6th century, Spanish conquistadors found this metal in South America, which reminded them of silver. They gave the new material an appropriate name. Translated from Spanish, platina means “little silver” or “little silver.” In those days, the new metal was little valued by people because of its refractoriness and high density. Platinum has been given names such as “immature gold” and “wrong silver.”

But later an interesting feature was found in the material: it turned out that it easily alloys with gold. Following this discovery, jewelers began mixing these metals to reduce the cost of producing jewelry and other accessories. The fake was practically impossible to distinguish from real gold. When this fraud was discovered, the import of platinum into Europe was banned for a certain period .

For a time, people believed that white gold and platinum were the same thing. This statement is incorrect, since the metals are different and similar only in appearance in color. The material became an independent chemical element only in the middle of the 18th century, when it was thoroughly studied. Platinum designation is Pt. The physical properties and operational features made it possible to use the metal in the manufacture of equipment and other purposes. Soon the price of the mineral increased sharply. Today platinum is considered one of the most expensive metals.

The lightest and heaviest aluminum alloys

- One of the lightest aluminum alloys is the foreign cast alloy 518.0 (7.5-8.5% magnesium) - 2.53 g per cubic centimeter [1]. The domestic alloy AMg11 (AL22) contains even more magnesium - from 10.5 to 13.0%. Therefore, we must think that it is even lighter, but we do not have exact data!

- The heaviest aluminum alloys are foreign cast alloys 222.0 and 238.0 with a nominal copper content of 10%. Their nominal density is 2.95 g per cubic centimeter [1].

- The lightest wrought alloy is 8090 aluminum-lithium alloy with a nominal lithium content of 2.0%. Its nominal density is 2.55 g per cubic centimeter [1].

- The heaviest deformable aluminum alloys are alloy B95 and foreign alloy 7175: 2.85 g per cubic centimeter [4].

Steel classification

Depending on the proportion of non-metallic impurities determined by the method of smelting a given grade, steel alloys are divided into:

- especially high quality;

- high quality;

- ordinary quality.

Based on their chemical composition, alloys are also divided into alloyed and carbon.

Carbon steels

Used primarily for the production of welded structures and contains from 0.25 to 2.14 percent carbon. Within the group, they are further divided into subgroups, and also according to the percentage of carbon:

- high carbon (0.6-2.14);

- medium carbon (0.3-0.55);

- low carbon (below 0.25).

They also contain silicon and manganese as additives. In addition to useful, purposefully introduced additives, the alloy may also contain harmful impurities that negatively affect its physicochemical properties:

- phosphorus reduces ductility when heated and increases brittleness when cooled;

- sulfur leads to the formation of microcracks.

Other impurities may also be present in the alloy.

Alloy steel

In order for the alloy to acquire the required properties during melting, useful additives or alloying elements are added to it, most often metals such as aluminum, molybdenum, chromium, manganese, nickel, vanadium and others. The properties of the alloy change quite significantly: the alloy acquires resistance to corrosion, special strength, high malleability, increased or decreased electrical conductivity, etc. An alloy with such additives is called alloy steel. Based on the percentage of alloying additives, they are divided into three groups:

- highly alloyed – over 11;

- medium alloyed – from 4 to 11;

- low alloy – less than 4.

By area of application, steel alloys are divided into:

- tool - high-strength alloys are used for the manufacture of tools, dies, cutters, drills and cutters;

- structural - used for the production of bodies and components of vehicles, machine tools, building structures;

- special. This group includes alloys with increased resistance to acidic and alkaline environments, radiation, stainless alloys, electrical materials, etc.

Some additives and treatments increase the density of the material, while others reduce it, for example:

Determination of product mass

All modern reference materials, GOST and technical specifications of enterprises have been adjusted in accordance with the international classification.

Using reference tables of densities of various materials, it is easy to determine their mass. This is especially true when items are heavy or appropriate scales are not available . To do this, you need to know their geometric parameters. Most often, you need to find out the mass of an object in the form of a cylinder, pipe or parallelepiped:

Metal rods are cylindrical in shape. Knowing the diameter and length, it is easy to find out the mass. Mass equals density times volume. Finding the volume of an object. It is obtained by multiplying the cross-sectional area by the length. The area of a circle, knowing the diameter, is easy to determine. The squared diameter is multiplied by 3.14 (pi), divided by 4.- We obtain the mass of the pipe in the same way. When finding the area, we take the difference between the outer and inner diameter of the section.

- To determine the mass of a sheet, bloom, slab or bar of rectangular cross-section, we determine the volume by multiplying the length, height and thickness. Multiply by the density from the reference book.

With such calculations, a small error is always allowed, because the shapes are not ideal. In practice it can be neglected. Manufacturers of metal products have developed special mass calculators for users. It is enough to enter unique dimensions in the appropriate windows and get the result.

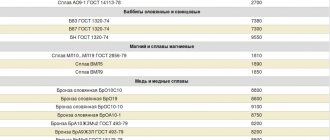

Features of the table used

In order to calculate the weight of the future product, which will be made from cast iron, you should know its dimensions and density index. Linear dimensions are determined in order to calculate the volume. A calculation method is used to determine the weight of a product in cases where it is not possible to weigh it.

When considering methodological tables, it is worth paying attention to the following points:

- All metals are divided into several groups.

- For each material, the name and GOST are indicated.

- Depending on the melting point, the density value is indicated.

- To determine the physical value of specific gravity in kilograms or other changes, conversion of units of change is carried out. For example, if you need to convert grams to kilograms, then multiply the table value by 1000.

Determination of specific gravity is often done in special laboratories. This value is rarely used when carrying out actual calculations during the manufacture of products or the construction of structures.