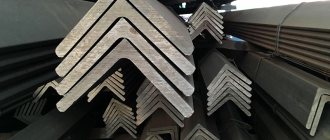

A steel corner 50x50x5 is a metal product with a cross-section in the shape of the letter G. The corner profile can have a small cross-sectional area (1-1.5 sq. cm) and a large one (up to 140 sq. cm).

Steel corner 50x50x5 is used to create building structures with welded or other types of connections. In addition, this profile is used for finishing external corners, as well as as a decorative element.

In accordance with the accepted standard, an equal angle corner (GOST 8509-93) and an unequal angle angle (GOST 8510-86) are manufactured. Both positions are performed with rolling accuracy A (high accuracy) or B (normal accuracy).

The range of equal-flange angles is made of a special type of steel, which provides high stability and is characterized by good resistance to intense loads. The equal-flange steel angle has a standard length from 4 to 12 m.

The 50x50x5 steel unequal angle has a specific scope of application and is in less demand than the equal angle angle, the scope of which is extensive. Unequal flange is used as one of the elements in a load-bearing metal structure, as well as for decorative finishing, bonding, and lining. We offer an assortment of “unequal-flanged angles”, manufactured on roll forming equipment from cold-rolled and hot-rolled sheets. You can view the full selection of products in our catalog or price list.

offers hot-rolled steel angles, equal and unequal, in a large assortment and in accordance with standard requirements.

Characteristics and production principle

Today, equal-flange steel angles are manufactured in accordance with legislative standards, which are prescribed in the documentation GOST 8509–93. For mass production of this category of rolled metal, universal square-shaped blanks are used, which ultimately acquire the desired shape with shelves of equal width. Among specialists, such details vary depending on accuracy indicators (the number of deviations from the established norm). Due to this, there are two most common classifications of corners:

- Products of ordinary precision are marked with the letter “B”.

- High precision parts - designated as “A”.

In industrial construction, conventional precision products are most often used. But if the corner will be used in the manufacture of critical metal structures that will be systematically subjected to heavy loads, then it is best to use high-precision parts. This is due to the fact that such products have higher strength indicators.

As for class “B” corners, permissible deviations from the established standards apply to them:

- A steel corner whose shelf width reaches 90 mm must have a permissible deviation of 1.5 mm.

- If the shelf width is 45 mm, then the permissible deviation should not exceed 1 mm.

- The permissible deviation in corners up to 250 mm should not exceed 3 mm.

- When the shelf width is 150 mm, the deviation level is within 2 mm.

It is also worth considering that experts distinguish between several types of equal-flange steel angles, which differ in thickness. Indicators from 0.3 to 0.5 mm are considered normal.

As for the production process, it is divided into two main stages. The hot-rolled manufacturing method is based on the fact that a steel billet is passed through special rotating shafts. Thanks to this, the required dimensions of the product are formed. Only after this the billets are passed through a rolling mill under high pressure.

It is important to note that twisting the product along the axis is considered simply unacceptable. The final curvature of the part should be within 0.4% of the entire length.

Calculator

| Calculation example |

Related calculators:

- Collection of loads on floor beams online.

- Calculation of a rectangular pipe

- Square pipe calculation

- I-beam calculation

- Channel calculation

- Calculation of a wooden beam

Modern classification

Today there are several main classifications of steel angles. Their differences lie in the scope of application:

- Unequal. This type of rolled metal is widely used for the construction of complex structures such as arches.

- Equal. Most often used in the construction industry, as well as for the production of furniture and various openings. This is especially true for situations where you need to get a perfectly even angle.

- Galvanized. Widely used in environments with aggressive environments and chemical exposure.

- Hot rolled. It is considered the most popular among similar products, as it can be used for the manufacture of critical units of load-bearing structures, where high tension in the material is predicted.

- Corner made of stainless material. Craftsmen widely value this type of rolled metal, as it can be used for rooms with high levels of humidity.

- Products made from low alloy steel. Such parts are used in cases where the structure is subject to heavy loads and negative atmospheric factors.

- Bent corner. The wide range of applications of this rolled metal is due to the fact that it is characterized by a simple installation scheme and low weight. But it is important to take into account the disadvantage of such products - low strength indicators, which prevents their use in certain structures.

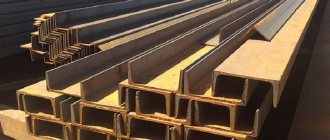

Comparing channel and profile pipe

Channel is a more “serious” profile. You are unlikely to see home furniture with a metal frame made of channel steel - for this they use corrugated pipe. And vice versa, in the load-bearing parts of the metal frame of massive buildings (shopping centers, hangars, exhibition complexes) the channel is found everywhere, the corrugated pipe is extremely rare. This happens due to the fact that the frame consists of elements that complement each other and carry a common load. In this case, a channel is more suitable: this rolled material can withstand loads well due to its profile and thicker walls. But the channel is not universal due to its profile. Therefore, small products “for oneself”, where there is no need to consider the load and a sufficient safety margin of a profile pipe, where the versatility of rolling is needed (the same piece of pipe can be used anywhere in the frame) is preferred to be made from pipe.

When asked which is better (stronger, stronger, stiffer): a channel or a profile pipe, we answer: you need to compare in practice. Rolled metal elements are good in each case. That is, in the conditions of production of frames for home furniture, a corrugated pipe is better, and in conditions of production of frames for massive buildings, a channel is better.

A durable and reliable steel corner can be used not only in professional construction, but also in private construction. The variety of its shapes and types makes you think about what properties of a metal corner you need to pay attention to, how all these types differ and how to choose the product that will be optimally suited to your needs, but at the same time not overpay for those properties that are not suitable for your construction needed.

Manufacturing

Metal corners come in two types according to the production method, each of which is regulated by its own GOST and has different properties. Experts can distinguish them even by their appearance.

Hot-rolled steel angle is made from a heated ingot of metal, so its outer corner is sharp, because the product is made according to the shape. It can withstand loads better and is more durable.

A cold-rolled metal corner is obtained by bending a steel strip on a bending machine. There is no scale on it, and the outer corner is rounded due to the bend. It is much less durable than a hot-rolled product, but it is extremely simple to make - you just need to bend the strip, so the variety of its sizes is much wider than that of the strictly regulated hot-rolled version. If you need a non-standard size, then a cold-rolled corner is at your service.

Accuracy

This parameter indicates how large the possible deviations from the ideal drawing are. The greater the deviation, the more uneven or slightly crooked the corner will be. However, even with standard accuracy it is usually enough to create an even structure; as a rule, increased accuracy is needed only for very small corners and certain specific high-precision structures.

You can distinguish accuracy by markings. The standard accuracy marking has the letter B, and the increased accuracy has the letter A.

Steel alloy

Like most metal products, steel profiles can be made from high-alloy, low-alloy or regular carbon steel. Low-alloy steel is the easiest to weld, high-alloy steel has increased strength, and regular steel is universal and the most inexpensive.

Shelves

The shelves of this product can be equal and nervous. In the first case, the metal strip seems to be bent exactly in the middle, and both sides diverging from the top are the same length. This is a very durable option, since such a stiffener best withstands loads.

However, in certain types of construction you need rolled steel, which in cross-section resembles the letter L - one side (shelf) is longer than the other. This type of rolled steel is slightly less durable, but it can be useful for certain structures. It is also used for additional reinforcement.

Optimal weight and length

Many experts prefer to use a 50x50x5 corner. The weight of 1 meter according to GOST is 3.77 kg. It is worth noting that the weight of such a workpiece can be determined in several ways. But the fastest and easiest option is when the master uses a special table for the assortment of equal-flange steel products from the relevant GOST standards. Thanks to this, you can find out the theoretical specific gravity indicators for each standard size.

In addition to the weight of the 50x50x5 corner, it will be useful to know some more nuances that must be indicated when ordering suitable transport for transportation. Thus, the final product can be of a measured length with values of 6, 9 and even 12 meters. But unmeasured corners vary in length from 4 to 12 meters.

You should always take into account that if this category of rolled metal will be used in difficult operating and weather conditions, then it is best to choose angles made of low-alloy steel. In this case, the following brands are in greatest demand: 09G2, 10HSND, 12GS, 09G2S or 17G1S.

Despite the fact that the length of measured products varies from 4 to 12 meters, each batch may contain an angular profile of unmeasured length (no more than 5% of the total mass). With unmeasured products, everything is completely different; their sizes cannot be less than three meters and more than twelve. In the case of an individual order, rolled metal can be produced in a limited, unmeasured length. If the work requires an angle of 6 meters or more, then the resulting deviations should not exceed 70 mm.

For certain construction work, the curvature of the corners is of great importance. In the case of high-precision products, this figure should not exceed 0.2%, but for ordinary accuracy - 0.4%.

It is worth considering that if the corner will be used in an industry where strength and anti-corrosion properties are of great importance, then it is best to choose those products that are made of steel 15 HSND and 10 HSND. After all, it is precisely this type of rolled metal that will have sufficient lightness and a long service life.

Weight of equal angles

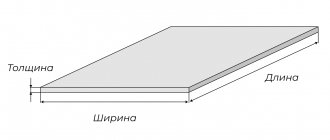

The weight and other characteristics of the corners depend on indicators such as width, wall thickness, and manufacturing accuracy. The shelf width can be from 20 to 250 mm. Products are marked according to the shelf dimensions. The labeling indicates the name of the product and the size of the shelf. For example, “Equal angle 50”.

The weight of a linear meter of products is determined by quality characteristics, including the following indicators:

- type of metal;

- steel grade;

- corner size;

- product thickness.

For each product there are calculation tables indicating the mass and number of meters per ton of the batch. For example, it is calculated that the weight of a linear meter of a 50x50x5 mm corner is 3.74 kg. And the number of meters in a ton is 267.48 m.

All the necessary parameters of the corners of interest can be found in the table:

| Weight table for equal flange hot-rolled angles | ||

| Size | Weight of 1 meter, kg | Meters in 1 ton |

| 20x20x3 | 0,89 | 1123,6 |

| 20x20x4 | 1,15 | 869,57 |

| 25x25x3 | 1,12 | 892,86 |

| 25x25x4 | 1,46 | 684,93 |

| 28x28x3 | 1,27 | 787,4 |

| 30x30x3 | 1,36 | 735,29 |

| 30x30x4 | 1,78 | 561,8 |

| 32x32x3 | 1,46 | 684,93 |

| 32x32x4 | 1,91 | 523,56 |

| 35x35x3 | 1,6 | 625 |

| 35x35x4 | 2,1 | 476,19 |

| 35x35x5 | 2,58 | 387,6 |

| 40x40x3 | 1,85 | 540,54 |

| 40x40x4 | 2,42 | 413,22 |

| 40x40x5 | 2,98 | 335,57 |

| 45x45x3 | 2,08 | 480,77 |

| 45x45x4 | 2,73 | 366,3 |

| 45x45x5 | 3,37 | 296,74 |

| 50x50x3 | 2,32 | 431,03 |

| 50x50x4 | 3,05 | 327,87 |

| 50x50x5 | 3,77 | 265,25 |

| 50x50x6 | 4,47 | 223,71 |

| 56x56x4 | 3,44 | 290,7 |

| 56x56x5 | 4,25 | 235,29 |

| 63x63x4 | 3,9 | 256,41 |

| 63x63x5 | 4,81 | 207,9 |

| 63x63x6 | 5,72 | 174,83 |

| 70x70x4.5 | 4,87 | 205,34 |

| 70x70x5 | 5,38 | 185,87 |

| 70x70x6 | 6,39 | 156,49 |

| 70x70x7 | 7,39 | 135,32 |

| 70x70x8 | 8,37 | 119,47 |

| 75x75x5 | 5,8 | 172,41 |

| 75x75x6 | 6,89 | 145,14 |

| 75x75x7 | 7,96 | 125,63 |

| 75x75x8 | 9,02 | 110,86 |

| 75x75x9 | 10,07 | 99,3 |

| 80x80x5.5 | 6,78 | 147,9 |

| 80x80x6 | 7,36 | 135,87 |

| 80x80x7 | 8,51 | 117,51 |

| 80x80x8 | 9,65 | 103,63 |

| 90x90x6 | 8,33 | 120,05 |

| 90x90x7 | 9,64 | 103,73 |

| 90x90x8 | 10,93 | 91,49 |

| 90x90x9 | 12,2 | 81,97 |

| 100x100x6.5 | 10,06 | 99,4 |

| 100x100x7 | 10,79 | 92,68 |

| 100x100x8 | 12,25 | 81,63 |

| 100x100x10 | 15,1 | 66,23 |

| 100x100x12 | 17,9 | 55,87 |

| 100x100x14 | 20,63 | 48,47 |

| 100x100x16 | 23,3 | 42,92 |

| 110x110x7 | 11,89 | 84,1 |

| 110x110x8 | 13,5 | 74,07 |

| 125x125x8 | 15,46 | 64,68 |

| 125x125x9 | 17,3 | 57,8 |

| 125x125x10 | 19,1 | 52,36 |

| 125x125x12 | 22,68 | 44,09 |

| 125x125x14 | 26,2 | 38,17 |

| 125x125x16 | 29.65 | 33,73 |

| 140x140x9 | 19,41 | 51,52 |

| 140x140x10 | 21,45 | 46,62 |

| 140x140x12 | 25,5 | 39,22 |

| 160x160x10 | 24,67 | 40,54 |

| 160x160x11 | 27,02 | 37,01 |

| 160x160x12 | 29,35 | 34,07 |

| 160x160x14 | 34,2 | 29,24 |

| 160x160x16 | 38,52 | 25,96 |

| 160x160x18 | 43,01 | 23,25 |

| 160x160x20 | 47,41 | 21,09 |

| 180x180x11 | 30,47 | 32,82 |

| 180x180x12 | 33,12 | 30,19 |

| 200x200x12 | 36,96 | 27,06 |

| 200x200x13 | 39,92 | 25,05 |

| 200x200x14 | 42,8 | 23,36 |

| 200x200x16 | 48,65 | 20,55 |

| 200x200x20 | 60,08 | 16,64 |

| 200x200x25 | 74,02 | 13,51 |

| 200x200x30 | 87,56 | 11,42 |

| 220x220x14 | 47,4 | 21,1 |

| 220x220x16 | 53,83 | 18,58 |

| 250x250x16 | 61,55 | 16,25 |

| 250x250x18 | 68,86 | 14,52 |

| 250x250x20 | 76,11 | 13,14 |

| 250x250x22 | 83,31 | 12 |

| 250x250x25 | 93,97 | 10,64 |

| 250x250x28 | 104,5 | 9,57 |

| 250x250x30 | 111,44 | 8,97 |

| 250x250x35 | 128,51 | 7,78 |

| Weight table for steel equal bent angle | ||

| Name and dimensions of the corner | Angle meter weight | Meters per ton |

| 36x3 | 1,57 | 636,9 |

| 40x2.5 | 1,48 | 675,7 |

| 40x3 | 1,76 | 568,2 |

| 50x3 | 2,23 | 448,4 |

| 50x4 | 2,90 | 344,8 |

| 55x3 | 2,43 | 411,5 |

| 60x3 | 2,70 | 370,4 |

| 60x4 | 3,53 | 283,3 |

| 60x3 | 2,67 | 374,5 |

| 70x4 | 4,16 | 240,4 |

| 70x4 | 4,10 | 243,9 |

| 80x3 | 3,64 | 274,7 |

| 80x4 | 4,79 | 208,8 |

| 80x5 | 5,92 | 168,9 |

| 80x6 | 7,01 | 142,7 |

| 80x7 | 8,11 | 123,3 |

| 80x4 | 4,74 | 211 |

| 80x5 | 5,87 | 170,4 |

| 100x4 | 6,05 | 165,3 |

| 100x5 | 7,49 | 133,5 |

| 100x6 | 8,89 | 112,5 |

| 100x7 | 10,31 | 97 |

| 100x4 | 6,00 | 166,7 |

| 100x5 | 7,44 | 134,4 |

| 100x6 | 8,79 | 113,8 |

| 120x5 | 9,06 | 110,4 |

| 120x6 | 10,78 | 92,8 |

| 120x5 | 11,10 | 90,1 |

| 160x4 | 9,76 | 102,5 |

Areas of application

Today, there are many different areas where 50x50x5 angle steel is successfully used. The weight of 1 meter of corner is considered optimal for implementing various construction and engineering tasks. Professional builders and designers consider this material indispensable, since it can be used to create durable metal frames and concrete structures, build durable bridges, overpasses, pavilions, canopies, stopping points and canopies.

The corner has found particularly wide application in architecture, as well as in the decoration of buildings and other objects: benches, gazebos, doors, fences, gates, fences and even stairs. You can often find angle steel in the furniture industry, as it is used to make durable frames, steel trims and other elements.

Metal corners are widely used in the automotive and carriage building, as well as in the production of large-sized equipment. Craftsmen use such details to harmoniously design corners when creating door and window openings, and also as an original decorative element for various structures.

Application areas of metal corners

- In homestead construction. Angular steel is used for the construction of large-sized greenhouses and small greenhouses, fences with chain-link mesh, portable and stationary gazebos.

- When constructing stairs - internal and external. The corner can be used for the manufacture of such metal products as step frames, porch platform frames, porch supports, stair railings.

- For strengthening window and door openings in brick or block masonry. The use of steel corner bars prevents the appearance of cracks in the wall and thereby extends the service life of the entire building.

- Production of canopies, street structures (benches, tables, swings), frames for bars on doors and windows, wickets, gates.

- Manufacturing of shelving in warehouses and in production , cabinet frames, trolleys, workbenches, various production equipment - testing and assembly stands.

- In everyday life - frames of metal doors, household brick stoves.

The widespread use of metal angles in construction provides the following advantages of rolled steel: a combination of strength and low weight, ease of transportation, storage and installation, durability subject to anti-corrosion treatment.

The main differences between aluminum products

Aluminum corners with different thicknesses differ from each other in the same way as steel ones. Determining the exact weight of such products is quite simple. Initially, the master needs to find out the specific gravity of 1 meter, which is then multiplied by the total number of meters in the batch. If the work is carried out using metal products that are manufactured in accordance with the standards of GOST 13737, then all calculations can be significantly simplified. The main thing is to have the appropriate regulatory document.

It is always important to remember that the weight of one meter of aluminum corner 50x50x5 is only 1,210 kg. In addition, such products have many operational advantages:

- It lends itself well to any type of processing.

- It is not subject to the negative effects of corrosion, which ensures the longest service life.

- Operates in any temperature conditions.

- It is possible to recycle with the least financial investment.

- Despite the light weight of aluminum products, they are highly durable and can withstand heavy loads.

- The good plasticity of the material simplifies installation work.

Experts note that aluminum corners are distinguished by their versatility and reliability. This is due to the fact that with their help you can build any structure that will have high strength characteristics without significantly affecting the weight of the finished structure.

What is stronger: a corner or a profile pipe: we delve into the nuances

As in the topic of contrasting a similar pipe with a channel, which we described separately, 2 specific products should be compared, and not both categories as a whole.

The strength of the product depends on the parameters:

- chemical composition of the metal used in production;

- manufacturing method (it was mentioned above that a hot-rolled angle is stronger than a cold-drawn one);

- geometric parameters of the product in question - length, thickness, width;

- weight;

- the presence of a weld (if we are talking about pipes);

- additional surface treatment (galvanization strengthens the product, preventing corrosion from destroying the metal in the long term).

Certification and implementation

The quality of manufactured equal-flange steel angles is controlled by GOST standard indicators. The main confirmation of the reliability and durability of corner metal products is a certificate, which is issued to manufacturers for a maximum of 3 years. When this period expires, the manufacturing company must go through all stages of certification again in a special Center. The manufacturer receives copies of the technical specifications for the manufacture of angles. Thanks to this, such a design always has high strength indicators that do not depend on operating conditions.

Most often, manufacturers sell whole batches of such parts, the weight of which does not exceed 70 tons. In addition, the products must be marked accordingly. Depending on the size, all products are packaged in special packs, which are also marked. Due to this, the transportation and unloading of products is greatly facilitated.

Separately, it is worth considering that in some cases the herringbone laying system - groove in groove - can be used. This technology is considered the most practical in the field of industrial construction.

Find out more about angle steel

- In addition to low-alloy structural grades of steel, the angle is made from high-alloy and even stainless steel raw materials, which, like galvanized products, are used in the food industry, including in aggressive environments.

- The angle works great for compression-tension and bending, of course taking into account axial moments, but it cannot be twisted around the longitudinal axis.

- Despite their resistance to temperature changes, structures made of angle steel can significantly lose their load-bearing capacity after just 5-10 minutes of exposure to an open flame. Therefore, in order to increase fire resistance, they are repeatedly coated with fire-retardant paints, and cladding with basalt wool can raise the fire resistance threshold of the metal to 150 minutes.

- Anti-corrosion treatment of the corner is also mandatory after completion of installation work.

Moreover, before applying any coatings, rust, slag and scale should be removed from welds, dirt and grease stains. Standard decorative and protective painting includes three layers: primer (strengthens adhesion), barrier and finishing (performed with enamel compounds). - Delivery of rolled metal products to the place of sale or directly to the consumer is mostly carried out by road or by rail. For automobile loadings, a limit is set to no more than 25 tons and 12 m in length, and a standard loading of a railway car should not exceed 70 tons of corners.

Characteristic advantages

It is in the construction industry that metal corners are most often used, since the price of these products is considered affordable, thanks to which large quantities of rolled metal can be purchased. The products themselves are presented in the form of a solid profile without any hollow spaces. Thanks to this, it is possible to achieve high performance and strength indicators, which is very important in the field of industrial and construction organizations. Most often, 50x50x5 corners are made of low-alloy and carbon steel, which determines such a high level of reliability of the metal corner.

It is also worth considering that the main advantages of steel angles include the following indicators:

- Good resistance to any deformation.

- Resistant to the negative effects of corrosion.

- Increased strength indicators.

- Resistant to sudden temperature changes.

- Possibility of reliable connection using a welding machine.

Before purchasing a metal corner, you need to carefully familiarize yourself with the technology of its production, which involves two universal methods. The first technology is based on rolling, when a metal billet passes through a multifunctional mill so that the steel angle acquires the desired shape and size. As for bent products, the bending technology itself involves the use of universal roll forming mills. It is worth considering that it is most suitable for thin-walled corners that cannot be used to reinforce floors.

Angle and profile pipes: definition, parameters, advantages

It’s easier to answer which corner or profile pipe is stronger when you know more about each type of product. Let's look at the main characteristics:

- Angles are rolled products with an L-shaped diameter. Produced by bending a steel sheet or by thermoforming. The second option is more durable. Products can have shelves of equal or different lengths. The length of products can be measured, unmeasured, multiple of measured, limited unmeasured. There are 2 classes of rolling accuracy - high (A), normal (B).

- Profile rolled products - pipes with diameters in the shape of a square, rectangle, oval, etc. They can be cold-drawn, electric-welded, hot-rolled, with or without seams. Lengths - unmeasured, measured, multiple. The maximum length is within 11.5-12.5 m. Wall thickness varies.

In the question of what is stronger than a profile pipe or an angle, at first glance it seems that rolled pipe is in the lead (due to 4 walls instead of 2, like an angle). But it's not that simple.

Square pillars still have a number of disadvantages

- the design turns out to be very labor-intensive, since it is necessary not only to ensure the vertical position of the pillars, but also to ensure that one of their faces is in the plane of the fence;

- since the weight of a square pipe is 30% more than a round one, its cost is 35% more expensive;

- the weld seam, present in pipes with a square cross-section along their entire length, serves as a place for the active development of corrosion processes, which are not hindered even by painting.

Therefore, we recommend that for fence posts you choose posts from used tubing pipes with a round cross-section and with the greatest possible wall thickness. It would be great if these pipes were made using seamless technology.

The joists are attached to the round posts in an overlapping manner using two short seams along the top and bottom edges of the joists. Such connections are not blown out, last a long time, and can be protected from corrosion with paint. The weld in this case is very strong, and the load-bearing structure of the fence has maximum rigidity due to the fact that the logs do not have to be cut. In addition, individual pillars do not protrude from the ground in this case.

Reinforced mounting angle: product dimensions

There are no more than ten options for corner sizes, which is quite enough for any construction work.

- HxLxBxS

- reinforced corner 40x40x40x2

- reinforced corner 50x50x35x2

- reinforced corner 70x70x55x2

- reinforced corner 90x90x40x2

- reinforced corner 90x90x65x2

- reinforced corner 105x105x90x2

- reinforced corner 130x130x100x2

Small sizes are used in furniture production to create frames and joints, where the fastening point is quite small and the strength requirements are high.

In wooden house construction, the cross-section of building timber is 100 mm by 100 mm or more. To reliably connect wooden elements to each other, reinforced fastening angles 90x90x65x2 and others are used.

When installing the corners, no cutting for fasteners is required, which means there is no weakening of the structure. Installation of perforated products is carried out on top of the connected structures. Therefore, the size of the reinforced corner is selected for a specific unit: the corner does not extend beyond the wooden element and, due to the stiffening rib, provides high load-bearing capacity.

What is stronger: corner or profile pipe?

Good afternoon, dear forum users! I plan to make a rack with spans of 2.5 meters, shelf width 700 mm. 20 mm plywood will be laid in the interior space. the lintels under the plywood will be made of professional pipe 20x40 mm. The load will be approximately 100-150 kg per shelf. what material is better to use, a 60x40 profile pipe with a wall thickness of 2 mm, or a 50x50 corner with a shelf thickness of 5 mm. I plan to hold concrete fence sections and 500x500 mm concrete slabs with a thickness of 50 mm on the racks. As you understand, deformation is unacceptable. What do respected gurus advise?

Best regards, Arman!

At one time they made something similar, shelving for sanitary ware. The pots and shelves are still standing. The structure was made from a 50x50 mm corner. [

Answer to the question: The best option to choose fence posts is made of tubing pipes (thick-walled pipe 5-8mm, seamless, durable - more than 50 years, 73 comes with a wall of 5.5 mm; this pipe will rot forever; the grade of steel is very cold/ the corrosion-resistant steel grade itself is NKT 20, steel NKT 30, steel NKT 30 KhMA and it costs 210 rubles/meter.).

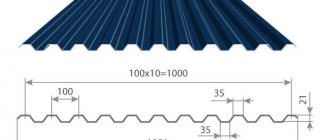

Which post should be preferred when constructing corrugated fences? The vast majority of people will say that a metal pipe is the best option. This is true. A pipe made of steel has the necessary strength to withstand bending loads, is durable and economical.

What cross-section should this pipe have: round or square? About half of people lean toward the first option, while the other half choose the second option. Aesthetic nuances aside, let’s consider what properties distinguish a square pipe from a round pipe.

Definitely, the bending strength of a square pipe will be much greater. If we take two pipes (square and round) with the same parameters, then the moment of resistance of the square pipe in cross-section will be approximately 1.7 times greater than that of the round pipe. This indicator is typical for square pipes, which are located parallel to the fence plane (that is, in 99% of cases). If the pillars are installed at an angle to the fence structure, the moment of resistance of a square pipe will exceed that of a round pipe by only 1.2 times.

But the technology, when the pipe is installed to the fence plane at a certain angle, has one significant drawback. In places where the logs are welded to the pole, corrosion will certainly form, which is almost impossible to combat. This is facilitated by constant humidity (due to precipitation), a sufficient amount of oxygen and lack of ventilation. Such conditions greatly accelerate corrosion processes, and the metal is destroyed very quickly. The weld also plays an important role in the development of corrosion. Only a few years will pass and the welded joint will completely fail. As a result, the fence will need repair or even replacement. Moreover, these destructions cannot be prevented or slowed down, since corrosion processes develop from the inside of the pipe.

People think that they can cut the fence logs in multiples of the post spacing, and then weld them end-to-end to each of the posts. But this, firstly, is not rational, since it requires a lot of work and considerable expenses. And, secondly, the strength and rigidity of the structure in the plane of the fence is significantly reduced. In this situation, the main load of the structure acts on the welds, which, according to engineers, is fundamentally wrong. In winter, under the influence of frost heaving forces, some of the pillars may rise. As a result, the welded joints cannot cope with the load and collapse. In addition, this requires high-quality welding work to ensure the tightness of the weld, in order to subsequently eliminate corrosion in the internal part of the log pipe.

A lot of people think that corrugated steel for a fence makes the structure of the fence more rigid, but this is far from the case. When the fence warps, the corrugated sheet simply breaks at the joints.