Brands B83 and B16

Babbitt is a tin or lead based anti-friction alloy intended for use as a layer poured or sprayed onto the bearing shell housing. Babbitt, the main component of which is tin (B83), is used to give the antifriction material increased viscosity and a minimum coefficient of friction. Babbitt, which is based on lead (B16), is used when the material needs to be given a property such as a high operating temperature.

Compared to lead, tin babbit has greater corrosion resistance, wear resistance and thermal conductivity. Lead-based babbits are used for bearings in diesel engines and rolling machines.

Application: B83, B16 | Chemical composition: B83, B16 | Properties: B83, B16 | Photo gallery

Chemical composition in % of babbitt grade B83

| Fe | Al | Cu | As | Pb | Zn | Sb | Bi | Sn |

| up to 0.1 | up to 0.005 | 5.5 — 6.5 | up to 0.05 | up to 0.35 | up to 0.004 | 10 — 12 | up to 0.05 | 80.941 — 84.5 |

| Note: Sn - base; the percentage of Sn is given approximately Source: GOST 1320-74 | ||||||||

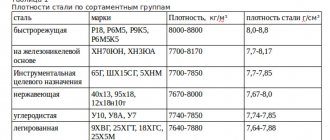

APPENDIX 4 (recommended). METAL MATERIALS SINTERED IMPROPERABLE AND HARD ALLOYS

1. Purpose and scope

- A detailed guide to increasing the electrolyte density in a battery at home

2. Links

3. Essence

4. Apparatus and materials

4.1. Precision scales with an accuracy of ±0.1 mg for sample weights up to 10 g and ±0.001% for sample weights over 10 g. Samples must be calibrated and have a density of at least 7 g/cm.

Damn.2

4.3. Vessel for weighing in liquid. To weigh test samples weighing less than 10 cm, a vessel is required that ensures that the liquid level rises when the test sample is immersed by at least 2.5 mm.

| Temperature, °C | , g/cm |

| 0,9981 | |

| 0,9979 | |

| 0,9977 | |

| 0,9976 | |

| 0,9974 | |

| 0,9972 | |

| 0,9970 | |

| 0,9967 | |

| 0,9965 | |

| 0,9963 | |

| 0,9960 | |

| 0,9958 | |

| 0,9955 | |

| 0,9952 | |

| 0,9949 | |

| 30 | 0,9946 |

2. When using brass hinges in air, the value is 0.00106 g/cm less than the true density of water measured in a vacuum.

5. Test sample

5.2. The volume of the test sample must be at least 0.5 cm. If it is necessary to determine the density of a sample with a volume of less than 0.5 cm, then several samples can be taken for one determination, and the volume of each individual sample must be at least 0.05 cm.

- How to calculate the specific gravity in different areas?

6. Conducting the test

6.1. Place the test sample on the upper grid (Fig. 1) or bowl (Fig. 2). The bottom grid should be completely submerged, the wire should hang freely from the bowl and should be partially submerged in the liquid. Remove any air bubbles and weigh ().

7. Processing of results

The density of the test sample in grams per cubic centimeter is determined by the formula

,

where is the mass of the test sample determined by weighing;

— liquid density in air, g/cm; - the mass of the volume of liquid displaced by a sample placed in this liquid, equal to the difference in the masses of the sample suspended in air and the sample suspended in water, g.

8. Test report

Properties of material B83

| Property | Unit. | Meaning |

| Foundry and technological properties | ||

| Melting temperature | °C | 370 |

| Mechanical properties at T=20oC | ||

| Short-term strength limit | MPa | 110-120 |

| Proportional limit (yield strength for permanent deformation) | MPa | 80-85 |

| Material hardness | HB 10 -1 = 27 - 30 MPa | |

| Physical properties at T=20oC | ||

| Density | kg/m3 | 7380 |

| GOST 1320-74 | ||

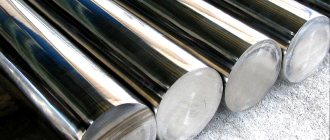

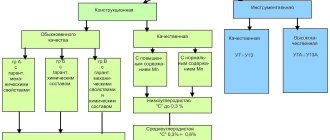

Steel - concept and its characteristics

- shear modulus;

- elastic modulus;

- density;

- linear increase rate.

Various areas of use of materials require different chemical and physical parameters from them. So, for example, steel alloys with a high modulus of elasticity are used for the manufacture of springs and spring-type dampers. These indicators purposefully change as a result of the addition of a variety of additives.

Chemical composition in % of material B16

GOST 1320 - 74

| Fe | Al | Cu | As | Pb | Zn | Sb | Bi | Sn |

| up to 0.1 | up to 0.01 | 1.5 — 2 | up to 0.3 | 63.34 — 68.5 | up to 0.15 | 15 — 17 | up to 0.1 | 15 — 17 |

| Note: Pb is the base; The percentage of Pb is given approximately by GOST 1320-74 | ||||||||

Standards

| Name | Code | Standards |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 1320-74, STP M320-74 |

| Castings from non-ferrous metals and alloys | B84 | OST 24.916.01-71 |

| Test methods. Package. Marking | B59 | STP M320-2003 |

| Hard alloys, metal-ceramic products and metal powders | B56 | TU 14-22-91-95 |

Properties of material B16

| Property | Unit. | Meaning |

| Foundry and technological properties | ||

| Melting temperature | °C | 410 |

| Mechanical properties at T=20oC | ||

| Short-term strength limit | MPa | 147 |

| Proportional limit (yield strength for permanent deformation) | MPa | 86 |

| Material hardness | HB 10 -1 = 30 MPa | |

| Physical properties at T=20oC | ||

| Density | kg/m3 | 9290 |

| GOST 1320-74 | ||

Production

Both ore and scrap metal are used to smelt babbitts. The share of secondary production in our country accounts for about 75%. Alloys are transported in the form of pigs, the weight of which is strictly regulated by state standards and does not exceed 22 kg.

Melting of pigs is carried out in special chamber-type electric furnaces. This process is relatively cheap. This is primarily due to the low melting point of the alloys. Typically, in medium-scale production conditions, 26 kW of furnace power is sufficient.

When melting, the main difficulty is obtaining the chemical composition stated in the state standard. Any deviation from the norm can lead to a significant change in performance characteristics, which will affect the longevity of the bearing in the future.

For this reason, pigs are pre-cleaned from contamination with special detergents. Next comes degreasing the surface. And only after all these steps have been completed is the babbitt placed in the oven.

Photo gallery

Tin babbits

| ||||||||||||||||||

Specific and volumetric weight of concrete in 1 m3, table of weights of all brands.

Concrete is the main component of any construction work, be it ordinary repairs or the construction of pits and structures.

It has high strength initially, but with the use of additives it can improve its characteristics. Also, when kneading, the volume of water spent is taken into account. Based on these characteristics, concrete is divided into four types: light and heavy, especially light and especially heavy.

Weight of 1 cube of concrete of all brands and classes, table:

Detailed weight table. Concrete grade Concrete class Weight of 1 m3 of concrete (kg) М100В7.52494М200В152432М250В202348М300В22.52502М350В252502М400В302376

Types of specific gravity of 1 cube of concrete.

The most common way to classify the mass of a cube of composition is by dividing it according to specific gravity.

According to the volumetric mass, the following types of concrete are distinguished:

What determines the weight of 1 meter of cubic concrete?

As in any other case, we need to start with theoretical foundations. First, let's find out what exactly this weight of concrete pavement is for every 1m3.

Weight of a cubic meter of concrete depending on the aggregate:

What are the main indicators of concrete quality?

- strength and durability;

- frost resistance and moisture resistance;

- degree of adhesion (hardening speed);

- weight of concrete per 1m3.

How to sell for maximum profit

The cost at which babbitt scrap can be sold depends entirely on the chemical composition and concentration of the alloy.

Resellers and small bases that do not have a license and special equipment will not be able to accurately determine the amount of tin or lead in a product.

Licensed companies for the purchase and processing of metal are the best option for profitable sale of babbitts.

Spectral analysis done using professional instruments will show the exact content of a particular metal.

For the removal of large volumes of illiquid goods (usually from 200 kg), transportation services are provided. The departure of cargo vehicles can be ordered by phone, having discussed the time and details of the transaction.

Finding a metal warehouse with favorable conditions is not easy. After reading reviews about a particular company on the Internet, you can make a mistake in choosing a collection point. Often these reviews are paid by the content master and written for monetary compensation by freelancers.

You can also find buyers of non-ferrous scrap metal with favorable conditions and prices on specialized forums or on social networks, where discussion participants will suggest the most profitable option in your region.

The easiest and fastest option to find the most favorable conditions for accepting babbitt scrap is to arrange a mini-tender (if the volume is significant) or independently collect information on 5-10 collection points. That is, either send out your offer, or call the company and write out prices and terms of acceptance.

for legal entities to correctly register the write-off of production waste. The procedure necessary for this can be ordered from specialists from a company that has the rights to provide legal support when accepting waste materials.

Reusing metal raw materials allows us to minimize the cost of mining rare earth ore, preserving the Earth's natural resources.

Tin and lead are non-ferrous exchange metals, the demand for them never falls. Selling babbitt scrap will bring good income if you choose the right collection point.

In this video you can see how the composition of babbitt is analyzed using special equipment:

Equipment

What equipment is used to fill bearings with babbitt? For this purpose, special sets of equipment are produced, for example, KO-2, on which bearings are manufactured by centrifugal casting.

This kit is available in several modifications:

- MPS - for filling plain bearings 8ТН.263.028 and 8ТН.263.029;

- D360 x L310 - for pouring plain bearings with an outer diameter of up to 360 mm, an inner diameter of 40 mm and a length of up to 310 mm;

- D950 x L500 - for pouring plain bearings with an outer diameter of up to 950 mm, an inner diameter of 60 mm and a length of 500 mm.

The use of special equipment allows you to pour babbitt more accurately, without overuse and defects.

Read also: Tool for cutting round holes in wood

For smelting babbitt from old bearing shells, special furnaces are also produced, for example, chamber furnaces of the PKN type of different sizes and power:

- PKN-0.6-2000 with a power of 100 kW,

- PKN-0.6-180 with a power of 26 kW.

The ovens are made of fire-resistant materials, and spirals of superfechral wire are used as heaters. They are equipped with a tray for installing bearing shells and a tray for draining molten babbitt.

Other types of furnaces are also used to pour the alloy into bearing shells, for example, PPN with a bottom spill valve. Crucibles with babbitt are placed in such furnaces. They are also heated by electric heaters. Such furnaces have a channel for emergency drainage and are controlled from a remote control on which operating modes are set. Ovens of the PPN type make it possible to dose babbitt into bearing shells.