home

About company

Directory

Galvanized sheet

Corrosion destroys about 10% of all metal produced in the world; every sixth or seventh blast furnace works in vain: the steel smelted in it completely turns into rust within a year. Even in developed countries with high technology, the damage caused by corrosion can reach 4% of GDP. One of the most effective ways to protect against corrosion is to apply a protective layer of zinc to the surface of metal structures. Galvanizing is several times cheaper than paint and varnish coatings, and, at the same time, extends the service life of the metal by 30-40 years.

Sheet (also rolled) galvanized steel is produced:

- hot galvanizing of thin-sheet cold-rolled steel coils;

- by applying galvanic coating;

- spraying (gas-thermal method);

- thermal diffusion galvanizing.

The most common is hot-dip galvanizing; this technology makes it possible to produce a strong and durable anti-corrosion coating with a thickness of 10 to 60 microns at the lowest cost. Matte white, sometimes with a gray tint without shine, the coating obtained by hot-dip galvanizing is inferior in decorative qualities to shiny and silver galvanized ones, but has greater hardness and excellent strength characteristics.

Galvanized sheet GOST 14918-80 (technical conditions and requirements)

Standard 14918-80 applies to cold-rolled carbon steel 0.5 to 2.5 mm thick that has been continuously hot-dip galvanized (which results in the formation of a corrosion-resistant Zn-Fe alloy on the metal surface). For galvanizing low-carbon steels, technical conditions are determined separately, by standard R 52246-2004.

| № | Classification of galvanized steel GOST 14918-80 | Groups, categories, classes | Abbreviation (used for symbolic designation) |

| 1 | Assignment Groups | General purpose | HE |

| For cold stamping | XSh | ||

| For cold profiling | HP | ||

| For painting | PC | ||

| 2 | Hood categories | Very deep draw | VG |

| Deep | G | ||

| Normal | N | ||

| 3 | Tread quality | Reduced thickness variation | UR |

| Normal thickness variation | HP | ||

| 4 | Galvanization layer thickness, class | I class | 1 |

| II class | 2 | ||

| Elevated | P | ||

| 5 | Appearance of galvanization/type of crystallization pattern (by agreement with the customer) | With crystallization pattern | KR |

| Without crystallization pattern | MT |

Sheet according to GOST No. 14918-80

The standard conditions apply to steel in the form of sheets and coils that are hot-dip galvanized in permanent galvanizing units.

The technical degree coefficients, which are established by standard norms, must be in accordance with the requirements of the first two quality categories.

Galvanized sheet steel is divided into:

1. By purpose:

- for types for cold stamping - X W,

- for cold profiling - X P,

- for painting - P K,

- general use - OH;

2. According to the ability to draw (steel category X W):

- conventional hood - H,

- deep drawing - G,

- very deep drawing - V G;

3. According to the uniform thickness of the special zinc coating:

- with normal thickness variation - HP,

- with reduced thickness variation - U P;

4. By mutual agreement of the customer and the manufacturer, steel can be manufactured:

- with zinc stains on the surface - KP,

- without zinc stain on the surface - MT;

5. Depending on the thickness of the special coating, galvanized steel is divided into three classes:

- elevated,

- first,

- second.

How many liters of water are in a cube?

Putty consumption per 1m2 - consumption of starting and finishing putty

Galvanized steel is produced in widths from 710mm to 1800mm, thickness from 0.5mm to 2.5mm from cold rolled steel.

Underlay for laminate: types, tips on selection and installation

OSB boards: technical characteristics, types, sizes, painting

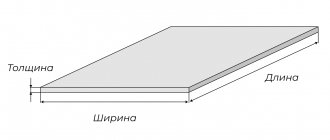

Galvanized sheet, dimensions according to GOST 19904-90 (assortment)

Dimensions, maximum deviations and requirements for manufacturing accuracy for galvanized steel are established by the GOCT 19904-90 assortment in the same way as for non-galvanized cold-rolled sheet steel.

Galvanized steel according to specifications in accordance with GOCT 14918-80 is manufactured in widths from 700 to 1800 mm (size increments depending on the range of 50, 100 and 150 mm), lengths from 1000 to 6000 mm (size increments 20, 80, 100, 150, 200, 300, 500 mm), however, by agreement with the consumer, if necessary, other sizes can be installed.

The thickness of the galvanized sheet is regulated in the range from 0.5 to 2.55 mm, and the assortment determines the following dimensional step:

- thickness range 0.5-0.8 mm - step is 0.05 mm;

- range 0.8-1.8 mm - step 0.1 mm;

- range 1.8-2.5 - step 0.2, last - 0.3 mm.

Galvanized sheet

View price – Galvanized sheet

Galvanized sheet is a rolled product that is made from high-quality and ordinary quality carbon steel, from sheet steel processed by the galvanizing method. galvanized sheets with a width of 500 mm or more, a thickness from 0.5 mm to 2.5 mm according to and from 0.3 mm to 4.9 mm according to GOST R 52246-2004.

Galvanized steel sheet is manufactured according to the following standards:

GOST 14918-80 Galvanized thin sheet steel from continuous lines

GOST R 52146-2003 Thin cold-rolled and cold-rolled hot-dip galvanized steel sheet with polymer coating from continuous lines.

GOST R 52246-2004 Rolled hot-dip galvanized sheets

GOST R 54301-2011 Thin cold-rolled electrolytically galvanized sheet with polymer coating from continuous lines.

GOST 24982-81 Rolled sheets of corrosion-resistant, heat-resistant and heat-resistant alloys.

GOST 17066-94 Rolled thin sheets of high strength steel.

TU 14-1-4695-89 Electrolytically galvanized steel sheet with polymer coating .

TU 14-1-4766-90 Electrolytically galvanized steel sheet.

TU 14-1-4792-90 Cold-rolled and hot-dip galvanized steel with organic coating.

Zinc protects the metal from corrosion and ultraviolet radiation, and has electrochemical resistance, which gives the metal durability and reliability. Due to this, galvanized iron sheets (galvanization) are widely used in many industries. It is used in construction and installation work, in mechanical engineering, the automotive industry, the production of various equipment and machinery, in shipbuilding, in the construction of granaries, and galvanized sheets are also used as decorative metal sheets for cladding facades . One of the main applications is roofing made of galvanized metal sheets , for the manufacture of tin and drainage products; galvanization is indispensable in the production of washing machine and refrigerator housings, drinking water tanks, guaranteeing a long service life for the coating.

The production of galvanized metal sheets is carried out in several stages. First, the sheet undergoes heat treatment, degreasing, pickling, washing, and only after that it is immersed in a galvanic solution, as a result of which a ferro-zinc alloy is formed on the surface of the metal, which leads to increased anti-corrosion properties. The sheet or roll is then cooled.

In Russia, galvanized sheets are produced by: OJSC Novolipetsk Iron and Steel Works, OJSC Magnitogorsk Iron and Steel Works.

Galvanized thin-sheet sheet from continuous lines GOST 14918-80

This standard applies to coils and sheets of cold-rolled steel galvanized in continuous hot-dip galvanizing units. Galvanized steel is produced in widths from 710 to 1800 mm inclusive, thickness from 0.5 mm to 2.5 mm inclusive. Dimensions, maximum deviations and other characteristics of the product range must comply with GOST 19904 (hot-rolled sheets).

Thin galvanized metal sheets are divided into groups:

1) according to purpose:

- for cold stamping - KhSh - for cold profiling - KhP - for painting - PK - general purpose - ON

2) according to the ability to draw (for group XSh):

- normal drawing - N - deep drawing - G - very deep drawing - VG

3) according to the uniform thickness of the zinc coating:

— with normal thickness variation — NR — with reduced thickness variation — UR

4) by the presence of a pattern:

— with crystallization pattern — KR — without crystallization pattern — MT

5) according to the thickness of the zinc coating into classes:

— advanced class (P), 1st class, 2nd class.

Zinc coating thickness classes GOST 14918-80

| Thickness class | Weight of 1 sq m of coating layer on both sides, g | Coating thickness, microns |

| P(increased) | More than 570 to 855 included | Over 40 to 60 included |

| 1 | More than 258 to 570 included | Over 18 to 40 included |

| 2 | From 142.5 to 258 inclusive | From 10 to 18 included |

The reduced thickness variation of the zinc coating (CP) must correspond to:

- for class P no more than 16 microns - for class 1 - no more than 10 microns - for class 2 - no more than 4 microns

Example of marking of galvanized sheet:

Ots A-O- 1.5x1250x2500 GOST 19904-90 08kpVG-MT-UR-2 GOST 14918-80

Galvanized sheet of increased rolling precision A, with a cut edge O, thickness 1.5 mm, width 1250 mm, length 2500 mm, according to GOST 19904-90 in terms of assortment, steel grade 08kp, very deep drawing VG, without crystallization pattern MT, with reduced thickness variation UR, 2nd class coating, according to GOST 14918-80 (galvanized thin-sheet sheet with continuous lines).

Galvanized steel sheet is intended for cold profiling, for painting, for the manufacture of stamped parts, containers and other metal products.

Theoretical calculation of the number of square meters per ton of galvanized sheet, weight of 1 m2 of galvanized steel sheet .

| Thickness of galvanized sheet, mm | Number of square meters in 1t | Weight m2 of galvanized sheet |

| Galvanized sheet 0.5 mm | 242,42 | 4,13 |

| Galvanized sheet 0.55 mm | 221,36 | 4,52 |

| Galvanized sheet 0.7 mm | 175,59 | 5,70 |

| Galvanized sheet 0.8 mm | 154,32 | 6,48 |

| Galvanized sheet 1 mm | 124,22 | 8,05 |

| Galvanized sheet 1.2 mm | 103,95 | 9,62 |

| Galvanized sheet 1.5 mm | 83,51 | 11,97 |

| Galvanized sheet 2.0 mm | 62,89 | 15,90 |

| Galvanized sheet 2.5 mm | 50,45 | 19,82 |

| Galvanized sheet 3.0 mm | 42,46 | 23,68 |

Buy galvanized sheet

From us you can purchase galvanized steel sheets of all types produced from warehouses of branches, warehouses in the Moscow region or directly from the factory. We provide metal sheet cutting, delivery and packaging services. Availability, dimensions of galvanized sheets, thickness of galvanized sheets and the price of galvanized sheets per ton can be found on the website in the price list for galvanized sheets . You can clarify the price of a galvanized steel sheet per piece, the weight of a galvanized sheet , calculate the quantity, issue an invoice and fill out an application, clarify payment options and request a certificate for a galvanized sheet - you can contact the manager by contacting him by phone:

(8452) 57-00-18, e-mail: [email protected]

Weight of galvanized sheet

The weight of a galvanized sheet (one square meter) can theoretically be calculated using the formula:

M=M1×t1+M2×t2

(1)

Where:

- M - weight of 1 m² of galvanized sheet, kg;

- M1 - weight of 1 m² of steel sheet without a cladding layer 1 mm thick;

- t1 is the thickness of the steel sheet without coating;

- M2 - weight of 1 m² of zinc cladding layer 1 mm thick;

- t2 is the thickness of the zinc layer on both sides of the sheet.

The specific gravity of carbon steel is 7.85 g/cm³, or, for convenience of calculations, it is generally accepted that 1 m² of sheet steel with a thickness of 1 mm weighs 7.85 kg. The specific gravity of zinc is slightly less - 7.13 g/cm³, that is, 1 m² of zinc with a thickness of 1 mm weighs 7.13 kg. Taking into account these quantities, formula (1) can be rewritten:

M=7.85×t1+7.13×t2

The thickness of the zinc layer depends on the coating class (GOCT 14918-80) and is indicated in the symbol:

| Class | Limit values for layer thickness, mm | Weight of tread layer on both sides, kg |

| I | From 0.018 to 0.04 Average value 0.029 | 0.258-0.570 Average 0.414 |

| II | From 0.01 to 0.018 Average value 0.014 | 0.1425-0.258 Average 0.200 |

| P (increased) | From 0.04 to 0.06 | 0.57-0.855 Average 0.712 |

To calculate the weight of a galvanized sheet, you can also use a formula that takes into account the weight of the coating depending on the class of layer thickness:

M=7.85×t1+Mp.s., where:

- M - galvanized sheet weight 1 m², kg

- t1 is the thickness of the steel sheet without coating;

- Mp.s. - the average weight of the tread layer depending on the thickness class, the value is standardized by GOCT 14918-80.

To calculate how much a galvanized sheet weighs (the weight of one sheet of the required size), use the formula:

Msheet=M×S, where:

- Msheet - weight of one galvanized sheet, kg;

- M – weight of 1 m², kg;

- S—sheet area, m².

Considering that the GOST 19904-90 assortment allows deviations from the design weight of up to 3% (due to regulated maximum deviations in thickness, length and width), as well as taking into account the small thickness of the cladding layer and the small difference between the specific gravity of steel and zinc alloy ( which may contain lead and aluminum), the theoretically calculated mass may differ slightly from the actual weight.

| № | Sheet thickness, mm | Weight of 1 m² of steel without zinc coating , kg | Weight of 1 m² of galvanized steel, 1 class of coating thickness , kg | Weight of 1 m² of galvanized steel, class 2 coating thickness , kg | Weight of 1 m² of galvanized steel, coating thickness class P , kg | Number of m² per ton of galvanized steel class 2 |

| 1 | 0,50 | 3,925 | 4,339 | 4,125 | 4,637 | 242,42 |

| 2 | 0,55 | 4,317 | 4,731 | 4,517 | 5,029 | 221,36 |

| 3 | 0,60 | 4,710 | 5,124 | 4,910 | 5,422 | 203,67 |

| 4 | 0,65 | 5,103 | 5,517 | 5,303 | 5,815 | 188,60 |

| 5 | 0,70 | 5,495 | 5,909 | 5,695 | 6,207 | 175,59 |

| 6 | 0,75 | 5,888 | 6,302 | 6,088 | 6,600 | 164,2 |

| 7 | 0,80 | 6,280 | 6,694 | 6,480 | 6,992 | 154,32 |

| 8 | 0,90 | 7,065 | 7,479 | 7,265 | 7,777 | 137,65 |

| 9 | 1,00 | 7,850 | 8,264 | 8,050 | 8,562 | 124,22 |

| 10 | 1,10 | 8,635 | 9,049 | 8,835 | 9,347 | 114,09 |

| 11 | 1,20 | 9,420 | 9,834 | 9,620 | 10,132 | 103,95 |

| 12 | 1,50 | 11,775 | 12,189 | 11,975 | 12,487 | 83,51 |

| 13 | 2,00 | 15,700 | 16,114 | 15,900 | 16,412 | 62,89 |

| 14 | 2,50 | 19,625 | 20,039 | 19,825 | 20,337 | 50,45 |

According to GOCT 14918-80, galvanized steel can be manufactured with a differentiated coating: on one side thickness class No. 2, and on the other - No. 1 or P, which is taken into account when calculating weight.

How to calculate the weight of galvanized steel sheets?

M=M1+M2, where M is the final weight of the sheet (kg), M1 is the weight of iron (kg), M2 is the weight of zinc (kg).

In this case, M1=T1 x l1 x H1 x P1,

where T1 is the thickness of the iron sheet (mm). When calculating, it is important to take into account that the thickness of the iron is 0.05 mm lower than the finished product for class 1 zinc special coating and 0.03 mm less for class 2; l1 - length of sheet iron (m); H1 - width of iron sheet (m); P1 is an indicator of iron density (7.85 t/m3).

M2=T2 x l2 x H2 x P2,

where, T2 is the thickness of the galvanized layer (depending on the category, where the thickness of the 1st category is 0.0381 mm, and the second is 0.0216 mm); l2 - length of special coating (m); H2 - width of special coating (m); P2 is an indicator of zinc density (7.13 t/m3).

Thanks to the formula, it is possible to make calculations before purchasing. This will allow you not to be deceived and to accurately calculate the required amount of material.

There are also tables that already have calculations and ready-made results. Therefore, in some cases, avoiding calculations, you can refer to the following tables:

Table for calculating the mass of galvanized sheet steel

| Thickness of galvanized steel | Number of m2 of galvanized steel in 1 ton | Weight 1m2 galvanized steel |

| 0.4mm | 299.40m2 | 3.34kg |

| 0.45mm | 267.92m2 | 3.73kg |

| 0.5mm | 242.42m2 | 4.13kg |

| 0.55mm | 221.36m2 | 4.52kg |

| 0.6mm | 203.67m2 | 4.91kg |

| 0.65mm | 188.60m2 | 5.31kg |

| 0.7mm | 175.59m2 | 5.70kg |

| 0.75mm | 164.2m2 | 6.09kg |

| 0.8mm | 154.32m2 | 6.48kg |

| 0.9mm | 137.65m2 | 7.27kg |

| 1mm | 124.22m2 | 8.05kg |

| 1.1mm | 114.09 m2 | 8.83kg |

| 1.2mm | 103.95m2 | 9.62kg |

| 1.5mm | 83.51m2 | 11.97kg |

| 2mm | 62.89m2 | 15.9kg |

| 2.5mm | 50.45m2 | 19.82kg |

Table for calculating the mass of galvanized steel with polymer coating

| Thickness of galvanized steel with special coating | Number of m2 of galvanized steel with special coating in 1 t | Weight 1m2 of galvanized steel with special coating |

| 0.4mm | 318.47m2 | 3.14kg |

| 0.45mm | 283.29m2 | 3.53kg |

| 0.5mm | 253.81m2 | 3.94kg |

| 0.55mm | 232.02m2 | 4.31kg |

| 0.6mm | 213.22m2 | 4.69kg |

| 0.65mm | 196.67m2 | 5.08kg |

| 0.7mm | 182.15m2 | 5.49kg |

| 0.75mm | 170.07m2 | 5.88kg |

| 0.8mm | 158.98m2 | 6.29kg |

| 0.9mm | 141.04m2 | 7.09kg |

| 1mm | 125.94m2 | 7.94kg |

Calculation of electric current by power: formulas, online calculation, selection of machine

Calculation of boards and timber in one cubic meter - formulas, calculation examples, tables

Hot-rolled and cold-rolled steel sheets

Dimensions and weight of the sheet (GOST 19903-90 and 19904-90) based on a specific gravity of 7.85 g/cm3

| Thickness (size), mm | Sheet weight, kg |

| 0.5 (1250x2500) | 12,26 |

| 0.55 (1250x2500) | 13,5 |

| 0.6 (1250x2500) | 14,71 |

| 0.7 (1250x2500) | 17,81 |

| 0.8 (1250x2500) | 19,62 |

| 0.9 (1250x2500) | 22,06 |

| 1 (1250x2500) | 24,53 |

| 1.2 (1250x2500) | 29,43 |

| 1.4 (1250x2500) | 34,34 |

| 1.5 (1250x2500) | 36,78 |

| 1.7 (1250x2500) | 41,69 |

| 1.8 (1250x2500) | 44,16 |

| 1.9 (1250x2500) | 46,60 |

| 2 (1250x2500) | 49,06 |

| 2.5 (1250x2500) | 61,31 |

| 3.0 (1250x2500) | 73,59 |

| 3.5 (1250x2500) | 85,84 |

| 4 (1500x6000) | 282,6 |

| 5 (1500x6000) | 353,25 |

| 6 (1500x6000) | 423,9 |

| 7 (1500x6000) | 494,55 |

| 8 (1500x6000) | 565,2 |

| 9 (1500x6000) | 635,85 |

| 10 (1500x6000) | 706,5 |

| 12 (1500x6000) | 847,8 |

| 14 (1500x6000) | 989,1 |

| 16 (1500x6000) | 1130,4 |

| 18 (1500x6000) | 1271,7 |

| 20 (1500x6000) | 1413 |

| 22 (1500x6000) | 1554,3 |

| 25 (1500x6000) | 1769,4 |

| 30 (1500x6000) | 2119,5 |

| 40 (1500x6000) | 2826 |

| 50 (1500x6000) | 3532,5 |

| 60 (1500x6000) | 4239 |

Features of galvanized sheet production

The production of these metal products is regulated by GOST 14918-80. There are several galvanizing methods:

- Hot . It is carried out in special baths with molten zinc. After processing, the product is blown with compressed air to remove excess zinc and dry it. This coating is characterized by: significant thickness, strength, and insufficient decorative characteristics.

- Galvanic (electrochemical) . This method allows you to obtain a uniform decorative zinc layer with high adhesion to the base.

- Cold . Produced using zinc-containing compounds. This coating has low resistance to external influences.

As a result of galvanizing, sheets with different coating thicknesses are obtained:

- increased – 40-60 microns;

- 1st class – 18-40 microns;

- Class 2 – 10-18 microns.

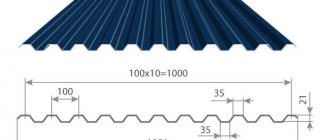

Calculation of the mass of corrugated sheets

The weight of 1 m2 of profiled galvanized sheet depends on the thickness of the rolled product and the geometry of the profile. The table shows the weights of the most popular brands of corrugated sheets.

| Brand of corrugated sheet | Thickness, mm | Weight 1 m2, kg | Brand of corrugated sheet | Thickness, mm | Weight 1 m2, kg |

| For roofing and load-bearing | Universal | ||||

| N 57 | 0,55 | 7,4 | NS 35 | 0,55 | 6,3 |

| 0,7 | 8,6 | 0,7 | 7,4 | ||

| 0,8 | 9,8 | 0,8 | 8,4 | ||

| N 60 | 0,7 | 8,8 | NS 44 | 0,7 | 8,3 |

| 0,8 | 9,9 | 0,8 | 9,4 | ||

| 0,9 | 11,1 | Wall | |||

| N 75 | 0,7 | 9,8 | From 15 | 0,55 | 5,4 |

| 0,8 | 11,2 | 0,7 | 6,8 | ||

| 0,9 | 12,5 | From 18 | 0,55 | 6,3 | |

| N 114 | 0,8 | 13,0 | 0,7 | 7,4 | |

| 0,9 | 15,6 | From 21 | 0,55 | 6,3 | |

| 1,0 | 17,2 | 0,7 | 7,4 | ||

To determine the mass of a sheet, the weight of 1 m2 is multiplied by its length and width.

Corrugated steel sheet

Thickness and weight of corrugated sheet (GOST 8568-77).

| Thickness, mm | Weight, kg/m2 |

| diamond knurling | |

| 2,5 | 21,0 |

| 3,0 | 25,1 |

| 4,0 | 33,5 |

| 5,0 | 41,8 |

| 6,0 | 59,0 |

| 8,0 | 66,0 |

| 10,0 | 83,0 |

| 12,0 | 99,3 |

| lenticular corrugation | |

| 2,5 | 20,1 |

| 3,0 | 24,2 |

| 4,0 | 32,2 |

| 5,0 | 40,5 |

| 6,0 | 48,5 |

| 8,0 | 64,9 |

| 10,0 | 80,9 |

| 12,0 | 96,8 |