Today we will look at one of the types of processing of wooden products - wood jointing . If you are going to build a house yourself, especially a frame house, then you will definitely need this.

Wood planing is a wood processing method that involves planing the plane of wood after sawing. The tool used for jointing is a jointer or plane (I will explain how they differ from each other a little later). The peculiarity of its work is to level the surface of the wooden workpiece, after which the working surface becomes smooth, even and without defects. Depending on the stages of jointing, different types of planes and jointers are used.

What is the difference between a planer and a jointer?

Planing and jointing machines are essentially the same thing.

They are designed for straight planing of wooden workpieces. This type of processing is carried out by removing chips to obtain a smooth surface. Such machines have the same structure and operating principle. They consist of beds, work tables and knife shafts mounted in them. The workpiece is placed on the table along a guide and is fed manually by the operator. The choice of name - planer or jointer - is decided by the manufacturer. Domestic companies mainly use the first option, European companies use the second.

Jointing and thicknessing without errors

Planer and planer machines work in a similar way, removing a layer of material from the face or edge of a board, so the purpose of these machines is often confused. Both serve to level the surfaces of lumber and give it a rectangular cross-section, but each is used in a specific way and performs different operations. A planer-jointer can make one face of a board flat and the adjacent edge perpendicular to the face, but it is not able to give this board the same thickness along its entire length - this is the work of a thicknesser. Thus, planer-jointer and thicknesser machines work in conjunction. The production of flat workpieces of the correct shape begins on a planer-jointer, so we will first consider it.

What to choose for construction at the dacha - a planer or an electric plane?

It all depends on the task at hand. If you need to build a house, it is better to purchase a machine. In this case, you gain in productivity. The work will be done faster, and you will spend less effort on it. The result is achieved due to the large planing width and precise positioning of the workpiece along the guide.

Compared to a machine, the main advantage of an electric plane is its small size. Thanks to them, it does not take up much space in the workshop. But for planing boards, it makes no sense to buy a tool with a width of less than 100 mm. Large planes weigh 4 kg or more and are not very convenient for processing small workpieces, used, for example, in the manufacture of furniture. There are no such issues with the machine; it is much easier to use. Its disadvantage is that it requires storage space. If you are not at the dacha all the time, the question of its safety arises. It is quite difficult to take it with you due to its large dimensions and weight.

Purpose and types of tools

A type of plane for finishing wood, it is a long plane with two blades Source livemaster.ru

Above we briefly mentioned what a jointer is for, but let's go into a little more detail. This tool is designed for finishing large pieces of wood, such as boards, beams and whetstones. It can be used to finish the planes and edges of a part. The body (block) of a manual jointer is made exclusively of wood, although metal varieties are noted on the Internet. This is not entirely true. If a tool of this size is made of steel, then it will simply be impossible to work with it due to its large mass.

The manual or electric jointer has the following features:

- used for finishing surfaces and edges of large workpieces (most often the length of the part is decisive);

- the knife used in this carpentry tool can be up to 80 mm wide;

- during the initial pass of the surface, small intermittent chips are obtained, and during the secondary pass, long and even chips are obtained, which indicates the cleanliness of the processing;

- On sale you can find both a manual jointer and an electric jointer: this indicates a wide selection and popularity of the tool.

I want to make a veranda and a fence along the site from unplaned boards, what do you recommend?

You can quickly make such boards smooth on a planer or jointer. With the help of such stationary equipment, you will complete most of the work with high quality; no grinding is required. It is enough to purchase any of the models presented in our online store at the lowest prices.

The Enkor and Caliber machines fall into this category. The lowest price is set for Caliber SSE-1280. But we recommend choosing a combined device that will allow you to perform not only jointing, but also thicknessing, i.e. processing the workpiece to a given size. You will definitely appreciate this opportunity during construction, as you can easily make identical bars, planks, planks, etc. Two models are popular among buyers - Enkor Corvette-26 and Caliber SSR-1500.

Machine MD 250/85-Р120 —Kiev—

Hello everyone, my name is Svetlana and in this article we will look at a machine with a surface planer MD 250/85-P120, which is a more advanced version of the MD 250/85 machine with a large set of functions and capabilities.

Let us immediately note that this model is not as popular as the MD 250/85 model because the price is three times higher. The main consumers of this equipment are home craftsmen who are not always willing to pay a lot of money for equipment for utility work.

So, the MD 250/85-P120 machine is intended for processing wood at home.

Is it enough to buy one surface planer to process boards?

The thicknesser is designed for planing wooden products to a specified thickness. To do this, the side on which the workpiece is based on the work table must be flat, otherwise it will be impossible to obtain the desired result. A surface of suitable quality can be prepared by jointing. Moreover, it is enough to process only one layer. Then, using a surface planer, remove excess material, setting the minimum planing depth.

If you use only planed boards, you can buy one thicknesser. Otherwise, you will need a planer or electric planer. A good option is to purchase a combined device that can be used to perform two operations - jointing and thicknessing. Upgrading from one function to another is quite fast. Such equipment is beneficial for small workshops.

What can replace a surface planer?

Re: Thicknesser with what to replace

?

Of course, a router is more important than a thickness

, but for thicknessing with a planer you need to use a bunch of devices, and still the speed of processing the material will be incomparable with

a thickness planer

. Although it will be suitable for thicknessing small boards.

Interesting materials:

What type of plug is for Russia? What current should the battery show? What current is supplied to electrical outlets? What is the current in the car? What is the current in a car battery? What kind of antifreeze can be mixed? What is the base for the fog lights 2114? What electrolyte level is considered normal? What level of radiation is considered normal? What is the type of plug in Russia?

Is it possible not to connect a vacuum cleaner to the machine?

During processing of workpieces (especially on a surface planer), a lot of “waste” is generated. Therefore, if the machine is equipped with an adapter for connecting an exhaust device, we recommend that you use a chip extractor or a construction vacuum cleaner. A household vacuum cleaner can also be connected to the device, but its small garbage container fills up very quickly.

If you don't want to buy additional equipment, consider that in addition to chips, dust is generated. It is harmful to human health. According to SanPiN 1.2.2353-08, wood dust from hard trees (oak, beech, birch, ash, etc.) when entering the body through the respiratory tract has a carcinogenic effect. Therefore, to protect yourself, use a respirator.

We advise you to pay attention to the combined machine Enkor Corvette-26, which is used to perform thicknessing and jointing. It is equipped with a bag for collecting wood waste, where the chips are directed using a built-in turbine. For the buyer, this option provides clean operation without the expense of purchasing additional equipment.

How are repairs carried out on a ship?

Maintenance is what keeps any mechanical equipment or machinery running. Whether it's a small machine or a large structure, effective maintenance can help with longevity and a favorable outcome. On a ship, maintenance is what keeps the equipment up to date and running smoothly. In this article, we will learn how maintenance is carried out on a ship.

In the ship's engine room, where the maximum number of machines are located, engineers and crew carry out maintenance for safe and efficient operation. Every machine on board a ship requires maintenance, which must be performed at regular intervals.

In the old days, the number of crew and engineers on a ship was large, so maintenance was quick and easy. However, in the present scenario, the number of crew members and engineers on the ship has been drastically reduced.

Many ships only have 3-4 engineers on board, and even the time required to maintain the ship has been reduced. Maintenance requires manpower and time, which may not be available at all times since the number of crew members is less and the amount of equipment is more.

For this reason, it is important to plan equipment maintenance in advance so that it can be properly repaired and maintained. Typically, the second engineer must plan the ship's maintenance schedule.

Effective planning and adequate use of equipment are the keys to productive maintenance. In this article, we will look at the main types of maintenance procedures performed on a ship.

Types of Maintenance Procedures

1) Preventive or planned maintenance system

It is known as PMS or Planned Maintenance System. In this type of system, maintenance is performed according to the operating hours such as 4000 hours, 8000 hours, etc., or at calendar intervals such as 6 months, a year, etc. of the equipment. Maintenance is carried out regardless of the condition of the equipment . Parts must be replaced if scheduled, even if they can be used.

2) Maintenance or Troubleshooting

In this system, maintenance is carried out when equipment breaks down. This is the reason why it is known as hardware repair. This is not an appropriate or good method as situations may arise where the equipment is required in an emergency. The only advantage of this system is that the operation of the machine parts is used for its entire service life or until it breaks down. This system can be costly as some other parts may also be damaged when it breaks down.

3) Condition Maintenance system

In this system, equipment parts are checked regularly. Using sensors, etc., the condition of the equipment is checked regularly and appropriate maintenance is carried out. This system requires experience and knowledge, as misinterpretation can damage the equipment and lead to costly repairs that may be unacceptable to the company.

Tags: general recommendations Image Credits Planned maintenance Ship maintenance system

.Power supply: installation location and case selection - How to properly plan and select parts for an air-cooled PC, part 1 Power supply

: installation location and housing selection

Block based power supply

Many modern PC cases place the power supply under the motherboard. This installation option has many benefits, so we highly recommend a chassis configured this way. As you can see from the diagram, the fan draws cool air from floor level through the power supply's own intake, uses it to cool the active components inside the power supply, and forces it out the back of the device.

Advantages for bottom mounting :

• Continuously blows cool air from the floor to the outside of the case • Directly pushes out of the case • Lower fan speed • Cooler operation allows for more efficient power supply • Less thermal stress on components, longer life • Lower center of gravity • No overhead power cable

Flaws:

• The chassis must have a bottom opening • It must also have an air filter • Possible impact on acoustics depending on the floor material.

Despite the minor drawbacks, the above configuration is preferable to some of the other setup options that follow, and you should always look for a case that fits it. But this is also where you can go wrong:

Do not install the power supply with its opening facing up in the chassis. You should only go this route with passively cooled "quiet" power supplies to allow warm air to rise. Otherwise, you are fighting the forces of convection and possibly creating a situation where a screw or other loose part can become caught in the power supply.

Power supply at the top of the unit

Older PC cases built to the ATX specification place the power supply under the top of the case. Air is drawn in from inside the case and then expelled. This supposedly improves dissipation and prevents heat buildup. However, this also causes the power supply to absorb most of the heat generated by the graphics cards and processor. Consequently, you get inefficient operation from the power supply, making maximum power and efficiency nearly impossible to achieve at temperatures exceeding 40°C (as these are typically based on an operating environment of around 25°C.) The durability of the components inside the power supply will suffer too.

Advantages for top mounting:

• Helps with cooling in some systems • Shorter cable required for 12V connection

Flaws:

• Higher PSU temperature • Inefficient and loud operation • System ages faster

The perfect chassis...

… does not exist. However, large, well-designed towers like the Corsair Graphite 600T come very close. There is nothing that can restrict the airflow within the structure. Space, cable routing at the rear, and multiple fans and air filters combine to create a solution that fits what we consider ideal.

As much as possible, you should stick to cases that don't restrict airflow from bottom to top. If you want to include a particularly long graphics card in your configuration, use a chassis that is as deep as possible. Otherwise the card will split the air flow. Thick cables should always be at the back. Additionally, anything that rattles around will significantly disrupt the air flow.

,

Recommend a good European-made station wagon.

We can recommend for you the DeWalt D 27300 surface planer, which is manufactured by an American company in Italy. It is connected to a single-phase network. When planing, the maximum planing depth is 3 mm. When thicknessing a pre-treated surface, 4 mm of material can be removed in one pass.

You do not need a workbench to use the device. The set includes legs. The assembled unit can be easily disassembled to transport to another location. If you need to move it, wheels that are mounted on two legs will help.

The machine can process parts up to 260 mm wide. To adjust the planing height, a rotary handle and scale are used. A useful detail is the side guide. It can be installed at an angle, which allows you to fix a workpiece with a beveled edge. The device also has a dust removal system that functions both during jointing and thicknessing. When switching from one operating mode to another, you simply need to rearrange the exhaust pipe.

How to care for a thickness planer?

The quality of operation of this equipment largely depends on its maintenance and proper operation. The main task is to keep it clean. Before performing any procedures, unplug the power cable from the outlet.

You need to clean your desktop regularly. The workpiece being processed passes through it, and the cutting head moves in parallel. If there is a layer of resin on it, then it will be impossible to accurately perform the operation. Craftsmen recommend wiping the table with white spirit. If you then apply soft wax or Vaxilit lubricant (sold in our online store) and polish the surface with a cloth, the workpiece will slide more easily.

In addition to the table, sawdust and resin accumulate on the feed and auxiliary rollers; they should also be wiped with solvent. It is recommended to periodically clean the planing shaft with a brush. The chain needs the same care. In addition, a thin layer of oil should be applied to it. A little lubrication is needed, since if there is an excess of it, sawdust sticks more strongly to the chain, which is why it wears out faster.

How to set up and sharpen a plane

Planing with a hand plane

Sharpening plane blades involves properly sharpening the plane knives without creating distortion of the blades and their correct installation.

The quality of use of a plane directly depends on the correct sharpening of the plane blade. It is sharpened on an emery stone, moving the bevel of the knife along the plane of the stone. The bevel of the knife must lie on the stone with its entire area. The angle of the blade when sharpening must be maintained throughout the entire sharpening process. Otherwise, the chamfer plane will be uneven, which will spoil the cutting quality of the plane knife.

Note: when sharpening a plane knife, pressure on the blade should only be applied while moving away from you.

The chamfer of the knife should be moved along the emery stone until a burr appears along the entire length of the knife blade. It is easy to identify by touch with your fingers. Then we place the blade flat on the block with its front edge and move it along the sandpaper in circular or straight movements with slight pressure. As a result, the burr disappears from the front edge and appears on the chamfer. We turn the knife over again and remove the burr from the chamfer. We repeat these techniques until, after several manipulations, we achieve the complete disappearance of the burr both on the front edge and on the chamfer of the knife blade. But this is only the initial stage of sharpening the knife and setting up the plane.

After the burr disappears, we edit the cutting part on the whetstone, having first moistened the whetstone in water. Using light circular movements, we move first along the front edge and then along the chamfer of the blade. This will be the next step in sharpening the knife.

Sharpening a hand plane knife

When sharpening a knife blade, you should periodically check with a square to see if the blade is warped. The cause of this distortion may be the incorrect position of the knife during sharpening or a manufacturing defect. In both cases, the defect must be eliminated. To do this, grind off the highest part first, then the rest.

Important: even minimal distortion of the knife blade is unacceptable. Its presence complicates the process of planing wood to a greater extent: the chips become broken, the gap between the block and the knife often becomes clogged and constantly has to be cleared.

Planer device

When grinding, the knife should be tilted in the opposite direction to the side on which the blade is skewed. At the moment of alignment, move clearly perpendicular to the cutting part.

Note: If a strong distortion occurs, it is better to sharpen the knife blade completely on a coarse-grained stone - this will speed up the process. This stone is also used for initial sharpening, immediately after purchasing a plane. The “grinding” on this stone turns out to be quite rough, so immediately after the formation of the first burr it is worth moving on to further sharpening, this time on an abrasive stone.

When sharpening a plane knife, you need to take one point into account. It is necessary to round both ends of the cutting part. If this is not done, then during jointing of wood the sharp corners of the knife will leave grooves on the planed surface of the workpiece, which will subsequently be difficult to eliminate. But this is the final stage of sharpening the plane knife.

Checking blade straightness

Installing the Planer Blade

After properly sharpening the plane knife, it must be correctly installed in the plane block. The main thing is to correctly set the release of the cutting part. The knife is inserted into the opening of the block and slowly clamped with screws in a metal block or a wedge in a wooden block.

We raise the plane at eye level with the sole of the plane up and make sure that the cutting part of the knife protrudes clearly parallel to the sole. The planing layer of wood depends on the release of the cutting part above the sole.

Excessive release of the blade will penetrate deeply into the wood, at the moment of planing the wood and remove quite thick chips, constantly clogging in the opening between the block and the knife.

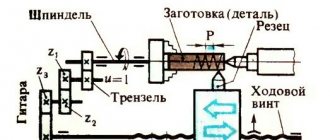

Planer setup diagram

If the release of the cutting part is too small, either the blade will remove too thin a layer, or jointing will be impossible at all.

After adjusting the knife, it is worth fixing it by tightening it with clamping screws or fixing the wedge with a gentle blow of a hammer.

Is it possible to process long boards on a small thickness planer?

With such equipment, the dimensions of the workpiece are limited only by the width and thickness. But if you process a long part, you may encounter a problem such as chipping. The board bends under its own weight at the entrance and exit from the machine, as a result, pits form on its edges. It's easy to avoid this - you need to lengthen the desktop. It is most convenient to use special roller supports for this. For example, such devices are produced by the company bo. They have a simple design. The rotating roller on which the workpiece rests does not interfere with its free flow to the cutting zone. When working intensively, it is difficult to do without supports. If planing long boards is an isolated case and you do not want to purchase supports, you will need an assistant. Ask him to support the board first as he enters and then as he exits the machine.

Which thicknesser to choose: Encore Corvette-21 or Caliber RR 1500 V?

Both of these machines are popular. Their power is the same. The maximum workpiece width of Caliber is 12 mm larger, and the planing depth is 0.3 mm larger. The difference is not significant and does not affect the quality of the treated surface. But the rotation speed of the planer shaft is higher in the Corvette. And the result largely depends on this indicator.

If you need a lightweight machine, the PP 1500 V wins, especially since it costs less. But we advise you to pay attention to three more factors that influence the choice of equipment. Compare the equipment of the devices. The Enkor company equipped the thicknesser with wrenches - open-end and hexagonal - for servicing the tool and a gauge for installing knives. Nothing additional is supplied with the Caliber plane. Check supplies availability. So, for the Corvette, a set of Encor knives can be purchased in our online store. For PP 1500 V you need to select suitable equipment from other manufacturers. Also make sure whether there is an Enkor or Caliber service center in your or your nearest city. Its presence is an important advantage when choosing a machine.

Tell us more about Caliber SSR-1500.

Caliber SSR-1500 is a universal machine. It can be used to plan workpieces and also process them to a given size. Compact and inexpensive, it's perfect for the home workshop. Used as a thickness planer, it is inferior in capabilities to specialized models (the height setting accuracy is 1 mm). But the jointing function provides certain advantages. If you have to deal with low-grade material, you can correct its defects - bending, propeller, etc. First, planing of one of the sides and the end is carried out, then thicknessing. The result is a high-quality part with a smooth surface.

The equipment is delivered almost ready for use; you only need to install a parallel fence, a protective bar and a planing height adjustment knob. The machine can be attached to a workbench. The drive mechanism for the knife shaft and autofeed rollers uses a plastic gear. But this should not be considered a significant drawback. The service life of parts depends on the operating mode. The SSR-1500 caliber is not intended for long hours of daily use. If used correctly, it will last a long time.

How to make it yourself

First, assess the dimensions of the room where the machine will be located and the frequency of equipment movements. The base with the work table is welded using a 50x50 mm corner or a 40x40 mm square pipe. Large sizes are acceptable, but they can make the structure heavier and make it difficult to move.

Tools and equipment you will need:

- lathe;

- drilling;

- angle grinder;

- welding machine;

- drill.

A ready-made knife shaft with axle boxes is required so as not to complicate balancing. An asynchronous motor with a power of 4-5 kW with a rotation speed of about 6000 rpm can be used as a motor. It is advisable to machine the pressure rollers or take them from old washing machines. The table is fixed to the base with adjusting bolts, the knife shaft is protected from the operator’s face and hands.

First, they check the readiness of the homemade thickness planer for work and set it up. The stage preceding timber thicknessing includes checking:

- sharpening knives, their location;

- contact density between the workpiece and the rollers;

- equal protrusion of the shaft knives;

- evenness of the position of the bed;

- horizontal desktop;

- correct installation of the cap, which removes chips from the surface of the wood.

What equipment can be purchased in your online store?

You can find out the necessary information about consumables and additional equipment for planing machines by going to a special section of our website, as well as reading the information on product cards. The main part of the assortment consists of knives. We recommend our customers to monitor their condition. Immediately sharpen or replace dull cutting tools. Using poor tooling not only degrades the quality of the finish, but also overloads the engine and breaks parts such as sprockets and chains. Purchase a set of knives in advance so that, if necessary, you can immediately replace worn-out equipment.

Among our spare parts you will find drive belts for Proma jointing machines. Additional accessories include stands for thicknessing machines. Roller supports solve problems with processing long workpieces.

Pay attention to products from Metabo such as silicone grease and Vaxilit. The first tool is used to maintain equipment. It significantly reduces the adhesion of sawdust to structural parts. The second lubricant is used for grinding the work table - it promotes better sliding of the workpiece.

Help me choose an inexpensive jointing machine.

The affordable Caliber SSE-1280 belongs to the household class. The manufacturer paid considerable attention to the safety of the equipment. A protective strip is mounted above the knife shaft. The magnetic starter prevents the machine from starting immediately after connecting the power supply. To turn on the device, you need to open the starter cover and press the button. There is a separate button to turn it off.

The Anchor Corvette 100 and 101 jointing machines are a little more expensive. They are larger in size than Caliber. Their advantage is the high speed of rotation of the knife shaft. So, in the Corvette 100 it reaches 16,000 rpm, which is six thousand more than the Caliber. The higher this indicator, the better the material will be processed. The one hundred and first model is not so “high-speed”, but it provides the ability to connect a chip ejector. The use of a sawdust removal system ensures cleanliness in the workshop and protects the health of the operator. Decide which feature is most important to you - price, speed or dust removal - and then you can easily make your choice.

What it is

The answer to the question of what a surface planer is and why it is needed can be configured in the following words: a tool for applying precise markings of lines, holes and other elements on a wooden surface. This description applies to a manual marking device.

There is also a woodworking thicknesser machine designed for adjusting thickness and simultaneous finishing. The device belongs to the category of planing devices used for planing a workpiece to a given size and a specified thickness. Mostly, workpieces that have been previously planed on jointing machines are processed in this way.

Manual surface planer

As already mentioned, a manual thicknesser is a tool designed for drawing a marking line parallel to selected baselines, or for transferring dimensions from a drawing to workpieces.

Healthy! In most cases, a manual surface planer is presented in the form of a stand with a clamp in which the scriber is fixed.

The body of the instrument is made of hardwood and is made in the form of a block with a rectangular hole. A rail (one or two) is fixed in it; fixation is carried out by wedging. For example, a two-slat thicknesser is used when applying marking lines for tenon joints.

If it is necessary to create large volumes of markings, or if there is no need to change sizes, the surface planer can be replaced with a bracket (bracket).

Healthy! A bracket is a marking device in the form of a wooden block with a protrusion that acts as a guide into which the required number of nails is driven.

Thicknesser

From the information provided earlier, it becomes clear why the manual thicknesser is narrower. It is intended directly for marking. The machine of the same name is used for finishing planing to specified dimensions. Passing through the knives, the workpiece receives the specified thickness and a perfectly flat and smooth surface. Such equipment is often used in the production of furniture blanks from natural wood.

Important! The thickness planer does not make curved saws. It only planes pre-leveled surfaces.

How does a thickness planer work?

The device of the thickness planer is built from the following components and elements:

- A knife shaft with spiral-shaped cutting elements, the design of which is made in such a way that the result of operation is a minimum of noise.

- A work table made in the form of a horizontal surface, due to which the depth of the workpiece is adjusted. Dimensions (length and width) can be different and are determined by belonging to a particular modification.

- A cast-iron frame that serves as the base on which the work table and knife shafts are located.

- A belt or chain drive that transmits torque from the electric motor gear to the knives.

- A screw device designed for calibrating a surface planer. Due to this, the cutting thickness is set.

- Moving rollers that facilitate the movement of the workpiece in a given direction. Installed in pairs, before and after the cutting shaft. The movement is carried out due to the torque of the electric motor.

- Top assembly with front and rear roller. The purpose of the mechanism is to improve adhesion to the workpiece. This makes it easier to control the direction of the board or timber.

- The lower unit that supplies the workpiece to the work table.

- A clamping unit necessary to create a certain force on the workpiece during its processing.

- Guide slides used to facilitate transportation of the thickness planer.

Types of thicknessing machines

Classification of thicknessing machines is carried out according to several criteria: the number of cutting edges and design features. According to the first criterion, there are 3 types of equipment:

- One-sided. Mostly they have small dimensions and are intended for household use. They have a cutting knife on only one side, which allows you to process one side of the workpiece.

- Double sided. Classified as professional equipment. Designed for processing the upper and lower edges of boards and timber. They are equipped with more powerful electric motors and provide better production capacity.

- Multilateral. This type of thicknessing machines is also classified as professional equipment. The complete set includes 3 or more cutting knives designed to give the workpiece a certain shape. This equipment is characterized by high power unit power and high performance.

The design features of surface planers divide the equipment into 2 groups. On this basis, there is a division into professional and household types:

- Mobile group. It includes portable household surface planers, the design of which implies free movement from one workshop to another. They have low power due to ease of transportation.

- Stationary group. Professional large-sized equipment used in production workshops. A distinctive feature of such thicknessers is their size, which is reflected in the difficulties of rapid transportation. Due to its high power and (mainly) the presence of two or more knives, it has high productivity.

Healthy! Also, the classification of thicknessing machines can occur according to the manufacturer, electric motor power, rotation speed of the knife shafts, and other technical characteristics.

Principle of operation

Before working on a thickness planer, you should familiarize yourself not only with the structure of the unit, but also with the features of its use. The principle of its operation is based on flat planing of the workpiece. The operator delivers it to the work table, from where, under the influence of self-propelled rollers, the product is pulled towards the rotating knives, which carry out the cutting. The cutting depth and dimensions of the workpiece are set before turning on the machine, at the preliminary preparation stage.

Important! It is prohibited to carry out any adjustment or repair work while the thicknesser is on. The machine must first be disconnected from the electrical voltage source.

The machines are equipped with an electric motor and drive and differ in power. Household jointers use 1-3 kW motors.

Do you have a Jet thickness planer with a helical cutter shaft? What are its advantages?

We recommend that you pay attention to the popular model of thickness planer - Jet JWP-209 HH. The helical knife shaft is its main feature. It contains 132 carbide knives. They are mounted on a shaft in six rows in the form of a spiral. Everything in this design is calculated: the location of each knife, its shape and sharpening angle. The result is a machine capable of processing any type of wood with high precision. At the same time, all main components of the device experience less load compared to conventional equipment of the same class. The engine, gearbox, bearings and even belts last much longer in such conditions. The service life of the knives themselves is also long. According to the manufacturer, they can process 20 times more wood than conventional flat ones. In addition, each helical shaft knife is sharpened on four sides. If one becomes dull, you can turn it and continue working. When all the edges become dull, install new equipment.

What is the difference between the Jet JPM-13 series machines?

This series is based on devices that are similar in appearance and overall dimensions. However, they also have differences. For example, the Jet JPM-13 CST thickness planer allows you to install shaped knives for milling instead of planing cutting tools. With their help, various recesses, waves, grooves and other decorative elements can be made on the surface of the workpiece. Understanding the features of the other two models is not difficult. Jet JPM-13 CSX 708524XM operates from a single-phase network, and a similar model of the XT modification operates from a three-phase network. The last machine is more powerful, other parameters are the same. Note that these devices belong to the professional class and are designed for long-term continuous operation. In addition, they have high rigidity, which is achieved through a cast iron frame. The machines weigh 90 kg.