Every home, regardless of its inhabitants, has a certain set of tools that will always come in handy. One such tool is pliers or pliers. Despite their superficial similarity, these two instruments have some differences. Both belong to the large group of pliers.

This kind of history began long before our era: just remember the ancient Greek blacksmith god Hephaestus, who was depicted with blacksmith's tongs and a forging hammer.

This group includes pliers, pliers, pliers, wire cutters, and round nose pliers. Each of the tools has its own production standards and is needed for different jobs.

In contact with

Pliers and pliers: what is the difference between the tools

Being an indispensable attribute of electricians and occupying a worthy place in the work suitcases of mechanics, as well as many other craftsmen, pliers and pliers have deservedly received the title of the most popular tools. However, no one really notices the differences between them, since the instruments look very similar. But there are still differences, and quite significant ones. It is not without reason that for each of them there are separate technical requirements and GOSTs. Metal shears: manual, electric, tools overview (read more)

Pliers are used in a variety of applications.

Pliers and pliers: what is the difference between the variations of pliers tools

The history of the appearance of devices of this group goes back at least to the era of the Greek gods. Since time immemorial, mankind has been familiar with blacksmith's pliers. Over time, changes occurred not only in human society, but also in tools. When exactly and by whom exactly the design of pliers, which are the prototype of modern products, was created is unknown. However, the undeniable fact is that the thing turned out to be incredibly practical and necessary.

Many people do not see the difference between pliers and pliers, since they look very similar.

Modern pliers tools are characterized by great diversity.

The main variations that are presented to consumers are:

- mites;

- round nose pliers;

- wire cutters;

- pliers;

- pliers.

Each of the above categories has subtypes that differ in such parameters as the size of the working surface, shape, and purpose. For example, round nose pliers are best suited for cutting cable cores.

On a note! The cone-shaped shape of the tool provides comfort when bending cable cores.

Pliers are considered a more functional tool than pliers.

Different shapes of the cutting part and its different dimensions dictate the operating characteristics of the cutters. For example, products designed for repairing electronic devices are characterized by smaller sizes. You should know that they are completely unsuitable for cutting cables for various purposes, as this is inconvenient and impractical.

To perform work related to delicate materials, special attachments are used - plastic or made from other raw materials. The presence of notches on the pliers allows for maximum reliability in fixing the part during the soldering process of boards. At the same time, the special shape and angle of the jaws make it possible to get into the most inaccessible areas.

What is the difference between pliers and pliers: the main parameters of the tools

According to the interpretation of GOST, pliers are a tool designed to grip and clamp pipes and parts of various shapes. Externally, the products are very similar to pliers. They are equipped with flat jaws, which are an extension of the working area for gripping bolts or tubes. In addition, the tools presented are most often equipped with side cutters to remove insulation.

Let's take a closer look at the difference between pliers and pliers.

Pliers and pliers have different working surface shapes.

The following features of these tools should be noted:

- the ability to adjust the gap of the working surface of the jaws and the degree of force of the product by rearranging the hinge is provided only for pliers;

- pliers are tools designed to perform only one action, while pliers are multifunctional products;

- pliers are equipped with wire cutters for cutting thin wire; high-strength steel is used in their manufacture;

- often pliers are characterized by a flat working surface with a notch along the entire length.

On a note! On the modern market you can also find 200 mm combination pliers, but this is the exception rather than the rule.

In addition, it is worth noting that the design of the pliers is designed for greater compression force. This means that manufacturers select the appropriate grade of material for these products—one that is characterized by a greater degree of strength.

Perhaps the most significant difference between pliers and pliers is that the former provide the ability to solve a larger number of different everyday tasks. In many ways, they can be an excellent replacement for end cutters, small house vices or side cutters, gripping almost any small-sized object.

With pliers, the width of the jaws along the entire length is always the same, unlike pliers.

What are pliers for: the secrets of the tool's functionality

This type of tool belongs to the group of metalwork and assembly products. Speaking about what pliers are made of, it is worth noting that their design is quite simple and is represented by the so-called jaws and handles. Thanks to the jaws, which have a rectangular cross-section and a pyramidal shape, they can be used to grip various objects or bend metal elements.

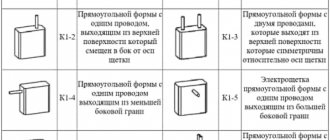

In accordance with GOST, pliers are produced in several variations:

- with short and long jaws - ranging from 25 to 55 mm and from 50 to 64 mm, respectively;

- with standard handles and insulating elements that provide the ability to perform work under high voltage.

As for the total length of the tool, it ranges from 12 to 22 cm. In the manufacturing process, high-quality tool steel U7A is used, which has undergone complete hardening. Finished products are subjected to anti-corrosion treatment by chrome plating, chemical oxidation or phosphating. The shade of the instrument directly depends on the processing method - it can be metallic, matte gray or black.

Pliers are used in plumbing and assembly work.

Speaking about the types of pliers, it should be noted that, in addition to the classic models, there are also other variations on the market, intended for work of one nature or another. For example, the so-called “platypuses” are pliers with elongated elements that resemble tweezers. At the same time, thanks to the powerful handles, they are characterized by high pressing force. There are also products with curved jaws, which are an excellent solution for working in hard-to-reach places.

Pliers: photos and a few words about the types of products

In addition to the above options, other types of products are no less popular.

These include:

- adjustable;

- clamping;

- isolated;

- for wires.

Clamping pliers are devices that function like a hand vice. Most of these instruments are equipped with an adjustable screw, which additionally serves as a lip clamp, thus increasing the pressure.

Pliers can have jaw lengths ranging from 25 to 64 mm.

On a note! In addition to being used as clamps in various situations, clamp-type pliers are often used in the process of welding work.

Adjustable pliers are another essential tool in every craftsman's kit. These products are ideal for turning and gripping a variety of objects, including nuts and bolts, by connecting the lips in a hinged manner. Due to their versatility, such tools can replace most wrenches.

As for insulated pliers, they have rubberized handles, which act as a guarantee of safety during electrical installation work.

Pliers: the embodiment of practicality and versatility

Since pliers (photos of products can be found on the Internet) are close “relatives” of pliers, they are very popular in the process of performing plumbing and electrical installation, as well as many other types of work.

Pliers are used by mechanics, electricians, mechanics and many other craftsmen.

One of the main features of pliers is the presence of notches with notches on their working surface. This part is designed to grip and firmly hold smooth round objects. Often pliers have a combined jaw surface. This means that, in addition to a separate recess for round parts, there is part of a flat working area. In addition, some tools are equipped with several recesses for parts of different sizes.

On a note! Many people wonder which is correct – “passatizhi” or “pliers”? According to the rules, you must use the second spelling.

A special feature of adjustable pliers is that they allow you to adjust the degree of compression of the jaws. It is for this purpose that their design provides for several variations in the location of the hinge in specially designed grooves. The process of rearranging it is quite simple; it comes down to spreading the handles and moving it to the desired recess.

In addition to the degree of compression, it is also possible to adjust the distance between the edges of the jaws, thus expanding the range of dimensions of the objects being grabbed. Regardless of the price, pliers are often equipped with side cutters. These elements can be used to strip insulation and cut wire or cable cores. In addition, they can be equipped with special edges on the front of the jaws, which makes it possible to cut hard wire.

The tool market offers a large selection of pliers from different manufacturers.

Another parameter that determines the difference between pliers and pliers is the expanded working area of the latter tools due to their equipping with notches on the handles located immediately behind the hinge-type connection. Thanks to this, it is possible to grip parts not only with jaws.

On a note! Today, Knipex pliers produced by the famous German company have won the special respect of many users. These products are famous for their high quality and reliability.

In addition, pliers can be either plumbing or electric type. Moreover, the latest models must certainly have markings indicating a maximum voltage of 1000 V.

What are pliers for?

Standard pliers are used to hold parts of various shapes, from flat to cylindrical, for cutting, bending wire and soft rods.

Also suitable for crimping wires and lugs, they can partially replace side cutters, wrenches and pliers.

This combined tool has found application in many areas of both professional human activity and outdoor activities, for example, fishing, where it is used during the preparation of equipment.

With appropriate skill, pliers allow you to remove locking rings if you don’t have suitable pliers at hand, and to straighten and bend the edges of thin metal sheets.

In fact, the scope of application is limited solely by human imagination, and they are used in the absence of a specialized tool.

Professional side cutters: little helpers in big things

The most common cutting tools include the so-called wire cutters. In essence, these are side cutters-pliers, the basis of which is the principle of leverage. It is due to this that the force that must be applied to the surface of the object being processed increases in order to cut through the material through the cutting edges.

Rubberized dielectric side cutters allow you to work with live wires.

The main components of the cutters are:

- A handle that acts as a lever. Its length determines exactly how much force the master will need to apply to carry out certain operations. Often, the handles have a special coating, which provides comfort and protection during the work process.

- Cutting edges. These parts vary in size, shape and location in relation to the plane of the handles. In addition, you can find nippers with pobedit tips on sale that will help you cope with even the most durable materials.

The range of modern tools market is represented by various models of side cutters. For example, precision products are intended for precision work, dielectric ones provide the ability to work with live wires up to 1000 V, and reinforced ones will cope with the task of cutting metal, fittings and wire with a diameter of more than 3 mm.

A feature of diagonal tools, which are used for cutting steel and copper wires, is that their heads are located at a certain angle to the surface of the handle. Professional models are made from tool steel, which undergoes multi-stage hardening. The two working sections of the presented devices are connected to each other by means of a hinge on the axis, which is capable of withstanding a monotonous load of up to 75 kg.

High-quality professional side cutters are made from hardened tool steel.

Device and characteristics

The pliers have a hinge-plier design, that is, their two parts are movably connected to each other by a hinge joint, forming two handles, and on the opposite side - jaws.

In the form of the latter lies the secret of the instrument’s versatility.

At the front, both jaws have a flat, grooved surface to hold parts.

Next, toothed recesses are located opposite each other.

Their purpose is to firmly grip spherical and round products, which makes it convenient to use pliers for working with nuts when there is no suitable wrench at hand.

It should be immediately noted that in the latter case it is advisable to use a profile tool so that the recesses do not destroy the edges of the head of the threaded fastener.

At the base of the jaws, at the very beginning, there are sharp blades, the operating principle and functions of which are similar to side cutters.

They are designed for cutting small-section wires and stripping the wires of insulation.

To work with wire with a larger cross-section, a kind of wire cutter is located on top of the tool opposite the hinge, capable of cutting through denser materials.

Material

As a rule, U7A and 8HF steels or other grades with similar characteristics are used in the manufacture of pliers.

At the same time, hardness, according to GOST:

- 51 HRCе – for cutting elements located on a hinge.

- 53 HRCе – for the cutting edges of side cutters.

- 45.5 HRCе – for clamping surfaces.

During manufacturing, the metal is subjected to heat treatment with additional hardening by high-frequency currents.

In addition, a protective coating that is resistant to corrosion is applied to the surface.

The simplest example is bluing, which is also called oxidation.

It involves treatment with hot oil steam followed by coating the surface with a protective varnish.

Blueing does not provide high-quality protection from high humidity, therefore such a tool is intended for indoor use.

Chrome-plated pliers have much better resistance to moisture, and at the same time have a pleasant appearance due to their characteristic shine, especially if the surface is polished.

A similar, but more resistant to mechanical damage, zinc coating, which is much less common than the previous option.

For ease of operation and at the same time protection of the handles, the latter have insulation, which comes in several types:

- Standard – plastic.

- Ergonomic - with rubber anti-slip pads that ensure a secure hold of the tool.

- Electrical insulating – hard plastic, ensuring the safety of the master during electrical installation with voltage values up to 1000 V.

The insulation on the handles is attached by hot-fitting, with glue or, in rare cases, with metal pins.

Form

In the classic version, pliers have a straight shape, however, there are also options curved at the hinge joint for special work.

The tool has also become widespread:

- With short jaws – they have a small opening, the jaws are set apart by a maximum of 35 mm.

- With extended jaws, the length of which reaches 200 mm.

The outer part of the jaws can be rounded or with diamond-shaped edges, which allows you to work in places with limited space.

Dimensions and weight

The length of typical pliers is 160 – 180 millimeters, width – 50 mm, thickness – from 10 to 13 mm. Such an instrument weighs 200–300 g.

Special purpose models can have a length of 100 – 510 mm.

Actually, to indicate length, manufacturers often use inches, which correspond to standard millimeter dimensions.

So, for example, the length of 8-inch pliers in the metric system is 200 mm, 7-inch - 180 mm, 6-inch - 160 mm, and so on.

GOST

Technical characteristics for pliers are described in GOST 17438-72.

The length standard for tools with rounded jaws is 200, 250 and 300 mm, and for options with faceted straight jaws - 160, 180 and 200 mm.

Secrets of choosing side cutters: how to avoid mistakes

Before you begin the process of selecting tools, you should clearly define what they will be used for. For use in the home, small classic side cutters are quite suitable. Using them, it will be possible to repair electrical wiring, cut wire, and also strip cables. If the tools are needed for professional use, each master focuses on personal needs.

In addition, you should pay attention to the material that was used to make the working part. The cutting edges of products that deserve the right to be called high-quality are made from hardened steel, and therefore are characterized by unsurpassed strength. Even after working with wires made of steel, it is unlikely that nicks will be visible on them. Ideally, the working surface of any side cutter should have an anti-corrosion coating.

An equally important element that deserves special attention is the handle of the tool. The longer it is, the more effort will be required during the work process.

Note! To prevent your hand from slipping at the most critical moment, it is better to give preference to tools whose handles have a textured texture.

First of all, when buying side cutters you need to pay attention to the material and length of the handle.

The handles of truly high-quality products are equipped with a coating that is resistant to temperature changes, as well as to oils and many other chemicals. Since this tool is designed for comfortable work in various conditions, all its elements must be as reliable as possible.

In conclusion, it is worth noting that side cutters (side pliers) are not a tool that cannot be replaced during home renovation work. However, installers, electricians and mechanics who often have to cut through cables, wires, nails and fittings will certainly appreciate their properties.

What you need to know about pliers?

As is known, a protective coating is applied to the surface of the pliers.

But no matter what its strength, over time the layer on the working part collapses, causing the lips to corrode.

To prevent rust formation, it is necessary to regularly lubricate the inner surface of the jaws.

It should be remembered that in the process of cutting wire, pieces often bounce off along an unpredictable trajectory, for this reason you should be careful and use safety glasses.

Goebbels: features and distinctive features of the instrument

Goebbels are a tool that is a type of pliers that is used by both amateurs and professionals. They are often used in pairs, and in a wide range of tasks - from installing plumbing to repairing vehicles.

According to the standard, all adjustable pliers are made from special tool steel, which is characterized by the presence of vanadium and chromium in its composition. Thanks to this, they acquire qualities identical to those of wire pliers, which allows them to perform work under voltage. During their manufacture, not only stamping is used, but also forging elements. In this case, key parts (head and fasteners) are ground.

Goebbels are made from steel, which contains chromium and vanadium.

As for the handles, they often occupy no more than 40% of the total length of the product. They are coated with a special compound that prevents slipping. This not only increases comfort while working, but also protects your hands from injury.

The head of the Goebbels, like a similar part of the pliers, is that part of the product that can have different levels of inclination, amounting to 90 or 45 degrees. Regardless of the value of this parameter, it is always quite narrow and relatively long. Due to the presence of a special recess in it, you can easily carry out work even in narrow and inconvenient places.

Depending on their design, Goebbels are divided into two main groups:

- With rack type of jaw spread. This structure is characterized by simplicity and reliability. It is represented by two parallel slats with teeth, between which the axis of the product moves easily and can be fixed by the master.

- With grooves for spreading the jaws. The design feature is the presence of an overhead milled cardan joint. For the purpose of breeding sponges, straight-line movements are used. As a result, a fastening is formed that prevents the hinge from slipping.

Professional Goebbels from the NWS brand are characterized by high quality parts.

When performing work at significant heights, the best solution would be to use a tool with a special loop designed to secure the wrist. This eliminates the possibility of the product falling at the most critical moment due to a careless grip. When working with plastic pipes or ceramics, it is better to give preference to sponge attachments, which will provide reliable protection to the surface of the part from various damages.

On a note! The modern market presents many models from different manufacturers. The well-known company for the manufacture of professional Goebbels and pliers NWS deserves special attention. The high level of quality of the brand's products is confirmed by the special Solingen marking.

In addition, you can find products whose homeland is Sweden or Germany. They are also distinguished by high quality materials, ergonomics and modern design.

Types of pliers and their prices

Pliers, being a universal tool, are still divided into several types and subtypes.

The option discussed above is a combination pliers, since their design allows you to perform several functions simultaneously.

In addition to the serrated grooves and cutting edges located on the jaws, there are cutters on the outer part of the hinge mechanism.

This design is also called multifunctional.

In addition to everything, on the inside of the handle, near the hinge itself, there may be recesses for pulling out the wire, a spike-shaped protrusion for crimping it.

By the way, pliers come with cutting edges and without them.

In the latter case, on the inner parts of the jaws, as a rule, there are two toothed recesses of different diameters, allowing for gripping round parts.

The handles are covered with plastic cover attachments, and the two-component versions are additionally equipped with rubberized anti-slip inserts, ensuring ease of use.

The cost of such options varies widely, depending on the features and manufacturer.

The price of the cheapest models does not exceed 250 rubles, and the most expensive ones go beyond 3 thousand rubles.

Multifunctional pliers, in turn, are:

Dielectric

With insulated handles that can withstand voltages up to 1000 VAC without danger to humans.

The insulated handles have the appropriate inscription, which confirms the possibility of using the tool to work with devices and wires connected to the electrical network.

Even the highest quality models with insulated handles have one feature - over time, the coating becomes thinner due to frequent friction with the palm, and therefore, to increase the safety of the master, its top layer is painted red, under which there is a main dielectric material with a different color.

As a result, abrasion of the top layer will be clearly visible, which will serve as a signal that further use of the tool is unsafe.

For high-quality performance you will have to pay from 600 to 1000 rubles.

Curved

With curved lips.

Installation

They have curved jaws, near the end of which there is a stripper that allows longitudinal stripping of wires.

This form makes it convenient to work with wiring, and provides fairly comfortable work where space is limited, for example, in junction boxes.

As a rule, they are produced with dielectric handles.

The price for quality is around 3 thousand rubles.

Curved combined

With handles bent at an angle of 30 degrees or more relative to the jaws.

Also called corner, actually because of their shape.

Platypuses

They have long jaws, reminiscent of tweezers, which they successfully replace, differing in greater compression force.

Extended

The length of the jaws of some models can reach 200 mm.

Reinforced

A massive tool with thicker elements.

Power pliers are another name indicating increased strength characteristics.

There are models with a nail holding function.

The average price is 1000 – 1600 rubles for high-quality 200 mm models.

Mini pliers

They are more compact and lighter than the classic versions, which allows them to work with fragile and thin parts.

The size of such a tool is 110-120mm.

But there are also very miniature models less than 110 mm long.

It should be remembered that small pliers are inferior in strength to full-size ones.

The cost rarely exceeds 600 rubles.

Energy saving type

They have an improved hinge mechanism, reinforced with a lever, due to which the force applied by the user during operation is reduced by 40%.

In turn, this leads to a decrease in the amount of lip expansion.

The price is around 1 thousand rubles.

Lever

They provide high-quality and comfortable work thanks to a special lever-type mechanism, which significantly increases the force transmitted to the lips to bring them together.

Models with a double lever mechanism are often equipped with a special latch that secures the handles in the retracted position during transportation, and a self-unclosing mechanism.

With increased levers

They have a wider opening of the jaws for gripping and clamping large parts.

Folding

They have a design similar to a multitool, that is, the main tool is hidden in the halves of the handles.

Prices start from 270 rubles.

In addition to classic pliers, there are specialized types:

Adjustable pliers

Due to their design, they are able to change the diameter of the recess.

Due to the fact that the handles overlap each other, like two halves of scissors, they received another name - cross pliers.

As a rule, they are used by plumbers to hold pipes, which is why they are often called pipe clamps.

Allows you to grip parts of various sizes and hold the cable while cutting it.

Adjustable plumbing pliers can perform the functions of a wrench.

Average prices are around 1 thousand rubles.

Clamping

Analogues of clamps, that is, they are designed for reliable clamping of a part, pressing two elements to each other.

They have one handle with a lock and a toggle mechanism, and the second with an adjusting screw.

The pliers operate on the principle of an eccentric mechanism.

The locking handle is slightly curved for comfortable operation.

This tool is convenient for unscrewing bolts and nuts that have all their edges completely licked off.

Price - from 800 to 1200 rubles on average.

Pliers for removing lids

They look like pliers and are designed for removing the covers of heavy trucks.

Cost – from 200 to 300 rubles.

All pliers can be conditionally divided into many types according to their purpose, while they may have minimal differences among themselves.

Here are just a few of them:

Locksmith

Used for repair and installation work where contact with current-carrying elements and wiring is not required.

Electrician's pliers

This includes the entire dielectric tool.

Electrical pliers, by the way, are not only metal, with specially coated handles, but also plastic.

In the latter case, we are talking about complete isolation of the tool.

Plastic pliers help to avoid short circuits during electrical work; for reliability, they are reinforced with fiberglass.

Fishermen's

Used for working with fishing gear.

Full-size fishing pliers have tapered lips and an elongated body for easy removal of the hook from the fish.

Mini fishing pliers often have a folding design and are equipped with a retriever, eliminating the loss of the tool.

Pliers and pliers: secrets of a successful choice

At the first stage of choosing tools, it is necessary to determine what specific tasks they are intended for. This need is due to the fact that some models can be used to perform a variety of jobs, while other products are characterized by a narrower specialization.

When purchasing pliers or pliers, it is recommended to give preference to trusted manufacturers.

Once the type of instrument has been determined, a little personal research needs to be done. To do this, you can read specialized reviews, watch videos, and also compare pictures of pliers and pliers manufactured by certain companies. Among other things, it should be remembered that products may vary in metal composition, handle finish, weight, degree of comfort in grip, performance and design.

On a note! If financial possibilities allow, it is better to give preference to professional tools.

And this is not a whim at all, but a real advantage of professional products over amateur ones. It will certainly be very disappointing to be left without pliers in the midst of work, or to throw away the side cutters after a dozen pieces of wire have been bitten off due to their unsuitability. As for the professional set of pliers, it will last a long time for everyday use.

It is better to buy professional tools, even if you plan to use them only at home.

In the selection process, the hinge also deserves special attention. There should be no backlash on it. If the stroke is soft, smooth, the surfaces touch evenly, and the handles on the handles are located securely and there is no free sliding, then you have found a truly high-quality product.

In many cases, pliers can be a completely worthy replacement for other tools. Before you go shopping, you should be as clear as possible about what tasks you plan to use them for.

The modern tool market has a huge assortment of pliers, the price of which varies depending on the type of product and manufacturer. Thus, each master has the opportunity to choose the optimal tool that will become a reliable assistant in the process of performing certain works.

How to choose pliers?

The configuration, shape and dimensions of the tool are always selected for specific tasks, which means which pliers to choose, the buyer decides based on his own preferences.

The following tips will help you buy a reliable model:

- It is better to immediately pay attention to a professional tool, as it can last for an extremely long time. The manufacturer often gives it a lifetime warranty, and is able to document the quality and reliability of its products.

- It is extremely easy to determine the low quality of a product by the presence of play in the hinge, jamming and biting of the lips, the presence of a gap between the internal surfaces or simply their uneven fit.

- The coating of the handles, especially dielectric models, should under no circumstances slide or move at all. Otherwise, using such a tool is guaranteed to be inconvenient, and sooner or later it can lead to injury.