How to make a homemade gearbox for a walk-behind tractor

To independently assemble the converting device on a walk-behind tractor, you need to stock up on the following tools:

- calipers and metal ruler;

- a set of screwdrivers of different sizes, including an oblique one;

- pliers and wire cutters;

- metal saw;

- electric drill with a set of metal drills;

- vice;

- hammers - large and small;

- rubber gaskets.

Also, using preliminary calculations, you can estimate the dimensions of the future transmission device.

To make the correct calculation, determine the parameters of your engine. For calculations it is necessary to clarify several data:

- Engine crankshaft speed. However, this value is not constant: if you “add the gas”, it will increase significantly. Therefore, calculations are based on the base - the number of idle speeds plus 10%.

- Estimated number of revolutions for the suspension axle. It is calculated taking into account the diameter of the wheels to determine the run-out per full revolution. Based on this, you can calculate at what speed the axis should rotate in order to ensure the most comfortable speed of movement of the walk-behind tractor. This is on average from 3 to 5 km/h.

Let's take a simple example: the engine power at idle, taking into account an increase of 10%, is 600 rpm, and to ensure a speed of 3 km/h, a rotation speed of 200 rpm is required. Therefore, the design gear ratio is 3:1. In other words, to reduce the rotation speed of the axle by a factor of three to ensure a travel speed of 3 km per hour, the torque increases three times.

Step-by-step instructions for assembling a chain gearbox

If you have certain skills, you can make any type of gearbox with your own hands, but the easiest way is to assemble a small-sized mechanism with a chain drive. Materials for it are easier to find and are reliable in operation.

To make a homemade chain mechanism, stock up on the following spare parts and materials:

- sprockets with the required number of teeth;

- driven shaft;

- cylindrical and eccentric bearings;

- protective casing;

- fasteners for connecting parts of the casing;

- chains with the required number of links.

You can use an old gearbox housing of a suitable size as a protective casing, drilling holes in it for mounting.

- The manufacture of a homemade gearbox for a walk-behind tractor begins with securing the drive sprocket to the output shaft of the engine. To secure it, you can use a key or flange. Depending on the design of the output shaft, even spot welding can be used.

- The driven shaft should be machined. The sprocket is fixed on it in the same way as on the drive shaft.

- A more reliable way is to make a shaft from two axle shafts, at the ends of which flanges are machined. The driven sprocket is secured between them, fastening the entire structure with bolts. In this option, the second stage sprocket will be secured more accurately and reliably.

- To protect the gear mechanism from dirt and mechanical damage, it is placed in a protective housing, which also serves as a reservoir containing liquid lubricant for moving parts.

- Sockets are drilled in the protective housing (crankcase) for installing support bearings. The driven shaft is mounted on cylindrical bearings, and the drive shaft is mounted on eccentrics. By changing, due to its design features, the position in the seat within a radius of 15°, the eccentric bearing also changes the position of the drive shaft, thus adjusting the chain tension.

If the calculation of the gear ratio is done correctly, then the gearbox, carefully assembled taking into account all the design features of your walk-behind tractor, will ensure the smooth operation of the mechanisms no worse than its industrial counterparts.

Category: Homemade products

Gearbox malfunctions

There are many reasons that can lead to the breakdown of this important unit, which will make the operation of walk-behind tractors from different manufacturers impossible. It is advisable to include among the main malfunctions characteristic of various models:

- oil leak due to high wear of the cuff;

- inappropriate lubrication parameters;

- the appearance of smudges on the output shaft;

- star rupture;

- broken chain/belt;

- Worn control lever threads.

It is important to note that most problems can be avoided by promptly changing the oil in the device. For this purpose, standard machine oil is used, which allows you to use the walk-behind tractor for many years without the need for repairs.

Equipment

Converters are either collapsible or non-dismountable. Basically, the latter type can often be found in the configuration of budget walk-behind tractors. They feature inexpensive spare parts that cannot be replaced. In the event of a breakdown, there is only one way out - replace the entire gearbox. The service life of such models declared by the manufacturers is 1-2 seasons, provided they are used correctly.

More expensive equipment can boast of a dismountable gearbox that can be repaired: failed parts can be replaced with new ones. Therefore, the service life is several times longer compared to inexpensive devices.

The converter package consists of:

- Cases - collapsible or not.

- The rotor shaft is responsible for torque.

- Gears of different sizes.

- Chain or belt - depends on the type of gearbox. In the case of a chain transmission, movement occurs due to sprockets - star-type disks. If the transmission is belt driven, then the equipment has pulleys on which the belt is put.

- Bearings - reduce friction between rotating elements and ensure their free rotation.

Through these components, movements are transmitted from the motor to the attached parts. Belt converters are weaker and unreliable. If the torque is high, then the belts begin to fly off the pulleys. But such a structure has a positive effect on the engine shaft. This situation can be avoided by replacing them with gear ones. But then you will have to change the pulleys too.

All parts are located inside the case. In addition to the installed set of components, you can also add elements for lubrication of bearings inside the device. These include an oil pump or a cooling device.

Chain or gear

A chain drive is a mechanism for transmitting motion using toothed sprockets and chains. The mechanism has its own advantages:

- transmits movement over long distances;

- one chain can rotate several shafts;

- high transmission stability and efficiency.

The disadvantages include:

- increased noise level;

- intensive chain wear;

- gradual stretching of the chain;

- high price.

Chains come in roller, bushing and toothed types.

The gear reducer is more complex than all the others. During operation, it reduces engine speed and increases the power output of the unit. A good walk-behind tractor is equipped with such an air-cooled gearbox. It may have a reverse, allowing the walk-behind tractor to move backwards. Disassembling and replacing gears is not difficult. In Chinese-made installations, non-separable gearboxes are used. If they break, you need to replace the entire body along with the filling.

Design and principle of operation

The design and operating principle of the main types of gearboxes are described above. In addition to them, chain gearboxes are used on walk-behind tractors; this design is used on Cascade brand cultivators. They operate with gears, the rotation between which is transmitted using chains. They have reverse.

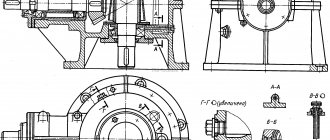

There are also combined mechanisms. The picture below is gear-chain type:

Model overview

In order to get some idea about walk-behind tractors with a power take-off shaft, it is necessary to become more familiar with the characteristics and features of some models.

NEVA MB-Compact S-6.0

The walk-behind tractor of this model is considered a real find for adherents of professional equipment. The unit has great functionality despite its compact size. Almost the entire range of mounted implements can be connected to the PTO, from a plow to a snow removal rotor.

The manufacturer specifies the following technical specifications:

- weight – 70 kg;

- power – 6 l. With.;

- low noise level;

- quick start and flawless operation in cold weather;

- cultivation depth up to 20 cm;

- high engine life;

- working width – 86 cm.

In addition, some modifications of the Neva can be equipped with an electric starter.

Agate (Salyut) 5P

The walk-behind tractor is used mainly for agricultural work on small farms. With the help of additional accessories, this unit can be used as a small tractor.

Has a downshift function. When transporting cargo weighing up to 500 kg, it reaches a speed of 10 km/h.

Technical data:

- weight – 78 kg;

- power – 5 l. With.;

- plowing depth 25 cm;

- adjustable processing width up to 90 cm;

- The steering column is equipped with two position switches for comfortable control.

Belarus 09N-01

The model is designed for versatile soil cultivation over an area of up to 5 hectares. The unit is distinguished by its unpretentiousness to working conditions and reliability. Thanks to the mass, wheel traction with the soil surface and excellent control are ensured. Belongs to the severe type.

The following characteristics can be noted:

- unit weight – 176 kg;

- developed power – 9.38 liters. With.;

- working width is adjustable from 45 to 70 cm;

- number of gears – 4/2;

- load capacity – 650 kg;

- speed up to 11 km/h.

Profi 1900

The walk-behind tractors were specially developed by German manufacturers for carrying out agricultural operations in areas with heavy soil and poor traffic. Thanks to its power of 14 horsepower, this machine is capable of providing easy working conditions where considerable effort must be made with a conventional walk-behind tractor. For evening work, these models are equipped with a front headlight.

Attached Specifications:

- walk-behind tractor weight – 178 kg;

- power – 14 l. With. (in some models up to 18 hp);

- gripping processing width – 80-100 cm;

- plowing depth – 15-30 cm.

In addition, the walk-behind tractor is equipped with a cold start mechanism and a vibration damping system.

Chinese agricultural machinery mainly differs from other brands in its low price. It is good if cost reduction is achieved by increasing the quantity of products. But sometimes manufacturers from this country reduce the price of goods by installing low-quality components.

One way or another, it is worth considering the most popular models.

Forte 105

Positioned as a multifunctional unit for performing agricultural operations on plots with a total area of up to 1.5 hectares. Used for cultivation, harvesting root crops, sowing seeds and many other tasks. The walk-behind tractor is able to withstand high loads for a long time.

Some technical data:

- average unit weight – 105 kg;

- power – 7 l. With.;

- processed width – 105 cm;

- processing depth – 35 cm;

- developed speed – 8 km/h;

- loading weight – 350 kg.

Weima WM1100BE

The walk-behind tractor, made according to Western standards, belongs to the heavy class units. The powerful engine is capable of fully providing high-quality functionality and completing all assigned tasks. The presence of a power take-off shaft allows the unit to operate with implements for various purposes throughout the year. This modification has an electric starter, which makes starting easier in extreme cold.

Characteristics:

- unit power – 9 l. With.;

- weight – 140 kg;

- processed depth – 30 cm;

- working width – 80-130 cm;

- load capacity – 300 kg;

- developed speed is 11 km/h.

You will learn how to make a power take-off shaft in the next video.

What type of fuel do you prefer?

In this context, all walk-behind tractors can be divided into three main categories.

- Electric. Most often this is a small type of walk-behind tractor. With this unit you can process up to 5-7 acres of land at a time. Most often they are used to loosen the soil in a greenhouse, where it is not possible to use an internal combustion engine. They can operate both from the mains and from a battery.

- Gas engine. They are equipped with models of medium and large sizes. As a rule, gasoline-powered internal combustion engines are 2-stroke or 4-stroke. The main criteria for choosing are the engine volume, measured in cubic cm, and its power, measured in hp.

- Diesel. Most often this is a single-cylinder 4-stroke internal combustion engine, installed on a medium and heavy walk-behind tractor. Diesel-powered appliances are more environmentally friendly and economical. But the price for their service is much higher. In addition, the fuel system itself is much more sensitive to high-quality fuel, which can be difficult to find outside the city.

In some cases, alterations occur. Owners of some gasoline walk-behind tractors adapt their devices to run on gas, which can lead to significant savings on fuel.

Do-it-yourself gearbox for a walk-behind tractor

Enthusiastic farmers are wondering: how to make a geared walk-behind tractor with your own hands? The question is relevant, since making such a miracle from materials and parts available on the farm is sometimes easier and cheaper than purchasing a regulator assembled by the manufacturer at the factory.

Indeed, in the “invention” of the converter there are no super complex manipulations, and a tool made on a walk-behind tractor with your own hands always serves correctly, however, first of all, you should acquire some tools:

- screwdrivers (straight and oblique type);

- hacksaw (for metal);

- pliers or pliers;

- vice;

- some other tools and consumables, the presence of which one way or another may be needed during the assembly process.

Assembly, or rather, preparation of the converter begins with welding the housing. It can be made of metal plates. Sometimes they use a housing from the Ural shaft with its subsequent modification.

DIY walk-behind tractor gearbox

For gears, you can turn to the Friendship chainsaw (4). In this case, the end of one of the shafts is cut off and a hole of the required diameter is drilled, while a second shaft is installed on the opposite side of the future gearbox, and with it bearings and a cage. The output shaft must be secured to the pulley.

Oil in the walk-behind tractor gearbox

Just like any mechanism, the lubricant to be filled is individually suitable for the geared walk-behind tractor. Its quality directly affects the performance of the cultivator. Depending on the conditions of use, you should choose the oil individually, but fortunately, universal brands like Motul come to the rescue, and the user can’t go wrong with the purchase.

Prices

However, there are also much more expensive models

What matters is how pricing is structured. And, above all, the price depends on the number of functions that the converter is equipped with

You can't ignore the quality of its build - it also greatly affects the cost. Power and the ability to use reverse are also important.

These are the general characteristics of the gearbox, but there are many more. From which it follows that the gearbox on a walk-behind tractor is a complex mechanism, the choice of which should not be mistaken.

What is a reverse gearbox

When planning to make a reversible gearbox with your own hands, you must first become familiar with this important detail in more detail. It is a special mechanism that, by transmitting the converted energy received from the engine, activates the main mechanisms of the unit. Similar devices are widely used in Buran snowmobiles and walk-behind tractors from various manufacturers. There are several types of gearboxes, among which the following types can be mentioned:

Each type has its own characteristics, advantages and disadvantages, which are worth studying in more detail. Reducing products are intended for use in cases where it is necessary to significantly reduce the number of revolutions, increasing the torque. As a rule, such a need arises in the field of agriculture, since reduction gearboxes are universally installed on tractors.

The angular gearbox seems to be one of the most effective, designed to ensure correct interaction of the power unit with the transmission. Due to their simple design, as well as long service life, such products are widely used in walk-behind tractors of various models.

The simplest design is the gear reducer, which is distinguished by a high degree of reliability and high wear resistance. The cost of such products is extremely low; they are used to transfer engine energy to the wheels.

Reversible modifications, for example PP 300, differ significantly from all other types of devices, since they can significantly expand the capabilities of the unit. They are equipped with a clutch placed between bevel gears, allowing the equipment to move in the opposite direction. It should be mentioned that this type of mechanism does not allow for impressive movement speeds.

Reverse mechanism device

Having found out the features that the 3D6 marine diesel engine and other types of reverse gearboxes have, it is necessary to become more familiar with its design. It is much more complex than other analogues, due to the need to convert movement in the opposite direction.

The main elements of its design include:

- coupling body, cover;

- discs - rear, front, pressure;

- forward/reverse shafts, as well as output;

- gear mechanisms, including driving and intermediate elements.

A homemade unit in its technical characteristics is almost completely identical to purchased analogues from various manufacturers, for example, Tehnomaster. However, the cost of its production will be significantly lower.

Self-assembly of the stroke reducer

Having all the necessary spare parts, you can begin assembling the speed reducer with your own hands. In order for the finished structure to cope well with its functions, you should act strictly according to the algorithm described below:

- First, make all the necessary calculations so that the result of the work is a well-balanced design. As a generator, you can take an element from the domestic Ural motorcycle;

- The main thing that is required from the device is high power and stable torque;

- Next, start cutting out the shell of the two bearings that will be needed for the drive shaft. It will start the gear. When working, take into account the diameter of the gearbox;

- Then you need to decide on the bearings. The flange must be located on the opposite side of the gearbox. There should be a metal washer inside it;

- Next, install the driven shaft on which the gear will sit. The product must be connected to the rotary generator shaft and transmission mechanism;

- Finally, you will need to secure the pulley to the driven shaft using a spring nut and washer.

Having made the creeper, it will need to be tested. To check the device, it should be connected to the hitch of the unit, and the wheels for the cultivator should be installed. If you did everything correctly, the wheels will spin slowly, while the cultivator itself will be pressed to the ground.

When choosing wheels for a motor cultivator that will work in tandem with a speed reducer, you need to pay great attention to their diameter. There is no need to choose too large parts so as not to load the unit’s motor

Wheels with a diameter of 25 to 30 cm will be optimal.

If homemade devices are planned to be used in conjunction with other attachments, for example, for a plow, then the creepers must have sufficient power to press the equipment to the soil. Be sure to take this into account when preparing spare parts for the manufacture of the device.

A creeper for a motor-cultivator is used at high speeds of the motor-cultivator, when it is necessary to reduce it to a speed effective for cultivating the land. Creepers are best used when working with additional trailed equipment, trailers, hilling soil and removing snow.

Walk-behind tractor design

Schemes for assembling homemade walk-behind tractors are as varied as the spare parts in each owner’s garage.

Dimensions are also chosen for practical reasons. With different compositions and dimensions, there are required elements:

- The frame is a durable structure for attaching other parts.

- Wheels - from homemade metal to factory-made rubber. The position of the wheel or wheelset axle is fixed relative to the frame by iron struts with pressed-in bearings.

- Engine - power from 5 to 10 horsepower. You can even use an electric motor with a battery, but the most popular are engines from a scooter or motorcycle. This choice is good because it has a ready-made speed control and even a transmission device.

- Gearbox is a unit for transmitting rotation from the engine to the actuator, converting speed and direction.

But the first gearbox you come across may not be suitable. You need to choose the type of structure, calculate the size of each part, so that the speed and power of movement of the mounted cultivator allows you to cultivate the land in a convenient mode - neither quickly nor slowly.

Varieties

The gearboxes with which walk-behind tractors are equipped seem identical only at first glance. In fact, these devices can be divided into three groups. The differences lie in the design features of the gearboxes. Let's get to know the representatives of this family in more detail.

Angular

Angle-type gearboxes are elementary structures that serve to connect the transmission to the power plant of the unit.

The structure of this node looks like this:

- Mechanism body.

- Belt drive pulley with fastening.

- Rotor shaft.

- Flange complete with mounting and bearing.

- Washer and fixing key.

Gear

This is a more complex mechanism, which is impossible to recreate at home without special skills and knowledge.

Gear reducers are called reduction gearboxes. Thanks to its design features, the mechanism reduces the engine speed, simultaneously increasing the power output of the walk-behind tractor.

Such gearboxes have a long service life, so they are suitable for performing various jobs, and do not suffer mechanical damage even under peak loads.

Reversible

This mechanism is based on a clutch that moves freely between bevel gears.

Such gearboxes enable the walk-behind tractor to move in reverse, which has a positive effect on the maneuverability of the equipment.

However, this comes at the cost of reduced performance and maximum speed. Therefore, each farmer decides independently whether to install a reversible gearbox or not.

Gearboxes installed on walk-behind tractors from different manufacturers have virtually no design differences. Therefore, disassembling the unit and replacing failed parts will not cause difficulties.

We select a walk-behind tractor based on its gearbox. Three main tips.

I consider the gearbox to be the main part of the walk-behind tractor. And when selecting a device, I always start from its type, characteristics and distinctive features.

The engine can be replaced by a Chinese one; wings and casing can be cut from a metal sheet yourself; The steering wheel can be welded up and good handles/levers can be purchased. It is impossible to make a gearbox at home.