The requirements for modern potato planting using specialized planting devices are becoming stricter every year. The depth, quality of cultivation, tractor power, even the process of planting and growing tubers are taken into account.

But don't worry. Equipment for planting potatoes from the Lida-Region Group of Companies will significantly reduce your costs and increase the productivity of planting potatoes.

We work directly with manufacturers, offering to buy high-quality planting devices in our store.

How to plant potatoes with a walk-behind tractor

Planting potatoes under a walk-behind tractor can be done in two ways:

- using a hiller;

- potato planter.

Regardless of the chosen method, the walk-behind tractor must be equipped with lugs. Otherwise, working on loose soil will be difficult. Cutting furrows for planting potatoes with a walk-behind tractor can be done using a cutter. On clay and rocky soils, such preparation will facilitate the planting process. How to properly plant potatoes with a hiller needs to be considered in more detail.

A potato planter is a planting device equipped with a hopper with a folding plate and a row-crop mechanism that loosens the soil. Working with this attachment is as simple as working with a hiller.

Before planting, check the functionality of the walk-behind tractor and its preparation in any way:

- make sure that the oil level and fuel volume correspond to the parameters required by the operating instructions;

- remove the wheel lock;

- open the fuel supply valve;

- set the ignition switch to the “on” position;

- start the engine.

Comparative cost analysis

| KS-1A | KS-1 | KSM-1 | Small potato planter | Potato planter for the Neva walk-behind tractor | |

| Moscow | 14500 | 12000 | 9500 | 12000 | 12000 |

| Saint Petersburg | 14000 | 13000 | 10000 | 13000 | 13900 |

| Novosibirsk | 14800 | 14500 | 12000 | 14000 | 15000 |

| Ekaterinburg | 14800 | 14300 | 13000 | 14500 | 14800 |

| Chelyabinsk | 15000 | 15000 | 14000 | 16000 | 16000 |

| Omsk | 14800 | 14500 | 12800 | 15000 | 15000 |

| Vladivostok | 15500 | 15000 | 14000 | 16000 | 16000 |

From all of the above, it becomes clear that the cost of potato planters directly depends on the model, compatibility with walk-behind tractors, dimensions and region. And the decision to purchase this or that model is up to you. However, before making such a serious purchase, it is necessary to consider all the advantages and disadvantages of the purchased unit.

Please rate the article!

[Total: 0 Average rating: 0]

Planting potatoes with regular and two-row hillers

Hillers for walk-behind tractors come in several types:

- single-row, forming only one furrow in one pass;

- double-row, forming two furrows in one pass;

- disk.

The design and principle of operation of the listed equipment are largely similar, since all hillers are designed to perform the same task.

Working with two-row tractors is complicated by the fact that moving them requires a much greater traction force from the motor vehicle and the operator.

Therefore, such attachments are recommended for use on light soils. Planting potatoes with a walk-behind tractor and hiller is carried out in several stages:

- Install lugs on the wheels.

- Unfold the wings of the hiller in accordance with the selected track width.

- They pass through the area, forming furrows with ridges.

- Potatoes are placed in the recesses, placing them at a distance of 20-25 cm from each other.

- Remove the lugs.

- Spread the wings of the hiller to the maximum possible distance.

- They pass between the rows, filling the furrows with soil.

Planting potatoes with a walk-behind tractor and a two-row hiller is a little more difficult. But just as in the case of a single-row, the unit is re-equipped before starting work:

- install lugs;

- attach the hitch;

- attach hinged mechanisms.

The next step is setting up a two-row hiller. It is important to find the correct distance between the working parts of the equipment. Typically this is 60-65 cm, i.e. the width of the future bed. When cutting furrows, each hiller should be exactly in the middle of the row spacing. Further work consists of placing tubers in the depressions and then filling the furrows.

DIY making

You can choose a potato planter and other necessary attachments in a specialized store, or you can make such a device at home. You just need to have some plumbing skills and purchase the necessary materials to make a mounting device for a walk-behind tractor.

Tools and materials

To make a potato planter with your own hands, you will need to purchase:

- Axles, bicycle chain (or chain from a car engine), bearings for wheel movement, making a chain elevator.

- Metal sheet for making a bunker.

- Square or round metal profile for mounting a frame holder and other purposes.

- Welding machine for firmly connecting potato planter elements to each other.

- Several electrodes for welding.

- Grinder and discs for cutting metal sheets into the required parts.

- An electric drill and drill bits for it for drilling work.

- Fastening elements to add strength to the device.

- Nuts and screws for mounting the structure.

- Wire (several meters) for fastening some elements of the device.

- Sandpaper or file for sanding and cleaning parts.

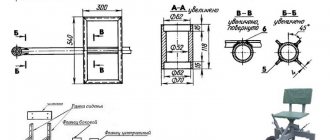

Before you start assembling the potato planter, you need to carefully study the drawing, think about the dimensions of the future device, its appearance, and the method of attachment to the walk-behind tractor. The dimensions of the planter should not be very large so that the design does not become too bulky.

The volume of the bunker for filling tubers is determined based on the calculation of the double length of the bed. The volume of the container should be enough for a walk-behind tractor with a bunker filled with potatoes to pass two furrows and return to the place of re-loading.

Planting potatoes with a potato planter

Planting potatoes using a walk-behind tractor and specialized equipment is much easier than using a bucket and shovel. The potato planter consists of several structural elements:

- potato bins;

- seed supply mechanism;

- devices for loosening the soil;

- disk mechanism for filling the furrow.

There are several types of devices for planting potatoes, but they all work on the same principle: they form a hole in the soil and immerse the potato in it. In this way, manual labor is mechanized, making it possible to process a large area in a short time with less effort. Planting using a potato planter and walk-behind tractor consists of several stages:

- Prepare the soil in the way that is most effective for a given type of soil. This could be plowing or harrowing.

- Adjust the potato planter: adjust the depth of the furrows and the width of the rows.

- Pour seed potatoes into the hopper.

- Place the walk-behind tractor in the desired location on the site and start the engine.

- Tubers are planted.

Planting potatoes under a plow with a walk-behind tractor

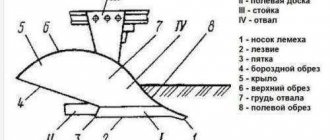

There is another way to plant potatoes with a walk-behind tractor: under the plow. Manufacturers offer 2 types of this equipment:

- single-hull;

- hiller plow with a V-shaped ploughshare.

The planting technique using these hanging elements has its differences. Working with a single-furrow plow consists of several repetitive actions:

- A plow is installed on the walk-behind tractor.

- Using bolted connections, the plowshare is placed in such a position that it sinks into the ground to the required distance: 10-15 cm.

- They walk one row with the plow, forming a furrow.

- Place the tubers in the recess, maintaining a distance of 20-25 cm between them.

- They turn around at the edge of the field and walk the next row with the plow so that the furrow is completely covered with soil.

- They turn around and begin plowing the next furrow at a distance of 60-65 cm from the first.

The difficulty with this planting method is that the position of the single-furrow plow is not easy to adjust. The walk-behind tractor always goes downhill, because one of its wheels is on soft plowed soil, and the second is on virgin soil.

Planting technique with a hiller plow with a V-shaped share:

- the area for planting potatoes is plowed, cutting furrows at a distance of 60-65 cm so that when forming each next depression, the walk-behind tractor runs along the edge of the previous row;

- lay the tubers in the furrows;

- They backfill the trenches by installing the walk-behind tractor so that its wheels run along two adjacent furrows, and the plow is located between the rows.

Kinds

The design of all units is approximately the same:

- a hopper (rectangular or conical) for placing potato tubers;

- a frame with wheels that can move along a tractor track or be located on the sides of the bunker and move along the arable land;

- furrow-forming openers;

- brackets for planting seed;

- devices for closing furrows.

Bunker

The performance of devices for planting potato tubers depends on their design:

- bunker device;

- bunker capacity;

- method of loading planting material;

- uninterrupted delivery of tubers for planting.

The modern market presents many models of domestic (for example, KSM) and foreign production (for example, Bomet). Manufacturers, wanting to satisfy all customer requests, offer equipment of various sizes, functionality, prices and quality. You can choose a device for a tractor, walk-behind tractor (see here) or even manual processing.

A potato planter with a fertilizer hopper is a multifunctional model and can add fertilizer to the soil, which is placed in special additional containers.

In order for the equipment to operate efficiently, it should be selected for the mounting and power of the tractor or walk-behind tractor, taking into account:

- required productivity - planting large plantations or small areas;

- connection diagram - trailed or mounted equipment;

- the type of soil on which you will have to work;

- duration of continuous operation;

- the need for additional options - spreading fertilizers, leveling the soil, etc.

Transport wheels

If you choose the option with transport wheels, it will be easier to turn the planter when the drive is turned off.

A review of Russian-made chainsaws will help you decide on the choice of chainsaw for your summer cottage.

Perhaps you will choose the Ural chainsaw. It is cheaper than imported analogues and is not inferior in quality.

Or take a closer look at the characteristics of the Lesnik chainsaw.

Compatibility

A single-row potato planter is quite suitable for amateur farmers.

For large areas, buy 2-row equipment as in this video.

For industrial volumes, a 4-row and more powerful one is purchased.

These indicators affect the number of simultaneously processed rows during operation:

- miniature models are used in conjunction with a walk-behind tractor;

- single- and double-row equipment is used in conjunction with mini-tractors;

- three- and four-row suitable for medium-power tractors;

- six rows and more are used with heavy tractors.

In this video, the criteria for choosing a potato planter.

When choosing a unit, its characteristics play a fundamental role, so you need to carefully read the manufacturer’s documentation and consider whether it will fit the tractor you have on the farm.

Types of gripping devices

Dosing units of potato planters, transporting tubers from the bunker to the furrow, are divided into elevator and disk. The tubers are captured one by one with special spoons attached to a mechanism that moves them through the thickness of the potato from the bottom up.

Dosing unit

- The disk mechanism (grasping spoons are located around the circumference of the disk) allows you to grab the tuber while moving the spoon from bottom to top in the potato layer and fixes it with a clamp.

- Then the potato is transported to the receiving neck of the coulter, into which the potato falls, freeing itself from the clamp.

- Used only for planting ungerminated material.

- The elevator mechanism (the spoons are located on a chain) captures the tubers and delivers them to the chute, which delivers the potatoes into the furrow behind the opener. Used for planting both unsprouted and spring potatoes.

Adaptation to soils

For loose soils, choose potato planters with high ground clearance (the distance from the ground to the bottom of the device) and rubber wheels with tractor treads. The device must be light in weight, even if it is necessary to cultivate large areas of land.

For hard and rocky soils, equipment with narrow forged wheels is selected. The larger and heavier the machine, the easier it will be to cope with this type of soil.

Planting with a hiller and a potato planter: what are the differences

Planting potatoes with a walk-behind tractor is done in different ways, each of which has its own advantages and disadvantages. The main difference in using a hiller and a potato planter is that in the first case the work is semi-automated, and in the second it is fully automated.

The landing speed also differs. When working with a hiller, after forming a furrow, you need to walk along the plowed row and place the tubers in the recess. After this, you need to fill the trench. The use of a potato planter provides higher labor productivity. In one playthrough, they perform two tasks at once: plowing and planting tubers.

Belarusian potato planters from Lida-region

Our company invites everyone to familiarize themselves with the product catalog and choose one of the many products:

- potato planters;

- potato pickers;

- equipment for applying liquid fertilizers;

- auto waterers and more.

High quality manufacturing, fast delivery, universal design and ease of aggregation with agricultural machinery. The technology will ensure the maximum possible yield at minimal cost.

Managers will answer all your questions, conduct detailed consultations, and advise on the optimal power of potato planters for your site.

Homemade potato planter for walk-behind tractor

Homemade devices for a walk-behind tractor can cope with the tasks assigned no worse than purchased ones. To make your own attachments, you need to know how to make them and from what. A do-it-yourself potato planter on a walk-behind tractor is made from the following materials:

- sheet metal 2-2.5 mm thick or plywood (for a bunker);

- metal pipes with a cross section of 25-40 mm;

- wires with a diameter of 5-6 mm;

- chains (the one that is installed on engines is suitable);

- bearings;

- profile steel pipe with a wall thickness of 2 mm (for frame parts);

- wheels

Tools needed:

- welding machine and electrodes;

- grinder with a metal disc;

- drill and drill bits;

- pliers, hammer, screwdrivers.

Drawings of a potato planter for a walk-behind tractor

The first stage of making a potato planter yourself is design. The selected equipment parameters must be reflected in the drawing. First of all, choose the type of device, which will determine the features of the future device. There are 2 types of potato planters suitable for self-production:

- With spoon feeding of tubers. This design includes a belt with attachments for storing potatoes—spoons—attached to it.

- With a flat belt feed, in which the tubers are laid using horizontal belts.

Optimal dimensions of a single-row potato planter for a walk-behind tractor:

- height from the lower end of the ripper to the upper plane of the hopper - 59-60 cm;

- wheel section - 150-200 mm;

- bunker height - 27-30 cm;

- Hopper width - 22-28 cm.

The basis of the design is a frame made of a profile pipe, to which all elements of attachments are attached. For manufacturing, you can use channel No. 8. The frame should consist of two longitudinal spars connected by three transverse crossbars. If necessary, the frame is reinforced with metal profiles.

Bunker assembly

A suitable cone-shaped container can be used as a hopper. If this is not possible, make the bunker yourself. To do this, in accordance with the drawing, all the necessary parts are cut out of plywood or sheet steel. They are connected using metal corners. Regardless of the material of manufacture, the container is painted with moisture-resistant paint in 1-2 layers. To ensure that the sprouted tubers in the bunker are not damaged, the internal cavity is covered with thin rubber. The finished structure is attached to the frame using bolts.

Wheels

The wheels of a homemade potato planter can be made with permanent lugs. In this case, you will need: a car disk, strips of metal and spokes. The lugs are metal plates welded to the base at a slight angle. The plates are cut from sheet steel.

Instead of homemade wheels, ready-made ones that are suitable in size are installed on the potato planter. They can be taken from garden carts or other equipment. Hubs are welded to the wheels, onto which 2 bearings are mounted. The wheels are attached to the frame.

Rippers and their holders

To make the holders, you will need a profile pipe, from which a square rod measuring 50x50 cm is welded. The rods are welded to the left and right sides of the frame. Rippers are cultivator paws assembled with holder stands. They are made of sheet steel and fixed using bolted connections.

Four-row planter SAYA-4 with conveyor planting apparatus

A special feature of the SAYA-4 machine is the conveyor falling mechanism, which ensures the planting of sprouted potatoes. If the conveyor spoons capture more than one tuber, a spring mechanism discards the excess potatoes and returns them along the slope table back to the feeding hopper. The bunker sensor automatically turns off the conveyor drive if the preset seed level does not match. Additionally, the planter is equipped with fertilizer sowing devices for simultaneous feeding of crops with mineral fertilizers.

Scheme of planter SAYA-4

| Indicators | SAYA-4 |

| Working width, m | 2,8 |

| Operating speed, km/h | 2,9-3,9 |

| Productivity ha/hour | 0,5-1,5 |

| Adjustable distance between tubers in a row, cm | 18-39 |

| Planting density, thousand tubers per hectare | 40-75 |

| Planting depth, cm | 6-21 |

| Hopper capacity, kg | 470 |

| Loading height of tuber hopper, mm | 1150 |

| Fertilizer hopper capacity, kg | 120 |

| Total weight of equipment, kg | 1550 |

Specific points when using the planter

When working with potato planters, you must follow a number of rules. This is more important for those who do not have experience in this type of work. Beginners often end up with crooked rows and when digging furrows, the tubers turn out to the surface of the soil. This happens due to inept use of attachments for the walk-behind tractor. Advice from experienced gardeners will help you overcome difficulties:

- It is important to maintain the same distance between the tubers: potatoes planted deep will take a long time to sprout.

- Ripper discs should be buried no more than 15 cm into the ground.

- To ensure uninterrupted feeding of potatoes into the furrow, it is necessary to maintain the distance between the wall of the hopper and the end of the spoon. The width of this gap depends on the size of the tuber. For small potatoes weighing 30-50 g, a distance of 3-5 mm is sufficient, for larger ones (weighing 50-80 g) - 10-12 mm.

- The planting depth is set by adjusting the height of the rippers relative to the wheel axis.

- The density of the seating with a synchronized drive depends on the rotation speed of the disks with a chain with spoons installed on them. Regulation is carried out by changing the location of the spoons or extending the chain.

Potato planting machines KSM 6, KSM 4

In Soviet times, the KSM-4 potato planter was the main equipment for planting potatoes in conjunction with the MTZ 80(82) tractor. Semi-mounted machine in older versions with a disc sowing mechanism, and in new modernized versions with an escalator apparatus. The sowing mechanism is driven from the rear power take-off shaft of the tractor. Some modern versions are driven by the support wheels of an agricultural machine.

A modern version of the potato-planting semi-mounted complex KSM-4

Technical characteristics of KSM planters

| Indicators | KSM 6 | KSM 4 |

| Working width, m | 4,2 | 2,8 |

| Operating speed, km/h | 5,9 | 5,9 |

| Productivity ha/hour | 2,1-3,8 | 1,4-2,5 |

| Adjustable distance between tubers in a row, cm | 18 — 30 | |

| Planting density, thousand tubers per hectare | 40 — 75 | |

| Planting depth, cm | 10-16 | |

| Hopper capacity, kg | 3200 | 2300 |

| Loading height of tuber hopper, mm | 420 | |

| Fertilizer hopper capacity, kg | 900 | 600 |

| Total weight of equipment, kg | 2950 | 2350 |

There is also a two-row version of this brand of planter - KSM 2 for aggregation with tractors of lower power LTZ T-40 and T-25 "Vladimirovets".

Review of popular potato planters

All potato planters have a simple design and are easy to maintain. There are models recommended for working with specific brands of walk-behind tractors.

For walk-behind tractor Neva

The Neva walk-behind tractor is a small-sized piece of equipment, and special models of attachments have been developed for it. The universal potato planter is equipped with a hitch that fully matches the element of the walk-behind tractor. Characteristics:

- weight - 25 kg;

- the width of the formed row spacing is 60-70 cm;

- productivity - 0.2 ha/h;

- average price - 10 thousand rubles.

The video shows the process of planting potatoes using a Neva MB-23 walk-behind tractor and an original potato planter.

Adjustment is carried out by changing the tension of the tape. Simultaneous application of fertilizers is possible.

Automatic potato planter

Automatic potato planters come in single-row and double-row varieties. At the same time, planting and hilling are carried out, high ridges are formed. Designed to work with large and powerful motor vehicles. Expensive models have a hydraulic hopper control function and are equipped with a telescopic rod and marker. Furrow makers can be floating or rigidly fixed. There is a ripper depth regulator.

For mini tractor

For mini-tractors, models of two-row and four-row potato planters are more in demand. Farmers note the high quality of the “ASK-2 with hiller” model from TEHNOS. The equipment ensures simultaneous planting and hilling of two rows of seed. It is distinguished by the formation of high and wide ridges. There are functions for adjusting the distance between rows and tubers.

Specifications:

- potato planter dimensions - 1800x1500x1400 mm;

- distance between rows (cm) - 62.5; 66; 68; 70; 75;

- distance between tubers (cm) - 18-52;

- weight 320 kg.

Where to buy a potato planter for a mini tractor

You can buy a high-quality potato planter for working with a tractor in the Gardenshop store. Products are available with a variety of parameters, performance capabilities and prices. Products are represented by Polish, Ukrainian and Chinese manufacturers, who successfully compete with global suppliers of agricultural attachments for tractors.

The Gardenshop company provides the opportunity to purchase goods at retail or wholesale, for full payment or in installments. The price range is quite large and amounts to $199-820. Delivery of attachments mounted on a tractor is carried out by a carrier company to any city in the country.

All offered potato planters for mini tractors have a one-year warranty. They have undergone technical control and pre-sale preparation, so they are fully complete, functional and free of defects.

A potato planter is a useful and effective equipment for installation on a mini tractor. It will help optimize the potato planting process and carry out planting work quickly, efficiently and easily.

Hilling potatoes with a walk-behind tractor

Hilling is a soil cultivation process that is necessary not only during planting and growing vegetables. Attachments of this type are also useful for harvesting potatoes. With the help of a hiller, the soil is loosened, which facilitates the harvesting process.

The first hilling after planting is recommended to be done in moist soil. If it is dry, large lumps of earth will appear when loosening, which can damage still weak sprouts. The second hilling is performed after the stems reach 30 cm in height. If the soil is “breathable”, two treatments are sufficient. For dense soils, a third will be required. The rules for working with a walk-behind tractor when hilling are the same as when planting potatoes. It is important to set the ripper to the desired depth and try to maintain the evenness of the rows.

Setting up a hiller for planting potatoes

The features of the device and adjustment of the hiller can be studied in detail in the equipment operating instructions by viewing the detailed pictures and drawing presented there.

Before you start loosening the soil between the rows of potatoes, it is necessary to make individual adjustments to the hiller, taking into account the power of the walk-behind tractor, the type of soil, weather conditions, the characteristics of the working attachment mechanism and the quality of its sharpening.

Setting up the hiller is carried out after a test run of the motor-cultivator on virgin soil with the same type of soil, which allows you to set the optimal angle of attack, operating speed and other features of the unit.

- A properly adjusted disc hiller should be precisely aimed relative to the strip. To adjust, you need to place the equipment parallel to the furrows with the desired angle of inclination and width of the bed.

- To set the required angle of inclination, turn the screw adjustment device. The angle of inclination of the disc blades also determines the plowing depth.

- The disc hiller is adjustable in width. Depending on the distance between the rows of potatoes, the knives can be set to a width of 40 to 70 centimeters.

- The hiller is installed on the plot so that the discs do not touch the row with potatoes, but go exactly in the middle of the row spacing.

Dear farmers specializing in growing potatoes, do you use mounted potato planters? How often do you hill up the plant?

Planters KORA

The equipment is produced by the German manufacturer UNIA. The company offers a range of planters in four-row and two-row versions:

- KORA-2 bunker for 400 kg, row spacing 70-75 cm

- KORA-4 bunker 840 kg, row spacing 75 -90 cm

- KORA-4H with a hydraulic lifting hopper for 1000 kg, row spacing 75 cm

- KORA-4HP hydropowered bunker capacity 2000 kg, row spacing 75 cm

Models are segmented by level of additional equipment and may differ in their design:

- bunker volume

- the presence of a hydraulic lift of the bunker

- stage for the operator

- equipped with a mechanism for automatically adjusting the embedment depth

The machines have twin escalator-type planting devices based on a rubber conveyor driven by support running wheels.

In addition to the models described above, the following manufacturers of four-row planters are on the market:

- Planters of the Grammer and Nassia brands made in the Netherlands.

- Cars of the brands Bomet and POLO 4H made in Poland.

- Machines L-202, L-207 manufactured in Russia: hopper 600 kg, row spacing 70 cm, loading height 450 mm, operating speed 4-10 km/h, productivity 1.26-2.4 ha/hour.

- Planting complexes SK-4 produced in Belarus.