Planting potatoes is a labor-intensive process that requires a lot of time and effort, especially if a large area is allocated for the crop. To make the work much easier, some gardeners plant potatoes with a walk-behind tractor, which they purchase for permanent use or rent.

The walk-behind tractor is a universal miniature tractor

Types of hillers

Let's look at the most popular models of devices.

OND double row

This device is intended for processing prepared soils, such as gardens, greenhouses, and small vegetable gardens. Its maximum working depth is 12 centimeters, and the minimum is 8 centimeters. This parameter can be adjusted. The width of the model’s wings varies between 25-45 centimeters.

This hiller has its pros and cons

The design has the following dimensions (in centimeters):

- length – 72;

- width – 35;

- height – 54.

Its weight is relatively small - 9.5 kilograms.

STV double-row

This model is popular for its versatility. The weight of models of this kind is 10-13 kilograms. The maximum width reaches one meter. The distance between rows can be adjusted within 20-65 centimeters. The maximum processing depth is 15 centimeters.

The main advantage of the design is that each owner can adjust it to their needs.

STV NPD single-row

These models are used to process fields. The average weight of this design is 5 kilograms. The processing width varies between 20-36 centimeters, and the maximum depth can reach 15 centimeters.

By using this technique, you reduce the risk of damage to the bushes.

Centaur

Centaur walk-behind tractors run on diesel and are made in China. Fuel economy and high efficiency are features of such machines. Planting potatoes with a Centaur walk-behind tractor does not require brute force, and large wheels allow the walk-behind tractor to easily overcome small obstacles.

For more information about the Centaur walk-behind tractor, watch the video:

Mole MK-4

The Mole MK-4 motor cultivator is suitable for small vegetable gardens. Its weight is 70 kilograms. The mole is equipped with a Honda gasoline engine with a power of 4 liters. With. Planting potatoes with a Mole MK-4 walk-behind tractor is unlikely to be convenient if you need to sow a large plot of land.

MTZ 05 MTZ 09

The Minsk Tractor Plant produces models of the “Belarus” family. MTZ-05 is a frameless single-axle walk-behind tractor with variable track. This model gained popularity in the domestic market, but was later supplanted by the new 09H.

The latest 9-horsepower model is more versatile and has six speeds; planting potatoes with the MTZ-05 09 walk-behind tractor should not cause any difficulties.

https://youtube.com/watch?v=yeVRpJ-RT74

With double hiller

Planting potatoes with a double hiller or double-row hiller on a Neva-MB2 walk-behind tractor is carried out as follows:

- The wings on the Neva are removed and lugs with iron extensions are installed.

- The distance from one hiller to another should be 65cm.

- The hitch is hung on metal pins.

- The beds are marked with a special device resembling a rake.

- The cultivator plows the marked ground at first speed.

- The tubers are placed in the bed at intervals of 35 centimeters.

- The grip of the hiller's wings expands.

- The potatoes are covered with earth.

- Rubber wheels are installed and the potatoes fall over again.

This method is suitable for a large volume of work.

OKA

OKA walk-behind tractors are also suitable for planting potatoes. They are equipped with a power take-off shaft, which makes them multitasking. The advantages of these domestic units are low cost, reliable operation on poor fuel, and an electronic ignition system.

Rotary plow

Planting potatoes with a walk-behind tractor using a rotary plow with backfill differs from usual in that the tractor plows in any direction. This saves a lot of fuel because you don't have to backtrack and re-do the furrow. Also, thanks to this, all work is carried out faster.

Under the plow

Potatoes can be planted with a motorized cultivator under the plow, and the garden does not require marking. This method is distinguished by the fact that the tubers are scattered immediately.

The Cayman, Patriot, Texas, Foreman, Viking, Forza walk-behind tractor is then installed in such a way that the bed is filled with soil from the next furrow. Due to this, landing is faster and smoother.

Salute 100

The Salute 100 walk-behind tractor is suitable for small jobs due to its lightness; for our procedure we will need a hitch and axle extensions. Before work, you need to remove the cutters from the axes and install extensions, and then lugs.

It is necessary to fix the hooks in the outer holes of the extensions to ensure the optimal width between the rows. The salute is equipped with a plowing depth limiter that needs to be removed, but otherwise the process is no different from the above.

FERMER

Planting potatoes with FERMER walk-behind tractors in small beds will be comfortable; it can be easily deployed and controlled, lifts the soil without problems and is suitable for both plow and hiller use. Saves fuel and is sold at an affordable price.

FORTE

Forte products are divided into two classes:

Lightweight, with a 4-stroke engine and a four-speed gearbox. These walk-behind tractors are easier to control and have off-road capability.

The heavy series has more powerful diesel engines and six speeds, which is suitable for working over large areas.

Characteristics of walk-behind tractors

A walk-behind tractor is a type of small tractor with a single-axle chassis. It is often used in small farms, in personal gardens and summer cottages. This universal unit helps solve various agricultural tasks related to cultivating the soil, planting tubers or seeds, mowing grass, removing snow, transporting goods, etc. During operation, the device is held by special handles and controlled by following it.

The first prototypes of modern walk-behind tractors appeared about 100 years ago. Nowadays many different models are produced, differing in their design, engine power and equipment.

Let's look at the main technical characteristics of the devices in the table:

| Variety | Weight, kg | Power, l. With. | Soil width, cm | Processing area |

| Ultralight | Approximately 20 | 3-3,5 | 60 | Up to 20 acres |

| Lungs | No more than 40 | 3-5 | 80 | Up to 60 acres |

| Average | 40-60 | 5-6 | 90 | Up to 1 ha |

| Heavy | Over 60-70 | More than 6 | 100 | 1-4 ha |

Ultralight and lightweight units are good for small areas, but usually only a hiller and cutters can be installed on them

Various models are equipped with additional equipment that allows for plowing, planting, hilling, harvesting, etc. For cultivating potatoes, a potato planter, hiller, and plow are usually used.

The devices can run on gasoline or diesel fuel. Diesel engines, as a rule, have low power, but are more economical than gasoline ones.

To choose the right model, you need to take into account several factors: the area of the area being treated, the possibility of using additional equipment, the weight of the unit, power, and cost.

Attachment options for the Neva walk-behind tractor

The basic functions for any version of the walk-behind tractor include preparing the soil for sowing and plowing it. Thanks to the various types of cutters installed on the unit, it is possible to loosen the soil to a depth of several centimeters, but cutters also have disadvantages. They can only handle regularly cultivated soil, but do not cope well with frozen or simply hard soil. In addition, cutters do not allow you to remove debris or snow or use the walk-behind tractor for other purposes. You can solve this problem if you buy attachments for the Neva walk-behind tractor. The following varieties are distinguished:

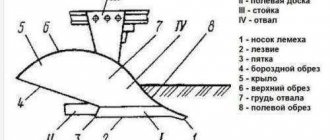

- A plow is a good option for additional equipment if you need to work with heavy soil. Weighing 7.8 kg, the P1 20/3 model is capable of plowing even very hard soil to a depth of 215 mm with a working width of 220 mm;

- Hiller is the second most popular equipment option for the Neva walk-behind tractor after the plow. A mounted hiller is used to add soil to the roots of plants. Different models of hillers are distinguished by the depth of entry into the soil and the width of the soil, as well as by weight;

Attachments for the Neva walk-behind tractor - hiller and plow

- A potato digger is a good choice if you're tired of having to fiddle with a shovel every time you harvest your potatoes. The KNM model is capable of entering the ground to a depth of 220 mm, while capturing 250 mm in width. This option will be very useful if you need to process a large area of a potato field as efficiently as possible, quickly and without much effort in terms of effort. Models of potato diggers are distinguished by weight, width of soil coverage and depth of penetration into the soil. Please note that to install this and other equipment described above on a walk-behind tractor, you will need special couplings, individual for each model;

- lugs - are installed as the wheels of a walk-behind tractor and are used to drive the unit deeper into the ground. They vary in diameter, width and weight, and can be used for hilling an area;

- cart or trailer - equipment designed to transform a walk-behind tractor into a transport vehicle. The dimensions of the trailer are selected depending on the engine power of the unit, and the maximum speed at which a walk-behind tractor with a trolley can move usually does not exceed 10 km/h;

- mower – allows you to use a walk-behind tractor for mowing the lawn or cutting grass for animal feed. Different mower options differ in the maximum height of grass cut, operating speed and coverage width;

The potato digger and lugs can be selected according to size, weight and plowing depth

- potato planter - special equipment that is suitable for all types of walk-behind tractors and greatly facilitates the process of planting potatoes;

- reversible plow - characterized by a large soil coverage, due to which there are no missed areas when plowing. When installing this equipment option, it should be taken into account that it requires a counterweight. If the walk-behind tractor model weighs less than 100 kg, then it is recommended to install a weighting agent on it;

- rake - equipment for removing leaves and various debris from the site. You can buy such a spare part for the Neva MB 2 walk-behind tractor and other models or make it yourself, provided you have a welding machine;

- snow removal equipment - makes the Neva walk-behind tractor useful in the cold season. There are several options for snow blowers for the Neva walk-behind tractor, each of which performs its own functions.

Special equipment that facilitates excavation work - a reversible plow and a potato planter

What is a walk-behind tractor?

A walk-behind tractor is a self-propelled mechanical device that can be used to automate the entire process of growing potatoes.

It is a unit consisting of the following main components:

- internal combustion engine;

- transmissions;

- chassis, consisting of an axle and two wheels;

- handles with which control is carried out.

In order for the walk-behind tractor to perform this or that work, additional equipment is attached to it.

Planting with a disc hiller

Planting potatoes begins with plowing the area and treating the seed material from pests. Wheels with lugs are used to prevent slipping during fairly heavy work by the mechanism. The furrows are cut using an ordinary hiller, adjusting the minimum distance between its wings.

Recommended furrow parameters:

- row spacing when planting is 55-70 cm - depending on the track size of the walk-behind tractor;

- the potatoes are located in the furrow at a distance of 25-35 cm - depends on the type of soil, potato variety, and fertilizers applied;

- planting depth 12-15 cm.

Planting potatoes with a hiller is the most profitable way, because... Apart from the hiller itself, no special attachments are required.

At the second stage, instead of special wheels, ordinary ones with rubber tires are installed, and the wings of the hiller are moved apart to the maximum distance. The mechanism is installed between the furrows with the potatoes laid out exactly in the middle, observing the size of the track. Two rows are filled simultaneously on one side and the other. Soft tires, passing along the row, do not cause significant harm to the planting material

Using a walk-behind tractor for spring plowing

Virgin land is usually plowed with a plow. The soil is then cultivated using milling cutters. In areas where the soil is cultivated annually, you can immediately begin processing it with cutters: this operation successfully replaces plowing with a plow.

There are 2 types of cutters:

- active (with active transmission), driven by the PTO;

- passive, installed instead of wheels.

Wanting to quickly process the plot, some gardeners make an unforgivable mistake: they install too many cutters. Excessive amounts of them lead to chain rupture and gearbox failure. In order not to overload the gearbox, on walk-behind tractors with a power of up to 5 hp. With. You should not hang more than 4 cutters. There is no need to operate the walk-behind tractor at high speeds: this does not bring any benefit, but it significantly reduces the service life of the gearbox.

Usually, by spring plowing, the soil becomes crusty, and the gardener has to lean on the walk-behind tractor to keep it going smoothly. But much less effort will be required if you process the area with cutters 2 times:

- the first time - to a depth of 5–7 cm. If the walk-behind tractor is pushed away from the covering crust, there is no need to try to deepen it: anyway, the cutters will “scratch” the ground at least a little;

- the second time - about 12–15 cm. The walk-behind tractor walks smoothly on already cultivated soil, and there is almost no need to lean on it. The plowing depth should be calculated so that the cutters do not reach the end of the fertile layer by at least 5 cm.

Both times, the walk-behind tractor should operate at low speeds: this will be better for both the gearbox and the soil. If you loosen it to the point of dust, then part of the fertile layer will be blown away by the wind, and after the first rain the beds will be covered with a crust that does not allow air to pass through. Loose soil with an abundance of small lumps is saturated with oxygen; fewer earthworms die during processing.

Planting with a potato planter

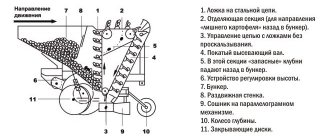

A potato planter is a mounted mechanism for a walk-behind tractor, consisting of a disc hiller, a hopper for planting material, a furrow maker and a conveyor that feeds tubers into the furrow - an integral complex that carries out planting potatoes. The person plays the role of process controller.

The planting speed is approximately 12 acres per hour, so on a small garden plot the use of an expensive mechanism is unprofitable.

It is recommended to adjust the trailed potato planter to the walk-behind tractor exactly according to the manufacturer’s instructions, setting the required parameters for the potato planting depth, the distance between the rows and tubers in the row and the angle between the hiller discs.

Using a harrow for weeding

A mesh harrow is a frame with blunt teeth designed for harrowing ridge plantings of potatoes.

The device is attached to the walk-behind tractor. Due to the inclination of the cells at 45º and the distance between the teeth of about 20 cm, it is possible to carefully lift the soil between the rows. Along with it, weeds turn up to the surface and dry out in the sun.

Using this method, using a mesh harrow and a walk-behind tractor, it is possible to weed a large area of a potato field.

Using a mesh harrow for a walk-behind tractor

Planting potatoes under the plow

It is recommended to first loosen the soil with a milling cutter. The wheels of the walk-behind tractor must be replaced with lugs.

Planting work is carried out in two stages:

- First, a furrow is laid into which the potatoes are placed.

- On the way back, the vegetables are covered with a moldboard when cutting the next furrow. In this case, one wheel of the unit follows the laid row, as a result of which the same distance between the rows is maintained.

For this method, you can use a homemade plow for a walk-behind tractor.

At the beginning of the journey, the depth of embedding the plow into the ground is adjusted (usually the size of the shovel bayonet is used). The distance between the furrows is adjusted according to the track width between the wheels of the walk-behind tractor. The work is performed at first speed.

Tuber preparation

The potatoes should be the same size. If the tubers are too large, they need to be cut, which will increase the risk of disease development and open access to pests.

Germination will take about a month. The planting material should be placed in a warm and bright room (+12-15 degrees). If dark spots begin to form on fresh sprouts, this indicates a disease. Tubers that are infected should be discarded.

Before planting, potatoes need to be soaked in stimulating and pickling solutions.

Important! It is not recommended to keep seed in solutions for a long time. It is better to lay the tubers on a flat surface, spray them with preparations and leave them to dry.

After the earth warms up to about +8 degrees, you can begin planting root crops.

Soil preparation

Pre-sowing work should begin with the laying of organic and mineral fertilizers in the autumn.

Stages of sowing in spring

Right before planting, you need to plow the soil to about 15 centimeters. For this procedure you will need a special attachment - a cutter.

Before planting the crop under the Neva walk-behind tractor, it is necessary to remove the wings of the unit. The main thing is to correctly configure all the equipment that is installed on the walk-behind tractor. This is necessary so that the car runs smoothly and requires little effort.

Advice! If you plow the soil well, you will not need to harrow the soil.

Hurming is necessary to ensure that the soil is saturated with moisture and oxygen. In well-loosened soil, the crops will sprout together.

It is at this stage that the walk-behind tractor will help facilitate the process of preparing the soil before sowing.

Preparing for work

The effectiveness of attachments to a walk-behind tractor directly depends on their correct operation. There is nothing complicated in using them, but there are a number of points that are useful to familiarize yourself with before hilling or performing other work using the device.

Settings

Setting up a hiller on a walk-behind tractor, as well as all the operating features of this device, are described in detail in any manual for summer residents, and it is not difficult for even a beginner to master them. However, there are always nuances that cannot be foreseen on paper. First of all, individual tuning is necessary because each individual case has its own set of factors, soil characteristics, weather, design and sharpening quality of the working parts of the device, and so on.

The technical characteristics of the unit itself also play an important role. Therefore, before the first trip to the garden beds, it makes sense to test the device on virgin soil with the same soil characteristics. By making such test passes, it is possible to feel the peculiarities of the “behavior” of the equipment, work out the angle of inclination, adjust the depth and speed of movement.

Use special attachments on the walk-behind tractor for hilling potatoes

Adjustment

The adjusted device ensures, first of all, the accuracy of its direction relative to the strip. Before setting up the disc hiller, you need to position the unit parallel to the furrows with the desired angle of inclination and width of the bed. Pre-verified operating parameters will ensure its effectiveness.

The angle of inclination is adjusted using a special screw device that tilts the device relative to the unit. The angle also determines the depth of plowing. In addition, additional adjustments are made using the holes in the hiller mounts. If an adjustable attachment is used, the furrow width must be set at this stage.

The lower parts of the discs move apart to a distance of 40 to 70 cm, depending on the width of the given row. In addition, when adjusting the width, you must also pay attention to the angle of inclination - the adjustable parts must be absolutely symmetrical. Next, the unit is installed on the site so that the furrow runs exactly between the discs. The passage is carried out along the row spacing without touching the plants.

Installation

Now let’s figure out how to install the hiller on a walk-behind tractor. First of all, the hiller with the frame is mounted: the stand of the device is inserted into the lock and secured with two bolts. A hitch is attached to the assembled device (the same as for the plow). The resulting structure is connected to the walk-behind tractor. The angle of inclination of the hitch in the direction of travel is adjusted using the hitch screw.

Storing potatoes for storage

It is advisable to harvest in dry weather. Having collected the potatoes after digging, you need to sort them out and sort them depending on their purpose:

- damaged tubers;

- planting material;

- potatoes intended for food (or sale).

Rotten tubers need to be burned. Punctured, chopped potatoes should first of all be consumed as food or used as animal feed.

Planting material (absolutely healthy potatoes the size of a chicken egg) is laid out in the light so that they turn green. The remaining healthy tubers intended for food or sale are kept in a dark, dry, well-ventilated place for about 5–10 days. During this time, the skin of the tubers will harden and the cuts will heal.

At the end of the “treatment period,” the tubers are laid out in boxes and taken to a clean, pre-disinfected and prepared cellar.

Author of the article: Daria Kuznetsova, journalist and summer resident with 15 years of experience

Field plowing equipment

The modern fleet of mini tractors includes about two dozen devices, domestic and imported, differing in functionality, power, and price. Let's look at the most popular of them.

Motoblock "Neva"

A domestic unit from a well-known plant among summer residents. This is a powerful device that can handle any soil.

Among the advantages:

In addition, this type of walk-behind tractor provides the user with ample opportunities to choose the optimal speed and comfortable handle position. At the same time, according to reviews from gardeners, “Neva” has not proven itself very well when working with a plow (short plowing depth).

The disadvantages include high weight (more than 90 kg), insufficient stability on uneven ground, and high cost.

Motoblock "Salute"

The author of this device, the Salyut association (Moscow), did everything to make it as convenient to use as possible. Its center of gravity is low and the engine is moved forward, making it easier to control than the Neva and able to easily maintain balance when connecting a plow.

Another advantage is its low weight and maneuverability, allowing the Salyut to be used in small areas. It should also be noted that the handles of the walk-behind tractor are narrowed and can be rotated 180°, which makes it very convenient for cleaning work.

A significant drawback is the lack of a differential, which makes turning difficult and making the cart inconvenient to use. In addition, some varieties of Salyut are characterized by a high noise level.

Motoblock "MTZ"

The brainchild of the Minsk Tractor Plant attracts with its compactness and maneuverability. Despite its high weight, the device is perfectly balanced and therefore extremely stable.

The latest modification, MT3 09N, will become a universal gardener’s assistant, and if you purchase an additional adapter with a seat, the walk-behind tractor can be turned into a mini tractor. Other advantages include wide functionality, large fuel tank capacity, and high power.

It should be remembered that MTZ is more intended for processing large areas; it is unprofitable to use it in small areas. In addition, the unit is picky about the choice of soil: it is not recommended to use it on heavy soils.

Firework

The second place in popularity is occupied by the Salyut walk-behind tractor with a power of 6.5 hp. To plant potatoes, you need to have, in addition to the unit, an additional plow, a hiller, and, above all, devices for adhesion to the ground.

Planting potatoes with a Salyut walk-behind tractor fundamentally looks like this: the mechanism moves in one direction and cuts a furrow for planting seed material, the same unit returns back and covers the furrow with soil.

The peculiarity of the walk-behind tractor is expressed in the selection of appropriate attachments.

MTZ walk-behind tractors came to us from the Soviet Minsk Tractor Plant, they are still popular today and are in demand among the Russian population.

An agricultural machine of minimal size turns out to be multifunctional and universal. It fulfills its purpose well.

The model has disadvantages:

- there are problems with gear shifting;

- a load of physical strength is required when switching the differential.

Each business owner purchases equipment based on considerations of cost and expediency. Requirements for agricultural practices do not change.

Methods for planting potatoes with a walk-behind tractor

When the area is prepared, you can proceed directly to planting potatoes. Using a walk-behind tractor, you can plant crops in different ways:

- Semi-automated method. A hiller is installed on the walk-behind tractor, which allows you to form and then cover the furrow with a layer of soil. The seed potatoes are placed manually.

- Automated method. All processes are carried out by a walk-behind tractor using a special mounted potato planter.

- Planting potatoes with a walk-behind tractor under a plow.

The choice of method depends on the equipment included with the walk-behind tractor and the area of the treated area. To understand the difference, let's take a closer look at the features of each of these methods.

Preparing the soil

The soil for planting potatoes must be enriched with oxygen. Only in this case can a high yield be achieved. Therefore, before planting vegetable crops, the field is plowed with a plow and cut into furrows with a hiller.

The soil for planting potatoes with a walk-behind tractor is prepared as follows:

Plowing a site using the “cutter to cutter” technology means re-passing the walk-behind tractor along the last plowed cutter in the opposite direction.

Circular tillage consists of spiral-shaped plowing of the area: from the edge to the center.

Planting potatoes with a walk-behind tractor and hiller

If potatoes are planted in a small area, then most often a hiller is used, which is attached to a walk-behind tractor. The purpose of this device is to lift the earth, creating a furrow and forming ridges on both sides of the passage.

Using a walk-behind tractor, form furrows for planting potatoes

There are several types of hillers:

- regular, with a fixed working width (lister);

- regular, with adjustable working width;

- disk.

The first two are very similar in appearance and resemble a knife made from two curved wings joined together at the front and spread apart at the back. The difference lies in their functional features.

Determining the embedment depth

The seeding depth for planting potatoes should be within 20 cm.

An even rut depth is achieved using a plow.

Checking the readiness of the walk-behind tractor for work

Before you take the equipment out onto the field, you need to make sure it is in good condition.

Checking the readiness of the walk-behind tractor for work includes:

Hiller with fixed working width

This hiller is quite primitive and does not allow you to adjust the row spacing. It is not very suitable for planting potatoes, since the working reach of such a device is only 20–30 cm. It is more appropriate to use it for planting vegetables that do not require a significant distance between the rows.

A non-adjustable hiller is more suitable for marking beds with narrow row spacings

Hiller with adjustable working width

The second version of the hiller is the most popular among gardeners. The design of this attachment allows you to adjust the width of the soil. Therefore, it is possible to set the desired gap between the rows. However, an adjustable hiller also has a number of disadvantages:

- To use it, you need a more powerful and heavier walk-behind tractor (with a power of at least 4 hp and a weight of more than 30 kg).

- The productivity of this equipment is somewhat lower, because when working with it, some of the earth from the ridges may fall back into the furrow.

- As the distance between the dumps increases, the load on the walk-behind tractor increases and fuel consumption increases.

Adjusting the grip width of the hiller allows you to change the row spacing

Disc hiller

This device is more productive than the previous ones, but is also several times higher than their cost. A disk hiller is a platform with two disks attached to it, which rotate when moving. It is possible to adjust the space between the discs and their angle of inclination. Among the advantages of such a hiller, the following should be highlighted:

- is less energy-consuming and more convenient to use;

- creates smoother and higher ridges;

- The discs rotate while moving, crushing and loosening the soil.

It is recommended to use a disc hiller with units that have at least two forward gears. Driving at the lowest speed ensures optimal use of the walk-behind tractor's power.

Experienced farmers consider the disc hiller for a walk-behind tractor to be the most effective.

You can improve the performance of the hiller by setting the angle of rotation and width between the discs

Regardless of the type of hiller, planting potatoes is carried out as follows:

- An attachment is attached to the walk-behind tractor and the minimum soil working width is adjusted; the unit is equipped with lug wheels.

- Using a walk-behind tractor, furrows are formed.

- Seed potatoes are manually placed in the resulting rows at equal distances.

- The wheels of the walk-behind tractor are replaced with ordinary rubber ones, the width of the hiller's wings is changed to the maximum.

- The furrows with potatoes laid in them are filled with earth using a walk-behind tractor.

Thus, when planting using a hiller, you need to make at least two passes with a walk-behind tractor along the site. To plant planting material in the ground, you will need an assistant.

Using a regular or two-row hiller

You can plant potatoes in any area using potato hillers for a walk-behind tractor: regular, single-row, which forms 1 hole in 1 pass, and double-row, making 2 holes in 1 pass.

Their structure, as well as the principle of operation, are similar, since they are designed to do the same job. The only difference is that moving a two-row device requires more effort from the equipment itself and the operator, but the work moves much faster, since 2 rows are grabbed at a time. Planting potato tubers using a walk-behind tractor with a single-row hiller is performed in the following sequence:

- Steel lug wheels are installed on it.

- The wings of the hiller are spread in accordance with the required track width (usually 60-65 cm).

- They walk through the potato field, cutting holes with ridges.

- Prepared tubers are manually placed in them at a distance of approximately 25-30 cm between them.

- Remove the lug wheels and replace them with regular ones with rubber tires. The wings of the hiller are spread to the maximum so that they can capture as much land as possible.

- Again they walk with the unit around the site, this time along the rows, filling the furrows with earth.

Planting potatoes with a walk-behind tractor with a two-row hiller needs to be done differently:

- First, lug wheels with extensions are installed on the unit, a hitch is attached, and attachments are attached.

- Then the hiller itself is adjusted, spreading each of its parts to the required width (so that at the moment of passing the beds, each of the 2 hillers is exactly in the middle of the row spacing), their wings are brought together as much as possible to make narrow and deep furrows. The row spacing when planting potatoes is standard, it is 60-65 cm.

- After this, the furrows are cut using a walk-behind tractor.

- Then they walk across the field and place planting tubers in them manually, maintaining a distance of at least 20-25 cm.

- After this, the walk-behind tractor is set up again, the wings of the devices for hilling are spread as far as possible and the unit is placed so that the hillers fall into adjacent rows and go through the entire area, covering the potatoes with soil. This completes the planting of potatoes.

With a plow

You can also plant potatoes on your plot using another device - a plow. Two types of these structures are attached to the walk-behind tractors: single-body and hiller plow with a V-shaped share. Working with a conventional plow is done like this:

- The device is installed on the unit in such a way that when moving it goes into the ground to a depth of 10-15 cm.

- Pass 1 row along the potato plot, forming 1 groove.

- Potato tubers are placed into it manually, retreating approximately 20-25 cm or more from each.

- The unit is deployed at the edge of the plot and the next hole is made next to the first one at such a distance that the plowed soil falls into it and covers the potatoes.

- Plow the next hole at a distance of 60-65 cm from the first.

- Place the potatoes in the groove again.

- They plow a hole next to it to cover the newly laid out tubers with soil.

- Repeat all steps until the entire field is planted.

The sequence of planting potatoes with a walk-behind tractor under a plow with a V-shaped share differs from the previous method:

- First, the entire potato plot is plowed, making grooves on it at a uniform distance of 60-65 cm. In this case, when cutting each subsequent row, the unit should go along the edge of the previous groove.

- Potatoes are placed in the prepared recesses at a distance of approximately 20-25 cm or more, depending on the nutritional area that plants of a particular variety need.

- The recesses are filled, moving the unit along the rows so that its wheels are in 2 adjacent grooves, and the plow is located in the middle. To avoid crushing the tubers, you need to install wheels with rubber tires on the unit, rather than lug wheels.

When planting potatoes with a Neva walk-behind tractor, before installing steel lug wheels from the unit, you need to remove the wings and install a single-row hitch instead of the central stop. Then attach a two-row hiller to it, spread its working parts by 60-65 cm and firmly fix it. Next, plant potatoes under the plow using the Neva walk-behind tractor in the same sequence as with other units

Using a potato planter

A mounted potato planter is a convenient and reliable device, specially designed to perform all work related to planting tubers in beds. It consists of several units: a wide and deep bunker for tubers, a mechanism that feeds them into the bed, a plow for cutting furrows, and a disk hiller that shovels soil onto the beds and forms ridges.

Planting potatoes with the help of such a potato planter is as simple and fast as possible, because 2 completely different tasks are carried out simultaneously: cutting furrows and planting tubers in them. This is especially true for large plots and allows the vegetable grower not to waste time manually laying out the tubers in the recesses and repeatedly going through the rows with a walk-behind tractor in order to cover them with soil.

Before starting work with a potato planter, the soil must be plowed and harrowed. Then the mechanisms of the walk-behind tractor and potato planter are adjusted, and the prepared tubers are poured into the bunker. They install the unit at the edge of the site and gradually go through it all, row by row. From time to time, planting material is added to the bunker when it runs out. Working with a potato planter on a Neva walk-behind tractor is the same as with equipment from other brands.

Marking rows - cutting ridges or furrows

Cutting furrows or ridges is the same process - a walk-behind tractor with a hiller is passed over the plowed area, drawing future potato rows on it with the hiller. The result of the work is alternating furrows and ridges.

Important! The distance between the ridges is the width of your rows. For potatoes, this is at least 60 cm. It is more convenient to carry out hilling on wide row spacings of 70 cm. Here the plants are better lit and are less injured during the second hilling.

There are two options for planting potatoes with a walk-behind tractor:

- In the northern regions, on heavy clay soils, potatoes are planted in ridges. In them, the earth warms up better, and in case of excess moisture, the elevation will not allow the tubers to rot.

- In warm regions, on fertile or light sandy soils, potatoes are planted in furrows.

Potato ridges are cut using a walk-behind tractor along the plowed area immediately before planting. Sometimes this process occurs simultaneously with the placement of tubers in the ground.

We make shallow furrows, 8-12 cm. With this planting, the walk-behind tractor goes smoothly, without slipping, and the potatoes grow exactly in the middle of the fertile layer.

Important! If you deepen the hiller (plow) further, the walk-behind tractor will begin to throw from side to side, and greater physical strength will be required to maintain a smooth move. The tubers will sit on the dead mineral layer of soil and the plant will starve.

Weeding potatoes with a walk-behind tractor

As mentioned at the beginning of the article, it is possible to weed potatoes with a walk-behind tractor. For this purpose, a flat-cut weeder is provided - a fairly popular device. This attachment allows you to prepare the area for planting or to process potato rows. There are known flat-cutters that have special drums for discarding weeds, as well as simple flat-cutters with knives.

When weeding potatoes, it is necessary to place the wheels in the furrows. When the walk-behind tractor moves, the knives cut off the weeds, and the drum (if there is one) throws them back relative to the direction of movement. When weeding, it is important to take into account that the younger the weeds, the easier it is to remove them, while more mature and strong plants may not be able to be treated with this device.

This is interesting: how to connect a potato digger to a Salyut walk-behind tractor.

Field plowing equipment

A walk-behind tractor, also known as a motor-cultivator, is widely used to facilitate heavy manual agricultural labor.

Before purchasing equipment for plowing a field, you must choose:

Choosing a walk-behind tractor

A mechanical self-propelled device with an engine is simply indispensable today for the following earthworks:

When choosing a walk-behind tractor, it is necessary to take into account the area of the area being processed.

The modern equipment market offers the following popular types of cultivators:

Choosing trailed equipment

To plant potatoes using a walk-behind tractor, you need trailed equipment.

Trailed equipment for walk-behind tractors:

Planting under the plow

Features of using a plow when planting potatoes:

You can plant potatoes using a plow in the following way:

The video shows how to plant potatoes with a walk-behind tractor under a plow. The video was filmed by the City& Country Style channel.

Planting with a disc hiller

Features of the disc hiller when planting potatoes:

Planting potatoes with a disc hiller

Application of potato planter

The potato planter consists of the following set of structures:

Features of using the potato planter:

Planting with a potato planter

Using a two-row hiller

Features of using a two-row hiller when planting potatoes:

Planting with a two-row hiller

Do-it-yourself hiller for walk-behind tractor

To manufacture this equipment, you need to adhere to clear rules and, if possible, use drawings. This will allow you to install all the parts correctly and quickly, so as not to have to redo the work later. You can independently make lister (classic) or disk type models.

Creating a lister hiller

Such a hiller for a walk-behind tractor is a traditional unregulated device, used most often. To create it, you need to draw or use ready-made drawings, according to which all the work will be very simple.

- The base is made of metal sheet, 3 mm thick. It will encounter resistance from the earth, so it must be as strong as possible.

- The bracket is made from a steel strip with a width of 4 mm; the part must be hardened.

- The field board is created from metal 5 mm thick; it is hardened in several stages using a gas burner.

- The stand is made of metal 8 mm thick, since it is the element that bears the entire load.

- We create the wings for the hiller from steel 2 mm thick; they must correspond to the dimensions of the selected pattern, because this is how they can be joined to the base.

- Next, they are slightly bent and welded to the base.

If you need an adjustable hiller, you need to attach the wings to the base using hinges, and the rods for adjusting the angle are installed in the tail of the base.

You can also make a two-row hiller, thanks to which the work speed will double. In this case, you need to add traction devices to the finished structure, and make the fastenings movable, which will allow you to adjust the width of the rows.

Making a disk hiller

When creating such a model, special attention is paid to the molding of the discs. Used cutters from a seeder or circular saws, which are attached to bearings with oil seals, are well suited for them.

- The disks must be installed at an angle, maintaining the distance between their lowest points. Also an important condition is their symmetry, otherwise the walk-behind tractor may lead slightly in different directions.

- All elements must be connected by welding or bolts; the discs are connected by adjustable adapters.

- Screw tarlaps, a leash and stands are also secured.

- Next, you need to use a beam with wings to secure the tool to the walk-behind tractor.

An equally important point is the correct selection of inclination angles and immersion depths, for which movable elements with bolted fixation are mounted on the bracket.

Manufacturing of propeller hillers

To work, you will need high-quality thick metal, a grinder and a welding machine.

- First, axles are made that need to be adjusted to the walk-behind tractor.

- Then you should make a stand and a base, which are welded by arc welding.

- You should immediately select the distance between the nozzles, the shape of the lugs and the installation angle, which will allow you to loosen the earth as efficiently as possible.

For convenience, you can make several bushings with brackets and different sets of blades, which will allow you to perform various types of hilling.

In order to properly make a hiller for a walk-behind tractor, you should also watch the video in which you will find complete instructions for creating a hiller.

Crop care

A walk-behind tractor and various attachments will make further care of the potato plantation easier.

Treatment after germination

The time from planting to the first potato shoots is the most important for the formation of full-fledged and healthy tubers. Germination will begin from the upper buds. The main thing that should not be allowed is breaking off sprouted branches. This will negatively affect the growth and development of potato fruits.

The role of the plow

After the first shoots appear, a weeder is used to weed and loosen the soil between the rows. It performs the tasks of a conventional plow.

Hilling

Accelerates the development of stems, destroys weeds and protects the plant from possible frosts. Performed 2–3 weeks after germination. A hiller is used for work.

Spraying with a walk-behind tractor

This can be done using a special sprayer, which is equipped with a pump.

Wire harrow for weeding

To remove weeds after sowing, but before the first shoots appear, a mesh weeding harrow is used, which is fixed to the frame of the walk-behind tractor and pulled across the field.

Potato processing

Weeding

A week after planting, it is worth loosening the soil. During this time, a dense crust formed on the ground, preventing the germination of plant stems and the access of oxygen. Weeding is carried out weekly. This helps fight weeds that negatively affect root crops.

Trailed grain harvesting equipment is classified as agricultural equipment and is used for harvesting grain and leguminous crops. A trailed grain harvester is reliable, high quality and productive.

Snow removal equipment is ideal for owners of suburban areas, since snow removal occurs with their own efforts. By clicking on the link, you will become familiar with the various models and characteristics of the Lynx snow blower.

Challenger tracked and wheeled tractors are used in work in difficult terrain conditions over large areas for cultivating land. The Challenger tractor is a reliable and smart work assistant.

For weeding work, a rotary or mesh harrow, paws and a weeder are used.

Hilling

Shoots appear in 3-4 weeks. Now after planting you need to hill up the potatoes. A walk-behind tractor will help with this. For hilling, one, two or three row hillers are suitable. If desired, you can apply fertilizer by installing an additional nozzle.

Potato harvest

The walk-behind tractor is used not only for planting, but also for harvesting potatoes. By autumn, the potato tops dry out and everything is ready for harvesting. You need to dig potatoes in August - September, in dry weather. For digging with a walk-behind tractor, a mounted plower or potato digger is installed.

But you can get by with a single-row hiller, which will lift the soil and the potatoes will lie along the edge of the ridge. All that remains is to go through and collect the potatoes. Planting and processing potatoes with a walk-behind tractor is not the only area of its application. Technical innovations have made the work of summer residents much easier.

The walk-behind tractor has now become a necessary tool for cultivating land. The unit is well worth the investment. You can see how walk-behind tractors can be used, in addition to planting potatoes, on the “Advice from an Old Plowman” website.

The choice of attachments depends on the owner’s requests. Using the example of planting, hilling, weeding and harvesting potatoes, you can see how using a walk-behind tractor makes life easier for gardeners.

Secrets of hilling and weeding potatoes with a walk-behind tractor

This useful unit will come in very handy even after the planting work is completed. With its help, potato bushes are hilled and weeds are controlled. But before use, you need to make sure that the attachment matches the distance between the rows. Otherwise, there is a risk of damage to emerging shoots or already mature plants.

Work begins in the early or evening hours to avoid the heat. Hilling is required at least 3 times:

- This is done for the first time when the sprouts are 5–10 cm high;

- after 14 days, similar actions are repeated;

- the third procedure is carried out when the shoots grow to 25 cm.

In addition, hilling cannot be performed on dry soil. But at the same time, it must be carried out when there is a high threat of night frosts.

Before the walk-behind tractor is delivered to the site on rubber wheels, the beds are watered and then allowed to shake out. The first ones are replaced on site with lugs. The work then looks like this:

- They constantly move in one direction. First you need to make mounds around the bushes on one side of the row.

- When they reach the end, they turn the unit around and do the same on the other side;

Attention!

Trimmed weeds do not need to be removed from the garden bed - they will protect young shoots from the negative effects of cold or heat.

Planting potatoes using a walk-behind tractor with a plow or hiller is both more effective and more fun than using a traditional shovel. All you have to do is choose the best method and follow the instructions. And if this is the first time planting potatoes using a walk-behind tractor with a two-row hiller or potato planter, a real video will come to the rescue.

Tips for Beginners

We offer some useful tips to help new gardeners when growing potatoes.

To make the beds even, you can pull ropes tied to pegs, along which it is convenient to form furrows.

It is better to plant during periods when the soil is moderately moist, since equipment can get stuck on wet soil, and more fuel is wasted on dry soil.

Various attachments are designed for planting potatoes and for subsequent care: hilling beds, loosening the soil and mechanized harvesting

When the height of the plants reaches 15-20 cm, they need to be hilled up, that is, covered with soil about 2/3. This job can be done much faster using a hiller. This is done as follows:

- attach a hiller to the walk-behind tractor and set the depth of its immersion in the soil, as well as the desired angle of rotation;

- regular wheels are removed and lugs are installed instead;

- The walk-behind tractor is placed in the center of the row spacing;

- the unit is moved at the lowest speed.

In the future, it is recommended to carry out hilling manually to prevent damage to the developing tubers.

The use of a walk-behind tractor when growing potatoes helps to significantly reduce the cost of time and effort and allows you to get a good harvest.