Lapping is the treatment of the surfaces of a part with a lap - a tool made of soft materials with a fine-grained abrasive powder or paste applied to its surface, with the help of which a layer of metal or a film of its oxides is removed from the treated surface. For these operations, allowances of up to 0.01–0.02 mm are left on the surface of the parts. The thickness of the metal layer removed by lapping in one pass does not exceed 0.002 mm. Lapping is used to obtain connections of precise geometric shapes with high surface cleanliness (gears, valves, oil seals, bushings, taps, etc.). GOI pastes are used as lapping materials, which contain chromium oxide (74–81%), silica, stearin, etc. Tools for lapping include discs, cylinders, cones, plates, bars, rings made in the shape of the parts being ground. Lappings are made from glass, soft cast iron, mild steel, copper, brass, lead, and wood.

Lapping and finishing are finishing operations when processing surfaces. The accuracy achieved with these types of processing is 0.001–0.002 mm.

Lapping produces connections that are impermeable to liquids and gases (taps, valves with seats, plungers with sleeves), and finishing most often corrects minor deformations that occurred during heat treatment.

The essence of technology

The purpose of the operation is to bring the surfaces of parts to the optimal characteristics necessary to work together with other structural elements.

Often, during operation, mechanism components operate under mutual friction, for example, a piston and a cylinder. The tolerance in this case is about 0.001 mm, which ensures the necessary tightness and free movement without jamming. Such precision can be achieved by finishing and lapping operations. But during its implementation, the metal layer is partially removed, therefore, when producing blanks, an allowance of 0.01-0.02 mm is left in order to obtain a part with an accuracy of 0.001-0.002 mm in the final result. The terms should not be considered synonymous; grinding differs from finishing in accordance with the current standards of GOST 23505-79. The working documentation should accurately indicate the name of the operation.

The main task during finishing is to obtain a smooth surface and maintain the geometric accuracy of the part according to the drawing. At the same time, the characteristics of processing cleanliness and tolerances can be completely identical in both types of work. Therefore, the register of working specialties has approved the professional standard for the specialty - “closer-lapper”. Both operations are finishing and if the part manufacturing technology requires heat treatment of the part, then it is done before metalwork.

The technology of finishing and lapping consists of applying abrasive mixtures in the form of pastes, gels, liquids to the surface of a part made of steel, aluminum and other metals and subsequent mechanical processing with special devices. The tools required for the job and the consumables used are indicated in the engineering documentation. By finishing, the surface is smoothed to the required values, removing excess metal with abrasive particles located on the surface of the processing tool. A distinction is made between direct and indirect coating of the lapping compound. In the first case, the abrasive is pressed into the surface of the device before the operation begins, and in the second, it is evenly placed over the entire area of the part.

Most often, a cast iron block is used as a lap, which holds the abrasive well on the surface. While often inferior in strength, it effectively processes hardened metal. In practice, lead and wood lapping are used. For cold grinding of complex surfaces, additional devices are used, for example, a tightening nut when finishing the thread. Preliminary operations are also possible according to the technology. In the machine tool industry, for example, surfaces are often scraped before being treated with abrasive mixtures. This improves the surface geometry and speeds up the process.

General information about lapping paste

Lapping paste is used for lapping valves that are part of internal combustion engines. The lapping procedure improves the physical and technical characteristics of valves (strength, elasticity, hardness, absence of cracks), and also allows to increase the service life of the valve. Lapping is performed in three cases:

- Replacing old valves with new ones. Lapping reduces the risk of cracking. This treatment minimizes contact of the metal surface with liquids, which reduces the risk of scale and rust formation.

- Overhaul of a car or engine. If the engine is used for a long time, scale forms on the valves, which negatively affects the technical and operational characteristics of the part. If the part is old, it can be replaced. If the part is in good condition, it can only be treated with PP - in this case there will be no need to replace it.

- Urgent car or engine repair. Mechanical damage during an accident is distributed unevenly throughout the car. If the engine has received slight damage, then you do not need to replace the valves - you can only treat them with lapping paste, which will strengthen the parts, making them stronger and more reliable.

There are two types of PP - homemade and factory-made. Homemade mixtures are made from scrap materials, and their cost is low. However, such mixtures have a major drawback - the quality of such PP is low, which reduces their functional properties. Today there is a large selection of factory mixtures that contain many useful components that have a complex effect on engine parts.

PP differ in a number of parameters - grain size, viscosity, type, presence of additional additives, brand, packaging volume. In Russia, various lapping pastes for valves are available for sale. The basic popular brands are VMP Classic, VMP Professional, ABRO GP-201, Done Deal abrasive-grinding mixture, GOI. The purchase should be made taking into account the technical characteristics of your engine. Ideally, the selection of software should be carried out by an auto repair shop employee who has the appropriate experience and qualifications.

This is interesting: Metal cutting

Passport

When purchasing or upgrading, the owner is required to have a passport for the machine. This is the relevant technical documentation that will be necessary during use. It is prohibited by law to operate and repair tools without diagrams and an instruction manual. In the grouping of metal-cutting machines, which was developed by the Experimental Research Institute of Metal-Cutting Machines (ENIMS), lapping machines are classified in the third group, the seventh type. Group 3 - Grinding, polishing, finishing, sharpening machines.

- Cylindrical grinding

- Internal grinding

- Roughing and grinding

- Special grinding

- Sharpening

- Surface grinding

- Lapping and polishing

Based on this classification, each metal-cutting mill of serial production is assigned a code (a number of 3-4 digits). The first number is the group, the second is the type, the third or fourth is the dimensions of the machine or the part it processes.

Cylindrical grinding of metal, cylindrical grinding work in Moscow

New supply technologies for the city of Moscow!

In order to find a supplier of the assortment All types of work on cylindrical grinding of metal, cylindrical grinding work in %CITY%, you do not need to surf the Internet for a long time and search for suppliers’ websites, compare prices, call and check availability. We offer you to automatically send your Purchase Request to all major Suppliers not only in the Moscow region, but also in the regions of the Russian Federation and the CIS you have chosen.

In fact, you will announce a Tender for all types of work on cylindrical grinding of metal, cylindrical grinding work in the city of %CITY% in the Moscow region.

Send a request to suppliers

Our automatic system is very simple. Metal100.ru is an information portal that presents the prices of the main suppliers of rolled metal products with daily updated price offers. As soon as you submit your supply request, the system will automatically notify all suppliers in the city of Moscow, as well as in other regions you specified. Having received your request, suppliers will make the appropriate calculations and offer you the best prices!

In addition, our website contains price lists of the main suppliers, and you can always compare the relevance of the proposals received.

Save time and money!

We also ask you to pay your attention to user authorization. As a rule, all authorized suppliers of rolled metal products have ratings and customer reviews. Unauthorized users are mostly small metal traders engaged in the supply of small wholesale quantities, which does not guarantee 100% fulfillment by the latter of their obligations in terms of timing and quality of products

Unauthorized users are mostly small metal traders engaged in the supply of small wholesale quantities, which does not guarantee 100% fulfillment by the latter of their obligations in terms of timing and quality of products.

Beware of scammers!

Convenient navigation of the METAL100 portal allows you to find the range of rolled metal products you need in the Moscow region in a few clicks. Compare the prices of suppliers of the assortment All types of work on Cylindrical grinding of metal, cylindrical grinding work in %CITY% and choose the best offer!

We wish you successful transactions!

Tools and accessories

The most common device for performing finishing operations is a lapping plate, which, as mentioned above, can be made of various materials. The choice of the type and material of manufacture of such a plate, which is a fairly universal device, is influenced by both the characteristics of the parts being processed and the requirements for the quality of the ground surface. Among all types of plates, the most widespread are products made from cast iron grades, the hardness of which (according to HB) is in the range of 190–230 units.

Industrial lapping table

The design and dimensions of a plate or other type of lapping tool are influenced by both the design features of the products being processed and the type of processing: roughing or finishing. It is the plates, as a device for performing lapping, that are used for processing flat surfaces. In this case, as mentioned above, special grooves are applied to the surface of the plates used to perform roughing operations, which can also have a spiral configuration. Such grooves not only retain abrasive material in the grinding zone, but also remove waste from it.

Naturally, it is not possible to grind in cylindrical surfaces, holes and parts with complex configurations using a plate. Therefore, for such purposes, a device is made, the shape of which is optimally suited for processing a part of a certain configuration. Thus, these can be lapping tools of round, cylindrical, annular, conical, disk configuration, etc. In particular, lapping of holes is carried out with a device that is made in the form of bushings fixed on special mandrels.

The tool with which grinding operations are performed is also divided into non-adjustable and adjustable. The second type of device is more universal; its design, consisting of a split working part, a cone and a sliding device, provides the possibility of changing its diameter.

To process cylindrical parts, it is not at all necessary to use a specialized lapping machine; universal turning or drilling equipment is quite suitable for this. In such cases, the workpiece can be fixed in the centers or chuck of the equipment, depending on what part of its surface needs to be ground.

Using a manual grinding and lapping machine when repairing flat seat fittings

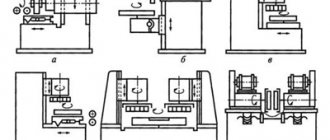

Machines that are originally designed for lapping are divided into general purpose equipment and specialized models. General purpose machines, which can be equipped with one or two lapping tools, primarily machine parts with flat and cylindrical surfaces. Smaller parts, when processed on such machines, are placed in a free state in a special separator, where they undergo lapping, located between two rotating lapping disks. Large parts are fixed on the machine using a special device and processed with one abrasive disc.

Lapmaster professional flat lapping machine designed for processing various materials, including metals and ceramics

More complex in design and less universal are specialized machines, the device of which is specially designed to perform the grinding of parts of a certain configuration: valve seats, cams of camshafts, crankshaft journals, gears, etc.

Finishing-grinding of the outer cylindrical surface

The finishing and lapping of the outer cylindrical surface of part 1 is carried out by lapping 3 in the form of a ring with slots. The lap is imparted a reciprocating rotational motion Dj and a reciprocating motion D2. Uniform additional rotation of the part is possible. Finishing and lapping is carried out manually or on a universal lathe. Similar patterns and movements are used when grinding internal cylindrical surfaces.

Floor-standing machines Lapmaster-Wolters

Floor finishing and lapping machines are specially designed to work in harsh conditions and with minimal maintenance. The machine consists of a welded sectional frame on which a gearbox, electric motor, work table and tanks for abrasive material and waste are installed. Access to the tanks is provided freely by lifting the lid. The lapping plate rotates counterclockwise and the forming rings automatically rotate clockwise. The machines work with abrasive mixtures of various grain sizes, oil or water based.

The machines can be additionally equipped with:

• a device for feeding and distributing the diamond suspension • various lapping plates • water cooling • a pneumatic system for regulating the load on the workpiece • a drive with infinitely variable rotation speed • soft start • additional lapping rings • parts that come into contact with water can be made of stainless steel .

The machine is delivered fully equipped and ready to work. The machine is controlled from a control panel attached to the machine frame at a convenient height. Lapping plate sizes from 610 mm or more in diameter.

Lapmaster 24 with Lapmaster 36 pneumatic clamps

Lapmaster 24 is a finishing, polishing, floor lapping machine with a lapping plate diameter of 610 mm, ideal for all engineering, mechanical workshops and workshops where an important task is the processing of product planes. Parameters: • lapping disk diameter: 610 mm • plate rotation speed: up to 70 rpm • diameter of the workpiece: 240 mm • loading weight: 250 kg per workplace (If all three workplaces are loaded, the load of each workplace must be reduced by 50%) • machine dimensions: width – 1100 mm, depth – 1100 mm, height – 1350 mm • machine weight: 550 kg (Including plate and rings) • noise level: 68 dB max. • timer: from 0.1 second to 999 hours • voltage: 400 V, 3 Phase, 50 Hz. Lapmaster 36 is a finishing, polishing, floor lapping machine with a lapping plate diameter of 914 mm, ideal for all engineering, mechanical workshops and workshops where an important task is the processing of product planes. Parameters: • lapping disk diameter: 914 mm • plate rotation speed: up to 70 rpm • diameter of the workpiece: 360 mm • loading weight: 300 kg per workplace (If all three workplaces are loaded, the load of each workplace must be reduced by 50%) • machine dimensions: width – 1300 mm, depth – 1300 mm, height – 1100 mm • machine weight: 1350 kg (Including plate and rings) • noise level: 68 dB max

Lapmaster 36 is a finishing, polishing, floor lapping machine with a lapping plate diameter of 914 mm, ideal for all engineering, mechanical workshops and workshops where an important task is the processing of product planes. Parameters: • lapping disk diameter: 914 mm • plate rotation speed: up to 70 rpm • diameter of the workpiece: 360 mm • loading weight: 300 kg per workplace (If all three workplaces are loaded, the load of each workplace must be reduced by 50%) • machine dimensions: width – 1300 mm, depth – 1300 mm, height – 1100 mm • machine weight: 1350 kg (Including plate and rings) • noise level: 68 dB max

• timer: from 0.1 second to 999 hours • voltage: 400 V, 3 Phase, 50 Hz

Angle editing and chamfering

Be sure to maintain the angle of inclination. If the knife previously cut easily, then the sharpening angle of the cutting edge remains the same. If the sharpening angle changes, it is better to make a new angle using a measuring tool. 25 degrees is considered the optimal angle; if there are deviations, it is better to decrease it.

But the question is also how accurately the edges of the cutting edge are brought together. This means whether the plane of the face is maintained or whether it has fillets.

Slopes or chamfers serve for a smooth transition from the butt to the cutting edge. There are various forms of blade releases. They are selected depending on its use. Sometimes the slopes have the same angle as the cutting edge, for example, Scandinavian ones. They are sharpened for lenses, both convex and concave.

When sharpening, you need to maintain an angle.

Finishing technique

For manual watering, there are two options:

- the knife is laid flat on the abrasive material;

- The stone is placed on the blade and the knife is secured.

The step by step process will be like this:

- To begin with, slowly move along the knife. Movements are made smoothly and in one direction.

- If we move the knife, the movements go in a circle or ellipse. You need to remember to lubricate and clean the stone in time. If we move the stone, then along the blade. When the movements become familiar, they can be done quickly.

- Then we look at the surface of the blade. A completely finished surface on all planes, including the cutting edge and chamfer, is smooth without scratches that contribute to the mechanical destruction of the blade. The chamfer may have deviations from the ideal plane and even have edges, but they all must be perfectly polished.

When finishing, you need to learn to strain only those muscle groups that are needed in this process. So fatigue will be less, and the instrument and its tilt will be better felt. Extra movements only complicate the work and do not improve the result.

§ 85. Lappings

Lapping is carried out with a special tool - a lap, the shape of which must correspond to the shape of the surface being ground. According to their shape, laps are divided into flat, cylindrical (rods and rings), threaded and special (ball, asymmetric and irregularly shaped).

Lappings can be movable or fixed. The movable lap moves during lapping, but the part remains stationary or moves relative to the lap. Such laps are cylinders, discs, cones, etc.

When using a stationary lap, only the workpiece moves. Such laps are bars, slabs, etc.

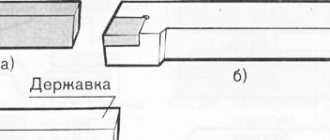

Flat laps are cast iron plates on which planes are finished. A flat lap for pre-treatment has grooves with a depth and width of 1 - 2 mm at a distance of 10-15 mm (Fig. 338, a), in which the remains of abrasive material are collected. The laps for final lapping are made smooth (Fig. 338.6).

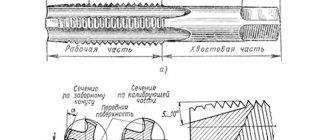

Cylindrical laps are used for lapping cylindrical holes. Such laps are unregulated (Fig. 339,a) and adjustable (Fig. 339,6); the latter are a split sleeve 3 mounted on a conical mandrel 2. The diameter of the lap is adjusted using nuts 7 and 4.

Conical holes are finished with conical laps, which are cast iron (less often copper) mandrels. The pre-grinding lap has a spiral groove to hold the abrasive lapping material.

Rice. 338. Flat laps: a – with grooves, b – smooth

Rice. 339. Cylindrical laps: a – unregulated, b – adjustable; 1,4 – nuts, 2 – mandrel, 3 – bushing

The lap for processing the outer conical surface is a conical bushing.

Special laps (complex shapes) are used for grinding surfaces of various shapes and hard-to-reach surfaces of small sizes.

Lapping materials. Lappings are made from cast iron, bronze, red copper, lead, glass, fiber and hard wood - oak, maple, etc.

Most often, laps are made of cast iron and copper, which have the necessary qualities for satisfactory indentation of abrasives: medium hardness, density, good wear resistance.

Copper is more difficult to process and is an expensive material, therefore, for finishing and lapping of steel parts, it is recommended to make laps from medium-hard cast iron (HB140 - 200).

Preliminary lapping removes a large layer of metal, so soft metal (copper) lapping is used. They hold coarse abrasive much better than gray cast iron. For final grinding, when a small layer of metal is removed, cast iron laps are used. They retain mainly the smallest grains and, due to their hardness, facilitate processing. Steel laps wear out faster than cast iron laps.

For final grinding with GOI pastes in order to obtain a mirror surface, laps made of Pyrex glass or mirror cast glass should be used, which should not have bubbles, deep scratches or cavities.

Caricature of laps with hard abrasive material. There are two ways to coat laps with abrasive powder:

direct and indirect.

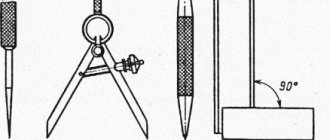

With the direct method, the abrasive powder is pressed into the lap before work. The flat lap is carved using a hardened steel bar or roller (Fig. 340, a). A round lap with a diameter of more than 10 mm is mounted on a solid steel plate, onto which a thin, even layer of abrasive powder is poured. The lap is rolled using another plate until the abrasive is pressed into the lap evenly over the entire surface (Fig. 340.6).

Rice. 340. Caricature of a ditch: a – flat, b – round

After caricature, the remainder of the abrasive powder is removed from the lap with a hair brush, the lap is lightly lubricated and used for work without adding free abrasive material until the lap stops processing the part.

The direct method of grinding laps has a number of advantages: the lap is sharpened more; during grinding, larger abrasive grains are crushed or pressed deeper into the slab; The accuracy of finishing by lapping with direct caricature is higher than with indirect caricature.

An indirect method of caricature is to cover the lap with a layer of lubricant and sprinkle abrasive powder on the lubricant.

During the grinding process, the abrasive grains are pressed into the lapping material, since it is softer than the part being lapped.

Work by lapping until the abrasive grains are completely dull. You should not add new abrasive powder during operation (especially before finishing grinding), as this leads to a decrease in processing accuracy.

Types of lapping operations

- Manual lapping

- Semi-mechanical lapping

- Mechanical lapping

Manual lapping

used in single production and when processing parts of complex shapes.

Semi-mechanical lapping

used in small-scale production. The main movement is carried out by the lapping machine, and the supply of abrasive to the lapping plate is carried out manually by the operator.

Mechanical lapping

Designed for large-scale and mass production. The main movement and supply of abrasive is carried out by a lapping machine, the operation of which is controlled by the operator.

Lapping pastes and suspensions are made from various abrasive materials such as Silicon Carbide, Aluminum Oxide, Boron Carbide, Diamond, etc. The choice of abrasive and grain size depend on the type and hardness of the material being processed and the requirements for the final processing result.

Grit M20-M40 is used for preliminary finishing of surfaces to a roughness of Ra = 0.16-0.63 µm, M10-M14 - for semi-finishing to Ra = 0.04-0.08 µm, Ml-MZ - for final finishing to Ra = 0.02-0.04 microns.

Lappings play a major role in finishing technology. The lap must be hard and wear-resistant to maintain the shape and accuracy of the working surface. Lappings are made from cast iron, steel, copper, bronze, glass, ceramics, aluminum, stainless steel, hard and tough wood, and composite materials. Lappings made of cast iron are the most common. Steel is used for the manufacture of thin long laps, glass is used for particularly precise laps, composite laps are used mainly with a diamond suspension for processing products made of hard alloys.

Depending on the type of processing, laps are made for roughing and finishing. Roughing laps have grooves in which the lapping paste or mixture and processing waste are retained. There are no laps for finishing the channels. When finishing flat surfaces, flat lap plates are used; when finishing cylindrical and conical surfaces, round laps are used.

Lappings for finishing holes are made in the form of bushings mounted on mandrels. Lappings are adjustable and non-adjustable. Adjustable ones have a split jacket with an internal cone with a taper of 1:50 and an expanding device, which, when moving the cone, increases the diameter of the lap. The initial diameter of the lap is usually 0.005-0.03 mm less than the diameter of the hole being machined. The length of the working surface of the lap is: for through holes 1.2-1.5 times the depth of the hole being machined, and for blind holes it is less than its depth.

§ 2. Abrasive materials used for lapping

Abrasive materials are crystalline, fine-grained or powdery substances of high hardness used for processing metals. These substances are characterized by the simultaneous participation in the cutting process of a large number of randomly oriented faces of abrasive grains.

There are natural (natural) abrasives (diamond, corundum, emery, granite, quartz) and artificial or synthetic (boron carbide, silicon carbide, electrocorundum, crushed glass, crocus).

Abrasives are used in the form of powders, grinding wheels and whetstones, sharpening stones, sandpapers, polishing and finishing pastes.

Based on their hardness, abrasive materials used for lapping can be divided into two groups: hard and soft. Hard abrasive materials include materials with a hardness higher than that of hardened steel; These include diamond dust, emery, electrocorundum, boron carbide, silicon carbide, etc.

Soft abrasives include materials that have a hardness lower than that of hardened steel. These include: powders of chromium and iron oxides (crocus), as well as GOI pastes, etc.

Abrasive grain size. Abrasive powders vary in grain size. Depending on this, they are divided into three groups: grinding grains, grinding powders and micropowders. Within each group, abrasives are distinguished by numbers.

The grit number for abrasive grains and abrasive powders indicates the grain size in hundredths of a millimeter. In the designation of micropowders, the number indicates the grain size in microns (0.001 mm).

For rough grinding, grinding powders with grit numbers 3 and 4 are used; for finishing lapping - M28 micropowders; M20; for finishing - M14; M10; M7.

Of the soft abrasive materials, GOI pastes are most widely used. They contain abrasive materials and surfactants.

GOI pastes are produced in three varieties:

- coarse paste with abrasive ability 45; 40; 35; thirty; 25 and 18 microns, dark green, almost black; this paste leaves noticeable streaks and matte finish;

- medium paste with abrasive ability 17; 15; 10 and 8 microns, dark green;

- thin paste with abrasive ability 7; 6; 4 and 1 microns, light yellow; This paste allows you to get a mirror shine.

The abrasive ability of pastes is expressed in microns and is determined by the thickness of the metal layer removed from the part by the paste when it passes a path equal to 40 M.

GOI pastes contain abrasive materials (chromium oxide), binders (silica gel, stearin, oleic acid, split fat, kerosene).

There are pastes: electrocorundum, boron carbide and chromium oxide.

Electrocorundum has a light yellow color, grain size 270; 320, used for rough preliminary grinding.

Boron carbide is black, 270 grit; 320; M28; M20; M14; M10; M7, used for preliminary and final grinding.

Chromium oxide has a gray-green color. Coarse paste M40; M35; M30; M25 is used for semi-finish lapping and polishing, and the paste, which has a dark green color, is the medium paste M17; M15; M10; M8, used for semi-finish lapping and polishing. The light green paste is M7 thin paste; MB; M4; M1 and is used for final grinding and glossing.

The use of GOI pastes during lapping compared to other abrasive materials increases labor productivity by 1.5-2 times and improves surface quality.

When grinding in, use a coarse paste, much less often a medium one. After scraping, apply a paste diluted with kerosene to the surface plate, apply the latter to the surface of the part and begin grinding. Grinding is carried out until the green paste turns into a black mass. After wiping the surface to be scraped clean, apply the paste again and repeat the grinding process 3-4 times.

Tools, accessories and materials

The choice of processing technology and necessary equipment depends on the number of products in the series. The following types of lapping operations are distinguished:

- Manual grinding. Technology for processing single parts, when it is impractical to set up complex equipment or it is missing.

- Semi-mechanical (mechanized) lapping. A special tool is used. For example, a lapping machine. Actively used in small-scale production. Part of the process is performed manually (supply of abrasive composition, processing of complex parts of the part).

- Mechanical. Fully automated process. High precision equipment and quality control system. Complex, expensive machines are therefore used in large enterprises for the production of serial products.

The quality of mechanical grinding is very high. Modern control systems make it possible to produce large-scale batches with a guaranteed accuracy of 0.001 mm. When performing automated lapping, the operation time is greatly reduced compared to manual processing. One operator can operate several machines, which increases economics and productivity. In addition, only a highly qualified mechanic can achieve the same quality of grinding surfaces manually.

The main part of the lapping machine is the plate. Despite the name, it may not be flat, but have a complex shape. Modern equipment for finishing parts is programmable, with precisely specified operating modes and movement algorithms. Position sensors signal the orientation of the workpiece, monitor product dimensions and surface roughness. The machine configuration depends on the shape of the part. There is equipment for processing external surfaces, holes, and internal cavities. The standard configuration of the machine can be vertical or horizontal. Innovative automated systems are universal. Robotic modules can operate in both vertical and horizontal planes. Such equipment is used in the automotive industry.

Lubricants

The working composition in which lapping and finishing operations take place consists of abrasive and binders that ensure high-quality grinding. Products are divided into three categories:

- Hard abrasives. Minerals of natural origin. Contains aluminum and silicon oxides. This category includes natural and artificial corundum (emery), CBN, and synthetic diamonds.

- Soft abrasives. Fine powders in lubricants. Well-known GOI (State Optical Institute) paste from this category. This also includes powders of the “M” series (the first letter in the name of the abrasive, for example, M20, M7, M28 and others).

- Diamond pastes. 4 types of abrasive grain size. Marked with the abbreviation AP and colors: red (coarse-grained AP60/80/100), green (medium-grained AP20/28/40), blue (fine-grained AP7/10/14), yellow (fine-grained AP1/3/5)

To increase work efficiency, you can use several compositions. First treat the surface with hard abrasives, and then with soft ones. Diamond pastes are expensive, so they are used only for finishing parts made of hard alloys, glass, and ceramics. Ferrous and non-ferrous metals are processed with soft abrasives. They are also used for polishing; for example, GOI paste was originally developed for the production of optics for various purposes.

Industrial oils, animal fat, and petroleum products (kerosene, paraffin) are used as a wetting and lubricating base. The abrasive can be supplied in ready-made paste form, in powder, or in solid form. Depending on the base, the characteristics of the composition, its density, and viscosity change. Sometimes it is advisable to use suspensions. Such as a mixture of water, kerosene and oleic oil. The working mixture can contain from 50 to 85% lubricants. After the surface roughness has been brought to the required values, the surface is washed. The abrasive should not remain on the parts. This is done with kerosene, clean water or with the addition of surfactants.

Areas of technology use

The process of finishing and lapping is quite labor-intensive and complex, which is why they resort to it when greater precision of the mating parts is needed. In many large products of great complexity, only one or several nodes can be made using this technology. Others are installed during assembly without precise modification. Finishing and lapping of surfaces, holes, threads is needed in the following production areas:

- during the manufacture of pumps;

- during engine assembly;

- when finishing mating, slippery surfaces in the automotive industry (machines, equipment);

- during the manufacture of measuring instruments and precision instruments.

In some cases, installation of machined parts is not the final operation. After the installation of the mechanism has taken place, the device is brought into working condition and, in the presence of fine abrasive material, the parts are brought to the required parameters on site. After this, the device is washed and, if necessary, lubricated.

Books tagged “Lapping and finishing”

The directory contains data on free abrasive processing processes, technological materials and components of mixtures, preparation, properties and procedure for using pastes and suspensions. The characteristics of abrasive-finishing and abrasive-polishing mixtures, finishing-lapping machines and technological equipment, laps, and control tools are given.

Designed for highly qualified workers and mid-level specialists in machine-building and instrument-making, tool and repair enterprises. Can be used by university students, students of technical schools and technical schools.

In the Grinding section

Tags: Abrasive materials, Abrasive pastes, Abrasive layer, Geometry of abrasive grains, Lapping, Abrasive grain size, Machining allowance, Lapping and finishing