A drawing is a graphic document used to depict an engineering object. For the convenience of its use, various interstate standards (GOST) have been developed, which specify the rules for presenting all elements involved in the creation of a particular product.

The thread is the main element of the screw drive and threaded connection. It consists of a series of bulges and depressions on the torsion bodies, which provides a fastening that can withstand high loads. Cutting is used as a method of combining or compacting structural links.

Purpose of thread and its elements

The thread is the main element of the screw drive and threaded connection. It consists of a series of bulges and depressions on the torsion bodies, which provides a fastening that can withstand high loads. Cutting is used as a method of combining or compacting structural links.

The thread provides a fastening that can withstand high loads.

Its main elements are:

- internal, external and middle diameters;

- profile is a cross section of a cut with a plane passing through the main axis of the part under consideration;

- profile angle - the angle formed by the sides of the profile;

- profile height is the length of the segment between the minimum and maximum cutting points in the cross-sectional plane of the axis in the direction orthogonal to the cutting guide;

- pitch - the length of the gap between two points of adjacent identical turns, measured parallel to the axis of the thread.

Key characteristics of cuts

The main characteristics of any thread, including pipes, are:

- Pitch (P, pitch) - the distance between adjacent turns.

- External diameter.

- Inner diameter.

- Stroke is the distance that the fastener moves in the longitudinal direction in one full revolution. For single-start knurling, the stroke is equal to the step, for multi-start knurling - the step multiplied by the number of passes.

Inch thread diameter

This data is enough to select a compatible fitting or fitting in the store. To make a threaded connection on a screw-cutting lathe or milling machine, you will need other characteristics of the thread, such as profile angles and others.

What is the image and designation of the thread

The designation allows, based on a combination of letters and numbers, to understand what type of cutting is presented for analysis. It includes: type, pitch and stroke, accuracy class and number of the corresponding standard. For a better understanding of the operation, an image is used - this is a drawing in which, in accordance with GOST, a structural element with a threaded surface is presented.

The diagram helps create a visual representation of the shape and geometric features of the carving.

Designation on drawings

When moving the contour of a flat figure (circle, triangle, trapezoid, etc.) along a spiral line, a cut appears on the surface of a given shape. The methods of its presentation in drawings are regulated in specially developed international documentation (GOST), which was created for an unambiguous interpretation of the designation of pain.

Image of external threads on shafts

The external cutting gauge appears throughout as a solid main line. In the image obtained by projection onto a plane parallel to the rod axis, the internal thread is indicated by a thin permanent line along its entire length. In a drawing with a projection of the orthogonal guide of the rod, the internal diameter of the thread should be depicted as a thin continuous arc constituting 3⁄4 of the main circle. If it is necessary to show the carving as invisible, then it is represented by identical broken lines along the internal and external diameter.

External thread on shafts.

Image of internal threads in parts holes

In the holes everything is different. The internal diameter of the thread is indicated by a continuous main line. In the image obtained by projecting onto the plane of the orthogonal axis of the rod, the external thread is shown as a thin permanent line. In the drawing with the projection of the orthogonal guide of the rod, the external diameter of the thread is represented by a thin continuous arc, which is 3⁄4 of the circle.

Internal threads in the holes of parts.

Symbol for metric thread (GOST 8724-2002)

The definition of a thread includes the letter M (from the English metric system), the size of the gauge and the pitch of the thread, delimited by the sign “x”. Example: M8x1.25. It is possible not to specify a large step. Example: M8. If the thread is left-handed, then the letters LH are added. Example: M8x1-LH. The definition of a multi-start cut consists of the symbol M, the diameter, the sign “x”, the combination of Ph, the stroke, the symbol P and the pitch. For certainty, you can specify the number of visits.

Metric thread (GOST 8724-2002).

Symbol for trapezoidal thread (GOST 9484-81)

The definition of a single-cut trapezoidal cutting contains the abbreviation Tr, the value of the outer gauge and the pitch. Example: Tr16x4. For a multi-start trapezoidal cut, the definition includes: the combination of Tr, the external diameter, as well as the pitch and stroke. Example: Tr16x8(P4)LH.

Trapezoidal thread (GOST 9484-81).

How to determine the diameter and type of cutting

When selecting a compatible threaded connection for an existing product, it is necessary to determine its parameters. This can be done in the following ways:

- Use measuring gauges. Special calibrated flat combs are inserted one by one into the profile turns until a complete match of the profiles is achieved. To determine the parameters of internal threads, cylindrical gauges are used. Each caliber is engraved with the profile it fits.

- Measure the parameters diameter and pitch with a caliper, determine the profile using the tables.

Pipe thread measurements should be carried out with a high-precision verified tool down to hundredths of a millimeter.

Designation of thrust thread (GOST 10177-82)

The definition of a thrust thread must contain the letter S, the pitch and the value of the diameter. Example: S90-10. For left-sided cuts, additionally LH is indicated. If multi-pass cutting is considered, then its definition is made up of the symbol S, diameter, stroke and in brackets the letter P, the value of the step. Example: S80-20(P20).

Thrust thread (GOST 10177-82).

Classification of threads

- according to the shape of the surface on which the thread is cut (cylindrical, conical);

- according to the profile shape (triangular, rectangular, trapezoidal, round, etc.);

- in the direction of the helical surface (right and left);

- by the number of passes - the number of helical lines (single-start, multi-start);

- by the location of the thread on the surface of the rod or in the hole (external and internal);

- according to their intended purpose (fastening, fastening and sealing, running, special, etc.).

The fastening thread is intended for a fixed connection of parts. Metric and inch threads are used as fastening threads.

Fastening and sealing threads are mainly intended for tight, hermetically sealed connections of parts. These include pipe and tapered threads.

Running threads are used to transmit axial forces and movement in lead screws of lathes, lifting devices, etc. Trapezoidal, thrust, and rectangular threads are used as running threads. They can be single-pass or multi-pass.

Mounting threads

The most widespread are fasteners. Their purpose is to screw together and secure individual parts.

Straight threads

Cylindrical pipe thread is a detachable connection consisting of spiral grooves cut inside and outside of parts. This type of thread is used for the installation of pipes, fittings, shut-off and control valves, as well as other pipeline structural elements. The thread has a triangular cross-section with an apex angle of 55°.

Metric thread

Metric threads are standardized and have a triangular profile with an angle of 60° at the apex.

Starting from 6 mm, for each metric thread diameter there is one large pitch and several small ones.

The symbol for a metric thread with a large pitch includes the letter M and the nominal (outer) diameter of the thread in millimeters. For example, M 56 (Fig. 7) means that the thread is metric with a large pitch, with a nominal diameter of 56 mm (the pitch size is not indicated).

In the symbol for a metric thread with a fine pitch, the thread pitch in millimeters is additionally indicated (since several small steps are provided for one nominal thread diameter), for example:

The right direction of the thread is not indicated. The left direction in the symbol is indicated by the letters LH, for example:

Metric threads can be made multi-start.

The symbol for a multi-start thread includes: the letter M, the nominal diameter of the thread, the numerical value of the stroke, and in brackets the letter P with the numerical value of the pitch.

An example of a symbol for a multi-start metric thread:

— metric thread with a nominal diameter of 24 mm, pitch 2 mm, stroke 6 mm, three-start.

Left-hand thread with the same parameters -

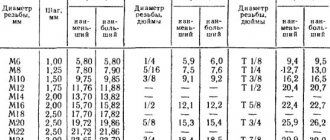

Inch thread

Inch threads for fasteners are standardized, but are used, as a rule, in the manufacture of spare parts to replace worn ones (if they had such a thread).

Thread profile - isosceles triangle with angle

Thread diameter is measured in inches. One inch (1″) is equal to 25.4 mm.

When designating a thread, its outer diameter is indicated in inches. For example, an inch thread with a diameter is designated 3/4″ (Fig. 8).

Pipe thread

Straight pipe threads have a triangular profile with an angle with rounded peaks and valleys. Threads are used in pipe connections. Pipe thread diameter is measured in inches. The nominal thread diameter in inches is a conditional value, since its value does not correspond to the outer diameter of the thread, as is customary for all other threads, but is equal to the nominal diameter (inner diameter of the pipe).

The symbol for a cylindrical pipe thread includes the letter G, indicating the type of thread, and the designation of the thread size (i.e., the size of the internal diameter of the pipe on which the thread is cut). For example, the designation G1 (Fig. 9, a) means that a cylindrical pipe thread is cut on a pipe with an internal diameter of 25.4 mm (i.e. one inch). The designation of an internal pipe thread (Fig. 9, b) is deciphered as a symbol of a cylindrical pipe thread in the hole into which a pipe with an internal diameter of 25.4 mm (i.e. one inch) is screwed. The symbol for left-hand threads is supplemented with the letters LH. For example: - cylindrical pipe thread size left.

The designation of cylindrical pipe threads (Fig. 9, a, b) and conical threads (for example, metric, Fig. 9, c) is indicated on the shelves of the leader lines.

Tapered threads

Metric conical thread with a taper angle of 1:16 (the angle of inclination of the generatrices to the geometric axis of the cone is 1°47'24") and a nominal diameter from 6 to 60 mm, GOST 25229-82, used in conical threaded connections. It can also be used in connections with internal cylindrical threads and external conical threads. The symbol of the thread indicates the letters MK, the diameter of the thread and its pitch.

Designation For left-hand thread

When connecting an internal cylindrical thread with an external conical thread, the designation is given in the form of a fraction:

Conical inch thread has a triangular profile with an angle. It is cut on the conical surfaces of parts with a taper of 1:16. In the designation of a conical inch thread, indicate the letter K, the nominal diameter in inches and the standard number (Fig. 11).

Tapered pipe thread according to GOST 6211-81 has a triangular profile with an angle and a rounded top. It is cut on conical surfaces of parts with the same taper of 1:16. The dimensions of the thread in the main plane correspond to the dimensions of the cylindrical pipe thread.

In the symbol for pipe conical threads, the type of thread is indicated (the letter R is for external threads, the letter Rc is for internal threads) and the designation of the thread size (nominal diameter in inches). For example, a pipe conical external thread with a nominal diameter (Fig. 12).

Running threads

Trapezoidal one-way thread according to GOST 9484-81 has a profile in the form of an equilateral trapezoid with an angle of 30° between the sides (Fig. 13, a). For each diameter, there are usually three steps. In the symbol for a one-way trapezoidal thread, the letters indicate the outer diameter and pitch, for example: (Figure 13, b).

Multi-start trapezoidal threads are designated by the letters nominal outer diameter of the thread, the numerical value of the stroke, and in parentheses the letter P and the numerical value of the pitch. A sign is placed between the nominal diameter and the thread stroke value, for example: The designation of the left-hand thread is supplemented with the letters LH, for example: (Fig. 13, c).

The thrust thread according to GOST 10177-82 has a profile in the form of an unequal trapezoid with an angle of 3° on the working side and 30° on the non-working side (Fig. 14, a). Like trapezoidal, thrust threads with the same diameter can have different pitches. The symbol for a thrust thread includes the letter S (indicating the type of thread), the nominal outer diameter and the pitch, for example: For a left-hand thread, the letters LH are indicated, for example: (Fig. 14.6).

The symbol for a multi-start thread contains the letter S, the nominal outer diameter, the stroke value, the letter P and the pitch value in brackets, for example: (Fig. 14, c).

Rectangular (square) threads are not standardized. Since the thread is not standardized, the drawing shows all the data necessary for its manufacture (Fig. 15). Rectangular threads have high efficiency, but have lower strength compared to trapezoidal and thrust threads.

Special threads

Special threads are:

- with a standard profile and non-standard pitch or diameter sizes. The designation of such threads includes the letters Cn (special thread), then indicate the designation of the thread, the dimensions of the outer diameter and pitch. For example, it means that the thread is a special metric thread with an outer diameter of 20 mm and a small non-standard pitch of 0.8 mm.

- threads having a narrow departmental purpose. For example:

- — eyepiece thread for optical instruments

- — Edison round thread for sockets and sockets of electric lamps.

Example notation:

- — round thread for sanitary fittings (for spindles of mixer valves, toilet and water taps) only with threads with a diameter of 12 mm.

Example of designation: where the thread diameter is 12 mm and the pitch is 2.54 mm.

Designation of persistent reinforced thread (GOST 13535-87)

The definition of persistent reinforced cutting contains the letters S, as well as an angle of 45, caliber and pitch. Example: S45200-13. If the thread is left-handed, the letters LH are additionally indicated. If it is necessary to define a multi-start thread, then indicate the letter S, the angle 45, the diameter, the stroke and the symbol P along with the pitch value, highlighted in brackets. Example: S4520024(P12) - two-start, stroke value 24 mm, pitch - 12 mm. For left-sided cuts, additionally LH is indicated.

Reinforced thrust thread (GOST 13535-87).

Necessary cutting tools

Cutting is widely used in everyday life and in production, so tools for making cutting are widespread. There are several types of cutting devices:

- Thread cutters are multi-toothed tools in which the thread cutting process is more productive than the cutters. They are divided into cylindrical comb, disk, prefabricated comb, heads for high-speed milling.

- Dies are a multi-edged tool for creating external cuts. There are round, solid, sliding devices, and split dies.

- Threading heads are special products for cutting internal and external threads and have a number of advantages compared to round dies. Depending on the comb design, heads are available with round radial, flat tangential and flat radial dies.

- Taps are an axial tool consisting of several blades designed for cutting internal threads. The following types are distinguished: manual, machine, wrench, machine, master, etc.

- Thread cutters are a tool for precise machine cutting of internal and external threads. They are divided into rod, single-strand and multi-strand shaped.

Threads used in everyday life

When building houses and renovating apartments, the most common inch pipe threads are:

- ½ and ¼ - with a pitch of 14 turns/inch (or with a pitch of 1.814 mm)

- and also: 1, 1¼, 1½, 2 with a pitch of 11 turns/inch (or with a pitch of 2.309 mm)

Less commonly used is a plumbing round thread, or Edison profile.

The 11 TPI pitch is maintained on pipes ranging from 2 to 6 inches in diameter.

Pipe cylindrical thread

A ½ pipe is the main diameter for intra-house and intra-apartment wiring; it provides sufficient water pressure from the main; most faucets for bathtubs, toilets, showers, washing machines and dishwashers are designed specifically for this connecting size. ¼-inch pipes are used for the last meters of wiring to plumbing fixtures that do not require high pressure and flow, for example, sink faucets. ¾-inch pipes are used at the entrance to the apartment or at the distribution manifold of the pumping station of the local water supply system. Pipes of 1 and 1 ½ inches are used much less frequently in the construction of large cottages equipped with swimming pools.