Question 38 Repair of threaded connections

There are the following types of threaded connections:

- bolted; It is advisable to use in connections of small thickness and frequently subjected to assembly and disassembly;

— screw; used when a bolted connection is not applicable due to the fact that there is no room for a nut;

- using a hairpin; used in conditions of frequent disassembly.

Threaded connections are made both using threaded fasteners and through threads cut into housings, shafts and other parts.

In threaded connections, especially those that absorb large or alternating loads during operation, increased wear and damage occur due to insufficient tightening of screws and nuts. The thread is also destroyed by over-tightening the nut or screw. Under the combined influence of various loads, wear of threaded connections is observed,

appearing as follows:

- bolts and screws stretch; the bolt rod elongates as a result of axial operating loads and tightening forces;

— the thread pitch and its profile are violated; the thread profile along the average diameter changes - the gap increases (observed in screws and frequently unscrewed fastening bolts);

— the nuts “stick” (the thread pitch changes under the influence of axial work loads);

— wear of the faces of the heads of bolts and nuts.

— the working surfaces of the thread profile are crushed under the action of work loads;

Worn or damaged mounting bolts and screws are not repaired, but replaced with new ones.

To make it easier to disconnect the connections, tap the nut, inject kerosene into the threaded connection, and cut off the nuts.

Defects in threaded connection parts and their repair;

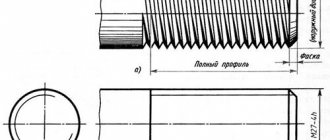

1) Wear, breakdown, collapse of threads on bolts, shafts:

- cut off the worn thread and (if this is allowed by strength conditions) cut a new one, processing it to the nearest diameter according to the standard; (parts of significant diameter).

— a bushing or threaded bandage is placed on the part (parts of significant diameter).

2) Wear, breakdown, collapse of threads in housings:

Worn or torn threads in the holes of a part are usually not restored, making repairs as follows:

a) the hole is drilled to a greater depth (if possible) and the thread is cut into it again; a new screw with an elongated threaded part is screwed into the recessed hole;

b) the hole is drilled out, a new thread of a larger diameter is cut and new screws with threads of the given diameter are installed; The hole for the screw in the second part to be connected is drilled out.

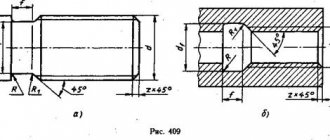

c) instead of the old stud, they make a new one with a shoulder and thread of two diameters (Figure 4.63, a): the larger one is for screwing the stud into one of the parts to be connected and the smaller one is for connecting to the second and tightening them with a nut;

d) restore the nominal (original) thread: the existing hole is drilled out, a new thread is cut, then an adapter sleeve is made (with external and internal threads designed for a normal screw), installing it flush with the plane of the part and locking it with a pin (Figure 4.63, b) However, the adapter sleeve must be thick-walled, so it is preferable to install it with epoxy glue (Figure 4.63, c)

e) a worn threaded hole in a part is “plugged” by drilling another hole next to it and cutting a thread of the required diameter in it. A new hole is also drilled in the second part to be connected.

Figure 4.63 - Schemes for repairing threaded connections using the installation:

A -

a new stud with a shoulder of two diameters,

b

- bushings with external and internal threads, in -

bushings for glue

3 Nicks and dents on the thread are eliminated by “pushing” with taps, dies or a mating part.

4 Compression of the faces of nuts and bolt heads is eliminated by sawing or surfacing, followed by processing of the faces.

5 Non-straightness of the axis of a rod, bolt, screw, or stud is eliminated by straightening in a vice or using a screw press.

Where are pin fasteners used?

Stud fasteners find their wide application in many industries, such as construction, automotive industry, electrical industry, plumbing, plumbing, pipelines, machinery and mechanisms.

If you need to tighten something, then a threaded rod is your hardware.

In addition to steel and stainless steel, studs are made from aluminum, copper, brass, titanium, plastic, nylon, PVC, rubber, etc. For protection, heat treatment and anodizing, galvanizing, phosphating, galvanizing in silver and even gold are used.

Thread restoration method

Damaged threads can be completely restored using the following technology:

1. Drill the threaded hole to the diameter indicated in the table below 2. Cut a special profile thread in it with a special tap 3. Screw a spiral repair insert (a durable stainless steel sleeve) into the resulting thread using a special tool.

Threaded insert

After such an operation, the thread becomes stronger than the original one in good condition. This effect is especially noticeable when the carving is made in a soft material such as aluminum. When a bolt (stud) breaks off in a threaded insert, there is no “biting” effect. A broken bolt (stud) can be easily removed.

Watch a video of how the threaded insert is used

What capabilities do threaded inserts have?

This method is especially relevant for restoring threaded holes in body parts of automobile engines, for example, a spark plug hole. The candle thread becomes very durable and reliable.

Threaded insert screwed in

Threaded insert screwed in

If the thread for a stud is broken, sometimes they drill it out and cut the thread to the next size. In this case, you have to use a stepped stud of unknown origin and dubious quality. And not every stepped hairpin can be found at the right time. If you repair the hole using a threaded insert, you still have the option of using a standard, branded pin.

Another use for repair threaded inserts is in brass exhaust manifold nuts. The result is a nut that combines a very strong thread and the property of not “sticking” to the studs.

Owners of some foreign cars should pay attention to the possibility of replacing the M12 x 1.5 thread with an M12 x 1.25 thread. It often happens that a bolt with such a thread is damaged, and it is almost impossible to find it in a retail chain in your city (we have such bolts in our store)

A turner will not turn out a decent bolt, because... The threads on factory bolts are formed by pressure (knurling), which provides the necessary strength. And on a lathe, the thread is made with a cutter, while the fibers of the steel bar are cut and the threads cannot bear the required load.

If you replace the thread in the body part with the more common in Russia M12 x 1.25, it becomes possible to select a bolt of the required size and strength from the assortment of Russian and European manufacturers of automotive fasteners presented in our catalog.

Video - how a threaded insert works, demonstration

What tools are used to restore threads?

1.

Drill

The drill diameter is selected from the table.

Table for selecting drill diameters for the most common threaded holes

| No. | Repairable thread sizes | Drill diameter |

| 1 | M5 x 0.8 | 5,2 |

| 2 | M6 x 1 | 6,3 |

| 3 | M8 x 1 | 8,3 |

| 4 | M8 x 1.25 | 8,4 |

| 5 | M10 x 1 | 10,25 |

| 6 | M10 x 1.25 | 10,4 |

| 7 | M10 x 1.5 | 10,5 |

| 8 | M12 x 1.25 | 12,25 |

| 9 | M12 x 1.5 | 12,5 |

| 10 | M12 x 1.75 | 12,5 |

| 11 | M14 x 2 | 14,5 |

| 12 | M14 x 1.5 | 14,5 |

| 13 | M14 x 1.25 (for a candle) | 14,25 |

2.Tap

To repair the spark plug hole, a stepped tap is recommended. It is centered in the old hole with its lead-in part, and immediately cuts a new thread, bypassing the drilling operation.

A stepped tap significantly reduces the risk of damage to the spark plug hole, but it is noticeably more expensive than a regular tap.

To lengthen the tap when repairing a deeply recessed spark plug hole, you can use a regular 10-point twelve-sided socket with the appropriate tool.

3.Spindle (tool for screwing the insert)

The working part of the spindle is similar to the threaded part of a bolt, with a hook at the end.

4.Repair insert

The insert is a diamond-shaped spiral.

At one end there is a leash, behind which the insert is rotated by a spindle. The inserts have different lengths.

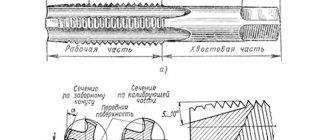

Using a thread tap

The tap is used to cut grooves, due to which the required geometry is formed. The instrument in question consists of two parts and can be classified according to a large number of criteria. The features of the work carried out include the following points:

- The tool is lubricated with oil. Due to this, the process of forming turns is simplified.

- When working three turns along the way, there are 1.5 turns in the opposite direction. This is done in order to remove chips from the cutting zone.

- The tool must be positioned strictly vertical to the surface.

- After the required surface has been formed, a control bolt is used. The first pass may be under a slight load, but after that there should be no problems.

It takes a relatively short amount of time to form turns. In this case, you can get high-quality and reliable threads that will last for a long period.

Repair methods

You can restore a broken thread by drilling a hole to a larger diameter and cutting a new one. This is a fairly effective method. But design features do not always allow drilling a hole. Among the advantages of this method are accessibility and low cost, as well as the absence of the need for any other details. But this will change the size and other characteristics of the thread. Also, by increasing the diameter of the hole, the structure may weaken.

Along with simple drilling, you can install a special threaded bushing. This technology is used when it is not possible to drill a repair hole. The method is quite simple, but it differs in that the characteristics of the thread do not change in any way. But it is not always possible to make a hole of a larger diameter, and the repair sleeve must be securely fixed in the hole.

There is a third, more effective, repair method that does not have significant drawbacks. A thread restorer is used here. These are special kits consisting of threaded inserts or metal-filled chemical products. This restoration method is good because it can be used anywhere, even when repairing a car in the field. There are several modern thread repair products available.

Today, products from brands such as Helicoil and Loctite are especially popular among specialists. There are other manufacturers that make similar thread repair kits. But their efficiency is much lower.

Russian Standards

- GOST 9066. Studs for flange connections…

- GOST 22032. Studs M2 - M48, screwed into holes...

©elesant.ru

More articles

- Basic standards for electrical installation work

- Introductory machine. Calculation, selection of an introductory machine for an apartment

- Built-in, overhead and hanging floor panels

- Charging the diesel generator battery

- Paper insulated cables

- Cable metal tray

- How to choose a stylish floor lamp

- How to properly install electrical wiring in a bathhouse

- How to reduce prices for electrical work

- Distribution panel complete set, circuit breakers, connection terminals

How to restore threads in a hole without a tap

The question of how to restore the thread in a hole without a tap is often asked by people who do not understand threaded connections at all. There is only one answer to this question. It is impossible to restore the thread to obtain maximum reliability without using conventional or special taps. There are only ways to build up damaged surfaces and strengthen the strength of joints to certain levels.

Using Epoxy Glue

This method is not suitable for restoring and strengthening connections subject to high loads and vibrations. There is also no point in using epoxy glue if components and structures operate at high temperatures.

Photo No. 4: epoxy glue for thread restoration

If there is no need to ensure high connection reliability, proceed this way.

Fill the hole with epoxy glue.

Wait until the polymer hardens.

Wait for the depravity to set.

Cold welding

Cold welding can also only be used when working with non-critical parts that are not subject to high loads and vibrations. The connections are more reliable than when using epoxy glue to restore threads.

Most often in our country, two-component formulations of the following brands are used.

Photo No. 5: ABRO cold welding

When using two-component cold welding to repair threads, proceed as follows.

Open the package and remove the components.

Thoroughly degrease the surfaces of the external (on the product intended to be screwed in) and internal (in the hole) threads. To do this, use the composition from the first tube. Handle everything carefully. The presence of deposits and debris will worsen the welding result.

Treat the damaged internal threads with anti-adhesive compound from the second tube.

Mix equal parts of the substances from the first and second tubes. Squeeze the compounds onto a non-metallic surface. For uniform (!) mixing, use a spatula.

Apply the resulting mixture to the product intended for screwing.

Provide the required temperature.

Do not touch the parts for the time specified in the instructions.

Note! Don't skimp on the mixture. When screwing the product in, its excess should come out from the pressure

This will ensure the correct formation of threads when restoring the thread.

Taps are special devices designed for cutting and calibrating internal threads. Below we will look at all the features of these metal-cutting tools. After reading the article, you will receive answers to the following questions.

Need to cut a thread but don't have a wrench handy? Dont be upset. In half an hour, if you have the suitable parts, you can make a tap holder with your own hands. You won't have to waste time going to the store. In this article we will tell you in detail how to make a homemade crank at home.

Even experienced craftsmen sometimes face the need to remove a broken tap from through or blind holes. In this article we will describe ways to solve this problem.

Which tap to choose if the master is faced with the task of drilling holes with internal threads to restore studs, nuts, broken bolts and similar work? We suggest you follow the recommendations - take into account the parameters described below.

Taps and dies, also called taps, are an indispensable thread-cutting tool in modern mechanical engineering. Moreover, they can be used both for cutting threads manually and for forming threads using a machine.

Dies are designed for cutting external threads. The tool is structurally similar to a nut with cutting teeth and holes for fastening in the driver.

A tap is the main tool for cutting internal threads.

Loctite products

This company is also well known for its quality and effective products. But unlike Helicoil, Loctite thread restorer is a completely chemical substance. Everyone knows the thread clamps of this brand.

To solve any problems with threads, the company offers anaerobic compounds. These are one-component liquid materials with varying degrees of viscosity. They are able to remain in their original state for a long time, and also quickly harden in small gaps of connected parts or in threads. In order for liquid thread to begin to polymerize, two conditions must be met. Thus, the presence of metal ions is necessary, as well as minimal contact with air. How to use Loctite thread repair agent? It is enough to apply the composition to one of the surfaces to be joined in such an amount that is sufficient to completely fill the repair gaps of the damaged thread.

Thread restorer after polymerization is a solid thermosetting plastic that has special properties. Thus, it steadily withstands any vibrations and shock loads, the connection has good sealing, and withstands corrosive and other aggressive influences.

These compositions are produced in the form of a stick, which contains a thick paste inside. It is enough to apply the mixture to the unit being repaired and after polymerization the thread will be restored.

Selection of material for thread restoration

As noted above, the market offers a wide range of cold welding materials produced by various companies.

Commercially available grades of material are divided into two main types - liquid and plastic.

- Liquid ones contain a hardener and a base mass that ensures bonding of materials.

- Plastic ones look like plasticine. A single-layer or two-layer bar must be thoroughly kneaded and mixed immediately before use.

Selecting products for restoring internal threads requires a serious approach

It is important to pay attention to the parameters of strength and ductility. Sufficient plasticity will allow the material to be given the most accurate shape, even in the case of the smallest details. Strength guarantees sufficient reliability of the connection of the material with the surface being repaired

Strength guarantees sufficient reliability of the connection of the material with the surface being repaired.

The most popular products currently are those manufactured under the Almaz, ABRO, Hi-Gear and Polymet brands.

Restoring external and internal threads by cold welding - step-by-step instructions

The best option for thread restoration is a two-component material, sold in two separate tubes.

Thread restoration is carried out as follows:

- After unpacking the material, the substance contained in the first tube must be thoroughly cleaned and degreased to restore the thread surface. This procedure should be approached responsibly, since the presence of particles of metal shavings or plaque can affect the quality of the connection;

- treat the surface of the threaded element with an anti-adhesive substance from the second tube;

- squeeze out the same amount of content from both tubes onto a non-metallic surface and mix thoroughly with the spatula supplied;

- apply the resulting mixture to the area of the threaded element to be restored and screw it into a hole of the appropriate diameter;

- After the time specified in the instructions, the part can be unscrewed - if all the technology conditions are met, the thread will be restored.

An important condition for high-quality thread repair is thorough mixing of the cold welding components until a homogeneous consistency is obtained.

The mixture must be applied to the part being repaired in such an amount that when the thread is turned out under pressure, its excess comes out, which ensures optimal formation of the pitch and shape of the threads.

Disadvantages of cold welding

The Cold Weld Rod is not a substitute for the actual standard welding procedure. Therefore, to use the composition, those jobs that it is capable of performing are selected. The disadvantages are as follows:

- Relatively low quality of strength;

- Various metals on workpieces and elements restored by welding;

- Not recommended in areas with an increased area of responsibility;

- Subject to temperature changes and negative environmental changes.

With repair insert

In the case where the above method is not suitable, a repair insert or foot will help out.

The operating procedure is as follows:

- We prepare a footer of the required size.

- Using a tap whose size corresponds to the outer diameter of the insert, we cut a hole for screwing in the fitting.

- After thoroughly cleaning the chips, install the insert and secure it with a retaining ring. As a result, the hole will look like in the photo and will be completely identical to the old one.

If you follow all the details of installing an insert with a double-sided thread, then the reliability of this repair method will be the highest. The only disadvantage of this type of repair is the need to have a lot of inserts of the required diameter and a tap in stock.

How to repair the expansion tank cap yourself and why it is important

There are many reasons for thread damage on aluminum parts.

One careless movement or too much force to tighten becomes the beginning of a new problem. But it can be solved very easily if you know and correctly apply the repair methods used by experienced car enthusiasts and professional car mechanics

Education: secondary specialized. Specialty: car mechanic. Professional diagnostics, repair, maintenance of passenger cars of foreign production 2000-2015. Extensive experience working with Japanese and German cars.

2 comments

- Denis says: I don’t understand why you need to go through the trouble of making a tap out of a bolt when you can take a ready-made tap.

- skivko1 says: This advice will be useful to someone. In Russia we are used to repairing cars ourselves.

Benefits of Helicoil

Hellicol thread repairer is easy to use. The manufacturer offers a wide range of sizes and diameters. The company produces sets with metric or inch threads. With these kits you can repair holes so that their diameter remains the same.

The repair thread is characterized by high wear resistance and mechanical strength. The connection is reliably protected from corrosion, as well as from high temperature exposure. The fit is very secure and the inserts do not require additional fixation. Another significant advantage is the minimal cost of repairs and the ability to restore the connection without the need to remove the part.

How to restore a thread with a tap while maintaining its diameter and location

If you need to restore the thread while maintaining its diameter, use one of the following methods.

Welding the hole and then cutting a new thread

This method is rarely used due to the fact that the strength of the new thread obtained using this technology will be lower. This method is also chosen in the absence of special devices (screws and spiral inserts).

This method of thread restoration includes the following steps.

Removing old threads by drilling.

Welding the hole. The choice of technologies depends on the materials of the parts.

To weld holes in steel products, electric arc or gas welding is used in protective environments.

When working with cast iron parts, gas or electric arc welding is used in a cold state or with general/local heating.

Electrodes (MNCh-1, OZCh-1, TsCh-1), cast iron rods with a high silicon content and other materials are used as additives.

Machining the hole flush with the base metal.

Cutting a new thread.

Note! When working with aluminum products, this method of thread restoration is usually not used. This is due to the fact that the metal actively absorbs gases during welding.

Pores form in the deposited layers. With severe shrinkage, cracks appear.

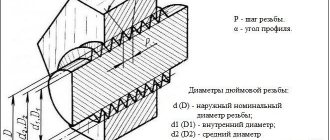

Restoring threads using a screwdriver

Screwdrivers are special cylindrical devices that have threads of the required diameter and pitch on the inside and large threads on the outside. Such products are made from steel, brass, bronze, copper and other materials. At the final stages of production, the screws are hardened and further strengthened.

Photo No. 2: screwdriver for thread restoration

If you need to restore the thread while maintaining the diameter using a screwdriver, proceed as follows.

Drill out the hole. The drill must be selected in such a way that the diameter of the resulting hole allows cutting a thread for screwing in the screw.

Cut the thread with a tap. Follow the rules listed above.

Screw in the screwdriver. It needs to be installed flush. If this is not possible, mill the part and remove the protruding part of the fixture.

At the border of the new thread and the screw, apply notches using a core. This will prevent the device from unscrewing spontaneously.

Repairing threads using a spiral insert

Spiral (also called wire and spring) inserts are also often used to restore damaged threads.

Photo No. 3: spiral inserts for thread restoration

These devices have high-precision rhombic threaded profiles on the inside. Almost all models are equipped with special driving tongues designed for screwing in devices.

For the manufacture of such products, especially durable high-quality stainless steel is used. This guarantees the resistance of the restored thread to deformation and corrosion.

Restoring threads using a spiral insert includes 4 stages.

Drilling. Drill out the hole. Select the diameter of the cutting tool according to the table that manufacturers provide with spiral inserts.

Image #1: Drilling the hole for the spiral insert

Thread Forming

Note! To cut threads, use special taps that differ from standard ones and come with spiral inserts. Follow all rules and recommendations

Image #2: Forming a thread for a spiral insert

Installation of the device. Place the spiral insert onto the supplied special tool and screw it into the hole.

Image #3: screwing the spiral insert into the hole

Removing the drive tongue. You can get rid of it using a special tool (manufacturers also supply it). To remove tabs from large-diameter inserts, ordinary pliers are suitable.

Using professional spiral thread inserts has the following advantages.

The required tension is ensured at the insert landing site. This completely prevents twisting. The devices are located in the receiving threads with virtually no gaps. There is no need to use glue for additional fixation of products.

Due to the elasticity of the inserts, loads and stresses are distributed evenly. This creates ideal conditions for the transfer of forces between the bolts and the receiving threads.

Spiral inserts are universal. They are used not only to restore threads, but also when it is necessary to strengthen connections. Spiral inserts are used when working with products made of low-medium and high-strength metals, as well as plastic and wood.

Glue composition

The components included in the adhesive mass are aimed at creating a homogeneous mixture. Plastic properties are created by epoxy resin. It improves the composition and makes it softer and more comfortable to use. To obtain a single solid component with metal, metallic substances are added. During the process of filling and repairing the chip, the polymer welding mass fills the parts that have received a defect.

The quality of the welding mass requires unique properties. They make cold welding common and attractive to consumers with different professional and construction needs. The seam obtained by cold welding will be inferior in some characteristics to the standard method, but will provide advantages in terms of speed of work, conditions and simplicity of the procedure.