Metal is the material that the angle grinder (angle grinder) was originally designed to work with. Now it is used to cut reinforcing bars, various metal sheets, pipes of various diameters, brick, concrete, stone, tiles and other building materials. Thanks to the presence of a variety of attachments, the grinder also allows you to polish and grind the surfaces of products. Cutting metal with a grinder is one of the main, most common jobs. To reduce the likelihood of injury, it must be performed correctly, with strict adherence to general and personal safety requirements.

Preparing to use a grinder for metal

The grinder belongs to the category of relatively dangerous power tools. You can get injured from a flying disc or a tool falling out of your hands. In both cases, the danger is associated with the high speed of rotation of the device's electric motor.

To increase the efficiency of the grinder and expand its functionality, the following additional devices are used in practice:

- tripods;

- retainers.

Their use makes it possible to improve the quality of sawing metal workpieces and increase the accuracy of the process. Working conditions also improve in terms of safety, and productivity increases.

The use of additional accessories allows you to use the tool as a machine designed to perform different types of work.

To make the cutting process as safe as possible, working on metal with an angle grinder should follow a number of rules. They are conventionally divided into preparatory and main (working) activities.

Before cutting begins, a number of manipulations must be carried out.

- Wear special work clothes and shoes (with anti-slip soles), gloves made of thick fabric or leather.

- Prepare a suitable disk based on the characteristics and type of metal being cut, and then install it with the markings facing the top, tightening it with a nut.

- Check the working attachments used for the presence of various defects that impair their integrity: potholes, cracks and other deformations.

- Use personal protective equipment: goggles, a respirator or mask (shield), and in some cases also headphones.

- Check the functionality of the tool, the reliability of its casing (working without it is strictly prohibited), and the condition of the power cord and plug.

- Prepare the workplace: remove flammable materials (lubricant, fuel, paper, rags) and all interfering things. Cover or move to a safe distance objects that could be damaged by hot metal particles.

If possible, the material to be sawn should first be securely fixed, for example, in a vice, in order to eliminate possible accidental movements. Holding workpieces in your hands or between your knees is prohibited.

Complex shaped cuts

When working with plastic, it is often necessary to make curved cuts.

With thin sheets, you can use a mounting knife, but if the thickness of the polymer exceeds 10 mm, then it is better to use an electric jigsaw. Manufacturers produce saw blades designed specifically for working with acrylic or polycarbonate, having a special tooth shape and a non-standard angle. When working with plastic with a thickness of more than 20 mm, it is permissible to use saw blades for wood with the finest teeth. In this case, you need to set the minimum number of engine revolutions, otherwise the material will begin to melt when cutting. No matter how hard you try, you most likely will not be able to get a perfect edge at the cut site. Therefore, after completing the work, it is necessary to sand the ends with sandpaper or a sanding block. Experts recommend using coarse abrasives at the beginning of grinding, gradually moving to finer ones. If you show maximum care and patience, the edge at the cut site will be perfectly smooth and will not cause any trouble even with precise joining of the elements.

Separately, it is necessary to mention safety precautions when performing such work. Cutting plastic should be done on a stable workbench or table with a working tool. It is also necessary to take care to protect your eyes with glasses, since some types of polymers, when cutting, can form fragments that fly over a considerable distance.

Useful tips

Correct use of the tool

When you start sawing any part using an angle grinder, you should adhere to these rules.

- When cutting metal, you need to hold the grinder firmly, with both hands.

- The wheels can be changed only after they have completely stopped rotating and cooled down to an acceptable temperature, disconnecting the power tool from the power supply.

- Do not place the working tool on the ground or table (do not let it out of your hands).

- It is required to periodically stop for about 5 minutes to rest and allow the disk to cool.

- It is necessary to constantly monitor the condition of the cutting wheel, preventing it from being pinched by the edges of the workpiece being cut.

- Do not leave the tool plugged in unattended.

- Use only discs of the correct size as specified in the operating instructions for the device you are using.

- It is better to do the work on a flat surface so that the body position is stable.

- Make sure that the power cord is kept away from the rotating circle, sharp edges, and objects heated above 100 degrees.

- Movements not directly related to cutting must be performed only with the power tool turned off.

- You need to position yourself on the side or behind the tool, doing the work with your own hands so that parts of the body are not in the cutting plane.

When cutting metal with a grinder is finished, you should wait until the disk stops completely and disconnect the power cord of the tool from the mains. Afterwards, it is recommended to ensure that there are no signs of fire. When cutting materials, a right-handed person should correctly hold the handle of the device in the area of the on/off button with his right hand. The left hand is placed on the handle screwed into the body of the power tool from above.

It is unacceptable to perform work using an angle grinder in a very tired state, or while under the influence of alcohol, psychotropic or narcotic drugs.

As for the question of which direction—toward or away from you—the disk of a switched-on angle grinder should rotate, there is no definite answer. The operating instructions indicate that the first option is correct. This is due to the fact that the resulting sparks fly away in the direction opposite to the operator, without causing harm. Also, fragments of the circle will fly in that direction if it breaks into pieces.

But if the rotating disk jams towards itself, the tool will fly off towards the worker. For this reason, many specialists prefer to cut metal so that the circle rotates “from itself”. A power tool torn out of your hands will fly in the opposite direction. This reduces the likelihood of injury, and clothing, shoes and gloves will protect the user from flying sparks.

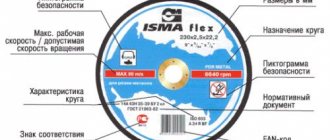

Disc selection

The diameter, thickness and type of disks are selected depending on the planned type of work. Diameters vary from 125 mm (small) to 250 mm (large, the most common) and affect the size (thickness and depth) of the cut.

A grinder for cutting metals requires a cutting disc with a thickness of 1.0-1.2 mm (professional ones reach 2.5 mm). Curly carving on thin metal requires the use of a disk with a small diameter or one that has already been used.

When cutting using discs of any diameter, it is necessary to use a protective coating - a casing. Essentially, this is a shield needed to catch small metal scraps generated during the cutting process.

Options for cutting and cleaning discs for grindersSource prom.st

Cutting sheet metal with a grinder

To cut metal of different types and thicknesses, use appropriate cutting wheels of various thicknesses and diameters. The algorithm for sawing sheets is as follows.

- To cut using a grinder, sheet metal is first laid on a flat surface.

- Mark with chalk (marker) the exact dimensions of the cut out fragments on the surface of the sheet.

- Sawing is carried out along the marked lines, without changing the angle of the initial inclination of the disk to the working surface, so that it does not jam and break the power tool.

If you don’t have the skills to saw sheet metal with a grinder, it is recommended to first practice on soft material - this will give you the opportunity to get a feel for how the tool works.

It is necessary to take into account that the lower proximal segment of the disc cuts metal more effectively.

When cutting a sheet of metal, the following recommendations should be taken into account to obtain a high-quality result.

- To improve cooling, it is necessary to water the sawing area with water, which will also increase the life of the wheel.

- You should start cutting metal only when the disk is rotating: you cannot turn on the tool if the stationary circle is in contact with the surface of the workpiece.

- To saw tin (thin sheet metal) or cut out various geometric shapes, it is more convenient to use small, machined circles (“bits”).

- You should not press the angle grinder with significant force: cutting should take place almost exclusively under the angle grinder’s own weight.

- If the cutting wheel stops in the slot (when the power tool is turned off), then work can be resumed only after it is removed.

If sawing the sheet occurs slowly, you should change the working attachment. Excessive load on the angle grinder when cutting metal will lead to overheating or jamming of the rotating wheel.

Types of devices

Adaptations for an angle grinder differ in the functions they can perform:

- smooth cutting;

- grinding;

- cutting rods and pipes (diameter within 50-125 mm);

- cleaning and peeling of obsolete layers of surfaces;

- polishing;

- use as a chain saw;

- collecting dust during the process.

The most popular among devices for high-quality cutting of pipes with an angle grinder are cutting discs. This type of product is produced by numerous domestic and foreign developers. Separately, it is worth noting the universal Japanese nozzles of the Hitachi brand.

Japanese Hitachi brand nozzlesCutting a round hole in metal using an angle grinder

In practice, it is often necessary to cut a circle in metal, and the only tool available is an angle grinder. But it is quite enough for this purpose. The algorithm of actions is as follows.

- Draw a circle with a compass on the surface of the metal or on a pre-made paper (cardboard) template with chalk or a marker.

- Holding the grinder at an angle to the surface of the sheet, make a preliminary marking cut of the metal along the marked contour, making short movements with the disk (sawing in small sections).

- Then, moving the nozzle in the same way, deepen the slot until it is completely cut out.

You need to cut along the outer contour of the circle so as not to reduce the size of the circle. If its diameter is small, then they cut by touching the metal with a disk point by point (without longitudinal movement of the nozzle). The round hole will have an oblique cut, as well as some minor flaws (they depend on the skill of the worker). Afterwards it is processed, if necessary.

The entire process of cutting a round hole in sheet metal using a special tool is shown in the video:

How to saw without dust

Any dust is harmful to human health. During renovation or construction, it settles everywhere. Cleaning it up afterwards takes a long time and is quite difficult. But the main thing is that it cannot be removed from the body. In order to work without dust, you need to make a small and inexpensive device for an angle grinder.

This device is very similar to a medical IV. We insert a dropper tube into a regular plastic bottle with a volume of 1.5 - 2.0 liters. We leave only the regulator on it. In the protective casing of the angle grinder we make a hole along the diameter of this tube. We insert another similar tube into this hole.

We connect these two tubes, pour water into the bottle and open its supply to the circle. After the first rough cut, we adjust the water supply, which should extinguish all the dust released during cutting.

With such a device you can process concrete, brick and many other materials that, when destroyed, emit a large amount of dust.

Features of working with thick metal, copper, cast iron, aluminum

When it is necessary to cut thick metal into separate fragments, it is recommended to additionally perform the following steps:

- constantly cool the area of contact between the metal and the disk using cold water due to the strong heating of the slot;

- make all cuts only in a straight line;

- different curved contours should be cut out in separate straight sections of short length, removing unnecessary parts;

- You need to completely cut the workpiece in several approaches, deepening the slot with each subsequent one;

- if you need to cut corners, I-beams, channels, rails, then each of their structural parts is sawed separately.

Cutting cast iron, stainless steel, as well as non-ferrous metals, such as aluminum and copper, is carried out using special wheels designed for working with these materials. All necessary information about the discs is contained in the markings of these products, printed on their sides. In this case, the circles differ in the composition of the fillers:

- in some, the additive is a super-strong material that can cut alloy steel;

- others use mild binders.

Cutting stainless steel with conventional metal cutting discs is prohibited, because they contain substances that lead to accelerated corrosion of the cut site . Aluminum and copper are very viscous non-ferrous metals. They are sawed using a grinder, pouring kerosene over the slot formed by the disc. In this case, it is necessary to comply with fire safety rules.

Jigsaw

To obtain a shaped cut on corrugated sheeting, which cannot be made with a hacksaw, use a jigsaw. Hand tools are used for a small amount of work, and cutting a large amount of material is performed using a power tool. Cutting with a jigsaw is faster than with scissors or a hacksaw, but slower than with a grinder. This tool has disadvantages:

- It is not suitable for all brands of corrugated sheets. Using a jigsaw, you can cut the material if the wave height is 25 mm or more.

- A jigsaw is not suitable for making long longitudinal cuts; the work takes a long time and is inconvenient.

Cutting corrugated sheets with an electric jigsaw

Many inexperienced craftsmen wonder how to cut corrugated sheets so as not to be afraid of damaging the material. Roofing made from profiled sheets, as a rule, has a thin polymer coating that can be damaged even by minor abrasive effects or high temperatures. To reduce the negative effect of cutting, you need to treat the edges with a primer, mastic or paint.

Recommendations for cutting metal pipes

Cutting pipes from different metals is a popular operation when carrying out repair and construction work. Products have to be cut off when installing sewer and heating systems and water lines. In this regard, the grinder copes well with various tasks. Discs for work are selected according to the material from which the pipe is made.

Using an angle grinder makes it possible to:

- sawing pipes at different angles, for example 45 and 90 degrees;

- cut large diameter products;

- cut profile (rectangular or square) pipes smoothly;

- perform longitudinal cutting of tubular blanks;

- sawing cast iron pipes;

- cut thin-walled tubes.

If you need to cut a large diameter pipe, then using a grinder allows you to complete this work without significant financial costs. But at the same time, labor productivity is low, and the risks are considerable. When long pipes lie on supports, only the hanging parts are sawed off. If you cut in the center, the cutting edges will jam the cutting wheel, which will lead to jamming of the tool and possible injury.

Specialists not only cut pipes from different materials at the required angles, but also cut holes of the required shapes in them. Work with profile and round workpieces is carried out in a similar way, with mandatory observance of safety regulations.

Sawing pipes at different angles

It is necessary to cut round and profile pipes at an angle of 45 and 90 degrees when laying various communications. In any case, it is necessary to saw off the pipe evenly so that the elements that need to be connected are connected to each other as tightly as possible.

A cut at an angle of 45 degrees for cylindrical pipes is carried out as follows:

- take an ordinary square sheet of paper;

- fold it exactly diagonally;

- This template is used to wrap the pipe;

- use chalk or other marking device to mark the future cutting line;

- remove the template;

- clamp the workpiece in a vice;

- cut off the marked piece of pipe.

When applying the template, either of the two short sides of this triangle should be parallel to the central axis of the pipe.

When it is necessary to cut at an angle of 90 degrees, the pipes are simply wrapped in a circle (cylindrical) or around the perimeter (profile) with a sheet of paper. After this, mark the cutting line. You can also mark a profile pipe very simply using a regular square.

If it is necessary to cut a significant number of profile pipes at an angle of 45 and 90 degrees, appropriate templates are made from this material, only with a larger cross-section. This allows you to perform the required measurements only once. In this case, a construction square or a protractor is used for initial marking. When the template is made, the cut pieces are inserted inside it, marking the cut lines. Then sawing is done.

Templates are also made for other angle values. This method increases labor efficiency.

Features of cutting cast iron and thin-walled pipes

Cast iron is a brittle material. To cut a cast iron pipe with a grinder, proceed in the following sequence:

- mark the cutting line;

- place a wooden block under the pipe, which will serve as a support for it;

- make a cut along the contour several millimeters deep;

- insert a chisel into the recess made;

- the instruction is hit hard and sharply with a hammer.

After the impact, the pipe will split along the cut line. Its edges will be quite smooth. If necessary, they are further processed.

To perform longitudinal sawing of a pipe, accurate marking is also important. To apply it, various devices are used, for example, construction thread (“beat”). The entire sawing process should be carried out carefully, slowly, so as not to stray from the marked line.

Thin-walled pipes are one of the varieties of this type of product. They are often made of non-ferrous metals: copper or aluminum. Cutting them is a difficult task. In this case, you should use grinder wheels that match the material of the workpiece.

Sawing thin-walled tubes must be done very carefully, because they can easily become deformed even when a slight load is applied.

To reduce the likelihood of bending of the cut part, various bulk fillers are poured inside it, for example, ordinary purified sand.

How to cut tiles and porcelain stoneware with a grinder without chipping

To avoid chipping when cutting tiles, it must be moistened with water. This will promptly reduce the temperature, which causes destruction. In this way, you can not only cut the tiles, but also cut out the necessary fragments. Another method is to use a stone cutting wheel. This circle does not crack or chip.

The situation with porcelain stoneware is a little more complicated. Porcelain tiles are somewhat thicker than regular tiles and are stronger. A manual tile cutter becomes dull very quickly without achieving results. Therefore, you can cut porcelain stoneware around the stone.

We make a contour cut along the drawn cutting line. Then another, a third. Until the uncut thickness of the material is less than the cut thickness. We move the porcelain tile to the edge of the table and break it with a sharp, but not very strong movement.

How to cut metal: a circular saw or a reciprocating saw

Tools from this category are divided into 2 subgroups:

- Reciprocating saws - act in the same way as jigsaws; their main element is a replaceable blade of 100–350 mm, which performs reciprocating movements during operation (it should be narrower, the smaller the radius of the workpiece). They are powered either from a centralized network or from a battery, and this is their plus and minus at the same time. They are portable, but you have to use electricity to use them, which is an additional expense. To cope with any of them requires skill and a good eye.

- Disc ones are easier to operate, and this is a powerful argument when you decide what is better for sawing metal. Their cutting elements are made of hard alloys, which means they are durable. Another advantage is the minimum amount of chips and the ability to make even narrow grooves. The wider the diameter of the circle, the greater the versatility. True, they are relatively expensive, have impressive dimensions and are heavy, this is a drawback.

Cutting pipes at right angles

The technology for cutting at right angles is quite simple. You just need to fix the metal part, mark the cut line, and directly cut the workpiece. The end of the cut part of the pipe should be above the support.

To mark the cut, use wide or narrow tape, a marker or a simple pencil. You just need to wrap the product, mark the cut location, and make an even cut. When winding, both ends of the tape must fit together accurately

Final part

You should not think that a grinder with a cutting disc is a tool used exclusively for dismantling metal structures and does not require careful operation. Quite the contrary. An angle grinder requires extreme concentration and accuracy in work. This is a rather traumatic tool, and therefore, when working with it, you should not forget not only about the correct markings, but also about safety requirements.

Only accurate calculation and cutting will allow the pipes to be perfectly aligned at an angle Sources

- https://instanko.ru/osnastka/kak-pravilno-rezat-bolgarkoj.html

- https://instrument-blog.ru/elektroinstrumenty/kak-rezat-bolgarkoj.html

- https://trubaspec.com/montazh-i-remont/kak-rovno-otrezat-trubu-instrumenty-i-sposoby-otrezaniya.html

- https://rezhemmetall.ru/sposoby-razmetki-i-rezki-metallicheskix-trub.html

- https://WikiMetall.ru/metalloobrabotka/kak-rovno-otrezat-trubu.html

- https://alsver.ru/rezka/metalla-bolgarkoy

- https://HouseChief.ru/kak-rovno-otrezat-trubu-bolgarkoj.html

[collapse]

Similar posts:

- How to work with an angle grinder correctly: step-by-step instructions

- Why is an angle grinder called an angle grinder, and what else is it called?

- FBS GOST blocks: foundation blocks 13579 78

- How to cut a plastic window sill evenly

- The thickness of the brick wall (with and without insulation),…

- How to cut a round pipe lengthwise into exactly 2 parts using a grinder

Thermal methods

An oxygen flame heated to a very high temperature, a stream of electrically charged gas, or even a jet of plasma - this is what can be used to cut iron, steel or any other metal. There are several methods, each with its own characteristics, but they all have certain advantages:

- The thickness of the workpiece does not play a special role - the passage will be almost instantaneous.

- Any material can be used, even very hard ones, and alloys are no exception.

- The technologies are highly scalable – both for small-scale and large-scale production.

It is in this area that experiments and research are being carried out today. If mechanical methods are considered a classic of manual labor, then thermal methods are promising from the point of view of automating the processes of producing parts. Therefore, let’s take a closer look at their varieties.

Gas cutting

In this case, the flame is brought to a high temperature without the use of electricity. There are three options for a medium that acts as an instrument:

- Pure oxygen - separation is carried out due to the influence of its heated jet.

- With the addition of flux - a powder that immediately has a triple effect: chemical, abrasive and thermal. Essentially, it is a catalyst that speeds up the process and produces a cleaner weld.

- Using a “spear” - a special tube that burns when working gas is blown through it; This minimizes the amount of scale.

The advantage of the method is its relatively low cost. And this is also a simple answer to the question of how to cut thick metal, but the method also has a lot of disadvantages. Among its disadvantages:

- significant consumption of material;

- low degree of accuracy;

- the need for subsequent cleaning of the edges;

- deformation of contact surfaces;

- general slowness of the process.

It is not surprising that experts sought to find a more advanced solution. Let's look at the results of their research right now.

Gas-electric technology

Here, current is already used - it heats the jet, which melts the material and carries away waste particles with its flow. One of two media options is used:

- compressed air is what is used to cut thick metal in most cases; and it also blows out the residues from the melting zone, which is convenient;

- oxygen - enters gradually but steadily, forms a stable arc that separates part of the workpiece from the whole and at the same time removes oxides.

Most often, this method is used when it is necessary to eliminate defects after welding. True, when the electrodes burn, the surface is often excessively saturated with carbon and it is necessary to additionally remove it, otherwise it will negatively affect the subsequent service life of the part. Noticing this phenomenon, experts tried to find an even more perfect solution, and achieved success.

Plasma technology

Ionized gas is the tool used to cut metal today (if we are not talking about hand tools).

It is heated to the state of a liquid and viscous stream, with the help of which the material is melted. Thus, it is not difficult to make an object of any shape, even curly or complex, with high precision and quickly. The benefits are as follows:

- Processing is carried out quickly, which allows you to achieve good labor productivity.

- Universal application - suitable for both hard cast iron and soft aluminum.

- Excellent quality of the final seams - no stripping or sanding required.

- Environmental friendliness and overall safety of operations.

Yes, tools are used for manual cutting of metal, and plasma is only applicable in production. Yes, it has certain disadvantages, but in the workshop, with regular and, especially, large-scale production, their influence is minimized. It is no coincidence that it is considered the most promising.

There are other methods, less common, but also interesting and worthy of attention.

Waterjet technology

Water saturated with solid particles (usually fine sand) is supplied to the line of the intended edge under pressure and a thin stream. Due to targeted action, this liquid separates the required part from the whole workpiece.

It has been successfully used since the mid-60s - it shows how you can cut sheet and thick metal, which is even more important. Over the past half century, the method has been improved to the limit, although in terms of accuracy and speed of obtaining results it is still somewhat inferior to advanced hot methods.

Guillotine

The material is placed between two knives, one of which is fixed to the frame at a certain angle, and the second is movable: it falls on the first and, due to the impact, separates the desired strip, segment, section from the part. Accuracy of fixation is ensured by the clamping system, as well as the back stop. To prevent the blades from hitting each other (which can lead to dullness and premature wear), there is a gap between them, but it should not be more than 3 degrees, otherwise the final edge risks becoming cone-shaped or wrinkled.

Among other disadvantages it is worth noting:

- bends;

- twisting;

- saber-shaped

But if the sheet is 3–5 mm, these defects can be avoided.

How is injection cutting of thick metal performed?

It is carried out with a special burner, the power of which is selected based on the thickness of the material:

- at 5–100 mm it is small;

- at 8–200 – average;

- at 10–300 – high.

The mouthpiece is subjected to the greatest temperature loads, therefore, according to GOST 5191–79E, it must be made of bronze, be replaceable, multi-nozzle and of a suitable size (from zero to six); There are non-separable and composite varieties.

Another similar option

You can do it differently. First, the same work is done as in the previous version - a strip is drawn, a corner is laid and pressed. But here the groove is made somewhat deeper - 4-5 mm. After the corner is removed, the remaining metal can simply be broken off, and the edge can be processed using an angle grinder with a grinding disc. However, there may be small pits on the edge, which makes the second option more acceptable.

The groove along the guide angle is made a little deeper than in the previous version