When it becomes necessary to drill holes in concrete or stone, you will need to use a special tool. For such purposes, not only drills, but also hammer drills are produced. These are completely different devices that have external signs of similarity. What is better to choose - an impact drill or a hammer drill for drilling concrete, and what differences do these tools have? These issues need to be examined in more detail.

Impact drill and hammer drill - what are these tools for?

To find out what the difference is between an impact drill and a hammer drill, you need to find out their functional purpose. Let's look at each tool separately:

- An impact drill or hammer is a popular type of electric tool that almost every craftsman has. It can be used to drill holes not only in metal and wood, but also in concrete. To drill through durable concrete, the device must be in the hammer drilling mode, otherwise the drill will not penetrate deep into the material. If the tool does not have an impact mode, then it is not intended for drilling concrete, brick and stone

- A rotary hammer or drill hammer is a professional type of tool that is designed directly for carrying out slotting and drilling work on concrete. Pistol-type devices have a mode switch, among which there is a drilling function. Enabling this mode allows you to use the tool to drill holes in metal and wood. However, the main purpose of the tool is to work with high-strength materials such as concrete, stone, brick, etc.

When a master drills a hole in concrete with an impact drill, he needs to apply pressure to the tool. Moreover, the amount of effort directly affects the speed of obtaining results. Unlike an impact drill, a hammer drill does not need to apply pressure, so the master can only guide the tool and hold it.

This is interesting!

If a hammer drill is a tool for processing concrete and brick, then a drill is more intended for working with metal and wood. Only often in everyday life does it become necessary to drill a hole in a concrete or brick wall. In order not to buy a separate tool for this, manufacturers have equipped electric rotators with an impact drilling function. Thanks to this mode, you can quickly and efficiently drill a hole in the wall for a dowel.

What is a hammer drill used for?

This tool is used to break any materials. It is often used by both cool “pros” who have been involved in construction and repair on an ongoing basis for many years, as well as home craftsmen.

Using a hammer drill you can:

- drill a hole in concrete, brick, blocks

- remove plaster;

- knock down a tile;

- break off bricks;

- make grooves on concrete walls.

Without this tool you can’t do any repairs or build a house. It’s convenient to work with – it’s fast and has almost no recoil.

The device attachments can be:

- borax;

- chisels;

- core drills;

- peaks.

As for the equipment, it can have the tail part of two systems. This is either SDS Max or SDS Plus.

The SDS Plus system is distinguished by the presence of four oval grooves for fastening. Two of them are at the end and are open, the other two are hidden. When the shank is inserted into the chuck, it moves along open slots like guides. Special locking balls secure it in closed holes.

Drills with SDS Plus shanks.

The SDS Max system has not four, but five mounting recesses. Now there are three open grooves, so the drill holds more firmly. This system is most often used in professional instruments.

The chisel attachment is placed on the hammer drill when something needs to be dismantled. The lance attachment is used for scoring walls before laying wires or for making holes in the wall. The crown bit will help you make a large through hole.

What are the differences between an impact drill and a hammer drill - let's look at them in parts

If the distinguishing feature of the purpose of rotary hammers and impact drills is insufficient information, then it is necessary to analyze these tools by disassembling them into their component elements. Knowing the differences in design will be useful in order to choose the most suitable tool for the relevant work.

The instruments under consideration differ in the following structural elements:

- Impact mechanism

- Operating modes

- Tool weight

- Equipment

- Performance

- Price

Let's take a closer look at impact drills and rotary hammers based on the above-mentioned structural elements, and find out when it is better to use the first version of the tool, and when the second.

What is the difference between an impact drill and a hammerless drill?

- Before we move on to the differences between an impact drill and a hammer drill, let’s look at the differences between an impact drill and a hammerless drill:

- Scope of application. An impact drill is more versatile; it can work with a larger number of materials.

- Accuracy. An impact drill can process more materials, but due to the presence of a push, it has lower accuracy. Therefore, when working with soft materials, switch to the simple drilling mode.

Impact drill device

In order to drill a hole not only in wood and metal, but also in brick and concrete, in addition to rotational movements, translational impact is required. Impact is designed to crumble the material, while drilling brings the crumbs out and helps the drill bit into the material.

That is, for effective drilling of hard materials it is necessary that rotational and impact movements occur simultaneously.

Impact drills consist of several main components: tool body, electric motor, gearbox, bearings, power buttons and speed control, chuck.

The rotation of the drill is provided by an electric motor, which transmits rotation to the chuck through a spindle and gearbox. When the impact function is turned on, two ratchets are connected inside the drill body, which, when rotated, repel each other, thereby creating an impact mode.

This impact system is called mechanical. And since ratchets are subject to high friction when rotating, they gradually wear out. With active use of the shock mode, this process will accelerate many times and eventually the shock function will come to naught.

The main function of an impact drill is still drilling, therefore the control mechanism of the impact drill is provided with a rotation speed regulator. This switch is very important for efficient work with different materials and consumables.

For example, for drilling bricks, it is recommended to set the regulator to a large number of revolutions; for drilling tiles, on the contrary, to a small number. The same analogy can be made using different nozzles.

Pobedit drills for concrete are best used at high speeds, core drills for wood – at low speeds. One of the most important design features of a drill is also the type of chuck installed.

Most manufacturers simultaneously produce tools with two types of chucks - key (cam) and keyless (quick-clamp). Their main difference is that to clamp the key chuck you must use a special clamping key.

While to clamp the quick-release chuck, it is enough to tighten it by hand. Both one and the other system have their advantages and disadvantages. A quick-release chuck will allow the operator to quickly change working attachments, while a key chuck will allow these attachments to be secured much more securely.

Reverse is also a very important system for the effective operation of an impact drill. By switching this mode, the operator forces the tool to rotate the working attachments in the opposite direction. This function is extremely necessary when the working attachment gets stuck in the material.

In order not to damage the hole when tearing the drill out of it, it is quite enough to turn it in the opposite direction. In addition, the reverse function is perfect for those cases when the operator will use the drill as a screwdriver. It will help not only tighten threaded fasteners, but also unscrew them.

Differences in the design of the impact mechanism

The main difference between an impact drill and a hammer drill is hidden inside. More precisely, the design of these instruments uses completely different types of impact mechanisms. Moreover, the mechanisms differ not only in appearance, but also in the force of impact.

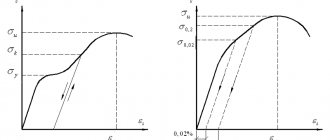

- On the hammer drill, the impact mechanism is implemented through electro-pneumatic and mechanical units. Moreover, the design of the impact mechanism on direct and barrel type devices is different. Direct type devices use a driven bearing that drives the piston. A piston moving in a sealed chamber uses the energy of compressed air to act on the firing pin, thereby moving it. The striker, under the influence of compressed air energy, acts on the back of the drill fixed in the device chuck. On barrel perforators, instead of a driven bearing, a gear is used, to which a rod connected to a piston is attached. The gear and bearing are driven by an electric motor. The impact mechanisms of rotary hammers are reliable, and due to such a complex design, they are capable of developing an impact force from 2 to 20 Joules

- Impact drills have a simplified design of the impact mechanism. It is implemented through the use of two ratcheting devices that are connected to the shaft and chuck of the tool. The shock mode occurs due to the fact that the bushings jump over each other, creating corresponding clicks. This type of mechanism is also called a ratchet mechanism. Screwdriver force regulators have a similar device. The maximum impact force of such devices does not exceed 2-3 Joules

Based on the above, it should be noted that you can drill a hole in concrete with a hammer drill very quickly. The drill will also cope with this task, but with a slight delay. Moreover, the delay time directly depends on factors such as the type of material, thickness, depth of the hole being drilled, as well as power. If you need to drill a hole with a diameter of more than 10 mm in concrete, then it is better to use a hammer drill for this purpose.

This is interesting!

You can drill a 10 mm hole in concrete with a drill, but the life of the impact mechanism will be significantly reduced with each opening.

Perforator device

There are controls on the body of the instrument, as can be seen in the following photo:

The internal structure of a rotary hammer cannot be understood without disassembling it.

- The following main components are hidden in the plastic case:

- electric motor;

- safety clutch;

- “drunk” bearing;

- flying piston;

- cartridge.

The principle of operation of a hammer drill is to convert the rotation of an electric motor into the shock-rotational movement of the nozzles. The electric motor drives the rest of the hammer drill mechanism.

The safety clutch ensures the safety of specialists during work. The driven bearing drives the piston, creating an impact force, and the cartridge ensures clamping of the attachments.

Principle of operation

In a hammer drill, the impact occurs due to the reciprocating movements of the first piston in the cylinder. Air compression is created between the pistons. The energy of the air sets in motion a second piston-impactor or hammer, which strikes another intermediate impactor of a smaller diameter or striker, which strikes the end of the drill. The return of the hammer occurs due to the rarefaction of air between the two pistons during the reverse stroke of the first piston. This principle of impact has become most widespread in jackhammers.

Sds plus sds max difference

Despite such a variety of convenient and practical SDS shanks, the following are common in construction: the SDS Plus holder and drill for simple household tasks and its “brother” the SDS Max chuck and drill for heavy professional work.

The unique technology of design and fastening of drills in tools makes them indispensable in our time: the SDS system has proven itself as a reliable innovation that extends the service life of the working tool and allows you to make maximum use of the functional and power capabilities of the tool without loss.

And the modern design of drills makes them convenient and practical for working with household and professional impact tools. The SDS Plus concrete drill is used with lightweight household hammer drills: 2-4 kg, they are used in home and industrial settings to drill holes in solid materials up to 26 mm deep.

The structure of the SDS+ shank is easy to remember: there are four grooves on the profile: 2 open and the same number of closing ones. The open ones serve as guides for entering the cartridge (40 mm deep). Locking balls fit into the closed grooves, securing the drill in the tool.

Drills are available in commonly used diameters – 6mm, 8mm, 10mm, 12mm.

Breakthrough drills SDS Max are visually different. The diameter of the SDS Max drill is twice as large as the SDS+ - from 20 mm, and is used as the working part of heavy hammer drills in construction and when dismantling surfaces.

Such drills are relevant for gating walls, ceilings, concrete, foundations, asphalt and other hard surfaces.

The design of the SDS max is a little complicated: the length of the drill allows it to be inserted into a hammer drill to a depth of 90 mm, and the fivefold number of grooves (of which 3 are open and guide, and 2 are closed and retaining) ensures reliable retention and free movement of the drill.

To work with such an SDS Max concrete drill, special SDS Max hammer drills are required.

- Models that are especially in demand among professionals are produced by the following brands:

- Hilti;

- Bosch Professional;

- DeWalt;

- Sparky Professional.

What operating modes are present on the instruments?

The differentiating feature between an impact hammer and a hammer drill lies in the functionality of these tools. The design of hammer drills has three operating modes, due to which it is possible to process not only concrete. These modes have the following names and purposes:

- Drilling - the regulator must be turned towards the drill image. When this mode is enabled, the tool will operate in drilling mode. When this mode is turned on, the impact mechanism is turned off, and rotational energy from the electric motor shaft is supplied to the cartridge through a gear mechanism. In this mode, you can not only drill metal or wood, but also mix various building mixtures

- Rotation with impacts - the adjuster must be set towards the designation of the drill with a hammer. In this mode, the tool drills concrete, brick, reinforced concrete and stone materials. To implement these actions, you need to install a drill in the tool chuck

- Drilling - the control switches to the hammer designation. In this mode, the hammer drill is a jackhammer that can be used to remove tiles, drill concrete, brick, etc.

Unlike rotary hammers, percussion instruments have two operating modes. This is three times the difference between an impact drill and a hammer drill. The first mode of the tool is the main one - drilling. An electric drill is used to drill holes in metal, plastic, glass, and wood. If you need to get a hole in concrete, you need to turn on the impact drilling mode. Even if this function is available, it is not recommended to actively use the tool for drilling concrete.

This is interesting!

The

regulator

on drills is often located in the upper part of the tool near the chuck. On rotary hammers, the mode switching regulator is located on the side.

Differences between a drill and a hammer drill

The main difference is the impact mechanism system

The most significant difference between a hammer drill and an impact drill is the operating principle of the impact system. So, in a drill, two gear mechanisms - ratchets - are used to generate a blow. The tool chuck is rigidly connected to the first of them, and its body is connected to the second. When the impact mechanism is not needed, a stopper is inserted between the ratchets and there is no contact between them. When the impact mode is turned on, the stopper is removed, and the gear train converts the rotary motion of the cartridge into a reciprocating motion.

This process is simply perfectly shown in the following video clip, despite the fact that the announcer in the video constantly calls an impact drill a hammer drill, in fact, the video shows the operation of a regular impact drill. It’s just that how do translators and announcers know the difference between a drill with an impact function and a hammer drill, they haven’t read our article :).

Video. Operating principle of an impact drill

With a hammer drill everything is different. The impact device can be either electromechanical or electropneumatic. The first type is most often used. In this case, there are two coils that, through electromagnetic interaction, cause the core to move back and forth. Next, the energy is transferred directly to the working part of the hammer drill.

The pneumatic mechanism can be of two types. Equipped with a crank drive or a system with a so-called “drunk” rolling bearing. In the latter case, the rotating rotor drives the piston, which transmits the shock energy to the working part.

Video. Drunk bearing impact mechanism

Well, the crank-type mechanism transmits its rotational energy using a piston, which pushes the working part of the hammer with compressed air.

Video. Impact crank mechanism

Functionality is important

In this regard, the hammer drill is significantly ahead of the drill - after all, it has three operating modes. This is a spin kick, a spin kick, and just a kick. Accordingly, using an electric hammer drill you can not only drill a wall, but also break through it. Hollow out a large hole, make a groove for a cable, break off a piece of a wall - all this can be done with such a powerful tool as a hammer drill. But a drill with an impact mechanism has only two modes - standard drilling and drilling using impact. Moreover, the force of this blow is not as powerful as that of a hammer drill.

What are the differences between the main characteristics?

For electric drills, the main characteristic is torque, or torque. The unit for its measurement is Newton meter. Rotary hammers are classified according to a different criterion. For them, the main thing is power, which depends on the impact energy. This value is measured in joules. And the torque of a hammer drill should not be large at all; it is often much less than that of an impact drill with a motor of similar power.

Leader in Performance

And then the hammer drill breaks forward again. After all, its impact energy is undoubtedly greater than that of an impact drill. Therefore, working with a hammer drill is much more comfortable - you don’t have to press on it as hard as on an impact drill. When working with the latter, it will be extremely difficult to punch a hole without significant pressure.

Main Application

For a drill, the main area of application is work on drilling metal, tiles and wooden surfaces. Well, the hammer drill is designed to overcome concrete and brick walls. Therefore, both in terms of hours or minutes spent and in terms of quality, it is difficult to compare the result of work performed by one and another tool. After all, for a drill, the impact function is only an additional one. However, just like the drilling functions of a rotary hammer. Do not neglect the instructions, using the tool “to the fullest” where only short-term use is allowed. It will end sadly - a good thing will break.

How much do impact construction tools weigh?

One cannot fail to note such an important distinguishing factor as the weight category of the instruments. The rotor is not only small in size, but also light in weight. This is due to the use of a low-power and high-speed electric motor capable of reaching speeds of up to 4000 rpm.

Rotary hammers are equipped with more powerful electric motors that develop low speed, but at the same time have high torque, which directly affects their weight category. Drilling devices are divided into three types by weight:

- Lightweight - up to 4 kg

- Medium - up to 6 kg

- Heavy - from 6 kg. These are barrel perforators, which, in addition to working mechanisms, have a special compartment for pouring liquid oil

The most powerful impact drill weighs no more than 4 kg. Light weight simplifies the operation of the tool, but not in all cases. When it is necessary to drill through concrete, the weight of the tool plays a big role. If, when drilling, the hammer needs to be pressed firmly against the surface of the material being processed, then the drill hammer does not need such actions.

terms of Use

To ensure maximum efficiency of tools and keep them in working condition for a long time, you need to adhere to a number of rules:

- Interrupt the operation of the device approximately every 40 seconds;

- Clean gaps and parts of mechanisms from blockages that accumulate during operation;

- Use suitable, well-sharpened drill bits and bits.

Important! The drill in general is more demanding of cleanliness; its operation is adversely affected by blockages, sand, dust and dirt that clog the motor brushes. The hammer drill does not have this feature, since its design is such that debris cannot get inside the housing and settle on the working units. But this instrument, in turn, is sensitive to negative air temperatures - water condenses in the pneumatic unit and ice can form, which negatively affects the functioning of the device.

Contents and types of fasteners

To understand how else a drill hammer differs from an impact drill, you need to pay attention to the fastening element. Drills and rotary hammers use completely different types of fasteners, which are designed to fix actuators - drills and augers.

Cam-type chucks are installed on the impact rotator. They are also called collet chucks, which consist of three cams that move simultaneously when the holder rotates. Chucks of this type are designed for fixing nozzles with cylindrical and hexagonal shanks. The cams compress the shank of the nozzle at three connection points, and thereby ensure its reliable fastening.

Rotary hammers use completely different chuck mechanisms. They are based on the quick-clamping principle of fixing the nozzle. The main feature of drill hammer chucks is that the attached attachment has the ability to move freely vertically. This free movement is necessary to generate impact force with the tool. Quick fixation of the nozzles in the hammer drill chuck is carried out by a ball that engages with a groove in the tail part of the nozzle.

Since these tools use different types of cartridges, the installed attachments will also have corresponding differences. The main difference lies in the design of the tail part of the nozzles. Conventional concrete drills are installed on the rotators, and drills are available for the rotary hammer. Outwardly, they are similar to drills for concrete, but the difference is that on the shank of the drills there are 2 open and 2 closed grooves.

This is interesting!

For impact drills, drill bits for concrete are not available with a diameter of more than 12 mm. The maximum hole size that can be drilled in concrete with this tool is 10 mm.

Tools used and type of fixation

Another parameter that distinguishes the devices from each other is the working tool and the type of element fixation. Most often used:

- crowns;

- borax;

- chisels;

- strobers.

Drills, as a rule, use a working element in the form of a drill, onto which a pobedit alloy is applied. This option is relevant for concrete pavements. It should be noted that the element is fastened to a special clamp in both versions. But their design in the devices is different. Rotary hammers involve the use of a number of systems that allow you to quickly change the working element. These are, in particular, SDS:

- plus;

- max;

- top.

For fixation, special grooves with a special configuration are used. It should also be said about the degree of freedom in relation to the clamp in the direction of the axis. This approach helps reduce the load during work.

A standard drill is used only if the device is equipped with a special adapter or a chuck with a cam mechanism is installed instead of the traditional one. The lock allows for quick and easy clamp changes. The standard model is included with the device. When a cam variation is used, a structure is formed that consists of two clamps connected to each other by a sequential chain, and one auxiliary one. But in this case, beating occurs during operation of the device, and the fastening is insufficiently rigid.

From the above it follows that rotary hammers are used to solve a wide range of problems compared to impact drills. In addition, they benefit in power and performance. This means that this option is more relevant for performing complex operations. It is rational to use drills for solving small problems.

What productivity do the tools have?

Due to the fact that the hammer drill is equipped with a powerful electric motor and a more advanced impact mechanism, it has high productivity. Impact-type rotators are inferior to rotary hammers, and in addition to low productivity, they are not yet designed for long-term use in impact mode.

Rotary hammers are divided into household, semi-professional and professional. A household hammer drill is also not designed for long-term use, but unlike an impact drill, it will cope with the task of drilling a hole in concrete much faster and more efficiently.

Tool life

Diameter of crown for rosette and their types

Each of these tools has its own service life and operating conditions. Of course, a lot depends on the owner’s attitude towards his products, so it is necessary to carefully monitor the condition of the hammer drill or drill, change consumables in a timely manner and lubricate the chuck.

A professional tool always costs more, but its service life is much longer; all parts are made of high-quality materials that are resistant to deformation. In this regard, a hammer drill is much more reliable than a drill, since it contains many components that differ from the design of an electric drill, which interact with each other, forming a single mechanism. The structure of the drill is much simpler, but the tasks that the unit performs are somewhat fewer. When choosing a rotary hammer or impact drill, you need to start from the functions that are needed in the tool and what tasks it will solve.

How much does an impact drill and hammer drill cost?

Many craftsmen prefer to drill holes in concrete with a drill, since the cost of this tool is always at an affordable level. Only as a result of such use it turns out that the tool quickly breaks down when drilling concrete frequently, or its performance decreases due to wear of parts. As a result, you have to repair the drill or buy a new one.

A hammer drill is more expensive than a drill, but it is worth the cost. The high price is due to the use of a powerful electric motor and a complex impact mechanism. However, compared to an electric hammer, a hammer drill will last 10 times longer if used as intended for concrete processing.

The average cost of an impact drill is 2,000 rubles, while a hammer drill can be purchased for at least 3.5-4 thousand rubles. There are cheap models of rotary hammers - household ones, which are intended only for occasional use.

This is interesting!

When buying a percussion instrument, do not look at its cost. First you need to decide how often you plan to use the device for drilling concrete. If often, then we definitely choose a hammer drill. If you need to use a tool for drilling holes in concrete from time to time, then there is no point in overpaying, and it is better to buy an impact drill.

Main purpose of tools

The main difference between an impact drill and a hammer drill is their functional purpose:

- for an impact drill - this is drilling materials of low density (wood, plastic, soft metals, etc.). In addition, the impact functions of the drill allow you to drill even concrete and brick. In conventional models, the working effect produced largely depends on the pressure force of the master. Therefore, to obtain optimal and acceptable impact energy, the pressing force should reach 10-15 kg;

- for a hammer drill this is chiselling . The impact function is inherent in the hammer drill from the very beginning, just like drilling. At the same time, it is not recommended to apply pressure to the hammer drill, as this may lead to breakage of the tool. The maximum limit of pressing force should be no more than 5 kg.

Depending on the general functions, a hammer drill can perform a fairly wide range of work compared to the functionality of an impact drill:

- beating work and driving in rods;

- chipping concrete walls;

- drilling of various surfaces, including wood, concrete and steel;

- chipping, chipping bricks, knocking down tiles, removing plaster and making holes;

- driving bolts, screws or self-tapping screws

What parameters are used to select tools?

Every craftsman must have an impact drill on his farm. It can not only drill metal and wood, but also concrete. If you plan to carry out repair and construction work, then it is recommended to purchase a hammer drill. Thanks to this specialized tool, you can perform various actions with durable materials - drill, drill, groove, etc.

When choosing percussion instruments, you need to take into account their following features:

- Power - the higher the indicator, the more efficient the tool. Only power directly affects the weight of the tool, so it is recommended to select tools based on power based on the complexity of the work.

- Design - hammer drills come in pistol and barrel types. The most popular are pistol hammer drills. They are lightweight and allow you to perform various manipulations with concrete. Barrel hammer drills belong to the category of heavy professional tools

- The presence of a reverse mode - this function is quite useful, as it allows you to rotate the tool chuck in both directions, which is very important when a drill or auger gets stuck in a hole

As for the cost and manufacturer, everything is simple here. If you need a reliable household assistant, then you should buy impact drills and hammer drills from well-known brand manufacturers. Such tools will never fail, and if they break down, you can always find spare parts. If the devices are used occasionally, then you should not choose the most expensive options.

Tool selection criteria

When choosing a power tool, you should pay attention to the following criteria:

- Power - the higher the power level, the more comfortable it is to use the tool at work.

- Availability of rotation speed adjustment.

- Equipped with additional attachments.

- Number of revolutions at idle (rotation speed).

- Volume of speeds (one, two, three, etc.).

- Possibility of movement (rotation) in both directions (reverse movement). In some cases, this helps remove a stuck drill bit.

- Possibility of creating holes of different diameters in different building materials.

Is it possible to drill a hole in concrete with a screwdriver?

If there are no special tools at hand, then a screwdriver is used to drill concrete. However, attempts lead to the fact that it is not possible to achieve a positive result. This is due to the fact that the screwdriver does not have an impact drilling function, so it is contraindicated to use it for working with concrete. A screwdriver is designed to work with self-tapping screws, but it can also drill through wood. Just keep in mind that screwdrivers are based on a low-power electric motor. If the motor experiences maximum load, it may simply burn out.

If you are going to drill through thick wood with a screwdriver with a 10 mm drill bit, then immediately abandon this idea. You should especially not use the tool for drilling concrete or mixing the mixture. It will not be possible to drill concrete with a screwdriver, since this device does not have an impact mode. It is also not recommended to mix bulk mixtures with a mixer attachment in the chuck. The engine will experience high loads (and it has very little torque), and therefore can burn out very quickly.

This is interesting!

Each tool has its own purpose, so before using one or another device, you should read the instructions.

What is better to buy and where to use

How to choose a hammer drill

The choice of the preferred instrument is determined by the nature of the operations that the buyer plans to perform. If he does not plan to work with very hard materials, he is better off buying a good drill equipped with a sufficient set of attachments. In private households, the need for a hammer drill arises very rarely; as a rule, third-party specialists are invited for such work. If the owner plans to carry out repeated work related to crushing, it is advisable for him to get hold of a hammer drill.

What is better to choose for drilling concrete - a drill or a hammer drill?

Based on the analysis described above, it is clear that although an impact drill and a hammer drill can be interchangeable, they have completely different purposes. An electric rotary hammer is designed for working with metal and wood, and rotary hammers are produced for working with concrete, brick and stone. You can drill into concrete with an impact drill, just as you can make a hole in wood with a hammer drill. However, frequent use of tools for their indirect purposes contributes to rapid wear of the mechanisms.

A good master always has two tools at his disposal - an electric hammer with a hammer function, and a hammer drill. Depending on the planned work, he will use the appropriate device. If you don’t have a drill or a hammer drill in your arsenal of tools, but you still need to drill a hole in wood or concrete, you can do this with any of the available devices.

This is only appropriate if a hammer drill is used to drill several holes in wood, and a drill is used to drill several holes in concrete. By the way, the brace, unlike a drilling device, is only capable of drilling concrete. When you need to get a groove or dismantle brickwork, the device in this case is absolutely useless. If renovation work is planned at home or in an apartment, then it is definitely not worth starting it without purchasing a hammer drill.

It is impossible to unequivocally answer the question of which is better - an impact drill or a hammer drill. The difference between these instruments is quite large, but the presence of drum modes makes them interchangeable. If during work you feel that the electric hammer you are using cannot cope with the task of drilling a hole in concrete, then you should use a hammer drill.

Functionality of the devices

The first difference is the functionality of the devices. This directly determines the operation of the tools. Drills have a wide range of applications, in particular:

- Drill holes on thin surfaces, including wood and plastic surfaces. Using the switch, the shock option is used.

- Making holes on hard surfaces. This is where the impact option comes to the rescue, allowing you to perform work even on brick surfaces.

- Tightening and unscrewing self-tapping screws, screws and screws. But such actions must be performed provided that the shock function is turned off.

We have already written about “How to choose a drill”

Rotary hammers also perform the above tasks. In addition, such tools cope with punching holes in materials that are characterized by high hardness. For example, reinforced concrete. During the work, various types of chisels are used, but subject to the need to make breaks or gutters in walls made of concrete or stone. Such tools operate in three modes:

- revs with impacts;

- like a jackhammer;

- performing revolutions without the shock function.

Drills have only two modes. This is drilling with and without impacts.

Operational differences

Depending on the purpose, the operating schemes differ. If you need to drill holes in metal and wood, then it is better to choose an impact drill - the result will be high-quality and even. Working with stone and concrete will require more effort and more time.

A hammer drill, on the contrary, is better used for working on stone - you don’t have to strain too much, and the result is better and faster. When used, the hands experience weaker vibration and become less tired.

For reference! When using a hammer drill on wood and metal, the holes will not be as smooth as when using a drill. In addition, you will need to install a special cartridge.

The drill is capable of performing the work of a hammer drill, but not for long

Rotary hammer functions

Unlike a drill, a hammer drill can operate in three modes: impact, rotation, and a combination of these actions. Therefore, a hammer drill can be used not only for drilling, but also for scoring a wall, creating holes and recesses of the required size. It is indispensable when performing work on replacing wiring at home. An impact drill, even comparable in power to a rotary hammer, will not cope with such a load.

Perforator device

With a hammer drill you can:

- make holes in solid materials (brick, artificial and natural stone, blocks, concrete). A core drill is used when large diameter holes are required.

- Remove plaster, brick or tiles from the walls. To do this, you need to select a chisel from the attachments.

- Carry out gating of the walls of the house. Need a lance attachment.

The disadvantage of the tool is that some operations may require adapters for attachments - this increases the already considerable weight of the device and makes it less convenient, lengthening the entire structure.

A rotary hammer is a professional tool with a thoughtful and reliable design. It allows you to perform heavy work at high speed. When doing home repairs yourself, you most often do not need such a powerful device, so an impact drill is often used for household purposes.