The most popular method of cutting metal nowadays is gas cutting. This is caused by a number of reasons. The main ones are:

- simplicity of the technological process. To carry out cutting, only two gases are needed: a gas heater for the material being processed (propane, acetylene, etc.);

- oxygen directly, which carries out the process of metal separation;

To perform this operation, you need a gas cutting machine - equipment for cutting metal with gas. This article will be devoted to getting to know this equipment.

By the way: other articles on our site are devoted to gas metal cutting technologies - you can easily find them if you use the “Site Search” service.

Gas welding, gas cutting and heating equipment Messer Cutting Systems

Thermal cutting of metals is the most cost-effective method both in domestic conditions and in industry.

Gas (autogenous) cutting methods provide good speed, acceptable quality at not too high operating costs. Any metalworking production begins with the preparation of metal and its cutting, followed by the operations of machining, assembly and welding, gouging, heating, etc. But not only metalworking industries use autogenous gas welding, gas cutting and heating equipment. It finds its application in radio electronics, the manufacture of refrigeration systems and air conditioners, jewelry, the glass industry, and auto repair. Gas-flame equipment provides soldering, melting, welding, cutting, heating, heat treatment, straightening, and descaling. Working with flammable gases, high pressure and open flames is a source of increased danger, therefore compliance with safety requirements and the use of special safety devices is mandatory. The ITS-Engineering company is the official distributor in Russia of the world-recognized leader in the production of autogenous equipment for gas welding, cutting and heating - Messer Cutting Systems (Germany). You can buy the entire range of Messer products from us from stock in Moscow or on order with delivery in the shortest possible time. The most popular models of equipment are always available: safety devices, gearboxes, manual gas torches and cutters, portable automatic gas cutting machines, nozzles, hoses, spare parts. In addition to standard gas welding and metal cutting equipment packages, we can work together to create a personalized solution for soldering, welding, cutting and heating. The Messer modular system allows you to create an individual tool, a torch for gas welding and cutting, by selecting the handle, the necessary insert or nozzle depending on the task. We can prepare a proposal for equipping your production with a Messer CNC gantry thermal cutting machine. For us, the task of ensuring human safety is always in first place, quality and reliability are in second place, and simplicity and ease of use are in third place.

Gas cutting machines

Gas cutting machines are divided into two classes:

- stationary _ This is powerful, high-performance equipment, the workpieces for which are delivered by special vehicles;

- portable _ These are small mobile units (massive ones are installed on self-propelled carts), the movement of which is carried out using: a spring mechanism;

- gas turbine;

- electric motor.

To use such a machine, it must be installed directly on the workpiece being processed (pipe, sheet, etc.) and directed in the desired direction (along a flexible copier, guides, etc.).

Models of both classes consist of the following main components:

- carrier. This is the “skeleton” of the unit on which the actuators and auxiliary mechanisms are mounted. For stationary machines, the “skeleton” is mounted on a powerful base;

- cutter. Powerful machines with high labor productivity are equipped with several cutters;

- leading. This unit is a drive mechanism, it is the source of movement of the entire machine and the workpiece being processed;

- Remote Control. From here all processes occurring on a gas cutting machine are controlled and monitored. There are types of control: manual;

- using CNC.

Portable gas pipe cutting machine “CG2-11”. East. https://www.mossvarka.ru/catalog/mashiny_gazovoy_rezki/.

The following models are very popular:

- portable gas pipe cutting machine model “CG2-11” brand “ZAO NPO “Vector” (Belarus);

- thermal cutting machine model “Kometa” brand “SPICOM” Barnaul.

Main types of equipment

- balloon and ramp reducers

; - safety devices

; - modular torch systems for heating, soldering and welding

; - hand cutters for cutting, gouging, heating

; - machine cutters

; - various accessories and consumables

; - portable automated cutting machines

; - Gantry CNC Thermal Cutting Machines

;

Gas cutting machine: conclusions

Gas is an explosive substance. To avoid injuries and casualties, the requirements must be strictly observed and the “Safety Rules” must be followed. Therefore, persons at least 18 years of age are allowed to maintain and operate gas equipment. They must go through the following stages of preparation:

- undergo introductory safety training when working with gas;

- on-the-job training;

- training course on safe work practices.

Upon completion of training, they must pass an exam on the theory and practice of safe working practices, which must be confirmed by receiving the appropriate “Certificate”.

Only competent, experienced welders with relevant work experience should always be involved in the selection, testing and training of working on gas welding equipment.

Sections: Gas metal cutting

Previous article: We cook a heat accumulator for heating and change the electrode holder on the welder Next article: HAAS CNC metalworking machines - perfect milling equipment

Basic services

- selection of autogenous equipment

; - non-standard solutions for heating systems

; - modernization of thermal cutting machines

; - Autogenous cutting robotization

; - supply of original spare and consumable parts

;

Areas of application of gas cutters

These units are used for the following purposes:

- for the purpose of cutting scrap metal before melting during sorting;

- for sampling seam defects that appeared during welding;

- to eliminate the consequences of accidents;

- to remove surface defects on ingots during foundry production;

- for the purpose of cutting metal sheets and rolled metal before installing metal structures;

- for the purpose of preliminary cutting of edges before welding;

- for the purpose of dismantling steel structures.

Application area

- soldering;

- cutting;

- welding;

- planing;

- heat;

- descaling;

- heat treatment;

- automated heating solutions;

Properly selected autogenous equipment allows you to effectively solve many production problems in various industries and in the domestic sphere. Correct operation and routine maintenance in accordance with safety standards and manufacturer's recommendations will allow you to enjoy the work and get a quality result. The use of original spare and consumable parts will ensure reliability and long service life of the equipment. We guarantee an individual approach and attention to each Customer; for us, it is important both for an individual entrepreneur who wants to buy autogenous equipment and needs a good quality cutter or burner for crafts or a workshop, and for a large enterprise with its own special tasks and wishes. We have something to offer every potential Customer.

Equipment for cutting metal with gas: machines

In cases where for some reason it is difficult to move the workpiece being processed (it is large in size and, as a result, mass, complex cut shape, etc.), the kinematic diagram of the equipment changes. It is built in such a way as to move the assembly with the cutting tool (the heavy workpiece remains stationary). This type of equipment is called a gas cutting machine.

Gas cutting machines, like machines, are divided into two large classes:

- mobile . These are small mobile units that are moved using transport carts;

- stationary _ According to their design, they are divided into the following types: P - portal. They are located on support posts located directly above the workpiece. The number of cutters may vary, pcs: 1…12;

- P-K – portal-console. Installed on a console mounted on a stand. The suspension mechanism is located directly above the workpiece being processed. The number of cutters may vary, pcs: 1…4;

- Ш – hinged. The cutters are mounted on articulated frames. This type of equipment is intended for vertical cutting only. The number of cutters may vary, pcs: 1…3.

Based on the type of cutting technology, such machines are divided into types of processing:

- Kf – oxygen-flux cutting;

- K – oxygen cutting;

- Gl – gas laser cutting;

- PL – plasma arc cutting.

According to the trajectory of movement of the contour with the working tool, machines are distinguished:

- L – linear. They perform straight-line cutting;

- M – magnetic. Perform figure cutting on a steel copier;

- F – photocopying. Carry out figure cutting according to design drawings. The process is carried out through photoelectronic copying followed by microprocessor control;

- C – digital. Machine tools with numerical control (CNC). They are designed for figured cutting of blanks.

Currently, the following models and brands are in great demand:

- CNC gas cutting machine model “Start-2” brand “Teploventmash”;

- small-sized machine for gas-plasma cutting of metal with CNC model “Crystal 1.5x1” brand “PKF “Crystal”.

The cutting process on the Start-2 gas cutting machine. East. https://stanki-tvm.ru/produkciya/stanki-gazovoy-rezki-s-chpu.

Classification

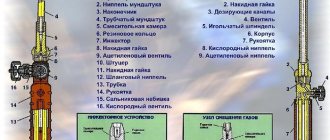

According to their purpose, cutters are divided into special and universal. Universal ones can be ejector or non-ejector, it all depends on how the combustible gas and oxygen are mixed in them.

According to the method of cutting products, gas cutters of any type are as follows:

- for surface treatment of metal;

- spear;

- separating;

- oxygen-flux.

Gas burners are as follows:

- oxygen ones are ejector structures in which a burning jet is formed using oxygen.

- kerosene - works with kerosene and is used for processing products up to 20 cm thick based on carbon steel.

- propane - this option is suitable for cutting cast iron pipes and other products made of ferrous or non-ferrous metal. A propane gas cutter is considered the most reliable and safe, while providing high productivity.

- acetylene - designed for cutting sheets and parts of large width, often used in oxy-fuel cutting, and are necessarily equipped with a special valve that regulates the power and speed of oxygen supply to the working area.

Universal cutters with an ejector are the most popular . Such units help to use flammable gas under certain conditions; the pressure should be 0.03−1.5 kgf/square centimeter. The universal device can cut metal products in different directions, it is simple and easy to use, and has small dimensions. It can be used to process metal with a thickness of 3-300 ml.

What should the cutter be made of?

Cutters can be made from brass; it is yellow in color. Made from copper, it will have a copper color. Or stainless steel, gray. It is not recommended to purchase cutters made from other materials.

For long-term use, it is recommended to purchase a disassembled cutter. It must have detachable connections in case, for example, the tip fails, the head wears out, or the tube burns out. Such gas cutters can be easily disassembled and damaged ones can be replaced without much difficulty or effort.

We wish you to make a good choice, be guided by this article and monitor the safety of your life and the life of your assistant - the cutter.