Lathe scoring cutter is a cutting working tool of a lathe, with which you can perform the following simple operations:

- remove allowances on cylindrical or conical workpieces;

- smooth the surface to be processed, give the part a given shape;

- form chamfers;

- cut off ledges;

- grind the ends;

- remove excess elements on the outer surface of the workpiece.

The lathe scoring cutter is rigidly fixed on the lathe. During operation, it cuts into the material of the part to a set depth and removes it in the form of chips.

Geometry characteristics

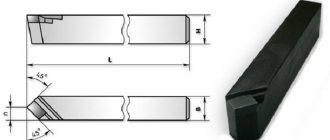

All cutter models have similar geometry and consist of the following main parts:

- The head is the main working section, usually made of steel alloy.

- Rod (body) – needed for fastening in a lathe.

- Support surface - it is used to fix the turning tool in the machine holder.

- Rake surface – ensures chip rollback from the surface of the workpiece.

- The main cutting edge is the one that cuts the part.

- The tip of the blade is the point where the cutting tool touches the workpiece.

- The main back surface supports the plate during operation.

- Rear auxiliary surface - allows the tool to move smoothly along the surface while processing the workpiece.

Experts often group the listed elements of scoring cutters into two main structural units. The rod and the supporting surface form a holder, which acts as a clamp on the machine. It can be rectangular or square in cross section.

Both surfaces of a lathe scoring cutter represent a working part, which is called the head. The sharpening angle of the cutters depends on the properties of the material of the plates and workpieces, as well as the processing technology.

Types of cutters for a lathe and their purpose

When describing the types of turning tools, several classifying characteristics are usually used. According to its design, it is divided into two types: solid and prefabricated. In the first case, the entire product is made in the form of a monolithic bar of metal. And in the second, removable or soldered carbide plates act as the blade. According to their technological purpose, turning cutters are divided into special ones, which are used for processing various profiles and threading, and general purpose products, used for external and internal turning, cutting and end trimming. Another distinguishing feature of a turning tool is the configuration of the cutting part, which depends on its operating modes and the type of turning work. For turning hard-to-reach places, a curved cutter is usually used, which has several varieties, differing in the length of the cutting part, the shape of the bend, sharpening and purpose (cockerel, bent, reverse cutters and others).

Another classification option is the division of turning tools according to the principle of machining cleanliness. There are usually two classes here: rough and finishing. The first is intended for roughing or pre-turning operations, and the second is for finishing operations. If the rough tool, with rare exceptions, is quite the same type, then among the finishing tools there are a number of varieties with their own names. Examples include blade and radius cutters with an arcuate blade, the purpose of which is precise finishing turning. Another separate type is a diamond cutter, used for turning work on super-hard materials. A cup turning cutter with a circular cutting surface has a unique design that can work for a long time without regrinding.

In addition to the standard classification, there are many names for specific turning tools, usually reflecting the features of its design or technology of use. These include a spring cutter with a wave-shaped cutting part, which springs during turning of hard and uneven materials.

A separate category of cutting tools for lathes are planing cutters. During turning operations using them, feed is carried out on a stationary part. In this case, the allowance is not cut off, as during rotation, but is removed by planing. In this configuration, a lathe performs the same function as a planer or slotter.

Pass-through straight, bent and persistent

The most common turning operation is turning the outer parts of cylindrical workpieces. In this case, three basic types of cutting tools are used, shown in the figure below.

The thrust cutting tool is designed for turning long and non-rigid products, since its design contributes to less bending of the part. The bent cutter has a blade located at an angle to the holder, so it can be used for longitudinal feed. All cutters of this type are fixed in the tool holder so that their tip is opposite the main axis of rotation of the machine. One of the varieties of the straight type is a spring cutter, which has an elongated and curved cutting part that springs during processing. The through-cutting tool is the most widespread and universal, therefore it is often made non-separable from high-speed tool steel.

Scoring cutters

The main purpose of this tool is to trim ends and form ledges on rotating workpieces. Scoring cutters work in both feed directions and can therefore form shoulders at different angles. Structurally, these are most often prefabricated high-speed cutters. The photo below shows trimming the end of a bronze blank.

Read also: Transformer for welding inverter

Parting cutters

This type of turning tool belongs to the group of grooving and cutting tools. It is distinguished from pass-through and scoring cutters by the specific shape of the cutting part. On its blade, on the sides of the main working edge, there are two auxiliary grooves that ensure cutting of the side planes of the groove. In addition, to reduce friction on the side surfaces of the groove being cut, the cutting part has a trapezoidal shape with a narrowing towards the holder. The head of such a tool, as a rule, has a reinforced shape, often curved upward (the so-called cockerel incisor). It is recommended to cut off as close to the chuck as possible, with the cutting edge positioned exactly against the axis of rotation and the tool body strictly perpendicular to the cutting plane. Cutting work is performed at lower speeds than turning, and when cutting steel and hard metals, coolant must be supplied to the processing zone. The photo below shows a segment.

Threading internal and external cutters

If turning requires high precision in the relationship between the thread axis and other planes of the product, then in this case it is recommended to use thread-cutting tools. The technology of applying threads with a cutting tool is based on the exact correspondence of the geometric parameters of its cutting part and the threaded profile of the product. Regardless of the type of thread, during such operations the feed must be synchronized with the spindle speed. Structurally, the cutting tool used for external threads is straight, and for internal threads it is bent. The photo below shows external thread cutting.

Boring cutters

This type of tool is designed for turning internal cylindrical surfaces in order to achieve precise alignment with the axis of rotation of the part. When turning boring, chip removal, heat removal and the use of coolant are difficult, so the tool is in more difficult conditions than when performing external turning. As a result, such turning is performed at lower speeds and shallow depths. There are two main types of cutting boring tools: thrust and through. The former are intended for dead-end holes, and the latter for through holes. For boring large diameters, tool holders of various configurations are usually used, which can also accommodate boring cutters. The photo below shows a boring.

Prefabricated tool

Structurally, turning cutters are produced in two main varieties: all-metal and prefabricated. In the first case, the entire product is made of a single metal bar, at the end of which the blade is sharpened. In the second, everything is all-metal except the blade, which in such a product is a cutting plate fixed at the end of the tool head. The cutting inserts in this type of turning tool can be attached by soldering or mechanically. In the first case, it is fixed by soldering or welding, and in the second - by various mechanical devices, among which the most common are threaded elements, clamps and eccentrics. Tips and inserts for cutters are made from special cutting materials, the main ones being tool steel, hard alloys and powder composite materials.

GOST 18880-73 (download PDF)

Varieties and classification

Lathe scoring cutters are produced by Russian and foreign manufacturers. There is a large assortment on the market, so they are grouped as follows:

- According to manufacturing technology: solid, composite.

- The level of processing they provide: roughing, semi-finishing, finishing;

- The direction of delivery is either right or left.

Lathe scoring cutters are called solid if they are completely made of tool steel of the same grade; for composite (prefabricated) ones, the elements are made of alloys with various additives. The holder is made from particularly strong and wear-resistant metal that can withstand long-term shock loads. The working head is made of carbide material, but, in addition, it should not heat up during operation.

For example, hard alloy T10K5 is suitable for the manufacture of a holder, and high-speed steel R9 is suitable for the cutting insert located on the head.

Prefabricated tools, with interchangeable inserts of various widths and thicknesses, are becoming increasingly popular. Cannot be sharpened. In addition, some of them have adjustable head extension length.

The characteristics of cutters made of carbide alloy must comply with the international standard GOST 18880-73, and those of high-speed steel GOST 18871-73.

Depending on the purpose and operating principle, the following types of cutters are produced.

Straight models

Their cutting edges are located parallel to the axis of the holder, they are smooth, without bends. Used for rough processing and grinding off excess areas, removing a significant layer of material. This will require several approaches. They did not gain much popularity.

Turning cutters, bent scoring

They perform similar functions, and also add the ability to process shaped surfaces. The curved shape allows you to grind hard-to-reach places and penetrate into the middle of parts, but are not suitable for finishing. The working part has a triangular cross-section and is curved relative to the holder axis. With such a cutter, a metal product must be processed perpendicular to the axis of rotation.

Toolholders come in only three standard sizes: 16x10, 25x16 and 32x20 mm.

Turning scoring thrusters

Such turning scoring tools are used to process parts made of materials of low rigidity. They are used for cutting thick layers of metal in one pass, as well as for trimming edges and grinding down stepped surfaces. The cutting edges and the axis of the holder are parallel.

Based on the direction of feeding, instruments are classified into left-handed and right-handed, which can be distinguished visually if you place your palm and look at the direction of your thumb.

Selection criteria

Depending on the material of the workpiece and the type of operation that needs to be performed using a cutter, the appropriate type of tool is selected.

For turning work, it is necessary to purchase lathe scoring cutters of different models: first, rough processing is performed with one type, then the tool is replaced to perform finishing processing.

There are several factors that should be taken into account when choosing a lathe scoring cutter:

- The material of the workpiece should not be more rigid than the tool itself.

- The need to comply with the dimensions and quality of surface treatment of the product.

Take into account the wear resistance of the tool, which directly depends on the strength of the material being processed.

It must be taken into account that the main elements can be made of different materials depending on the functions performed. For example, in order for the holder to provide reliable fixation in the tool holder, it must be shock-, heat- and wear-resistant.

Manufacturers typically use two types of materials to make cutting inserts:

- High speed steel. This alloy is characterized by relatively low strength, so tools are not recommended for processing hard materials. Such products become dull quickly. A large layer of material can only be removed gradually, over several approaches.

- Carbide materials. They are universal due to their special strength and super durability. Such properties are imparted by introducing, for example, cobalt or titanium into the alloy. To prevent tools from becoming too expensive due to expensive additives, a combined material of high-speed and carbide steel is used. Such products will also last a long time.

Working video, enjoy watching.

The consumer properties of turning scoring cutters can be assessed by markings indicating the grade of the alloy with the designation of alloying additives. For example, the T15K6 product is made of steel, which contains titanium carbide and cobalt, and the numbers indicate their percentage.

Nowadays, the inscription “HSS” is increasingly found on lathe scoring cutters. This designation indicates that the turning cutter is made of alloy steel, which is popularly nicknamed “quick cutter.” This is alloy steel, into which additional components are introduced to improve physical and mechanical properties. It follows from this that the composition of steel may be different for different cutters. It could even be cheap powder steel.

All these parameters influence the further choice of feed and cutting speed values, as well as tool life, i.e. the duration of continuous work until the cutting edges become dull.

When is sharpening required?

The need to sharpen cutters for a lathe arises in two situations: during the manufacture of a new tool and in case of wear during operation. It is impossible to work with a worn or incorrectly sharpened cutting tool, as this leads to a sharp loss of turning accuracy and a decrease in the surface quality of the part. Other consequences of sharpening problems include vibration and excessive heat.

Rules for sharpening

The purpose of sharpening turning tools is to bring their surfaces to the specified geometric characteristics and to give proper sharpness to the cutting edges. To properly sharpen a turning tool, it is necessary to follow the sharpening technology and use abrasive wheels that match the material of the product. It is also important that the sharpening machine is equipped with an adjustable tool rest, which allows you to fix the tool being sharpened at the required angles. The procedure for sharpening a turning cutter is as follows: the corners of both rear surfaces are removed first, and after checking and measuring them, the front surface is sharpened. The last operation is to fine-tune sections of all surfaces in those places where they are adjacent to the cutting edge of the blade.

Tools used

On the machine for sharpening turning tools, two grinding wheels with different abrasives should be installed: from electrocorundum and green silicon carbide. The first is intended for sharpening work on tool steel, and the second wheel is used for sharpening carbide materials. Lapping and finishing, which is the finishing operation, is carried out on a separate sharpening and grinding machine with minimal runout and high speeds. Here, CBN or diamond grinding wheels are used as abrasive tools.

What are the operating modes?

To perform the necessary operation, the cutter must be firmly and securely fixed in the lathe. During operation, he cuts the cutting part to the required depth into the metal and cuts it off in the form of chips.

Lathe scoring cutters operate with transverse or longitudinal feed. The work of such a cutting tool can be roughing, semi-finishing and finishing.

The speed of turning work should not significantly affect the wear of the equipment and allow abnormal operating conditions (overheating, processing of material with an unsuitable or blunt cutter), potentially dangerous for the machine and the worker.

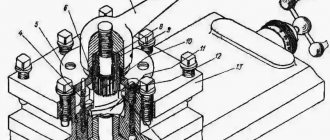

How to install a cutter on a machine

The turning tool is mounted on the carriage of the movable support using a single or multi-position tool holder. To correctly install the cutter, it must be accurately aligned relative to the main axis of the machine in the perpendicular and parallel directions. The cutting edge of most turning tools must be strictly opposite the axis of rotation, which requires the tool to be adjusted in height. To do this, they usually use mild steel plates of different thicknesses, which are placed under its base. An important installation condition is also the rigid fixation of the cutter, so it must be clamped without backlash or gaps.

If any of the readers have experience working on a lathe, please tell me how many turning tools and what type should be available in a home workshop. We look forward to your response in the comments to this article.

Reviews

Users who have had the opportunity to evaluate the pros and cons of specific models of turning cutting tools from their own experience share their own opinions on various Internet forums.

In particular, consumers constantly argue about which turning tools to buy, cheap or expensive. Some argue that there is no point in overpaying for a brand, others want only the best from the manufacturers’ range. For some, the most important thing is the result, and not the tool used to achieve it. And some people think that it is important to enjoy working with a good tool.

And then there are turners who make turning cutting tools themselves, work with them, and sell them to others, claiming that their products are the best.