First of all, I would like to say in general terms what a channel is. Channels are special metal parts that are very widely used in construction in order to give the greatest strength to frames and structures.

The 12 mm channel is in demand in many types of production:

- In construction for the construction of bridges, columns, etc.

- For mechanical engineering.

- Car manufacturing.

Channel 12 allows not only to give the frame strength and stability, but also to increase the load-bearing load that the frame must withstand. This is how the channel strengthens internal and external walls, and also assembles individual parts of buildings and structures.

Channel 12 technical specifications

The established quality standards of GOST 8240-89 provide for the following product characteristics:

- channel area 12 - 43.1 sq.m / ton of profile;

- workpiece height - 120mm;

- shelf thickness - 7.8mm;

- the specific weight of a channel of 12 linear meters is 10.4 kg with a steel density of 7850 kg/m3;

- product wall thickness - 4.8 mm;

- shelf width - 52mm;

- cross-sectional area - 13.30 cm2;

- R internal rounding, no more than 7.5 mm;

- r shelf rounding - 3mm.

The maximum load on the 12th channel is indicated in the accompanying documentation, but if you wish, you can always request information from the plant’s engineering department - class=”aligncenter” width=”800″ height=”800″[/img]

Table with dimensions of channels for economical shelves with parallel edges.

| Series E channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5E | 50 | 32 | 4.2 | 7.0 | 6.5 | 2.5 | 6.10 | 4.79 | 22.9 | 9.17 | 1.94 | 5.62 | 6.02 | 3.05 | 0.993 | 1.23 |

| 6.5E | 65 | 36 | 4.2 | 7.2 | 6.5 | 2.5 | 7.41 | 5.82 | 48.9 | 15.05 | 2.57 | 9.02 | 9.42 | 4.13 | 1.127 | 1.32 |

| 8E | 80 | 40 | 4.2 | 7.4 | 7.5 | 2.5 | 8.82 | 6.92 | 90.0 | 22.50 | 3.19 | 13.31 | 13.93 | 5.38 | 1.257 | 1.41 |

| 10E | 100 | 46 | 4.2 | 7.6 | 9.0 | 3.0 | 10.79 | 8.47 | 175.9 | 35.17 | 4.04 | 20.55 | 22.68 | 7.47 | 1.450 | 1.56 |

| 12E | 120 | 52 | 4.5 | 7.8 | 9.5 | 3.0 | 13.09 | 10.24 | 307.0 | 51.17 | 4.84 | 29.75 | 35.12 | 10.03 | 1.638 | 1.70 |

| 14E | 140 | 58 | 4.6 | 8.1 | 10.0 | 3.0 | 15.41 | 12.15 | 495.7 | 70.81 | 5.67 | 40.96 | 51.76 | 13.13 | 1.833 | 1.86 |

| 16E | 160 | 64 | 4.7 | 8.4 | 11.0 | 3.5 | 17.85 | 14.01 | 755.5 | 94.43 | 6.50 | 54.41 | 73.17 | 16.70 | 2.024 | 2.02 |

| 18E | 180 | 70 | 4.8 | 8.7 | 11.5 | 3.5 | 20.40 | 16.01 | 1097.9 | 121.99 | 7.34 | 70.05 | 100.51 | 20.87 | 2.219 | 2.18 |

| 20E | 200 | 76 | 4.9 | 9.0 | 12.0 | 4.0 | 23.02 | 18.07 | 1537.1 | 153.71 | 8.17 | 88.03 | 134.07 | 25.54 | 2.413 | 2.35 |

| 22E | 220 | 82 | 5.1 | 9.5 | 13.0 | 4.0 | 26.36 | 20.69 | 2134.2 | 194.02 | 9.00 | 111.00 | 179.05 | 31.54 | 2.606 | 2.52 |

| 24E | 240 | 90 | 5.3 | 10.0 | 13.0 | 4.0 | 30.19 | 23.69 | 2927.0 | 243.92 | 9.85 | 139.08 | 249.03 | 40.07 | 2.872 | 2.78 |

| 27E | 270 | 95 | 5.8 | 10.5 | 13.0 | 4.5 | 34.87 | 27.37 | 4200.2 | 311.12 | 10.97 | 178.25 | 316.24 | 47.43 | 3.011 | 2.83 |

| 30E | 300 | 100 | 6.3 | 11.0 | 13.0 | 5.0 | 39.94 | 31.35 | 5837.1 | 389.14 | 12.09 | 224.00 | 395.57 | 55.58 | 3.147 | 2.88 |

| 33E | 330 | 105 | 6.9 | 11.7 | 13.0 | 5.0 | 46.15 | 36.14 | 8021.8 | 488.17 | 13.18 | 281.23 | 497.02 | 65.78 | 3.282 | 2.94 |

| 36E | 360 | 110 | 7.4 | 12.6 | 14.0 | 6.0 | 52.90 | 41.53 | 10864.5 | 603.58 | 14.33 | 350.05 | 618.92 | 77.76 | 3.420 | 3.04 |

| 40E | 400 | 115 | 7.9 | 13.5 | 15.5 | 6.0 | 61.11 | 47.97 | 15307.9 | 765.40 | 15.83 | 445.41 | 770.89 | 91.80 | 3.552 | 3.10 |

The dimensions of the economical channel (E series) are controlled according to GOST 8240-97 (the data in the tables corresponds).

Channel weight 12

Regardless of the fact that the product is made of alloys and has the appropriate strength, the 12-meter channel has a low weight per linear meter. This is an important factor due to which the product is in great demand. The weight of 1 meter of channel is 12 – 10.4 kg.

Channel 12 has a huge range and has different lengths of the product and direction of the edges. Each profile is marked depending on the location of the shelves. For example, channel 12 P has shelves parallel to each other, while channel 12 U has shelves located at an angle.

Table with sizes of special channels.

| Series C channel number | h | b | s | t | R | r | Shelf slope % | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | |||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | ix cm | Iy cm4 | Wy cm3 | Iy cm | ||||||||||

| 8C | 80 | 45 | 5.5 | 9.0 | 9.0 | 1.5 | 6 | 11.80 | 9.26 | 115.82 | 28.95 | 3.13 | 22.24 | 7.63 | 1.38 | 1.57 |

| 14C | 140 | 58 | 6.0 | 9.5 | 9.5 | 4.75 | – | 18.51 | 14.53 | 563.70 | 80.50 | 5.52 | 53.20 | 13.01 | 1.70 | 1.71 |

| 14Ca | 140 | 60 | 8.0 | 9.5 | 9.5 | 5.0 | 10 | 21.30 | 16.72 | 609.10 | 87.01 | 5.35 | 61.02 | 14.09 | 1.69 | 1.67 |

| 16C | 160 | 63 | 6.5 | 10.0 | 10.0 | 5.0 | – | 21.95 | 17.53 | 866.20 | 108.30 | 6.28 | 73.30 | 16.30 | 1.83 | 1.80 |

| 16Ca | 160 | 65 | 8.5 | 10.0 | 10.0 | 5.0 | – | 25.15 | 19.74 | 934.50 | 116.80 | 6.10 | 83.40 | 17.55 | 1.82 | 1.75 |

| 18C | 180 | 68 | 7.0 | 10.5 | 10.5 | 5.3 | – | 25.70 | 20.20 | 1272.00 | 141.00 | 7.04 | 98.50 | 20.10 | 1.96 | 1.88 |

| 18Ca | 180 | 70 | 9.0 | 10.5 | 10.5 | 5.3 | – | 29.30 | 23.00 | 1370.00 | 152.00 | 6.84 | 111.00 | 21.30 | 1.95 | 1.84 |

| 18Sat | 180 | 100 | 8.0 | 10.5 | 10.5 | 5.0 | 6 | 34.04 | 26.72 | 1791.01 | 199.00 | 7.25 | 305.48 | 43.58 | 3.00 | 2.99 |

| 20C | 200 | 73 | 7.0 | 11.0 | 11.0 | 5.5 | 10 | 28.83 | 22.63 | 1780.37 | 178.04 | 7.86 | 128.04 | 24.19 | 2.11 | 2.02 |

| 20Ca | 200 | 75 | 9.0 | 11.0 | 11.0 | 5.5 | 10 | 32.83 | 25.77 | 1913.71 | 191.37 | 7.64 | 143.63 | 25.88 | 2.09 | 1.95 |

| 20Sat | 200 | 100 | 8.0 | 11.0 | 11.0 | 5.5 | 6 | 36.58 | 28.71 | 2360.88 | 236.09 | 8.03 | 327.23 | 46.30 | 2.99 | 2.93 |

| 24C | 240 | 85 | 9.5 | 14.0 | 14.0 | 7.0 | – | 44.46 | 34.90 | 3841.35 | 320.11 | 9.29 | 268.89 | 43.70 | 2.46 | 2.35 |

| 26C | 260 | 65 | 10.0 | 16.0 | 15.0 | 3.0 | – | 44.09 | 34.61 | 4088.00 | 314.50 | 9.63 | 1115.60 | 171.60 | 5.03 | 3.91 |

| 26Ca | 260 | 90 | 10.0 | 15.0 | 15.0 | 7.5 | 8 | 50.60 | 39.72 | 5130.83 | 394.68 | 10.07 | 343.15 | 52.62 | 2.60 | 2.48 |

| 30C | 300 | 85 | 7.5 | 13.5 | 13.5 | 7.0 | 10 | 43.88 | 34.44 | 6045.43 | 403.03 | 11.74 | 260.74 | 41.41 | 2.44 | 2.20 |

| 30Ca | 300 | 87 | 9.5 | 13.5 | 13.5 | 7.0 | 10 | 49.88 | 39.15 | 6495.43 | 433.03 | 11.41 | 288.78 | 43.93 | 2.41 | 2.13 |

| 30Sat | 300 | 89 | 11.5 | 13.5 | 13.5 | 7.0 | 10 | 55.88 | 43.86 | 6945.43 | 463.03 | 11.15 | 315.35 | 46.29 | 2.38 | 2.09 |

Series C channels are hot-rolled steel channels, which come in general and special purposes and can have the following dimensions: height 50 - 400 mm, shelf width 32 - 15 mm. The dimensions of the C series channel are controlled according to GOST 8240-97.

Features of channel 12

Due to the fact that the channel is manufactured in accordance with GOST, the entire range has many advantages and features. A distinctive feature of channel 12 is the rounding of the flange, which is also prescribed in GOST and has certain standards.

GOST channel 12 is a generally accepted instruction for the presented range. This document must be followed by every company producing this channel. If the channel is made according to all the above documents, then the result is an ideal material that can be used for your purposes.

Each channel has its own quality certificate, which confirms that the product is manufactured in accordance with GOST. Channel 12 is no exception and also has such a document. The quality certificate for the 12-meter channel can be seen in the following photo.

How are channels produced?

In accordance with GOST 8240-97, channel 12 is manufactured at enterprises. The material for the channel is alloys with the addition of structural carbon and low-alloy steel. Such steels are marked st3ps and 09G2S, respectively. The chemical composition of the first is very diverse and includes many different metals. In addition, ferrous metal or aluminum can be used.

The entire range of 12mm channel bars manufactured in accordance with GOST 8240-97 has special designations that indicate the manufacturing method. So, for example:

- C - special channel. GOST does not specify the dimensions of this channel. Often, such an assortment is manufactured according to a special order with certain parameters required by the customer.

- The P-channel is manufactured with shelves parallel to the base.

- U-shelves are located at an angle to the base.

- E-economical option. Manufacturing takes place in accordance with GOST, but less metal is used in the production process.

- L - light profile. Light metals such as aluminum are used for production.

- B - special marking, which indicates that such a channel is intended for automobile and carriage building.

- T-profiles for tractors.

In order to better understand the various channel markings, you can see the following photo.

The entire range of channel manufacturing differs in production methods:

- Hot rolled method.

- Bent or cold rolled.

- Special.

Channel 12 is produced according to option 1, namely hot rolling. All this is specified in GOST 8240-97.

Common parameters:

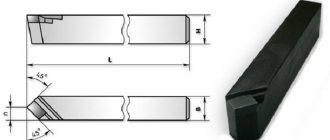

Channels 12 and 12P have identical parameters with the exception of the flange radius r.

- shelf base height (h): 120 (mm);

- shelf width (b): 52 (mm);

- wall thickness (s): 4.8 (mm);

- shelf thickness (t): 7.8 (mm);

- internal radius (R): 7.5 (mm);

- radius of curvature of the shelf with the slope of the internal edges of the shelves (r): 3 (mm);

- radius of curvature of the shelf with parallel edges of the shelves (r): 4.5 (mm).

Important: the data is valid for hot-rolled steel channels in accordance with GOST 8240-89.

Price

The price of hot-rolled channel 16 GOST 8240-97 depends on the following parameters:

- Measure of length;

- Price of one meter;

- Weight of one profile;

- Method and terms of delivery.

The price of a wholesale batch depends on how many products are contained in 1 ton and what the remainder is (there is a smaller beam in each batch, since division does not lead to a whole number). In the Moscow region, the price per ton or per meter for channel grade 16 starts from the following values:

- With parallel shelves: from 29,800 rub/t with a length of 9 m; from 26680 rub/ton (material - galvanized steel), length 12 m;

- With a slope of the internal walls of the shelves: from 23,400 rubles/ton (1 product has a length of 12 m), from 24,400 rubles/ton with a product length of 9 m;

- Price per 1 linear meter with a hot-rolled channel length of 12 m: from 615 rubles.

Hot rolled channel 12: range, characteristics

In the production of this type of shaped steel, the following are used:

- carbon steel of ordinary quality (st3 sp/ps) - for structures operated under moderate loads and normal weather conditions;

- low-alloy steel (09G2S) – for metal structures intended for operation at low temperatures and increased loads.

The dimensions of hot-rolled channel are regulated by GOST 8240-97, in accordance with which a profile is produced with the internal edges of the shelves located at a slope of 4-10%, and with parallel internal edges of the shelves of the “P”, “E”, “L” series. The range of slope angles of the internal edges can be tightened at the customer's request.

Table of dimensions and weight of channel 12

| Channel type 12 | Wall height, cm | Shelf width, mm | Wall thickness, mm | Shelf thickness, mm | Weight of 1 m channel 12, kg |

| With a slope of the inner edges of the shelves (U) | 12 | 52 | 4,8 | 7,8 | 10,4 |

| With parallel inner edges of shelves (P) | 12 | 52 | 4,8 | 7,8 | 10,4 |

| Economical, with parallel shelf edges (E) | 12 | 52 | 4,5 | 7,8 | 10,24 |

| Lightweight, with parallel edges of shelves (E) | 12 | 30 | 3,0 | 4,8 | 5,02 |

The profile products of the economy series have a thinner wall, the light series have a smaller width and thickness of the shelf, and wall thickness, compared to the products of the “P” series. The standard length of the rods supplied to the consumer is 2-12 linear meters; by agreement with the customer, it can be increased. When calculating how much a channel weighs, an average steel density of 7.85 kg/dm3 is used.

A hot-rolled channel with a wall height of 120 mm is capable of withstanding fairly high bending and deflection loads. This profile is used in load-bearing structures as the main load-bearing or additional reinforcing element. Areas of its application: frame construction, production of frames for finishing materials (installation of ventilated facades), strengthening of foundations, installation of fences and stairs, production of non-standard production equipment, mechanical engineering.

Table with dimensions of channels with parallel flange edges.

| Series P channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0 cm | ||||||

| no more | XX | YY | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | Iy cm | |||||||||

| 5P | 50 | 32 | 4.4 | 7.0 | 6.0 | 3.5 | 6.16 | 4.84 | 22.8 | 9.1 | 1.92 | 5.61 | 5.95 | 2.99 | 0.98 | 1.21 |

| 6.5P | 65 | 36 | 4.4 | 7.2 | 6.0 | 3.5 | 7.51 | 5.90 | 48.8 | 15.0 | 2.55 | 9.02 | 9.35 | 4.06 | 1.12 | 1.29 |

| 8P | 80 | 40 | 4.5 | 7.4 | 6.5 | 3.5 | 8.98 | 7.05 | 89.8 | 22.5 | 3.16 | 13.30 | 13.90 | 5.31 | 1.24 | 1.38 |

| 10P | 100 | 46 | 4.5 | 7.6 | 7.0 | 4.0 | 10.90 | 8.59 | 175.0 | 34.9 | 3.99 | 20.50 | 22.60 | 7.37 | 1.44 | 1.53 |

| 12P | 120 | 52 | 4.8 | 7.8 | 7.5 | 4.5 | 13.30 | 10.40 | 305.0 | 50.8 | 4.79 | 29.70 | 34.90 | 9.84 | 1.62 | 1.66 |

| 14P | 140 | 58 | 4.9 | 8.1 | 8.0 | 4.5 | 15.60 | 12.30 | 493.0 | 70.4 | 5.61 | 40.90 | 51.50 | 12.90 | 1.81 | 1.82 |

| 16P | 160 | 64 | 5.0 | 8.4 | 8.5 | 5.0 | 18.10 | 14.20 | 750.0 | 93.8 | 6.44 | 54.30 | 72.80 | 16.40 | 2.00 | 1.97 |

| 16aP | 160 | 68 | 5.0 | 9.0 | 8.5 | 5.0 | 19.50 | 15.30 | 827.0 | 103.0 | 6.51 | 59.50 | 90.50 | 19.60 | 2.15 | 2.19 |

| 18P | 180 | 70 | 5.1 | 8.7 | 9.0 | 5.0 | 20.70 | 16.30 | 1090.0 | 121.0 | 7.26 | 70.00 | 100.00 | 20.60 | 2.20 | 2.14 |

| 18aP | 180 | 74 | 5.1 | 9.3 | 9.0 | 5.0 | 22.20 | 17.40 | 1200.0 | 133.0 | 7.34 | 76.30 | 123.00 | 24.30 | 2.35 | 2.36 |

| 20P | 200 | 76 | 5.2 | 9.0 | 9.5 | 5.5 | 23.40 | 18.40 | 1530.0 | 153.0 | 8.08 | 88.00 | 134.00 | 25.20 | 2.39 | 2.30 |

| 22P | 220 | 82 | 5.4 | 9.5 | 10.0 | 6.0 | 26.70 | 21.00 | 2120.0 | 193.0 | 8.90 | 111.00 | 178.00 | 31.00 | 2.58 | 2.47 |

| 24P | 240 | 90 | 5.6 | 10.0 | 10.5 | 6.0 | 30.60 | 24.00 | 2910.0 | 243.0 | 9.75 | 139.00 | 248.00 | 39.50 | 2.85 | 2.72 |

| 27P | 270 | 95 | 6.0 | 10.5 | 11.0 | 6.5 | 35.20 | 27.70 | 4180.0 | 310.0 | 10.90 | 178.00 | 314.00 | 46.70 | 2.99 | 2.78 |

| 30P | 300 | 100 | 6.5 | 11.0 | 12.0 | 7.0 | 40.50 | 31.80 | 5830.0 | 389.0 | 12.00 | 224.00 | 393.00 | 54.80 | 3.12 | 2.83 |

| 33P | 330 | 105 | 7.0 | 11.7 | 13.0 | 7.5 | 46.50 | 36.50 | 8010.0 | 486.0 | 13.10 | 281.00 | 491.00 | 64.60 | 3.25 | 2.90 |

| 36P | 360 | 110 | 7.5 | 12.6 | 14.0 | 8.5 | 53.40 | 41.90 | 10850.0 | 603.0 | 14.30 | 350.00 | 611.00 | 76.30 | 3.38 | 2.99 |

| 40P | 400 | 115 | 8.0 | 13.5 | 15.0 | 9.0 | 61.50 | 48.30 | 15260.0 | 763.0 | 15.80 | 445.00 | 760.00 | 89.90 | 3.51 | 3.05 |

For channels of the U and P series there is a size that is not subject to control - this is the maximum deviation in wall thickness.

Bent channel 12: production features and characteristics

A bent channel has rounded external corners, the same thickness of the wall and flanges, and can be equal or unequal. The production of equal flange profiles is determined by GOST 8278-83, unequal flange profiles - by state standard 8281-80. Unequal-flanged steel has rather limited, highly specialized areas of application. Manufacturing accuracy – normal, increased, high.

Assortment table for equal flange bent channel 12

| Wall height, cm | Shelf width, mm | Wall thickness, mm | Cross-sectional surface area, cm2 | Weight 1 m, kg |

| 12 | 25 | 4 | 6,2 | 4,87 |

| 12 | 50 | 3 | 6,2 | 4,91 |

| 12 | 50 | 4 | 8,2 | 6,44 |

| 12 | 50 | 6 | 11,86 | 9,3 |

| 12 | 60 | 4 | 9,0 | 7,07 |

| 12 | 60 | 5 | 11,09 | 8,71 |

| 12 | 60 | 6 | 13,06 | 10,25 |

| 12 | 70 | 5 | 12,09 | 9,49 |

| 12 | 80 | 4 | 10, | 8,32 |

| 12 | 80 | 5 | 13,09 | 10,28 |

Bent metal profiles are produced on profile bending mills from hot and cold rolled strip blanks. During the bending process, some surface defects are corrected. In the production of bent channels, in addition to ordinary quality, high-quality structural and low-alloy carbon steels, galvanized blanks and strips of corrosion-resistant steel are used. Galvanized profiles are used in conditions of high humidity, while stainless steel profiles are used in enterprises that have high requirements for corrosion resistance, hygienic and aesthetic characteristics.

In addition to steel of various grades, aluminum and copper, as well as alloys based on them, are used to produce U-shaped rolled sections. Products made from aluminum alloys are used in structures for which a combination of low specific gravity, corrosion resistance and good strength is important.

Classes E and L

The economical and lightweight series of shaped metal products are distinguished by wall thickness: it is less than the standard one. In grade 16p the parameter is (in mm):

- Economical - 4.7 (wall) and 8.4 (each shelf);

- Lungs - 3.4 (wall) and 5.3 (each shelf).

It is this characteristic that determines: the mass of one meter and the total weight of the beam, the quantity in one ton, the retail and wholesale price. Accordingly, the physical characteristics change: load resistance, strength, rigidity. The scope of application of beams, their durability, reliability, and, therefore, the quality of construction depend on these parameters.

Technical requirements for manufacturing - steel grades, strength and quality parameters

In addition to the above characteristics regulated by GOST 8240, for the design and subsequent construction of any channel structures, it is necessary to know its other parameters: the grade of steel from which it is made, strength (physical and mechanical) and other properties, including various indicators of workmanship. All this information should be sought in other GOSTs - technical specification standards.

In total, GOST 8240 hot-rolled products are subject to not one, but seven technical specification standards - one for each specific area of practical application and method of using these channels. And, of course, in each of these standards, all of the above-mentioned characteristics (strength, steel grade, etc.) are strictly defined and radically different from those regulated by the other six GOST technical conditions. Moreover, this becomes obvious even after simply reading the list of all technical specification standards for GOST 8240 channels (including profile No. 12). Here is the list of GOSTs:

- 535-2005 - this standard applies to steel products for general and specialized use, made from carbon steel of ordinary quality;

- 19281-2014 – applies to high-strength steel products, which are made from high-quality unalloyed and low-alloy steels and are used for assembly or construction of various structures;

- 27772-2015 – for rental, which is used for the construction or assembly of steel building and other structures, as well as used for many other purposes;

- R 52927-2015 and 5521-93 – for steel metal products used for the construction of ships, as well as a variety of marine and river structures and structures for various purposes and climatic conditions;

- R 55374-2012 and 6713-91 – for steel products intended for the construction of bridges and the assembly of their various structures.