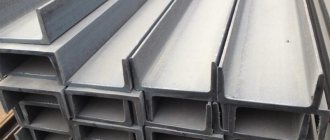

Such a common element of many supporting structures as a channel is a U-shaped profile that can be made of various types of steel, including stainless steel. Channels can differ not only in size (a special table is used to determine each of them), but also in manufacturing technology.

We understand the range of channels

Channels are produced using cold-rolled and hot-rolled technology. U-shaped metal profiles of different brands also have differences in the design of the shelves. Thus, there are channels, the inner edges of the shelves of which are parallel to each other, as well as products, the shelves of which are made with a certain slope on the inside. However, no matter what version the shelves are made in, the entire range of profiles with a U-shaped section is distinguished by high rigidity, combined with low weight. It is these properties that make it possible to successfully use channels of any size for the manufacture of highly loaded structures for construction and any other purposes.

The main advantages of U-shaped profiles include:

- high strength, ensuring resistance to bending loads;

- the ability to successfully withstand not only bending, but also multidirectional loads (rupture, compression, etc.);

- high resistance to shock loads, which can lead to mechanical damage to the structure (a metal channel, which is made with high quality and in accordance with GOST, has practically no weak points in its design that can cause its destruction from various loads).

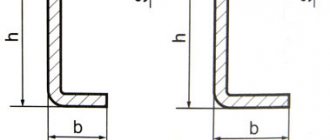

Parameters of a channel with a slope of the internal edges of the shelves

Marking

If you look at the range of channels, you can see that it includes metal profiles with a wide range of sizes. With such a variety of options offered, it is very difficult to choose exactly the brand of channel that will be optimally suited for solving a particular problem. Naturally, the manufacturers took this point into account. To designate their products, they use markings, which can be used to get a fairly complete picture of the characteristics and dimensions of the U-shaped profile.

Parameters of a channel with parallel flange edges

Markings that comply with GOST 8240-97 include both digital and alphabetic designations. The first number in the designation is the main characteristic; it corresponds to the size of the channel, that is, the distance between its flanges. By the letter in the marking you can determine what type the channel is. These can be products in which the internal edges of the shelves are made with a slope or are parallel to each other (“U” and “P”, respectively), metal profiles of economical (“E”) or light (“L”) type, special purpose (“S” ).

If you need to know all the other dimensions of a channel of a certain brand from the assortment, then for this there is a special table in which they are indicated. The choice of a product of a certain brand is made depending on what kind of loads the structure for which it is planned to be used will be subjected to.

With slanted shelf edges

Size chart for channels with inclined internal edges of shelves (click to enlarge)

Explanation of the additional parameters shown in the table:

- I—moment of inertia;

- W is the moment of resistance;

- i is the radius of gyration.

With parallel edges of shelves

Size chart for channels with parallel flange edges (click to enlarge)

Economical with parallel shelf edges

Size chart for economical channels with parallel flange edges (click to enlarge)

Light series with parallel edges of shelves

Size chart for light series channels with parallel flange edges (click to enlarge)

Special

Size chart for special channels (click to enlarge)

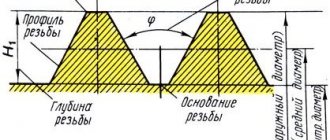

Maximum deviations of parameters

Maximum deviations of channel parameters

Table of maximum deviation of channel parameters (click to enlarge)

Theoretical weight

Theoretical channel weight table (click to enlarge)

Main parameters of channel 12: dimensions, weight and cost

A metal product called channel 12 with parallel flanges has a body thickness of 7.8 mm and a wall thickness of 4.8 mm. Such products are produced in lengths from 2 to 12 m. Longer copies can be made to order. The popularity of this type of profile is due to its positive qualities, contained in the optimal ratio of weight, strength and relatively low cost.

Profiles made of low-alloy steel are subject to operation at high temperatures and under conditions of increased exposure to chemicals. Also, the products have excellent resistance to compression and bending, but at the same time have poor resistance to torsion.

The weight of 1 meter of channel 12 can be found using the table above or using an online calculator. The price of the product depends on this parameter. According to the table, the weight of channel 12 per 1 meter is 10.4 kg.

Channel 12 - drawing with dimensions according to GOST

Like channels of other sizes, this type of product has additional markings with different characteristics. The most popular is the 12P channel, which has parallel flanges with edges without slope.

The dimensions of the 12P channel are given below:

- width – 52 mm;

- linear meter weight – 10.40 kg;

- length in ton – 95.94 m.

The channel with mark 12 also has other series. For example, 12L is a rolled metal product with dimensions of 120x30 mm, characterized by inclined shelves. The weight of 1 m of such a profile is 5.02 kg, and the footage of 1 ton is 199 m.

Helpful advice! The marking of the channel 12C indicates its special purpose, 12E - an economical series of products with shelves without slope. Their size is standard - 120x52 mm, and their weight is slightly lower - 10.24 kg. Accordingly, a ton of material contains almost 97 m.

Together with the digital value indicating the width of the profile, a letter is placed indicating the structural features of the material

Some features of choice

The range of channels, of course, is significantly inferior in variety to the range of angles, but this does not prevent the selection of a product of the required dimensions and characteristics to solve a specific design problem. When choosing a specific brand from the assortment, you should be guided by the following rule, which is relevant for products of any profile: having decided on the type of channel that meets your requirements, you should include in the specification for the drawing the brand that is located closer to the beginning of the table.

The assortment, in which various types of channels are presented in table form, allows you to determine not only their sizes, but also a number of other important parameters:

- linear meter weight;

- cross-sectional area;

- axial moment of inertia;

- axial moment of resistance;

- radii of inertia.

The last three parameters are calculated relative to the central axis of the channel section.

It is very important to choose those brands of channels whose mechanical characteristics are not lower than the calculated ones by more than 5%. If this condition is not met for the selected brand of product, then it is better to take a channel one number higher.

Determining the weight and price of a channel per meter: table of sizes, cost of profiles

Complex calculations of specific gravity, in addition to mathematical skills, also require updating the school course in physics and geometry. Therefore, it is better to use ready-made calculations given in special tables, or use an online calculator. To do this, just enter the necessary data and get an accurate result.

The cost of channels is determined in accordance with linear meters. The price formation is influenced by the profile height, which determines the product number, as well as the grade of steel from which the product is made. For example, a channel made from low-alloy steel will cost an order of magnitude more than similar products made from carbon steel. This is due to the fact that the first type of raw material has increased strength characteristics.

The current average prices for channels on the Russian rolled metal market are shown in the table:

| Channel number | Weight per linear meter, kg | Length in ton, m | Price per linear meter, rub. |

| 5 | 4,8 | 207 | 200 |

| 6,5 | 5,9 | 169 | 240 |

| 8 | 7,1 | 142 | 265 |

| 10 | 8,6 | 115 | 350 |

| 12 | 10,4 | 97 | 420 |

| 14 | 12,3 | 82 | 480 |

| 16 | 14,2 | 71 | 520 |

| 18 | 16,3 | 60 | 600 |

| 20 | 18,4 | 55 | 760 |

| 22 | 21,0 | 48 | 870 |

| 24 | 24,0 | 42 | 1020 |

| 27 | 27,7 | 35 | 1150 |

| 30 | 31,8 | 32 | 1400 |

| 40 | 48,3 | 21 | 4250 |

Above is a general table. In order to have an idea about each type of channel, its individual features, sizes and characteristics, it is worth getting to know each type in more detail. Below, as an example, we will consider the most popular types and sizes of channels that are in high demand and widely used.

Weight, price, dimensions of channel 20: all the necessary information about the profile

Channel 20 belongs to the category of universal rolled metal products made from hot-rolled steel. It is used in almost all industries - not only in the construction of load-bearing structures, but also for the construction of bridges, in the automotive and carriage industries, as well as in heavy engineering. The production of products is regulated by several GOSTs, according to which technical characteristics and permissible deviations from the norm are established.

Channel 20 has three main types that meet certain Gosstandart requirements:

- general use and special purpose - GOST 8240-97;

- special for the automotive industry - GOST 19425-74;

- special for carriage building - GOST 5267.1-90.

All these types of rolled products are characterized by common parameters, such as the height, width of the flanges and the weight of the channel 20. It should be noted that the profile can be either equal flange or with inclined flange edges. The dimensional characteristics of profile 20 are as follows:

- height – 200 mm;

- shelf width – 76 mm;

- wall thickness – 52 mm;

- Shelf thickness – 9 mm.

Channel 20 is most in demand in construction for the construction of supporting structures

The weight of different types of channel may vary slightly. For example, for a 20P channel the weight of 1 meter is 18.4 kg. Series P channel 20 is most in demand in the construction market. It is used both for the construction of frames and for the construction of bridges, the creation of large machine tools, as well as for other purposes. According to GOST 8240-89 for hot-rolled and GOST 8278-83 for bent channels, profiles are made with lengths from 4 to 12 m.

Other brands

In addition to the main and most common options for channel metal, there are 3 more brands of this product:

- "E" - economical. The main difference is a thinner wall and shelves, less weight. It is used in cases where there is no need to hold massive structures.

- "L" - light. Like the previous one, it is produced only with parallel shelves, but from lighter materials, for example, aluminum.

- "C" is special. Produced for use in certain areas, for example, in car and mechanical engineering. According to GOST, it has an individual size chart.

Design

Also, the types of channels differ in the position and size of the shelves. According to the size of the shelves, they can be divided into:

- Equal - the lengths of the shelves are the same.

- Unequal - the length of one shelf is longer.

The edges can be located either parallel or at an angle, which is marked accordingly:

- “P” is a profile in which the edges are located parallel to one another.

- “U” – the edges of the profile are located at a slope.