Among the most useful and functional devices for the home workshop, the gasoline soldering torch ranks one of the leading places. Such a device is capable of qualitatively connecting all kinds of metal structures using liquid metal technology. The device operates on the basis of a gasoline-air combustible mixture, which is formed in the burner, and allows further smelting work to be carried out.

The rotary tap located on the handle acts as a regulator of the direction and power of the flame , which significantly simplifies the combustion process.

Today, metal smelting is carried out using two types of solders:

- Low-melting.

- Refractory.

If when working with low-melting metals almost all existing types of soldering irons are used, then in the case of refractory metals it is necessary to create maximum temperature indicators . In this case, you simply cannot do without using a burner. Currently, there are several varieties of such a universal device that can operate on the basis of different fuel mixtures, but at the same time heat the structure to the required temperature.

Among the most common and convenient torches are models for soldering and welding, which operate on gas or a gas-air mixture. You can purchase them at the appropriate store or try to create them yourself .

Design and operation of a homemade gasoline burner

If there is a need to reproduce the soldering (welding) process at home, then a gasoline torch will help you with small metal parts.

This type of metalworking equipment is sometimes sold in specialized stores. Due to the simplicity of the design, interchangeability and accessibility of individual components of the unit, modifications of burners made by hand are successfully used in everyday life. The material in this article will tell you about torches for soldering and welding metals and the possibility of their production at home.

Device design and advantages

A gasoline torch for soldering and welding has the following components:

- burner;

- nozzle;

- current-carrying tip with electrode wire;

- welding arc;

- weld pool;

- Weld;

- base metal;

- drops of electrode metal;

- gas protection.

In a simplified version, the device consists of a gasoline tank or fuel tank, an air compressor, gasoline hoses and, in fact, the burner itself. The latter, in turn, also consists of several elements.

A gasoline torch for metal soldering includes the following parts (structural parts):

- frame;

- a bushing with a hook made of metal;

- a tube;

- heap;

- emphasis;

- filler;

- air flow regulating ball;

- rubber o-ring.

When purchasing a gasoline torch for soldering and welding, you should not forget that most often the device does not include gas-resistant hoses and torches, so most likely you will need to purchase them separately.

Gasoline and gas burners are designed quite simply , so they can also be made with your own hands at home without much difficulty.

Despite the simplicity of assembly and design of the device, a gasoline torch for soldering and welding has undeniable advantages. Firstly, the low weight and size of the device make it lightweight, portable and convenient to use at work. Secondly, thanks to the creation of a fuel-air mixture, the device ensures the appearance and retention of high temperatures, which, in turn, guarantees the highest quality result upon completion of the soldering process.

Features of jewelry

Gasoline burners for repairing and making jewelry are separate from other devices. They are used for smelting precious metals. The devices are characterized by their miniature size and large heating area .

Currently, most factories use high-precision laser systems, which improve the quality of the finished product. Despite the fact that jewelry burners are practically not produced, their use is relevant for jewelry repair. That is why modern goldsmiths very often ask the question: “How to make jewelry burners with your own hands?” On specialized forums you can always find descriptions and drawings of high-quality models.

Gasoline blow torch

A gasoline burner is designed for the process of high-quality fastening (soldering) together of metal components of a single structure using molten metal. The solder used for soldering has a solid physical state and can be either low-melting or refractory.

Work with a refractory alloy is carried out exclusively with burners.

Design and principle of operation

When purchasing a gas torch for metalworking by soldering and welding, you should not assume that the kit contains all the elements necessary to organize the work. Since each gas-air burner apparatus has individual drawings, and there are no clearly defined design standards, we will consider the basic (simplified) set of working elements:

- tank for storing gasoline (fuel);

- air compressor;

- gasoline blow torch;

- gas-resistant hoses providing fuel supply,

- stand.

A gasoline burner is a heating device in which the combustion process of gasoline converts it into a gaseous state. Combustion occurs in the evaporator, where oxygen is supplied from the air by a nozzle. As a result, a gasoline-air flammable cocktail is formed, a mixture of the combustion product of gasoline and air, which is involved in the soldering process. The rotary tap located on the handle functions as a regulator of the direction and power of the flame.

Bring an open flame source to the nozzle of the working element and you will see an instant flash of a flammable mixture. Stable combustion of fuel will last for 5 minutes (+/-2 minutes). The temperature at the end of the flame reaches 1000° C or more.

Benefits and safety of work

Heating devices for soldering, the initial fuel of which is gasoline, have become widespread in various fields due to their ease of use and thermal performance.

A positive characteristic of the heating device is the ability to operate without preheating.

- relatively small weight and dimensions of the device;

- portability and ease of use (compared to its gas counterpart);

- high-quality soldering and welding of metals.

How to use?

Before you start using the burner, you must carefully read the instructions and recommendations of the manufacturer. A distinctive feature of such equipment is that it can be used exclusively in open areas.

If you need to operate a gasoline burner in an unventilated area, you can turn it on for a short period of time, and then thoroughly ventilate it.

In order to ensure maximum safety when using the device, you must strictly follow the operating instructions. Otherwise, a fire or explosion may occur.

Let's look at the process of using a gasoline burner.

First of all, it is necessary to refuel the equipment with the appropriate fuel. It is best to use high-quality gasoline so that the device does not fail and there are no problems. Under no circumstances should the tank be filled completely; filling 3/4 full will be sufficient. The remaining space is necessary to create pressure during operation. Creating pressure using a special pressure pump, which is usually included with the device. For this, 10 pumpings will be enough. After the necessary pressure has been created, you will need to pour fuel into the tray. Alcohol is considered the ideal option, as it does not produce much soot. After ignition, the burner will heat up the evaporator. The needle valve can now be opened

At this stage, be sure to pay attention to the fuel, which must be gaseous. Be careful that there are no drops here.

If they are detected, the heating process will need to be carried out again. During the work, it is imperative to monitor the torch, increasing or decreasing its power, using a shut-off valve for this. If the operation of the burner cannot boast of stability, or attenuation is constantly observed, then the nozzles should be cleaned with a special needle. After finishing the work, you need to extinguish the torch. To do this, simply close the valve.

In order to ensure the maximum level of safety during operation of the equipment, it is worth adhering to safety regulations.

- Under no circumstances should you continue to use a gasoline burner if a fuel leak is detected.

- It is not recommended to use fuel whose quality properties differ from those recommended by the manufacturer.

- Do not use the burner for a long time. This may cause the cylinder to become very hot and cause it to explode.

- Before starting operation, it is worth checking the integrity of the safety valve each time. If problems are detected, it is better not to turn on the equipment.

- It is better to refrain from using a gasoline burner in an unventilated area.

DIY gas burner: manufacturing instructions

In this article we will look at how to make a gas torch for soldering with your own hands. This device is often in demand both in private households and for commercial purposes - for individual technical creativity and various types of construction tasks. In particular, gas burners are used for soldering, metalsmithing, forging, roofing, jewelry work, and for other purposes they produce flames whose temperature exceeds 1500°C.

In metalworking, using a gas torch, you can heat a metal workpiece so that in the end it turns out to be sufficiently hardened. When carrying out welding work with some metals, the areas of future seams must be heated.

Parameters for making a soldering torch

Firstly, the device must be made of refractory metals. With a properly adjusted burner, temperatures in excess of 1000°C can be achieved. Secondly, the burner must be equipped with a reliable operating valve, which will shut off the gas supply in the event of a dangerous situation. Thirdly, you need to use a reliable connection to a tank with a valve or a 5-liter propane tank with a reducer, which will eliminate the risk of accidents.

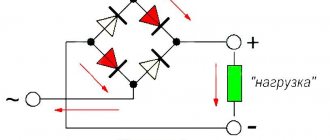

Below is a typical diagram and principle of operation of an injection gas burner:

Fuel container.

In the case of gas burners, gas is supplied from a cylinder. Possible options:

Large gas cylinder

This is purchased at gas stations. An empty cylinder is either refilled or exchanged at the same gas stations. It’s better to ask lamp workers about these cylinders - the cylinders are absolutely the same, for jewelry - a 5 liter cylinder will last for a very long time, definitely enough for a year. The gas in such cylinders is under pressure; to regulate the pressure at the outlet, a gas reducer is usually installed - this also applies to lampworkers, where this has all been discussed many times.

Small replaceable gas can (gas cartridge).

Sold on construction markets, as a rule, it is liter. When it runs out, they throw it away and put in a new one. It does not require a gearbox. You can connect to such a can via a hose (which is more convenient to use) or simply screw the burner onto the can itself without a hose. Tourists use something similar in the field.

Small refillable can.

Many people have encountered this - most of the accomplices have burners with small refillable cans. The can and the burner are mounted together; hoses are not needed in this case. They are refilled with gas for lighters from a tobacco stall, they say that it is better to look for a special gas for such burners - it can be found in household markets, and in radio electronics stores, and in jewelry equipment stores - it seems that it is cleaner and more satisfying (more calorie-rich, that is - gives more heat when burned).

Gasoline tank

Highly purified gasoline of a certain oil fraction (“nefras”) is poured into the tank; at the household level it is called “galosh”; it is sold in hardware stores and at household markets in departments with all sorts of solvent-varnishes in containers from 0.5 to 5 liters. They usually pour about a glass - this is a day you can work.

DIY burner - drawings

The inner diameter of the liner tube (1) should be 0.5 mm smaller compared to the inner diameter of the nozzle. A washer (2) with air holes is welded inside. The sleeve (2) secures the tube with the nipple.

The design differs in that when moving the tab in the nozzle, it is possible to adjust the air suction through the ventilation holes - and, as a result, adjust the fire temperature over a wide range.

Is it possible to make a blowtorch work during mining?

The principle of operation of a conventional blowtorch is to ignite gasoline vapors, which are pushed out under the action of compressed air.

This effect is achieved by forcing air into the burner fuel tank. What happens if you pour used oil into a blowtorch?

Oil itself, even under pressure, does not evaporate well - it needs to be heated. Due to poor atomization, the flame will be uneven and it will be difficult to ignite the burner. The oil burns with the formation of a large amount of soot and soot, so the jet will quickly coke, its cross-section will decrease, and the lamp will fail. Increasing the cross-section of the nozzle will also not give the expected effect - the oil will be sprayed in large drops, which will not allow obtaining a uniform flame of the torch.

In addition, used oil often contains impurities: diesel fuel, gasoline, antifreeze and even water, which can lead to flashes inside the lamp. To use waste as fuel for a blowtorch, you will have to install a filtration system, which will further complicate the task.

Considering all the difficulties, using a gasoline blowtorch as a burner during mining is difficult and unsafe. Therefore, it is necessary to modify or completely change its design.

Making a gas burner from scrap materials: step by step

List of materials and tools:

• drill; • Bulgarian; • hammer; • sandpaper; • brass blanks for the divider nozzle; • thin brass tube with a diameter of 15 mm; • wooden blocks; • vice; • silicone seal or FUM tape; • hoses for connection; • valve for adjustment.

How to make a nozzle and handle

First of all, we take a brass tube and attach a handle to it - for example, from an old burner, or from a wooden block, having processed it beforehand. We drill a hole in the block for a brass tube with the appropriate diameter. Having inserted the tube into the timber, we secure it with silicone or epoxy resin.

Next, we proceed to a more labor-intensive and time-consuming stage of work - manufacturing the nozzle. The hole size should preferably be 0.1 mm.

You can use a drill to make a slightly larger hole, and then adjust the edges to 0.1 mm. The hole must have the correct shape so that the flame is even.

Chipguru

- Forum Forum Rules

- Rules for Editors

- Competition rules

- Flea Marketer's Guide

- Educational program on the forum Change the color of the forum

- How to insert photos

- How to insert links

- How to embed a video

- How to indicate offtopic

- How to quote

- Stitching messages

- Theme icons

- Subscribe to topics

- Auto-subscribe to topics

- Metal

- Bearings

- Steel grades and alloys

- Thread diameters

- Unanswered topics

- Active topics

- Search

- our team

Homemade burner: description and characteristics of the device

If we talk about the burner design, it includes the following components and elements:

- The burner itself.

- Nozzle.

- Conductive tip with electrode wire.

- Welding arc.

- Welding pool.

- Weld.

- Base metal.

- Drops of electrode metal.

- Gas protection.

A simplified version includes a gasoline tank or fuel tank, an air compressor, gasoline hoses and the burner itself, which, in turn, consists of individual parts.

Models that are used for soldering metals have the following structural elements:

- Body.

- Metal sleeve with hook.

- With a pipe.

- In a bunch.

- With emphasis.

- Filler.

- A control ball (designed to change the air flow).

- Rubber sealing ring.

If you are going to purchase a torch for soldering and welding, do not forget to pay attention to the presence of gas-resistant hoses .

In most cases, they are not included in the basic kit, so there is a need for additional purchase of such parts. The design of gasoline and gas burners is very simple , so you can make the design at home using improvised materials. However, despite the ease of assembly and the absence of complications in the configuration of the device, the gasoline burner remains a very valuable tool, which is characterized by many undeniable advantages.

- Firstly, such a solution is lightweight and compact in size, which makes it very convenient for further use.

- Secondly, the creation of a gasoline-air mixture allows you to create and maintain a high temperature regime, which is necessary to achieve maximum quality of the final result.

Hoses.

Hoses are needed to connect fuel containers, blower devices and burners. In the case of gasoline burners, ordinary rubber or plastic “guts” will do. Large pressurized gas cylinders require special, durable threaded gas hoses. For liter gas cans, good gas hoses are also desirable, but “guts” with clamps will also do - the main thing is that nothing is “poisoned” (there is no gas leakage). To connect gas hoses, you may need adapters - the diameter of the threaded connections varies in different countries. Usually the adapters are turned by a turner. You can also ask lampworkers about adapters - they have imported burners that do not strictly fit our hoses and cylinders, however, the issue can be resolved.

Schematically, the burner with the kit looks like this:

Gasoline blow torch

The principle of operation of a gasoline generator for soldering

The operating principle of a gasoline generator is very similar to the operating principle of a conventional blowtorch. However, instead of pumping air, as happens in a blowtorch, fuel and air from the burner are supplied using a small compressor (can be an aquarium compressor).

Thus, gasoline is mixed with air, and at the exit from the nozzle we obtain a ready-made fuel mixture. To regulate the amount of fuel mixture, a shut-off valve is provided on the tube coming from the gas tank. In addition, the design of the gasoline burner includes a receiver, which is designed to dampen pulsations from the compressor.

Let's look at what is needed to make a gasoline generator for soldering.

Preventing clogging

The operation process is inevitably accompanied by clogging of the fuel channels and nozzle. This is due to the use of low quality fuel . Impaired cross-country ability leads to the fact that gasoline and air are mixed in the wrong proportions, which affects the quality of work. To prevent this from happening, experts recommend using the following prevention methods:

- Use gasoline with a low octane number.

- Clean the device after each use.

- Add injector additives to the fuel.

- Periodically clean the system with affinity carburetor flush. It deals with deposits most effectively.

Materials and tools for work

Tools for work

To make a regular burner, you will need the following parts and tools:

- drill;

- Bulgarian;

- hammer;

- sandpaper;

- brass blanks for nozzle and divider;

- thin brass tube Ø15 mm;

- wooden bars;

- vice;

- FUM tape or silicone seal;

- connecting hoses;

- control valve.