A sharpening stone can be synthetic or natural, made of silicon, aluminum oxide, or diamond-coated. There are also water and oil stones for sharpening cutting surfaces.

The most popular manufacturers of whetstones are the USA, Russia, China and Japan. The standard surface grain parameters of a tool in the latter country are recognized throughout the world and are considered an accurate indicator of its effectiveness.

The price of sharpening stones varies - from 116 rubles to infinity. If we take the optimal price-quality ratio of the product, then its cost will be 3-6 thousand rubles.

Sharpening stone: what is it, what does a whetstone mean?

A sharpening stone is a tool that belongs to the category of universal ones and is used for the full maintenance of knives, razors, scissors and other objects with a cutting edge.

They are considered the optimal choice for sharpening because they allow you to independently choose the intensity of processing of the cutting edge and adjust the pressure force - this is the main difference between sharpening stones and machines with high speeds, work on which often leads to damage to cutting tools.

The whetstone can come in different sizes, the smallest are called whetstones.

| Materials for making whetstones | Natural, synthetic |

| Coating grain | Small, medium, large |

| Types of whetstones | Diamond, ceramic, water, abrasive, emery and others |

| Production | Japan, Russia, USA, China |

| Price | From 300 rubles and above |

Grinding stone grit: table

When choosing a sharpening stone, pay attention to its grain size - a parameter that indicates the level of aggressiveness of the impact on the sharpening surface; its characteristics and types are presented in the table.

Too large grains on the surface of the whetstone leave grooves/scratches on the cutting surface; this is unacceptable for some materials and tools. And professionals consider a sharpened surface to be ideal if it is free of burrs and any other defects. Therefore, the coarse grain size of the stone is suitable for rough repair and restoration work.

If you use a sharpening stone with a fine-grained surface, the quality of the work will be very high, but it will take a really long time to get the desired result. Experienced sharpeners recommend having sharpening stones with different grit levels available in order to start the process with rough sharpening and finish with bringing the cutting surface to “ideal”.

Stones from the Small NANIWA Flattening Stone series of various grain sizes

What is grit

Grit, grit is the level of grit of sharpening stones. This technical parameter is indicated in numbers, for example: if we are talking about a stone with a grain size of 120 grit, then it is used for rough sharpening of the cutting surface (coarse grain), finishing the sharpening work with fine grain stones (1200, 3000, 8000 grit).

Main types of sharpening abrasives

Natural stones are included in the highest price category due to the depletion of the natural resource, the presence of manual work to produce the bar, or the high cost of extraction. They are used by professional sharpening craftsmen; for this reason, purchasing such a stone for household needs would be an extremely impractical solution.

Some samples need to be soaked with water and lubricated with oils. They have a wide range of grits for all stages of blade sharpening. Natural stones are among the most expensive in the field of tool sharpening and have long earned the respect of craftsmen.

The only drawback of working with such stones is the requirement of skill and experience. Unprofessional sharpening with natural stone will knock off the knife blade and ruin the stone.

Here are the most famous types of natural sharpening stones: Arkansas Natural Stone (Novaculite, Washita, India), African ZuluGrey, Japanese Water Stones (Nakayama, Oozuku, Narutaki, Shabudani, Okudo), Belgian Blue Stone and Cuticule.

Synthetic stones are made from abrasive with a rigid binder. Let's list some of them:

- Artificial water stones. They are an alternative to their natural counterparts. Work requires wetting with water or special oil. Storage in water is allowed several days before starting work. After sharpening, it is recommended to dry the stone. The price of artificial specimens is cheaper than natural ones, but remains at a high level.

- Diamond sharpening stones are very durable materials: they are often used to level other sharpening stones. Fine-grained specimens last longer than large ones, due to the slow chipping of the abrasive. When working, it is recommended to use lubricant - soap or plain water. On various Internet sites, the structure of diamonds is illustrated in the form of regular polyhedra, although this is fundamentally incorrect: under a microscope, the crystals look like an ordinary stone of irregular shape, the planes are different and some edges are visible. The disadvantage of diamond follows from its advantage: high sharpening speed, therefore, if handled improperly, you can remove an excess layer, damage the cutting edge or leave a deep scratch.

- Ceramic bars have high wear resistance like diamonds, sharpening quality like natural stones, but at the same time low sharpening speed. Such products are suitable for finishing and maintaining the sharpness of the blade. They do not need water or oil; after work they are washed with water and wiped with a cloth. Suitable for sharpening household tools: needles, fishhooks, scissors, razors.

- Abrasive synthetic bars of low price category. Such products made in the USSR were in every home. Carborundum and electrocorundum grains, which are hard materials, grind metal well, but due to the weak binding composition they quickly chip. After working with the product, rinsing with water is recommended. Or, sharpen the tool using lubricant initially.

What types of sharpening stones for knives are there?

Sharpening stones for knives are divided into two main types - natural and synthetic.

| Natural | Synthetic |

| Consist of minerals mined as minerals | Made from heavy-duty materials bonded together at high temperatures during processing |

| Two subspecies are considered popular - Arkansas and Japanese | There are 3 main subtypes - diamond, water and ceramic |

| There are 3 strength classes - soft, medium, hard | Features a long service life |

Water

Sharpening water stones (wet) belong to the category of artificial (synthetic), made from carbide and oxides of silicon, aluminum, and chromium. The production technology of this tool is such that the presence of particles of different sizes in the structure of the stone is not allowed - this negatively affects the results of sharpening cutting devices.

Depending on what binder material is used in production, water stone can have different hardness. For example, if the “bundle” is ceramic, then this indicator will be high, and if bakelite is used, it will be lower.

The peculiarity of a water (wet) whetstone is the need to soak it before starting work. Depending on the grit level of a particular instrument, soaking time can vary from 5 minutes (coarse grain) to 15 minutes (fine grain). You can tell that the tool is ready for use by looking at the air bubbles in the water - as soon as they stop forming, you can start sharpening the cutting surfaces.

Russian water stones Petrograd Water stones RUBANKOV.NET Sharpening water stones GRINDERMAN Chinese water stone

After soaking, the grinding surface is an accumulation of a mass of water, tiny metal particles and abrasive chips. This ensures uniform sharpening of the entire cutting surface.

Emery

Emery whetstones are used for electric machines that are equipped with grinding wheels (“emery pads”). At home, you should use white emery stones - they are durable, suitable for sharpening soft metals, and can be used for straightening knives and scissors. The composition of the material is soft, the temperature when the metal rubs against the stone is low, and the result is a fairly high-quality sharpening of tools.

There are also green sanding stones that are designed for working with hard metals. They have a high friction temperature, so they are not used for sharpening kitchen knives and scissors - scale will instantly appear on the blade, and the cutting surface will be hopelessly damaged.

Green grinding wheel White grinding wheel

Sandstone grits can be 8, 12, 16, 25 and 40, with 8 being the finest surface grit and 40 being the coarsest.

Diamond

Diamond is recognized as the hardest mineral in the world, it is used in the manufacture of sharpening tools with different grain sizes. The working layer of this mineral is made very thin, because the material is too expensive, but this does not affect the service life of the sharpening stones. It is believed that you can use such a sharpening tool for 10 years or more.

Diamond sharpening stones act very aggressively on the cutting surface and, although they allow you to complete the process in a few minutes, they quickly render it unusable and cause breakage of knives and scissors. Experts recommend that beginners limit themselves to medium-grained bars without such coating.

The difference between a diamond sharpening stone is that its surface is not clogged with foreign particles , so after use the tool is simply rinsed with cold water.

Watch the video about budget diamond sharpening stones:

A really high-quality stone of this type is quite expensive, but if you buy cheaper analogues, the surface will wear away very quickly. Accordingly, the service life will be reduced significantly.

Ceramic

The most modern type of abrasive stones is ceramic, in the production of which special materials are used (they are also used for the production of microcircuits). Ceramic can be used directly to make bars for sharpening cutting surfaces or an abrasive surface.

Sharpening tools on ceramics takes a long time and slowly; often such stones have a specific shape, which allows craftsmen to sharpen needles, nail scissors, fishing hooks, and blades. To begin work, ceramic stones are not wetted with water, but must be washed at the end of the process.

Ceramic stone (alumina ceramic) Fine Grit Tojiro F-472 – Ceramic water stone

Natural

The most popular are Arkansas and Japanese. Arkansas stones are a natural combination of quartz and rocks. The materials for its manufacture are mined in America, but their reserves are strictly limited, so the cost of such an instrument is always very high.

The second subtype of natural stone is Japanese waterstone. The material is mined in many regions of the country, but due to restrictions on its extraction, the cost of a sharpening tool will be “obscenely high.”

Professional natural stone Arkansas Translucent 1200 grit Japanese water stone S-3000/1000 on a stand

Oily

Oil sharpening stones are made from durable ceramics and have a longer service life because a more durable binder material is used in production. The peculiarity of oil whetstones is the variety of their shapes, which makes it possible to work with non-standard tools such as “bread” knives and serrated ones.

The surface of the stones has absolutely the same grain size, and this significantly speeds up work on them. There is also a drawback: it is impossible to achieve a “mirror” surface of the blade; it is better to use them at the “grinding” stage, when you need to make the blade thinner or remove small defects from its surface.

Watch the video review of Washita natural oil stone:

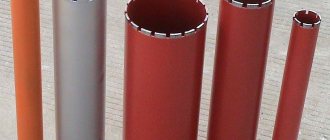

Round

Round sharpening stones are used for working on machine tools. They can be made from different materials, but more often they are synthetic - the machine produces too high speeds, so the hardness of the device must be maximum so that the blade or the stone itself does not collapse during operation.

The slipper type of tool is also available in small sizes; it is a cylinder that can be used to sharpen any knives. Manufacturers warn that it is impossible to achieve a perfect result with such stones, but they are effective as a “correction”.

Round whetstone

Sharpening rules

For the best quality sharpening, you need to decide which sharpening stone to choose for kitchen knives. It is recommended to use several types of bars with different grain sizes. It would be best to have about 5 different bars. It is equally important to choose the optimal size - it should not be equal in length to the knife; the most suitable option would be 1.5-2 times larger. You don’t need to attach much importance to the width; it is selected depending on personal convenience. Before work, it is advisable to place the sharpening stone in water or oil for 10-20 minutes. This is necessary to improve its sharpening properties - this will make it easier to work with.

The working surface should be smooth and free of unnecessary objects. The block should be placed and secured on a table or countertop. To prevent slipping, it is recommended to place a cotton rag or rubber mat under it to prevent slipping. It is strictly not recommended to hold a sharpening stone in your hands, as in this case the blade will come out uneven, and there is also a danger of injuring yourself with the knife. Before starting work, you should decide which angle should be used for sharpening, depending on the purpose of the knife and the properties of the material from which it is made. The interval for tilting is 15-65 degrees. The table will tell you how to choose the sharpening angle on the whetstone.

| Knife type | Sharpening angle (in degrees) |

| Dining room | 55-60 |

| Kitchen household | 30-35 |

| Professional kitchen | 25-30 |

| Povarsky | 20-25 |

| For fish | 25 |

| For meat | 30 |

| Vegetable | 35 |

| Penman | 20-25 |

| Carpentry | 30-45 |

| Chopping | 45-60 |

With a smaller sharpening angle, the knife will become dull faster. If the edge is too sharp, it is more susceptible to rounding. Often, too sharp a blade begins to crumble.

To maintain a constant angle when sharpening, you need:

- Fix the knife sharpening stone motionlessly on the table surface;

- Place the blade of the object being sharpened at the selected angle;

- Start moving the blade in a certain direction, maintaining the angle of inclination. It is best to make movements from yourself;

- The movements should be smooth; you should not move the knife along the block too quickly, as this will cause scratches and burrs on the blade;

- Since you need to sharpen both sides of the blade, you should alternate them. It is best to turn the knife over after each movement and do the same with the other side;

- For each side you need to make from 30 to 50 smooth movements, this will ensure high-quality and uniform sharpening of the knife;

- The blade may be wetted during the process, depending on the material of the bar.

In conclusion, I would like to add that there is no universal sharpening stone; each type of steel has its own option.

Source: posuda-gid.ru

Stones for sharpening knives: the best by manufacturer

The best manufacturers of stones for sharpening knives are considered to be Russia, Japan, China and the USA; Soviet-made tools can still be found on sale, and many professionals prefer them.

Russian made: Petrograd, Grinderman, Gritalon

Sharpening stones, which are produced in Russia, are distinguished by the correct price-quality ratio.

Of the most popular, it is worth highlighting:

| Name | Description | Photo |

| "Petrograd" | This brand produces silicon carbide stones that are distinguished by a variety of surface hardness. It is important that the degree of graining exactly corresponds to Japanese standards - they are recognized throughout the world as the best. | |

| "Grinderman" | The production is located in St. Petersburg, the company not only produces various sharpening tools, but also provides full service. | |

| "Gritalon" | They produce synthetic abrasive tools that can be used both for sharpening machines and for manual work. The material used in production is silicon carbide. |

Japanese: Suehiro, YOSHIKIN, Yaxell, Samura

Sharpening stones made in Japan are usually used for manual work and with water; the most famous brands of such tools are:

- Suehiro;

- Yoshikin;

- Yaxell;

- Samura

The difference between such stones is that when sharpening cutting surfaces, new layers of abrasive are constantly “opened”, and particles of the previous ones are mixed with water and have the best possible effect on the blade.

Sharpening stone Samura Sharpening stone Yaxell Sharpening stone Global MinoSharp from the manufacturer Yoshikin Sharpening water stone Suehiro

The Japanese produce sharpening stones with different degrees of grain, so when using a tool with fine grains at the last stage, it makes it possible to bring the cutting surface to perfect condition without the additional use of pastes, felt and dressing slings.

Japanese water stones are distinguished by the highest productivity, which can only be compared with diamond tools. But the latter increases the risk of excessive thinning of the blade at the final stage of finishing the cutting surface.

Japanese whetstone grit standards are recognized by international organizations and are used for designation by most manufacturers.

Soviet

Soviet sharpening stones are bars of absolutely regular shape, onto which a coating of abrasive material (base – silicon) was applied. You can still find Soviet sharpening stones and whetstones on sale at flea markets - they are considered high quality and “eternal.”

On the territory of the USSR, they used their own, individual markings, which are radically different from modern ones.

What was indicated on each product:

- dimensions;

- accuracy class;

- manufacturer (each had its own mark);

- dimensions;

- hardness level;

- structure characteristics;

- product type;

- material used in manufacturing;

- grain level.

Microcorundum block for straightening USSR razors, 1970

Chinese: Ganzo

Chinese sharpening tools include silicon carbide and aluminum oxide stones, which are characterized by fairly high quality, long service life and low cost. The most famous manufacturer is Ganzo. Such tools are especially good for sharpening ordinary kitchen knives - their grit level does not exceed 1000 grit, which allows you to bring the blade to the desired sharpness with one whetstone.

Recently, sharpening stones from China made of vacuum ceramics and boron carbide have appeared on the market. They have an almost eternal service life; even with prolonged sharpening of the tool, they do not wear out.

Chinese sharpening tool Ganzo

Arkansas: Dan's, Smith's, Lansky

Three companies stand out from the manufacturers:

- Dan's;

- Smith's;

- Lansky

Arkansas is a state in America where abrasive material is mined and grindstones are produced. Mineral reserves in this part of the country are already greatly depleted, so the cost of the tool is very high even by the standards of the Americans themselves. However, Arkansas stones have always been popular and are now considered the best quality on the market.

Lansky whetstone Smith's whetstone Dan's whetstone

Varieties

A sharpening stone is a small elongated rectangular product coated with an abrasive material. Abrasiveness (granularity) is the main quality of sharpening stones, ensuring their high hardness. This allows the stones to be used for processing various materials, for example, metal, leather, wood, and other minerals. The shape of sharpening stones can be rectangular, bar-shaped, oval, or circle-shaped.

The types of stones used to sharpen knives are very diverse. Each of them has a certain set of properties and characteristics, which makes them suitable for a particular type of knife. There are 5 main types of materials for bars.

Their surface is covered with microscopic crystals, similar in structure to diamond chips. Such a material is created artificially and can have a polycrystalline or monocrystalline structure. This type of bars has many advantages:

- Diamond sharpening will quickly give the blade excellent sharpness;

- Such a stone does not require lubrication when sharpening; you can simply moisten it with water;

- Few people have sharpened diamond stones to the end - they are distinguished by their durability and strength;

- The material does not become clogged when working with metal shavings; after sharpening, it is enough to rinse the block and wipe it with a rag.

A diamond whetstone for sharpening knives also has disadvantages:

- The ability to quickly sharpen a knife to maximum sharpness can damage the blade if sharpening is done by an untrained person;

- Their cost is usually more expensive than other types of sharpening stones, which is often the decisive point when choosing - the minimum price is 800 rubles.

Such stones are used mainly for sharpening large knives or tools such as axes and saws. When sharpening, it is recommended to periodically wet the surface. You should avoid applying too much pressure, otherwise it will damage the blade.

There are two types of diamond stones, differing in the way they are coated:

- Galvanic bonding, in which nickel crystals are applied to a working surface lubricated with a special glue. Stones with such coating can sharpen a blade quickly and efficiently. Such a double-sided block is bad because the coating is not renewed, gradually grinding down to the base. When working, scratches may also remain on the blade;

- Organic bond – they use diamond crystals, which slightly reduces the sharpening speed, but also protects the knife from scratches. The bond layer is continuous, which allows the stone to be ground down to the last piece.

Ceramic

Ceramic sharpening stones are used quite often; their main producers are China, Poland and Germany. They consist of a mixture of electrocorundum and silicon carbide, bonded together with a special substance. Their main advantage is durability. Having medium or fine grain, they take an extremely long time to wear out. Such bars will last for a long time.

The disadvantage of ceramics is the strong contamination of the working surface with metal chips formed during sharpening. Because of this property, ceramic stones are more often used to remove scratches after treatment with stronger materials, such as diamond stone. When using a ceramic bar, you must use a lubricant, such as a solution of detergent or soap. They also have a relatively low price; you can find options from 400-500 rubles.

From Arkansas stone

The stone material is rare in nature - most deposits are located in America, the state of Arkansas. Due to the high cost of mining this stone, its cost starts from several thousand rubles. Arkansas stone sharpening stones have a fine crystalline structure. They consist of natural compressed quartz, which gives them high abrasiveness. There are 4 types of stones:

- Soft;

- Solid white;

- Solid black;

- Solid transparent.

Such a sharpening stone in the form of a bar is capable of removing a very thin metal layer from the blade, which ensures high-quality, durable sharpening. The whetstone is used for straightening knives and various tools. When working with stone, it is recommended to use a special lubricant or oil, otherwise the working surface will become clogged. It will be extremely difficult to clean it later.

From Japanese water stone

The material for them is mined in the deposits of Japan, which have recently significantly depleted their reserves. Such water stones for sharpening knives are also called “touchstone”. They have a fine-grained structure. They are similar in grain size to Arkansas stone bars, but are softer. In Japan, such a block has been used since ancient times for sharpening knives and traditional weapons: tanto, katana and samurai swords. The cost of high-quality products can reach significant amounts of several thousand.

Before starting work, it is recommended to soak the stone in water for twenty minutes. This will clear the pores of dirt and restore the abrasive surface. If during sharpening several bars with different abrasiveness will be used, then each needs a separate container with water. This will avoid clogging the finely porous surface of one stone with particles of another, larger one.

A huge advantage of a whetstone in the form of a whetstone made of this material is its ability to restore a blade with any degree of damage. The only drawback is the rapid wear of the surface. To restore the original appearance, professionals grind the stone down with hard sandpaper.

Artificial bars

An equally common type are bars made of artificial materials such as corundum, carbide, silicon and chromium oxide. These are the best sharpening stones for knives. Their surface is covered with crystals, which are stronger than steel, which makes it possible to cut off a thin layer of metal during operation. A special base is used as a holding material, the material of which is softer than steel and the crystals deposited on it. This property allows spent crystals to fall off the base, which helps restore the working surface.

Artificial bars are not inferior in quality to natural products, which makes them a good alternative at a fairly low price - from several hundred rubles. This type of stone is widespread throughout the world.

Sharpening stones for machine tools

Sharpening stones for machine tools vary in shape and composition. They can be used for sharpening not only cutting tools, but also any other metal products. Most often you can find a stone made of silicon carbide, but the most durable is considered to be CBN - an abrasive material based on boron nitride, which makes the tool as durable as possible.

All sharpening stone attachments for machines are divided into two types: black – the most resistant/strong and green. The first is used for rough sharpening of the cutting surface, while green is used to bring it to the desired state.

Sharpening machine 150 mm Titan BNS25-150

Sharpening whetstone - the age-old companion of knives

With the use of the first bronze weapons, it became necessary to maintain them in good condition. The introduction of new metal tools into primitive everyday life also dictated the need for artisans capable of giving the blade the required sharpness.

It was in those days that the ancestor of whetstones for sharpening knives appeared. The first touchstones were oblong-shaped stones made from sandstone and silica rocks. Later, each warrior had with him a small whetstone for sharpening his weapons.

Which sharpening stone to choose for kitchen knives

For kitchen knives, it is better to choose a water sharpening stone - they “work” faster and allow you to straighten the cutting surface without changing tools until you get the desired result. But you need to remember that some knife materials can rust when in contact with water, which will hopelessly ruin your kitchen tool. In this case, it is better to use oil sharpening stones - sharpening takes a long time, but it is always of high quality, and the blade of the knives does not rust.

As for the grit level of the whetstone, 1500 grit is sufficient for kitchen knives, because 240 grit is too coarse an abrasive surface that greatly thins the knife blade.

How to choose a sharpening stone for tools

The selection of a whetstone should be made taking into account the following parameters:

- Abrasive grain size . It can be small, medium and large. The latter is necessary to eliminate chips on the surface of the cutting tool, because only coarse grain size can remove layers of damaged metal.

- Material of manufacture . In terms of characteristics and service life, synthetic sharpening stones are many times superior to natural ones, but this ratio is appropriate to take into account only when choosing a device from the middle price category. If you are planning to purchase a high-quality sharpening stone, then you should pay attention to Japanese manufacturers.

- Dimensions . If a stone is purchased for sharpening kitchen knives, then the shape and size practically do not matter. But if you constantly use a sharpening device on hikes, at work you should choose small sizes, even pocket-sized options.

What grit to choose for sharpening a knife

The grain size for sharpening a knife should be selected depending on the goals pursued; experts say that you need to have at least 3 stones in your arsenal:

- 120 grit – for rough metal processing;

- 1000 grit – to level the surface;

- 2000 grit – for straightening the blade.

But practitioners believe that knives can be sharpened with a stone with a grain size of 1500 grit. Such kitchen tools come straight from the store sharpened and only need to be slightly adjusted during use.

Grit selection

The grit of sharpening stones (abrasiveness) is the number and size of the particles that make up a particular type of sharpening stone. With a large grain size, sharpening stones will erase the metal layer from the blade faster and more roughly; it can easily leave scratches and burrs. Such bars are used to change the shape of the blade or to quickly process it initially, which makes it possible to remove large chips and scratches from the damaged surface. In the future, you can use a more abrasive, soft whetstone for sharpening. Soft sharpening stones are used to finalize the blade to remove scratches and abrasions and polish it to a mirror shine.

It is best to have a large selection of stones of different grain sizes. This will allow you to choose the best option in each specific case. To sharpen knives, it is recommended to use several types of abrasive, starting with harder ones and gradually moving to soft ones. Since an ordinary kitchen knife interacts with ceramic plates and other hard materials every day, there is no point in using soft stones right away. Hard Arkansas-type whetstones or hard synthetic whetstones are best, as they give the knife a distinctive shine when sharpened. For scissors, slightly stiffer types are used, as this avoids too many particles from soft stones getting into the metal.

If you start sharpening a knife with a material that is too soft, the sharpness of the knife will be extremely fragile - the knife will become dull quite quickly. You shouldn’t use abrasives that are too hard either, as they will leave a lot of scratches and chips on the blade.

How can you more accurately determine the grain size of a sharpening stone? For this purpose, there are special tables of grain size, which indicate its coefficients depending on the materials. A table for sharpening stones allows you to determine what grit is needed for each type of knife.

How to make a whetstone with your own hands

You can make your own whetstone from ceramic tiles or silicon carbide and epoxy glue, but first you need to prepare a template and then follow the instructions.

From ceramic tiles

You need to take a fragment of ceramic tile measuring 30x8 cm; if there are mortar residues on the back side, then they must be removed. The relief side of the ceramic tile is ground down on a grinding wheel or sand-lime brick by active friction. During this process, fine abrasive dust will be formed - it must be removed periodically. You can bring the surface completely smooth with regular sandpaper.

As soon as the back side of the ceramic tile becomes smooth, the remaining abrasive particles are removed/washed off and completely dried. The whetstone is ready, you can use it to sharpen your kitchen knives, but you will definitely have to sharpen them until they are impeccably sharp and smooth.

Watch the video on how to make a whetstone for finishing a knife from ceramic tiles:

Made of silicon carbide powder and epoxy glue

You need to purchase 100 g of silicon carbide powder, prepare a wooden board with cuts on one side to fix the abrasive bar, and epoxy glue. For ease of work, you should wear medical gloves and use syringes.

Execution order:

- Mix 6 cubes of resin and 1.2 ml of glue (epoxy glue preparation kit) in a bowl.

- Mix thoroughly and add a little abrasive powder.

- Stir again and add silicon carbide powder again - this must be done until the dry material runs out.

Next, you need to prepare a cardboard box of the desired shape (a rectangular or square block is needed) and pour the prepared adhesive mixture into it. Cover the top with a board, sawn side down, and press down with a weight.

Cardboard boxes of the desired shape

After 3-4 days, the glue will completely harden - and the block is ready for use. You will need to clean its edges and trim it with a file. To make the surface abrasive, you need to drop water on it and rub the frozen surface with a piece of glass with a small amount of sand.

Homemade sharpening stone for knives is ready

Such homemade sharpening stones do not have a long service life, but can be useful in force majeure circumstances.

Sharpening household tools

To sharpen kitchen or woodworking tools, it is most practical to purchase a double-sided sharpening stone: large/medium or medium/fine (size of abrasive crystals). Natural stones are not taken into account, since they require a certain skill.

For the above purposes, diamond stones for sharpening knives produced by the Venev plant are quite suitable. The domestic enterprise, located in the Tula region, is a monopolist in the field of diamond tools on the Russian market.

Some Venev bars exhibit a manufacturing defect - problems with flatness. This deficiency is not critical and can be corrected. To sharpen any tool, you need to secure a block or stone on a flat surface, since you will need both hands when working.

The fasteners can be factory-made or ordinary planks nailed to the workbench as a stop. When sharpening a knife, you need to grab the handle with your right hand and the blade with your left (for right-handers) and try to use the entire surface of the stone for even chipping.

Place the tool with the butt towards you and the blade away from you, placing it on a stone. Sharpening is done by moving the stone away from you and slightly to the right, sharpening the left side. To sharpen the right side, the handle is taken in the left hand.

Both sides are sharpened the same number of times. Do not change the angle of the blade in relation to the block, otherwise the cutting edge will quickly become dull.

You need to grind until metal dust forms, check the sharpness on a sheet of paper - the knife should cut the paper freely with minimal effort. If the result is the opposite, you need to repeat the procedure. You can wash off abrasive particles from the knife and stone after work or during the sharpening process.

Sharpening scissors is easier and faster than sharpening knives. When you need to quickly sharpen scissors for several uses, you need to take a glass bottle or any cylindrical metal object (a needle will do).

Next, this equipment needs to be cut with scissors - literally. That is, make cutting movements across a metal object or along the neck of a glass bottle. This sharpening gives sharpness for a short period.

For best results, you need medium sandpaper, a file or a fine-grit sharpening stone. When using abrasive sandpaper, you simply need to cut it or rub it with scissors on the blade with the outer chamfers (cutting plane).

The internal parts of the blades cannot be sharpened - this can lead to complete malfunction of the tool. When using a file, you need to sharpen from the joint of the blades to the tip, running it along the outer edge of the blade.

When using a small whetstone, you can also work as with a file, and when using a large one, put scissors on it and also sharpen the outer cutting edge.

When sharpening, be sure to observe the angle; if it decreases or increases, either the wear of the blade will increase or the cutting ability will decrease. It is not recommended to check the sharpness of the tool using your own body parts.

So, some citizens test the sharpness of a knife by cutting off the hairs on their hand. The paper method is much safer. An abrasive corundum stone of medium/fine grain size is suitable for sharpening a meat grinder knife.

It is necessary to sharpen in a circular motion clockwise; together with the knife, the grate is also sharpened in the same way. During work, it is necessary to constantly wet the surfaces and carefully monitor the planes of the knives to prevent distortions.

When the cutting planes are sharpened to a shine, you should apply the knife to the grate and check for gaps between them - there should not be any.

Modern human life is accompanied by a variety of metal tools, which, in turn, require attention and care. To this day, for 5,000 years, sharpening stones and stones have been coping with this task, the demand for which is only increasing every year.

Source: warbook.club

Stone for dressing water stones

When using water stones, irregularities form on their surface, which impairs the quality of sharpening knives and other cutting tools; you can correct them:

- sandpaper;

- silicon carbide powder;

- sand;

- diamond block.

But it is easier and faster to sharpen the sharpening tool with special stones - synthetic water stones with diagonal cuts along the surface of the same depth. They can be hand-held or tabletop. In the first case, straightening is carried out with a stone with cuts, in the second, the damaged whetstone is ground/straightened on a fixed one.

The most popular stones for dressing water stones:

| Name | Description | Photo |

| Table stone from the Large series NANIWA Flattening Stone for Sharpening Stones (Truing Stone) | It has the same grain size (24 grit) and is made of silicon carbide. | |

| Table stones from the JUUMA Flattening Stones series | Made from aluminum oxide, they are a series of four stones of different grain sizes. It is noteworthy that they are able to rule even each other. | |

| Suehiro Hand Stones | They have a medium grain size (200 grit), are intended for straightening synthetic water stones, correcting both subtle unevenness and deep “pits” and grooves. |

A little theory

The modern process of sharpening a cutting edge is conventionally divided into three stages: roughing, sharpening, finishing. Accordingly, sharpening stones/stones of various grain sizes are used for metal processing: coarse-grained, medium-grained and fine-grained.

The concepts of hard, medium and soft whetstones/stones also apply. The concept of grit is the size in microns of crystals (grains) that remove metal layer by layer.

Coarse-grained bars are designed for rough work: they inaccurately process the blade, removing metal in large fractions. Fine-grained stones grind down the irregularities left by a larger stone, thereby bringing the cutting edge to perfection.

When working with some stones, it is necessary to moisten them with water or oil.

This is due to two reasons:

- There are samples of stones/bars that work extremely inefficiently without lubrication and wear out quickly. When a cutting edge rubs against a stone, the water between them is a kind of reagent that forms a suspension with the abrasive. Thanks to this very suspension, the block grinds off the metal. A striking example of such stones are Japanese water stones.

- When metal rubs against the surface of the whetstone, particles of stone and metal clog the pores of the whetstone, reducing its abrasive ability; the flow of water washes away excess dirt, keeping the working surface of the sharpening whetstone intact. It should be noted that the abrasive, when sharpened dry, can scratch the polish of the blade, which is also not very good.

Stones for knife

Ceramic and diamond stones are used for knife blades in the kitchen. They are characterized by fine grain and therefore cannot sharpen the cutting surface efficiently - usually such kitchen devices are used for quickly straightening the blade.

The service life of such blades is short, the abrasive coating on them is thin. Some manufacturers produce a device with three stones - coarse, medium and fine, which makes it possible to increase the level of sharpening of kitchen knives.

How much does a whetstone cost?

A whetstone can cost 116 rubles or several thousand - it all depends on several parameters:

- material of manufacture;

- manufacturer;

- surface graininess.

The average price of a whetstone, where the price/quality ratio can be called optimal, is 3-6 thousand rubles.