08/19/2020 Author: VT-METALL

Issues discussed in the material:

- Metal turning technology

- Metal turning equipment

- Cutting tools for metal turning

- Types and causes of defects after metal turning

- Safety precautions when turning metal

Metal turning is one of the most popular technologies for manufacturing parts using special equipment. It is based on a method for removing excess layers from a workpiece to make it meet the specified parameters.

Turning allows you to produce various parts from most known metals: steel, copper, titanium, bronze and many others. In our article we will talk about the basic principles of this technology, describe the equipment and tools, and also analyze the types of defects and ways to prevent them.

Equipment and tools

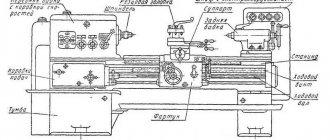

On lathes, workpieces are processed by rotating them around a horizontal and vertical axis. The main tool used is cutters. All turning equipment is marked with the number “1” and is divided into 9 types, taking into account the features of the device.

The tool rotates using a special device on the caliper. Grinding and milling work is performed on a lathe.

Types of lathes

There are main types of lathes used in production:

- screw-cutting lathe;

- turning-turret;

- rotary turning;

- turning and grinding;

- lobotocar.

Screw-cutting lathes are the most widely used. They process long parts such as shafts and short cylindrical ones.

Carousels are used for the manufacture of bushings, rings and other large parts whose diameter is greater than their height.

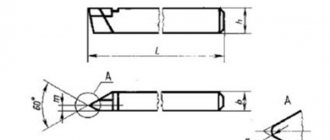

Classification of incisors

According to the location of the cutting edge and the direction of movement of the caliper, cutters are divided into two types:

- rights;

- left.

According to the shape of the working part:

- straight - the working part and the body have common lateral surfaces;

- bent - the cutting edge protrudes beyond the plane of the body and has a variable cross-section.

For external processing, types of cutters are used, named after the operations they perform:

- checkpoints;

- groove;

- shaped;

- threaded;

- boring

Lathe equipment is widely used for machining ends. At the same time, face and cutting cutters are installed on the caliper. In addition, the following are mounted on the tailstock:

- drill;

- countersink;

- taps;

- boring cutters.

There are certain geometric parameters of the cutter that are applied to the wedge. The cutting edge can be located at an angle to the direction of movement and perpendicular. For cutting tools - parallel to the axis of rotation.

Metal turning

Introduction of CNC

With the advent of CNC machines, the processing of parts with complex radial and involute surfaces has become much easier. Productivity has increased in the production of large batches.

Several operations are performed on one installation, including milling. The equipment may have 2 movable supports and several turrets.

Equipment and tools

The technology of turning works involves the use of special equipment - lathes. With their help, parts are produced whose shape is a rolling body. In modern production, seven main types of lathes are used:

- turning-turret – designed for the production of small parts in large quantities; equipped with a turret head, which allows you to quickly change the cutting tool and reconfigure the equipment for another type of work;

- screw-cutting lathes – characterized by the ability to combine high rotation speed of the chuck with longitudinal movement of the tool; used for large-scale and mass production;

- rotary lathe – universal machines with a faceplate and a large frame;

- turning and milling – universal equipment for individual, mass and serial production of parts with complex shapes;

- automatic lathes – machines with a large number of spindles, designed for the manufacture of parts with complex geometry of multi-profile surfaces;

- frontal lathes - specialized equipment for working with frontal surfaces; used for piece production of parts, as well as for small series.

Time to complete work

Production time depends on many factors. The main ones:

- Complexity of the product;

- Availability of well-drawn drawings that show all dimensions! ;

- Number of products;

- The workload of our production;

- Availability of necessary materials for production.

If necessary, you can order urgent turning work, such orders are launched on the same day, but you need to understand that the price for this work will be at least twice as high, since production is constantly busy and in order to start an order on the same day you need to send turners to the second shift. Which is overtime and requires at least double pay.

Other types of lathes

In addition to the metal lathes listed above, there are several other types of equipment.

Due to its high cost and large dimensions, it is used in large-scale mass production of various parts of machine mechanisms - shafts, bushings, products of complex profiles with holes that are not coaxial with the axis of the part, etc. Similar machines include: Rotary lathe - processing equipment large-sized workpieces (over 2000 mm in diameter).

Turret lathe – a machine for manufacturing parts from calibrated rods. The cutting tool in this machine is mounted on a rotating drum, into which individual blocks with equipment fixed in them are inserted.

CNC machines and machining centers are a separate type of machine that reduces the participation of the master in the processing process to a minimum and ensures high accuracy. Such equipment can perform a great variety of operations, while the operator is assigned the role of an observer and his main task is to remove finished parts; the machine performs all other actions independently according to a given program, which is compiled by a specialist.

Note: there are machines that can be converted to process not only metal, but also wood (Jet BD-7). They have the ability to mount a stop for chisels. Please pay attention to this if you are working with various materials.

Our capabilities - what kind of work we do

- all types of technological operations according to customer drawings - from simple trimming to shaped boring;

- turning parts up to 700mm in diameter, up to 1500mm in length;

- turning of various materials – from hardened steels to rubbers

- cutting any standard or non-standard threads according to specified parameters;

- we will perform turning of shaped surfaces, including spherical ones;

- turning production of screws with screw surfaces of variable pitch and diameter.

The main stages of manufacturing a part using the turning method

Turning is performed using special cutters: turning chisels. They are equipped with elongated handles, which allows you to hold the tool securely. There are different types of chisels. A semicircular is required for roughing.

- Carrying out the first pass, remove chips to a thickness of 1-2 mm. Use the middle (middle) part of the chisel. All subsequent passes are performed only with side parts.

- Remove chips until 4-5 mm of metal remains for finishing. When moving to it, change the tool to an oblique chisel and place it on the edge.

- By pressing evenly on the tool, finishing is performed. If you need to make an internal hole, use cartridges and face washers.

- Check the accuracy of the work performed using calipers, calipers, micrometers, nutrometers, etc.

Types of turning work

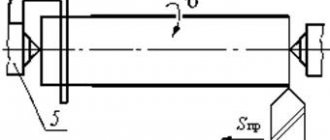

The difference between turning and milling is that the part rotates on the lathe, and the cutter and other auxiliary tools are fixedly fixed in the tool holder or tailstock. In this way, rotation parts are obtained that have a cylindrical and conical shape. Typical parts in turning are considered to be: body, nut, cup, bolt, pin, flange, washer, shaft, bushing, gears and others.

Modern cutting tools make it possible to obtain complex elements of almost any configuration. The main turning operations include:

- treatment of external surfaces;

- trimming ends and ledges;

- turning grooves and cutting off the workpiece;

- processing of internal surfaces and turning of internal grooves;

- drilling, countersinking, reaming, lapping;

- cutting external and internal threads with a cutter or tap;

- processing of surfaces of complex shape;

- rolling corrugation.

In metalworking there is the concept of quality and cleanliness of processing. For complex and critical components, it is often necessary to produce parts that correspond to an 8-12 accuracy grade, and the roughness of the processed surfaces must be at least class 5-6. This quality of workmanship is achieved by using modern carbide tools and processing on precision lathes. The qualifications of a turner or CNC machine operator must be at least level 5.

Turning work also consists of mandatory instrumental control of the workpiece. It takes place in two stages: the first is the control of linear dimensions by the worker himself during the operations performed, the second occurs during the final check in the quality control department. Monitoring compliance with the specified parameters is carried out using the following measuring instruments:

- calipers and depth gauges;

- smooth and threaded micrometers;

- end gauges (plugs, staples, tiles);

- rings and templates for checking threads;

- indicators and special devices;

- measuring machines.

Accurate adherence to part manufacturing technology allows us to produce parts in small and large batches, as well as individual products with high accuracy and a minimum level of defects.

Safety precautions when turning metal

Certain safety precautions must be observed when performing operations on turning equipment. Otherwise, you can damage the product, break the cutter, or get injured:

- We must not forget about protective work clothing. The kit should include: a robe, a headdress, fully closed shoes, and safety glasses. Neglect of equipment can lead to burns and wounds from chips and flying metal fragments.

- You cannot work with gloves!

- The cutters must be well sharpened and, when using a lathe, centered and secured.

- You need to hold the chisels firmly with both hands when working with them.

- It is imperative to rough the workpiece before shaping it.

- You cannot be distracted and leave the working machine unattended.

- You shouldn’t rush, you need to correctly calculate your strength when feeding manually.

Working metal on a lathe requires practice. Each new machine must be mastered, and different operations must be tried on defective workpieces. This will provide an opportunity to understand the characteristics of the equipment, gain greater accuracy and achieve increased productivity. By following the recommendations listed above, you can get excellent results and also avoid defects and injuries.

Daily maintenance of lathes

High-quality spare parts for machine tools and timely care of parts of turning and screw-cutting equipment ensure long service life of the machine and the quality of manufactured parts. The most important thing when servicing a machine is to prevent damage to its functional parts, so every day after finishing work it is necessary to carry out simple manipulations to care for and prepare the equipment for the next operations. They include:

- cleaning the surface from various technical debris (chips, dust, etc.);

- dissolving dirt and oily stains with kerosene, wiping elements dry;

- oil lubrication of all parts without paintwork;

- filling the grease fittings with grease.

How to choose a favorable balance of quality and cost?

The meaning of the quality indicators of turning and the analysis of the reasons that cause them allow us to draw a simple and logical conclusion : it is possible to make a part as high-quality as existing technologies allow today - if you take the most modern machines, the best tools and the most highly qualified turning professionals for this .

And if you require truly exemplary quality, we are the ones who can provide it. Because we have advanced equipment, use tools from the world's best companies, and the work is performed by craftsmen whose level is confirmed by both experience and qualifications.

We can make the perfect part for you – but you won’t always need such a part. Because as quality increases, so do the costs of doing the work. This means that the quality does not always have to be exorbitant - but it should always be what you need. And you can always find a reasonable balance between the quality of the parts manufactured by our company and the cost of this production - after all, acceptable quality can be obtained with us on a simpler machine and at a lower price.