The mechanical properties of steel made with alloying additives meet the stringent requirements for industrial use. To obtain steel with certain properties, silicon, manganese, chromium, titanium, molybdenum, tungsten, nickel and other chemical elements are introduced during the smelting process. One of the special steel grades produced is 60C2A, which has high strength and pronounced springing properties. The main feature of this steel is its increased yield strength. This feature makes it possible to produce various products with spring properties.

Chemical composition

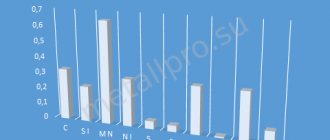

In addition to iron, grade 60C2A steel contains about 0.6% carbon, 1.6 to 2% silicon, 0.6 to 0.9% manganese, up to 0.3% chromium, up to 0.25% nickel and up to 0. 2% copper. In addition, impurities of sulfur and phosphorus are allowed in amounts up to 0.025%.

Purpose of alloying components

Steel is an alloy of iron and carbon in an amount of up to 2.06%. Increasing the amount of carbon increases sensitivity to heat treatment, hardenability, and the ability to obtain greater strength and hardness. But at the same time, ductility decreases, the metal becomes brittle, unable to withstand shock loads.

In order to balance the properties of the material, simultaneously obtain opposite characteristics (hardness and toughness, strength and corrosion resistance), and reduce the influence of impurities that cannot be completely eliminated, 60C2A steel includes alloying components. They make it possible to neutralize the disadvantages introduced by a high amount of carbon. And in some ways replace it, getting even better results.

Silicon is introduced into the composition for the purpose of deoxidation. Possessing a greater affinity for oxygen than iron, it displaces it from oxides in the melt.

In addition to deoxidation in amounts up to 1%, silicon has a beneficial effect on strength and elasticity.

Manganese, like silicon, displaces iron from oxides. In addition, it prevents the formation of iron sulfides, which increase the tendency to form hardening cracks that occur during thermal hardening of parts with complex shapes.

The inclusion of manganese in the alloy up to 1%, like silicon, increases strength and toughness. In large quantities, it causes grain growth, which reduces strength indicators, in particular the ability to withstand shock loads.

Thus, silicon and manganese mutually complement each other in composition. They work together to increase strength, endurance and toughness. But the reasons leading to increased fragility of the alloy are not allowed to develop.

Chromium, like silicon and manganese, has a greater affinity for oxygen than iron. It helps protect the melt from oxidation and increases hardenability.

Nickel helps protect the alloy from corrosion and, in small quantities, reduces the susceptibility to hardening cracks.

Copper in small (up to 1%) quantities increases strength and resistance to corrosion. At higher concentrations, it leads to the precipitation of intermetallic compounds along grain boundaries, which significantly changes the mechanical properties during tempering.

Comparing the chemical composition and the influence of individual components on the properties of the alloy, it can be assumed that the 60C2A grade should have high strength, elasticity, and impact strength, achieved by observing special heat treatment techniques.

General characteristics of steel

By the way, a metal alloy such as steel can be found in the automotive industry, when it is necessary to produce some spare parts for cars.

This alloy is perfect for making parts for aircraft, various instruments, as well as many other building structures and some tools. Such widespread use of steel is justified by the fact that this alloy has many positive properties:

- Physico-chemical.

- Mechanical.

- Technological.

If you try to change the chemical composition of this widespread alloy, then you can get it with different properties. This difference will allow it to be used in many industries , not only those related to technology, but also to the national economy.

All carbon alloys have a classification. This division may be based on the following factors:

- Carbon content.

- Purpose.

- Quality.

- Degree of deoxidation.

- The structure is in an equilibrium state.

Mechanical properties of steel 60С2А

The strength properties of 60C2A are determined by the heat treatment modes performed. Since the interest is in the performance characteristics of the parts, the article does not discuss the performance of steel in castings. They are of practical interest only for technologists of large metalworking enterprises engaged in the production of rolled metal.

Here we will consider the strength indicators of commercial steel in the form of a circle and a strip.

As already mentioned in the general description of the 60C2A brand, optimal performance is achieved by quenching in oil and subsequent tempering in order to relieve internal stresses.

Round steel after quenching and tempering has a tensile strength of 12.7 kg/sq. mm, proof strength 11.7 kg/sq. mm. The proximity of the yield point to the tensile strength indicates the high elastic properties of steel.

The endurance limit of 60C2A with a symmetrical tensile cycle is 49 kg/sq. mm, torsion 29.5 49 kg/sq. mm.

To understand the meaning of these numbers, it is worth remembering that the tensile strength of steel 3 is about 37 kg/sq. mm.

Heat treatment

Hardening is carried out at 870 degrees, the product cools in an oil bath. Tempering is carried out at 470 degrees, which makes it possible to obtain troostite (ferrite-cementite structure). It maintains a hardness of 35-45 HRC.

Temperature treatment is:

- initial – annealing;

- final – hardening;

- middle - vacation.

Tempering increases the hardness of 60S2A steel to 365-445 HB. If the coiling of the spring is carried out with a single heating, then the next stage is heat treatment.

Application of grade 60С2А

The scope of use of steel is determined by its properties. Steel 60S2A is widely used for the manufacture of heavily loaded structural elements experiencing alternating loads.

These are various springs, friction discs, Grover washers, spring rings, collets, torsion bars - elastic rods that work in torsion. The latter are found in suspensions of heavy tracked and wheeled vehicles, elastic shafts of multi-threaded gearboxes that transmit high power.

Hardening

Hardening is carried out in a shot blasting machine, in which each point is exposed to shot for 20-30 seconds. Feeding is carried out at a speed of 70-100 kg/minute, the diameter of the elements is 0.8-1.2 mm. This treatment creates an even silver color.

The second treatment option is captivity. The spring is kept in a compressed state for 20-40 hours. The procedure is carried out after heat treatment of steel 60C2A. Repeated compression (5-10 times) and shot peening are also used.

Briefly about the 60 gates in the 2 lines of Human Design (60.2 Adaptability, Determination)

60.2 Determination / People with the potential to bring lasting change to the world / Gate of Acceptance (challenge?) / Broken Chalice / Sidhi-Dar-Shadow: Justice-Realism-Limitation

There is always something in your life that you feel is limiting you and preventing you from developing. By your behavior, you demonstrate that you accept the restrictions, although inside you may feel depressed because of this.

Determination. Saturn is exalted. Understanding the nature of limitation in order to accept its restraint when necessary and thus be able to take advantage of opportunities when they arise. Energy that can adapt to restraint. The earth is in decline. Adaptation to containment that becomes habitual and maintains the nature of the constraint even though it no longer exists. Energy for adaptation that can become stuck without the possibility of mutation.

Astromech of 60 gates in 2 lines

Egocentric interpretation

When we get to the second line, we get an outward projection. These people project outwardly that they can accept limitation. Many of them may suffer from pressure in their lives. Remember that this is just a projection of the nature of this hexagram coming out. This does not necessarily mean that they accept restrictions. What they project outward is that they accept the limitation. This line is called Adaptation.

Situations:

Nine second. You will not leave the outer courtyard. Misfortune.

Give up your usual way of thinking and acting. Reconsider your views on what is happening, otherwise the path will be closed. Adapt and fit into your environment.

Exaltation

A. Limitations are Saturn's favorite theme and he exalts the line. Saturn provides energy that can adapt to limitation. An understanding of the nature of constraint is developed in order to accept those constraints when necessary and thus take advantage of opportunities when they arise.

Energy that can adapt to restraint. Basically, these people project outwardly that they are limited. They don't know that there is something on the other end of the MS. So every time someone breaks through this, they have a door to this limitation. Generally speaking, these people will always be reserved, and in this restraint, accepting this limitation as a projection, there cannot be a deep melancholy within: Why am I accepting this limitation? Is this limitation really valuable? Is this constraint the right constraint? Is this limitation a mutation that I need?

A fall

B. Pragmatism and down-to-earth views, characteristic of the Earth, lead the line of opportunism to decline. Under the influence of the Earth, adaptation to limitation is strengthened, which becomes habitual and maintains the nature of the limitation even when it no longer exists. Energy appears for adaptation, which can get stuck without mutation occurring.

The second line will accept the limitation and will have the reserved, exalted side always open to the possibility that the limitation will end and then it will seem that: "Accepting the limitation was the right thing to do."

On the decline side of this energy: energy for adaptation, which can get stuck without possible mutation. The restriction suddenly goes away. For example, you have someone who walked every day in West Berlin. When he got to a place where there was a wall, he would turn around and go home. When the wall was removed, he could not cross this line. The limitation is gone, but there is no mutation, no change in path or method. This is the other side of the second line.

There is a deep dependence on second line limitation: people who are addicted to their medicine even when they are healthy.

You may also be interested in: karmic purpose here, compatibility in love relationships, psychosomatic reasons here, keys of the matrix of fate https://matix.fractalhd.ru/, human design human design, fortune telling with tarot cards is the most accurate

Steel 65G

Spring steel 65G is characterized by increased wear resistance, while being relatively cheap. It is these characteristics that have allowed this type of steel to find wide application in mechanical engineering.

Washers, springs and springs, bearing housings, brake bands and discs, flanges and gears, feed and clamping collets, as well as other elements of components and structures - all of this is made of 65G steel. As a rule, rear axle leaf springs in trucks are made from it. Not used in welded structures and for work with shock loads.

Steel 65G, like any spring steel, has good cutting properties and can be oxidized (blued, blackened). 65G strip or sheet are successfully used for making knives.

Throwing knives are mainly made from this steel, and less often - cutting knives. Cossack checkers are made from 65G steel using the forging method.

It is believed that 65G steel is one of the cheapest materials for making knives, so knives from this steel will be made for a long time.

Similar physical and mechanical properties made it possible to use 65G sheet instead of such types of steel as 55S2 and steel 60S2A, 70 and 70G. You can also replace the use of U8A and 9Khs steel. Often when the phrase “spring steel” is used, they mean 65G steel.

Chemical composition Art. 65G

| Silicon (Si) | 0.17-0.37 |

| Copper (Cu), no more | 0.20 |

| Manganese (Mn) | 0.90-1.20 |

| Nickel (Ni), no more | 0.25 |

| Phosphorus (P), no more | 0.035 |

| Chromium (Cr), no more | 0.25 |

| Sulfur (S), no more | 0.035 |

Technological properties

| Started 1250, ended 780-760. Cooling of workpieces with a cross-section of up to 100 mm is carried out in air, while those with a cross-section of 101-300 mm are cooled in a mold. |

| not applicable to welded structures. KTS - no restrictions. |

| In the quenched and tempered state at HB 240 and sB = 820 MPa Ku tv.spl. = 0.85, Ku b.st. = 0.80. |

| prone at Mn content>=1\% |

| Flock sensitivity |

| insensitive |

| Ac1 | 721 |

| Ac3 | 745 |

| Ar3 | 720 |

| Ar1 | 670 |

| Mn | 270 |

Impact strength, KCU, J/cm2

| +20 | -20 | -30 | -70 | |

| 110 | 69 | 27 | 23 | 12 |

| 725 | 431 | Hardening 810 C, oil. Holiday 400 C. | |

| 480 | 284 | Hardening 810 C, oil. Holiday 500 C. | |

| 578 | 1470 | 1220 | HB 393-454 |

| 647 | 1420 | 1280 | HB 420 |

| 725 | 1690 | 1440 | HB 450 |

Hardening 800 °C.

| 1.5 | 3 | 4.5 | 6 | 9 | 12 | 15 | 18 | 27 | 39 |

| 58,5-66 | 56,5-65 | 53-64 | 49,5-62,5 | 41,5-56 | 38,5-51,5 | 35,5-50,5 | 34,5-49,5 | 35-47,5 | 31-45 |

| 50 | 30-57 | 10-31 | 52-54 |

| 90 | Up to 38 | Up to 16 | 59-61 |

Physical properties

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 215 | 213 | 207 | 200 | 180 | 170 | 154 | 136 | 128 | |

| 84 | 83 | 80 | 77 | 70 | 65 | 58 | 51 | 48 | |

| 7850 | 7830 | 7800 | 7730 | ||||||

| 37 | 36 | 35 | 34 | 32 | 31 | 30 | 29 | 28 | |

| 20- 100 | 20- 200 | 20- 300 | 20- 400 | 20- 500 | 20- 600 | 20- 700 | 20- 800 | 20- 900 | 20- 1000 |

| 11.8 | 12.6 | 13.2 | 13.6 | 14.1 | 14.6 | 14.5 | 11.8 | ||

| 490 | 510 | 525 | 560 | 575 | 590 | 625 | 705 |

Application of steel 65G

Used for the production of springs, springs, thrust washers, brake bands, friction discs, gears, flanges, bearing housings, clamping and feed collets and other parts that require increased wear resistance and operating without shock loads; wire of square, rectangular and trapezoidal sections, intended for the manufacture of spring washers; knives of earth-moving machines (bulldozers, scrapers, cultivators, graders and motor graders, as well as for knives of bulldozer and grader equipment of excavators, rollers and other earth-moving machines); flattened heat-treated tape with a thickness of 0.15-2.00 mm for the manufacture of spring parts and springs, with the exception of winding ones; measuring tapes; hardened and tempered carded wire of round and shaped profiles, used for the manufacture of brackets for needle products; wire of square, rectangular and trapezoidal sections, intended for the manufacture of spring washers.

Application of U10A steel.

Standards

| Name | Code | Standards |

| Sheets and strips | B23 | GOST 103-2006 |

| Long and shaped rolled products | B32 | GOST 1051-73, GOST 7417-75, GOST 7419-90, GOST 8559-75, GOST 8560-78, GOST 14955-77, GOST 14959-79, TU 14-1-5416-2001, TU 3-761-80 , TU 14-1-2118-77, TU 14-1-501-73, TU 14-11-245-88, TU 14-1-1271-75, TU 14-136-367-2008 |

| Long and shaped rolled products | B22 | GOST 1133-71, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006 |

| Alloy steel wire | B73 | GOST 14963-78 |

| Ribbons | B34 | GOST 2283-79, GOST 21996-76, GOST 21997-76, TU 14-1-2992-80 |

| Medium and high carbon steel wire | B72 | GOST 26366-84 |

| Sheets and strips | B33 | GOST 4405-75, TU 14-1-1123-74, TU 14-1-1409-75, TU 14-1-1986-77, TU 14-1-2108-77, TU 14-234-61-89, TU 14-130-278-96 |

| Classification, nomenclature and general norms | IN 20 | OST 1 90005-91 |

| Blanks. Blanks. Slabs | B31 | TU 14-1-1213-75 |

Hand over alloy 60S2HFA (GOST 14959 - 79) in St. Petersburg

Steel, structural leaf spring

60S2KhFA is a metal alloy based on iron (Fe), its content in 60S2KhFA must be at least 95%. The alloy 60S2KhFA necessarily contains silicon, chromium, carbon, manganese, and vanadium. The permissible amount of impurities is determined in the chemical composition table.

Urgent demand

- Urgently! Alloys AMS5537 (L-605), AMS5536 (Hastelloy X)

- Urgently! Nickel N-1 (cathode sheets)

- Urgently! Railway rails - scrap, liquid scraps

Private advertisements

- sell ferrous metals, steels and alloys

- purchase non-ferrous metals and alloys

- purchase non-ferrous metals and alloys

- purchase non-ferrous metals and alloys

- purchase non-ferrous metals and alloys

- purchase ferrous metals, steels and alloys

- purchase non-ferrous metals and alloys

- purchase ferrous metals, steels and alloys

- sell ferrous metals, steels and alloys

- sell ferrous metals, steels and alloys

- purchase ferrous metals, steels and alloys

- purchase ferrous metals, steels and alloys

- sell non-ferrous metals and alloys

- sell non-ferrous metals and alloys

- sell petroleum products and their waste

All ads + Add yours Useful tools

- Determine the brand Determine the alloy by composition

- Pipe or angle weight Metal calculator

- For scrap acceptors Calculation of the profitability of the transaction

Determine the alloy by chemical composition Determine the mass by the shape of the product Calculate the profitability of the transaction

Product range

Steel 40x - characteristics and application

There is a large range of products made from 60С2А, as well as similar steels, such as: 60С2, С60, 65 g, 60С2ХА, 60СА2.

There are the following types of rolled products according to GOST: strip, rolled products, calibrated rods, strip, forged blanks, forgings.

Foreign analogues of steel 60S2A include:

- Poland-60S2A;

- Germany-60MnSiCr4;

- Japan-SUP 6, SUP 7;

- Bulgaria-60S2A;

- China-60Si2Mn;

- USA-9260,G92600;

- France-61 SiCr7;

- England-251 H60.

Currently, new structural grades with similar properties are being developed, new methods are being introduced to obtain quality and mechanical characteristics while reducing energy costs for production.

Ra Uru Hu o 60.2 Adaptability, Determination

60.2 Determination▲ Saturn. From understanding the nature of limitations and accepting constraints when necessary comes the ability to take advantage of opportunities that arise. Energy that can adapt to constraints or influences. Earth. Adaptation to a limiting principle or influence that becomes a habit, maintaining the nature of the limitation even when it no longer exists. Energy to adapt, which can get stuck before reaching the final mutation.

Second line people project outwardly that they can accept limitations. Most of them suffer greatly due to the pressure they endure in their lives. Do not forget that this is only the nature of the hexagram projected into the outer world. This does not mean that they actually accept these restrictions. The line is called Determination. Saturn is exalted. From understanding the nature of constraints and accepting constraints when necessary comes the ability to take advantage of opportunities that arise. In the white book: energy that can adapt to a restraining principle or influence. Basically, these people project outward that they are limited by some principle or influence (that something is holding them back). They don't know that there is something on the other end of the channel. Therefore, only from time to time, when someone breaks through this barrier (destroys the barrier), the path to these restrictions is opened for them. Generally speaking, these people will always be under a limiting principle or influence, and in this state, accepting their limitations as a projection, they may experience deep melancholy within. Why do I accept these restrictions? Do they have real value? Are these restrictions going in the right direction? Are they the mutation I need?

On the other hand, we have an adaptation to a limiting principle or influence, which becomes a habit, preserving the nature of the limitations even when they no longer exist, the Earth is damaged. This is the essence of this second line. By projecting outwardly that it will accept the limitations and be at their mercy, exaltation is always open to the possibility that the limitation may end and then there is a feeling: “Aha, it was right to accept these limitations.” The damage is the energy to adapt, which can get stuck before reaching the final mutation. The restriction can suddenly be lifted, it suddenly goes away. These are the people who go for a walk every day in West Berlin. Having approached the place where the wall stood, they turn around and go home. The wall has been removed, but they cannot cross the line. The limitation disappeared, but the mutation did not occur, the path did not change.

The second line is deeply attached to its limitations (narcotically dependent on them). These are people who continue to take medications even when they are healthy.

Commentary on Article 60.2 of the Labor Code of the Russian Federation

1. Article 60.2 establishes the rules for engaging an employee, along with the work specified in the employment contract, to perform additional work in a different or the same profession (position) during the established duration of the working day (shift).

2. According to Part 1 of the commented article, the employer can entrust an employee to perform such additional work only with his written consent and for an additional fee. The amount of additional payment in accordance with Art. 151 of the Labor Code is established by agreement of the parties to the employment contract, taking into account the content and (or) volume of additional work (see commentary to Article 151).

3. In accordance with Part 2 of Art. 60.2 additional work assigned to an employee along with the work specified in the employment contract can be performed by him in the order of combining professions (positions), by expanding service areas, increasing the volume of work, or in connection with the assignment of duties of a temporarily absent employee.

Combination of professions (positions) is the performance by an employee, along with his main work in the profession (position) determined by the employment contract, of additional work in another profession (position) for the same employer during the duration of the working day (shift) established for him. As a rule, the employee is entrusted with combining a vacant position or profession.

In contrast to combining professions (positions), when expanding service areas or increasing the volume of work, the employee performs work in the same profession or position, which is stipulated by the employment contract, but to a greater extent compared to what he performed in accordance with the employment contract.

The performance by an employee of the duties of a temporarily absent employee without releasing him from work in the profession (position) stipulated by the employment contract is permitted both in the same profession (position) that the employee performs in accordance with the employment contract, and in another profession (position).

It should be borne in mind that in cases where, in order to fulfill the duties of a temporarily absent employee, an employee is released from work stipulated by the employment contract, then in this case there is a temporary transfer to another job to replace the temporarily absent employee. Such a transfer is carried out in the manner prescribed by Art. 72.2 (see commentary to it).

4. The law does not establish either a minimum or maximum period for which an employer can entrust an employee to perform additional work along with his main job. In each specific case, the period during which the employee will perform additional work in the order of combining professions (positions), expanding service areas, increasing the volume of work, or in connection with the assignment of duties to a temporarily absent employee, is determined by the employer with the written consent of the employee (Part. 3 Article 60.2). If the employee does not agree with the period determined by the employer, this period may be determined by agreement of the parties. If the parties cannot agree on the period during which additional work must be performed, the employee has the right to refuse to perform it.

The period during which an employee, without release from work specified in the employment contract, will perform the duties of a temporarily absent employee is limited by the period of absence of this employee.

5. According to part 4 of the commented article, the deadline for completing additional work determined by the parties is not binding on them. The employee has the right to refuse to perform additional work ahead of schedule, and the employer has the right to cancel the order to perform it ahead of schedule, warning the other party about this in writing no later than three working days in advance.

At the same time, as follows from the content of this norm, neither the employee nor the employer is obliged to indicate the reason why they early refuse the agreement to perform additional work.