Leadless design (SMD) resistors, like other components, require markings. From it you can get information about the resistor value and its accuracy. But in the case of SMD components, dimensions become a problem. It is impossible to apply a complete alphanumeric designation in a limited space. Marking in the form of color stripes is also not a solution - there is also not enough space to place the required number of tags. Determining the first familiarity location (where to start reading from) will also become a problem: a thickened line or a marking shifted to one side will also require additional space. Therefore, a special notation system has been adopted for leadless elements.

Characteristics

These miniature resistors are perfect for surface mounting. Marking allows you to find out the size, power and resistance of the product.

The shape of SMD resistors is rectangular, square, round, oval, the profile is low. Low-profile elements are placed on the board very compactly and significantly save usable space.

SMD resistors are classified according to a number of parameters, such as:

- Nominal resistance

. This value is measured under certain environmental parameters, the most important of which is temperature. Usually the nominal resistance is considered to be measured at a temperature of +20 °C and normal atmospheric pressure. - Tolerance on nominal resistance

. Possible tolerances are from 0.05 to +5%. The most popular and affordable parts with tolerances of +/-1% and +/-5%. More accurate models must be pre-ordered, and they are much more expensive than less accurate analogues. - Temperature coefficient of resistance change (TCC)

. This parameter characterizes the reversible relative change in the resistance of the part when the temperature fluctuates by 1 °C. Temperature changes in the part are possible due to changes in ambient temperature or self-heating of the resistor. The unit of measurement for this value is ppm. Modern SMD resistors are produced with TCR, the value of which is in the range of +/-5...+/-200 ppm. If parts from the same manufacturer are used to create a circuit, then the values of their nominal resistances and TCR are closer to each other than is reflected in the passport for each part. Therefore, using parts from the same manufacturer allows you to improve the accuracy of the circuit both at a constant temperature and when it changes. - Power dissipation

. This parameter depends on the size and is determined from the table.

Resistor assemblies

Rice. 8. Resistor assembly 4609X-101-222LF

A resistor network (resistors array) is a combination of several resistors placed in one housing. There are a large number of different types of these products, but, unfortunately, there is no clear system of their classification, both in the literature and among manufacturers.

Resistors inside the assembly body may not be connected to each other (Isolated), i.e., each resistor has two terminals on the assembly body, or configured in a specific circuit (Bussed). Often there are products in which pin 1 of each resistor is connected to one common pin of the assembly, and every second pin of the resistors has its own pin on the product body. In addition, you can find assemblies with series, series-parallel and other types of resistor connections inside the housing. Assemblies can be classified by the number of resistors included in them, by tolerance value, maximum operating voltage, power dissipation, standard size, mounting type (SMD and lead-out), etc. These components are very convenient to use in ADC and DAC circuits, used as voltage dividers, used in computer equipment, consumer electronics, etc.

Examples

- 4600X series from Bourns with operating voltage up to 100V

Rice. 9. Bourns 4600X Series Resistor Array Configuration

- CAY16 series from Bourns in SMD size 1206 package with isolated resistors

- Bourns 4114R-2 Series - 14 pin resistors with one common pin

Typical sizes of SMD resistors

The dimensions and shape of these parts are determined by the JEDEC regulatory document. Markings are applied to the housing, which indicate the length and width of the resistor in inches. This is the most common option used by manufacturers, suppliers, and sellers.

For example, 0804 means the part is 0.08 inches long and 0.04 inches wide. In the SI system, dimensions are indicated in millimeters. To convert to millimeters, inches are multiplied by 2.54. Designation of resistor 0804 in the SI system - 2010. Length - 2.0 mm, width - 1.0 mm.

To select the desired type of part and decipher the codes, you can use an SMD resistor calculator or a special “Resistor” program. With their help, you can find out the nominal resistance of an existing resistor or, conversely, find out what the markings for the desired value look like.

Each size of SMD resistor has a certain maximum power dissipation.

| Power, W) | ||

| 0201 | 0,6 | 0,05 |

| 0402 | 1,1 | 0,062 |

| 0603 | 1,6 | 0,1 |

| 0805 | 2,1 | 0,125 |

| 1206 | 3,1 | 0,25 |

Power dissipation

If electric current passes through a resistor, the electrical energy is converted into heat energy and the resistor heats up. Heat is dissipated into the environment. Moreover, thermal energy must be transferred to the environment so that the temperature of the resistor and its surrounding elements remains within normal limits. The power released by the resistor is determined by the formula:

Here V

- voltage in volts across a resistor with resistance R

in ohms,

I

is the current flowing through the resistor in amperes.

The power that a resistor can dissipate without degrading over a long period of time is called the maximum power dissipation

. In general, the larger the resistor body, the more power it can dissipate. Resistors of various powers are produced and you can find resistors from 0.01 W to hundreds of watts. Carbon resistors are usually available in 0.125–2 W ratings.

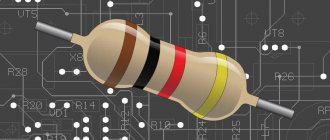

Color-coded 0.125, 0.25, 0.5 and 1 Watt resistors in a computer power supply

Types of markings for SMD resistors

Surface mount resistors are very small parts, so the standard wire-wound system is not suitable for this application. Parts 0402 are not marked, and resistors of other standard sizes are designated in various ways specially developed for them. The choice of a specific option depends on the size and tolerance.

Three or four digit markings

Resistors with tolerances of 2%, 5%, 10% of all standard sizes have designations in which the first two or three digits characterize the numerical value of the nominal resistance. The latter is a multiplier that shows to what power 10 must be raised to get the final result. For example, 103 means a rating of 10,000 ohms or 10 kohms.

In the designation of resistors with a nominal resistance of less than 10 ohms, the letter R is used, which is placed in place of the decimal point. For example, 0R5 - indicates a nominal resistance of 0.5 ohms.

Marking with two numbers and one letter

This option is used for precision (very precise parts with a resistance tolerance of 1% or less), which have very small dimensions. They are marked in accordance with the EIA-96 standard.

This marking consists of two elements:

- numbers - characterize the code of the nominal resistance of the resistor;

- letter - defines a multiplier indicating the power to which 10 must be raised to get the final result.

Markings with numbers at the beginning and a letter after them can be used for parts with tolerances of 2%, 5%, 10%. Such markings are deciphered using tables.

Thermistors sizes 0805 and 0603

| NTC Thermistors EWTF05 Rating: 10 kOhm, 22 kOhm, 47 kOhm, 100 kOhm. | NTC Thermistors EWTF03 Rating: 10 kOhm, 22 kOhm, 47 kOhm, 100 kOhm. |

Resistance marking of SMD resistors of the E24 series with a nominal deviation of 5%

| Marker. | Denomination | I | Marker. | Denomination | I | Marker. | Denomination | I | Marker. | Denomination |

| 0 | 0 ohm | I | I | I | ||||||

| 1R0 | 1 ohm | I | 101 | 100 Ohm | I | 102 | 1kOhm | I | 104 | 100kOhm |

| 1R1 | 1.1 ohm | I | 111 | 110 Ohm | I | 112 | 1.1kOhm | I | 114 | 110kOhm |

| 1R2 | 1.2 ohm | I | 121 | 120 Ohm | I | 122 | 1.2kOhm | I | 124 | 120kOhm |

| 1R3 | 1.3 ohm | I | 131 | 130 Ohm | I | 132 | 1.3kOhm | I | 134 | 130kOhm |

| 1R5 | 1.5 ohm | I | 151 | 150 Ohm | I | 152 | 1.5kOhm | I | 154 | 150kOhm |

| 1R6 | 1.6 ohm | I | 161 | 160 Ohm | I | 162 | 1.6kOhm | I | 164 | 160kOhm |

| 1R8 | 1.8 ohm | I | 181 | 180 Ohm | I | 182 | 1.8kOhm | I | 184 | 180kOhm |

| 2R0 | 2.0 ohm | I | 201 | 200 Ohm | I | 202 | 2.0kOhm | I | 204 | 200kOhm |

| 2R2 | 2.2 ohm | I | 221 | 220 Ohm | I | 222 | 2.2kOhm | I | 224 | 220kOhm |

| 2R4 | 2.4 ohm | I | 241 | 240 Ohm | I | 242 | 2.4kOhm | I | 244 | 240kOhm |

| 2R7 | 2.7 ohm | I | 271 | 270 Ohm | I | 272 | 2.7kOhm | I | 274 | 270kOhm |

| 3R0 | 3.0 ohm | I | 301 | 300 Ohm | I | 302 | 3.0kOhm | I | 304 | 300kOhm |

| 3R3 | 3.3 ohm | I | 331 | 330 Ohm | I | 332 | 3.3kOhm | I | 334 | 330kOhm |

| 3R6 | 3.6 ohm | I | 361 | 360 Ohm | I | 362 | 3.6kOhm | I | 364 | 360kOhm |

| 3R9 | 3.9 ohm | I | 391 | 390 Ohm | I | 392 | 3.9kOhm | I | 394 | 390kOhm |

| 4R3 | 4.3 ohm | I | 431 | 430 Ohm | I | 432 | 4.3kOhm | I | 434 | 430kOhm |

| 4R7 | 4.7 ohm | I | 471 | 470 Ohm | I | 472 | 4.7kOhm | I | 474 | 470kOhm |

| 5R1 | 5.1 Ohm | I | 511 | 510 Ohm | I | 512 | 5.1kOhm | I | 514 | 510kOhm |

| 5R6 | 5.6 ohm | I | 561 | 560 Ohm | I | 562 | 5.6kOhm | I | 564 | 560kOhm |

| 6R2 | 6.2 ohm | I | 621 | 620 Ohm | I | 622 | 6.2kOhm | I | 624 | 620kOhm |

| 6R8 | 6.8 ohm | I | 681 | 680 Ohm | I | 682 | 6.8kOhm | I | 684 | 680kOhm |

| 7R5 | 7.5 ohm | I | 751 | 750 Ohm | I | 752 | 7.5kOhm | I | 754 | 750kOhm |

| 8R2 | 8.2 Ohm | I | 821 | 820 Ohm | I | 822 | 8.2kOhm | I | 824 | 820kOhm |

| 9R1 | 9.1 Ohm | I | 911 | 910 Ohm | I | 912 | 9.1kOhm | I | 914 | 910kOhm |

| 10R(100) | 10 ohm | I | 102 | 1kOhm | I | 103 | 10kOhm | I | 105 | 1MOhm |

| 11R(110) | 11 ohm | I | 112 | 1.1kOhm | I | 113 | 11kOhm | I | 115 | 1.1 MOhm |

| 12R(120) | 12 ohm | I | 122 | 1.2kOhm | I | 123 | 12kOhm | I | 125 | 1.2 MOhm |

| 13R(130) | 13 ohm | I | 132 | 1.3kOhm | I | 133 | 13kOhm | I | 135 | 1.3 MOhm |

| 15R(150) | 15 ohm | I | 152 | 1.5kOhm | I | 153 | 15kOhm | I | 155 | 1.5 MOhm |

| 16R(160) | 16 ohm | I | 162 | 1.6kOhm | I | 163 | 16kOhm | I | 165 | 1.6 MOhm |

| 18R(180) | 18 ohm | I | 182 | 1.8kOhm | I | 183 | 18kOhm | I | 185 | 1.8 MOhm |

| 20R(200) | 20 ohm | I | 202 | 2.0kOhm | I | 203 | 20kOhm | I | 205 | 2.0 MOhm |

| 22R(220) | 22 Ohm | I | 222 | 2.2kOhm | I | 223 | 22kOhm | I | 225 | 2.2 MOhm |

| 24R(240) | 24 ohm | I | 242 | 2.4kOhm | I | 243 | 24kOhm | I | 245 | 2.4 MOhm |

| 27R(270) | 27 Ohm | I | 272 | 2.7kOhm | I | 273 | 27kOhm | I | 275 | 2.7 MOhm |

| 30R(300) | 30 ohm | I | 302 | 3.0kOhm | I | 303 | 30kOhm | I | 305 | 3.0 MOhm |

| 33R(330) | 33 Ohm | I | 332 | 3.3kOhm | I | 333 | 33kOhm | I | 335 | 3.3 MOhm |

| 36R(360) | 36 Ohm | I | 362 | 3.6kOhm | I | 363 | 36kOhm | I | 365 | 3.6 MOhm |

| 39R(390) | 39 Ohm | I | 391 | 390 Ohm | I | 393 | 39kOhm | I | 395 | 3.9 MOhm |

| 43R(430) | 43 Ohm | I | 431 | 430 Ohm | I | 433 | 43kOhm | I | 435 | 4.3 MOhm |

| 47R(470) | 47 Ohm | I | 471 | 470 Ohm | I | 473 | 47kOhm | I | 475 | 4.7 MOhm |

| 51R(510) | 51 Ohm | I | 511 | 510 Ohm | I | 513 | 51kOhm | I | 515 | 5.1 MOhm |

| 56R(560) | 56 Ohm | I | 561 | 560 Ohm | I | 563 | 56kOhm | I | 565 | 5.6 MOhm |

| 62R(620) | 62 Ohm | I | 621 | 620 Ohm | I | 623 | 62kOhm | I | 625 | 6.2 MOhm |

| 68R(680) | 68 Ohm | I | 681 | 680 Ohm | I | 683 | 68kOhm | I | 685 | 6.8 MOhm |

| 75R(750) | 75 Ohm | I | 751 | 750 Ohm | I | 753 | 75kOhm | I | 755 | 7.5 MOhm |

| 82R(820) | 82 Ohm | I | 821 | 820 Ohm | I | 823 | 82kOhm | I | 825 | 8.2 MOhm |

| 91R(910) | 91 Ohm | I | 911 | 910 Ohm | I | 913 | 91kOhm | I | 915 | 9.1 MOhm |

| 106 | 10MOhm |

Resistors, or resistors, as well as capacitors, are the most common components of electronic circuits. Surface mount resistors are manufactured by applying resistive paste to a ceramic substrate and then sintering it under high temperatures. On the surface of the resistor, the resistance value is usually indicated in the symbol. To increase power dissipation and improve stability of performance, the ceramic base can be replaced with a metal one. SMD resistors are designed for automatic installation and soldering by reflowing solder paste in the vapor-gas phase of an infrared heating oven. Resistors are packaged in blister tape, which in turn is wound on a plastic reel.

Along with a wide range of passive components: resistors, capacitors, inductors, chokes, connectors, switches, the company supplies active components from stock: SMD transistors, SMD diodes, zener diodes, LEDs, microcircuits.

What is an SMD resistor - internal structure

This device consists of a ceramic substrate coated with a resistive layer of a certain material and contact pads, as well as a protective coating (polymer, resin, glass). The layer resistance depends on the type of material and its thickness. Various constituent elements can be made of chromium, nickel, tin, ruthenium, silver or palladium oxides, as well as various alloys.

The design of the SMD resistor includes:

- A substrate made of a dielectric with good thermal conductivity – aluminum oxide.

- The resistive layer is a thin metal (chromium) or oxide film (ruthenium oxide) up to 10 microns thick. The material of the resistive layer has a low TCR, which ensures stability of parameters when temperature changes and the ability to produce precision resistors. To produce parts with a nominal resistance of less than 100 ohms, constantan is used for the resistive layer. The resistive element determines most of the electrical properties of an SMD resistor.

- Contact areas. They are formed from several layers. The inner layer is made of precious metals - palladium or silver. The intermediate layer is nickel, the outer layer is lead-tin. The use of these materials ensures ideal connectivity of the layers, which determines the reliability of contacts and the noise level.

The composition of the resistive layer, the nature of its processing, and the technology of application to the substrate are most often the know-how of the manufacturer and are kept in the strictest confidence.

Classification by manufacture

In addition to the typology of elements according to appearance and installation location, there is a classification according to production criteria.

Input resistance components are made:

- wired _ The resistive component is a wire wound around a core. In order to reduce parasitic inductance, a bifilar winding type is used. The wire is selected from materials that have a low resistive temperature coefficient, including those with low resistivity;

- metal film . The main resistance element is a metal film;

- composite . The composition of such elements includes alloys.

Attention!

For the manufacture of SMD resistors, metal film is used. Accordingly, the division is into thin and thick film.

Elements are also divided into constants and variables. From the name you can guess that the load of the first remains unchanged throughout the entire period of operation. For variable components, the resistance indicator is changed using a special slider.

Surface Mount Technology of SMD Resistors

Installation of surface resistors in amateur workshops is carried out using a hair dryer, and in production conditions it occurs in special ovens.

Stages of mounting parts on a board in serial and mass production:

- Small spacers made of silver or gold, lead-tin plates are placed on the board, on which SMD components will be fixed.

- Using the machine, solder paste and a mixture consisting of flux and solder are applied to the prepared mounting pads.

- After preparing the printed circuit board, components are fed into the device (Pick machine) in trays, on rolls of tape or in tubes. The machines then place them on the board. Equipment productivity can reach 60,000 elements per hour.

- The assembled board enters the oven at a temperature sufficient to melt the solder.

- After removal from the oven, the boards are cooled and cleared of loose solder particles.

Quality is checked by visual inspection, during which missing parts and the degree of cleaning are determined.

The development and implementation of surface mount technology (SMT) has made it possible to automate the board assembly process and make it faster, simpler, cheaper and more efficient. In practice, a hybrid of surface-mount and through-hole mounting technologies may be encountered.

The use of surface-mount resistors has a positive effect on the weight and size of radio-electronic devices and their frequency parameters.