The mallet is an integral part of the tools of plumbing and carpentry masters; it is also used in other works.

This hammer is still the same percussion instrument, but performs completely different tasks, unlike its metal counterpart.

In addition to the classic wooden version, which every schoolchild met in labor lessons, there are highly specialized types of it, which expands their scope of application.

We will talk about why a mallet is needed, how and what it is made of, the main types, and the nuances of choosing it for specific tasks.

What is a mallet for?

Not very common in everyday life, the mallet has found its use where blows with an ordinary hammer can cause damage to the material being worked with.

The tool is often used for straightening sheet metal. A good example in this case is the straightening of a car body.

When carrying out roofing work, in particular on complex roofs, where processing of joints and edges at the intersection of seam joints is required, this particular tool is also used.

And the folding of the metal itself is done with a mallet.

As for working with wood, the mallet is used for tamping, for example, furniture elements during assembly, or laminate flooring when laying it.

Carpenters often use the tool in conjunction with a chisel or chisel, especially if the handles of the latter are made of wood or plastic.

Disadvantages of materials

All materials have their own specific advantages and disadvantages that must be taken into account. Wood is often used in production. It is characterized by the following features:

- Relatively low cost. Wood is much cheaper compared to other materials; blanks can be found almost free of charge.

- With prolonged use, cracks and other defects may appear. Temperature effects and changes in humidity cause cracks and chips to appear in the structure, which significantly reduce the strength of the material.

- For the manufacture of rubber tools, a material without defects is required, since even minor knots can reduce the service life.

- Some types of wood are difficult to process and are much more expensive, while others will not last for a long period.

Rubber is characterized by higher performance characteristics. An example is that it does not respond to temperature changes and exposure to high humidity.

The rubber tool does not change its basic performance characteristics throughout the entire period of use.

Device and characteristics

Structurally, the tool consists of a handle and a striking part - a striker, which is made of various materials and different shapes, depending on the purpose.

The handle is inserted into the through hole of the striker with a slight taper on the side of its rounding.

This design prevents the latter from breaking during operation.

Striker and handle material

Hard wood, including birch, is used to make the mallet handle.

Some models have a rubber coating where the hand holds the tool.

Less common are metal, plastic and fiberglass handles.

As for the striker, for its manufacture they use:

• Wood of dense and sticky species, for example, butt birch, elm, hornbeam.

• Hard rubber – for tools used to work on materials that can easily be pressed.

• Fluoroplastic is a polymer with high chemical resistance. This material is not destroyed by water and does not dissolve in it, and is also insoluble or poorly soluble in most organic solvents, having a low wear value.

NOTE:

Drying oil serves as a protective coating for wooden strikers and handles.

Striker shape

Depending on the task, select a tool with the appropriate cross-sectional shape of the head:

• Round – typical for tools designed to perform straightening and installation work; it is also used when laying paving slabs.

• Rectangular – designed for chiselling work, for example, paired with a chisel or chisel, roofing work and folding.

• Square – it is mainly used for folding and roofing work.

NOTE:

The tool head can be either straight or wedge-shaped.

Self-production

If there is an urgent need for a tool and it is impossible to purchase it, professional builders recommend making the device yourself. The process of creating a mallet consists of the following steps:

- making a handle;

- choice of material for the bike;

- collection and fixation of parts.

The cut handle must be processed on a grinding machine, which will help make the surface smooth and even. A recess in the middle of the handle will simplify the process of doing work and increase ergonomics.

Before creating the head, it is necessary to make a layout. If dense and thick rubber is not available, you can use pieces of leather, from which you need to cut out the required number of circles of the selected diameter.

To assemble the beater, you need to string the circles onto the handle and glue them together with special glue. The assembled structure must be secured with a vice and the glue must be allowed to dry. To prevent the homemade bike from slipping, you need to secure it with a regular washer. The main advantages of a do-it-yourself design are noiselessness, ease of operation, practicality, versatility and low price.

To make a completely wooden instrument, you need to turn the parts required in size and connect them together. This procedure will not cause difficulties even for novice craftsmen and will require a small amount of time. Carrying out repair and construction work requires craftsmen not only to have professional experience and knowledge, but also special equipment and tools that will significantly simplify and speed up the process, and also make it possible to perform high-quality work.

One of the indispensable metalworking and carpentry tools is the mallet. Simple and primitive equipment has not lost its relevance for many decades and continues to be used for finishing and installation work. To purchase a high-quality and reliable tool, you must definitely contact specialized stores that sell products from well-known manufacturers.

One of the main criteria when choosing a product is the statement that a quality product cannot have a low price.

To learn how to make a mallet with your own hands, see the following video.

Dimensions and weight of mallets

Considering the wide range of tasks for which a mallet is used, its weight ranges from 225 - 450 g for light models, 450 - 900 g for medium ones, and more than 900 g for heavy ones.

At the same time, the dimensions visually may not correspond to the weight, for example, a heavy tool may be small, because sometimes, to further weight the striker, lead is poured into its center.

As for the length of the handle, it can vary widely, since it is believed that the longer it is, the stronger the blows can be performed.

A classic wooden instrument weighs on average about 300 g and is 30 cm long.

Types of mallets and their prices

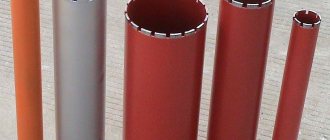

Standard mallets are divided into several types:

Wooden

The classic version, which is used when molding structures and materials, in dismantling and assembly work.

The cost of a budget instrument ranges from 80 to 400 rubles.

The price of high-quality models can exceed 2.5 thousand rubles.

Rubber

For materials that are highly pressure sensitive.

The tool is usually equipped with a wooden or metal handle.

Body work is performed with just such a mallet, since the increased elasticity of the rubber prevents the formation of chips in the paintwork.

In addition, the tool is also common among roofers working with copper, aluminum and galvanization.

The average price is about the same as the previous option.

The price of a large and heavy instrument reaches 3 thousand rubles.

There are also models of 10 thousand.

Inertialess

It is used in cases where increased requirements are placed on maintaining the integrity of the surface of the material.

A striking example is furniture assembly.

Inside the striker of such a tool there is an elongated cavity with a metal ball or shot, which upon impact prevents the striking part from rebounding.

For a good tool you will have to pay 200 - 400 rubles.

Special mallets include:

Construction

With a head made of rubber material, used for installation of soft metal and metal-plastic structures.

Zhestyanitskaya (metalworks)

For sheet metal work.

This mallet is suitable for straightening and folding material.

The round handle has a slight taper on one side.

The firing pin is made in the form of a rectangle.

Turning

It is used for the same purposes as tin, however, all its parts are made on turning equipment.

Carpentry

Designed for performing chisel work with a chisel or chisel.

The sides of the instrument are flat, wide, parallel to each other.

One side of the striker is flat, and the opposite side is rounded, while the ends relative to the axis of the handle are cut at an angle of 6 - 7 degrees and are not parallel to it.

This mallet is also well suited for adjusting the planing tool, namely, knocking out the incisors.

Plastic for roofing work

Used for installation using double standing seam technology.

The strikers are made of impact-resistant polyethylene.

Tiler's mallet

The main feature is a rubber head with a round heel.

For laying paving stones, models weighing up to 400 g are used, and for paving slabs - 600 - 800 g.

Mallet "Carver's Hammer"

It has an oblong shape, reminiscent of a one-handed rolling pin or a hand bell.

This wood carving hammer is made from hardwood.

Another name is a sculptural mallet.

The price of a quality instrument is within 5-6 thousand rubles.

Double-sided plastic hammer

A tool with round heads made of plastic, such as TPR.

This mallet is intended for construction and installation work.

Textolite mallet

It has electrical insulating properties and is intended for bodywork and jewelry work.

It is irreplaceable when working where there is a need to prevent sparks from static electricity (straightening gas tanks, etc.).

Each type of mallet is universal, in other words, it can be used not for its intended purpose, but depending on the characteristics of the material being processed and the planned result.

Which mallet should you choose?

For most carpentry work, you should use a mallet with a wooden head.

In this case, the dimensions and weight are selected individually. Particular attention should be paid to the wood itself.

As already mentioned, it should be a heavy and sticky breed.

It’s good if the striker and handle are made of different wood, which will reduce the impact on your hands.

An external inspection will help you avoid troubles in the form of poorly processed surfaces of both the handle and the head itself.

In addition, the drying oil coating will protect the instrument from drying out.

As for the rubber tool, it is considered more universal, and the selection criteria are as follows:

- Weight. Obviously, as this indicator increases, the impact force also increases. But there is one caveat: a fairly heavy tool requires more impact force from the worker, which will lead to rapid fatigue. Weight is determined by experience, personal feelings and depending on the work ahead.

- Length – selected based on the preferences of the person who will work with the tool. A long handle will provide a stronger blow.

- Handle. In addition to wooden and plastic options, attention should also be paid to fiberglass handles. They are highly durable, do not dry out and do not lose their original shape over time. In addition, fiberglass is resistant to organic solvents.

- Striker size. For rough work, a tool with a large impact head is selected, while delicate tasks require small strikers.

If the tool store does not have a mallet that can satisfy any special preferences of the master, you can assemble it with your own hands according to individual sizes.

Buying tips

To choose the right quality wooden hammer, you should carefully read the following tips from experienced craftsmen:

- if you have a large amount of carpentry work to do, then choose a tool with a wooden striker;

- pay attention to what kind of wood the head is made of, since the striking surface must be made of dense viscous wood (birch, oak, beech, maple, pear);

- ideally, the hammer and the handle of the mallet should be made from different types of wood, which will significantly reduce the impact of the impact during operation;

- carefully inspect the appearance of the hammer, do not buy a wooden tool with a poorly processed surface;

- give preference to mallets with linseed oil coating.

What you need to know about mallets?

In most cases, mallets are sold on the construction market with a head made of black rubber.

During operation, such models leave marks at the point of contact of the striker with the material being processed.

An example is the installation of plastic windows with a white frame, where such marks are especially noticeable.

However, a rubber hammer is indispensable in such work.

The solution is to use white rubber mallets, which are less popular, but do not leave marks.

How to use a mallet?

The process of working with a mallet is practically no different from a hammer.

The only thing you need to be able to do is control the force of impact on different materials.

Without relevant experience, you should start with a small amplitude of tapping and then evaluate the result.

When leveling sheet metal of small thickness, care should be taken to provide a flat wooden backing to compensate for the excess force applied.

The tool should be operated in such a way that the first striker is in contact with the material being processed along its entire length.

Otherwise, dents may form on the metal.

When working with a chisel or chisel, blows should also be applied with adjusted force so as not to cut off excess.

The use of a rubber mallet when laying tiles is due to the shock-absorbing ability of its striker.

To align the material along the required axes, lightly tap on the protruding sides of the surface.

When it comes to laying tiles, strong impacts should be avoided, especially in the corners.

Although the mallet is designed for this type of work, excessive tapping force can still damage the fragile material.

And the tile itself will immediately shrink excessively, and you will have to dismantle it and add mortar.

Carpenter's hammer

The carpenter's hammer has become very widespread. A similar carpentry mallet, rubber or wooden, is designed for working with decorative materials. At the same time, the characteristics have increased significantly due to the use of more modern materials.

A rectangular mallet is used when working on forming and straightening metal. Rubber and wood are used in production. Among the features we note the following points:

- The work involves performing strong blows.

- The working part is made of elastic material, so no serious defects appear on the surface.

Rubber or wooden tools have become very widespread. However, do not forget that working with fragile material is prohibited. Even a slight mechanical impact can cause serious defects.