The parameters of one of the most popular types of rolled metal - steel equal-flange angle - are determined by GOST 8509-93. The use of GOST in the production of such products not only unifies their types, but also improves the interaction between producers and consumers. The dimensions and weight of equal-flange steel angles, which are manufactured in full compliance with the regulatory document, make it possible to use these characteristics to accurately calculate material consumption, which is very important when carrying out construction and repair work.

Photo of equal-flange steel angle

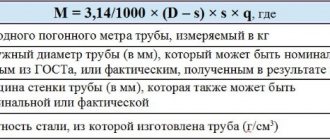

GOST 8509-93

b - shelf width; t—thickness of the flange;

R—radius of internal curvature; r is the radius of curvature of the shelves;

F is the cross-sectional area; i—radius of gyration;

I—moment of inertia; Ixy is the centrifugal moment of inertia;

x0 is the distance from the center of gravity to the outer edge of the shelf.

| Angle number | b | t | R | r | F, cm 2 | Reference values for axes | Weight 1 m, kg | |||||||||

| x - x | x 0 — x 0 | y 0 - y0 | Ixy, cm4 | x0, cm | ||||||||||||

| mm | Ix, cm4 | Wx, cm3 | ix, cm | Ixо max, cm4 | ixo max, cm | Iyо min, cm 4 | Wyo, cm 3 | iyо min, cm | ||||||||

| L20x3 | 20 | 3 | 3,5 | 1,2 | 1,13 | 0,4 | 0,28 | 0,59 | 0,63 | 0,75 | 0,17 | 0,2 | 0,39 | 0,23 | 0,6 | 0,89 |

| L20x4 | 4 | 3,5 | 1,2 | 1,46 | 0,5 | 0,37 | 0,58 | 0,78 | 0,73 | 0,22 | 0,24 | 0,38 | 0,28 | 0,64 | 1,15 | |

| L25x3 | 25 | 3 | 3,5 | 1,2 | 1,43 | 0,81 | 0,46 | 0,75 | 1,29 | 0,95 | 0,34 | 0,33 | 0,49 | 0,47 | 0,73 | 1,12 |

| L25x4 | 4 | 3,5 | 1,2 | 1,86 | 1,03 | 0,59 | 0,74 | 1,62 | 0,93 | 0,44 | 0,41 | 0,48 | 0,59 | 0,76 | 1,46 | |

| L28x3 | 28 | 3 | 4 | 1,3 | 1,62 | 1,16 | 0,58 | 0,85 | 1,84 | 1,07 | 0,48 | 0,42 | 0,55 | 0,68 | 0,8 | 1,27 |

| L30x3 | 30 | 3 | 4 | 1,3 | 1,74 | 1,45 | 0,67 | 0,91 | 2,3 | 1,15 | 0,6 | 0,53 | 0,59 | 0,85 | 0,85 | 1,36 |

| L30x4 | 4 | 4 | 1,3 | 2,27 | 1,84 | 0,87 | 0,9 | 2,92 | 1,13 | 0,77 | 0,61 | 0,58 | 1,08 | 0,89 | 1,78 | |

| L32x3 | 32 | 3 | 4,5 | 1,5 | 1,86 | 1,77 | 0,77 | 0,97 | 2,8 | 1,23 | 0,74 | 0,59 | 0,63 | 1,03 | 0,89 | 1,46 |

| L32x4 | 4 | 4,5 | 1,5 | 2,43 | 2,26 | 1 | 0,96 | 3,58 | 1,21 | 0,94 | 0,71 | 0,62 | 1,32 | 0,94 | 1,91 | |

| L35x3 | 35 | 3 | 4,5 | 1,5 | 2,04 | 2,35 | 0,93 | 1,07 | 3,72 | 1,35 | 0,97 | 0,71 | 0,69 | 1,37 | 0,97 | 1,6 |

| L35x4 | 4 | 4,5 | 1,5 | 2,67 | 3,01 | 1,21 | 1,06 | 4,76 | 1,33 | 1,25 | 0,88 | 0,68 | 1,75 | 1,01 | 2,1 | |

| L35x5 | 5 | 4,5 | 1,5 | 3,28 | 3,61 | 1,47 | 1,05 | 5,71 | 1,32 | 1,52 | 1,02 | 0,68 | 2,1 | 1,05 | 2,58 | |

| L40x3 | 40 | 3 | 5 | 1,7 | 2,35 | 3,55 | 1,22 | 1,23 | 5,63 | 1,55 | 1,47 | 0,95 | 0,79 | 2,08 | 1,09 | 1,85 |

| L40x4 | 4 | 5 | 1,7 | 3,08 | 4,58 | 1,6 | 1,22 | 7,26 | 1,53 | 1,9 | 1,19 | 0,78 | 2,68 | 1,13 | 2,42 | |

| L40x5 | 5 | 5 | 1,7 | 3,79 | 5,53 | 1,95 | 1,21 | 8,75 | 1,52 | 2,3 | 1,39 | 0,78 | 3,22 | 1,17 | 2,98 | |

| L45x3 | 45 | 3 | 5 | 1,7 | 2,65 | 5,13 | 1,56 | 1,39 | 8,13 | 1,75 | 2,12 | 1,24 | 0,89 | 3 | 1,21 | 2,08 |

| L45x4 | 4 | 5 | 1,7 | 3,48 | 6,63 | 2,04 | 1,38 | 10,52 | 1,74 | 2,74 | 1,54 | 0,89 | 3,89 | 1,26 | 2,73 | |

| L45x5 | 5 | 5 | 1,7 | 4,29 | 8,03 | 2,51 | 1,37 | 12,74 | 1,72 | 3,33 | 1,81 | 0,88 | 4,71 | 1,3 | 3,37 | |

SEE OTHER SIZES OF CORNERS HERE

L20 - L45, L50 - L75, L80 - L110, L125 - L180, L200 - L250

DOWNLOAD THE FULL VERSION OF THE DOCUMENT:

DOWNLOAD FILE TO YANDEX.DISK

DOWNLOAD FILE TO GOOGLE.DISK

VIEW FULL RANGE

Equal angles have a very wide range of applications. Of these, you can combine different sections (Tee, cross-section, channel, I-beam). Corners are used as racks, braces, and belts. Sometimes corners are used as stiffeners for various floorings. It is not recommended to use corners as the main load-bearing beams in metal frames, because excessive consumption of steel will be unjustified.

Corners are used for various auxiliary structures (Support tables on columns for installing beams, support tables on beams and trusses, for installing purlins. Corners are widely used for the manufacture of seasonal structures, such as canopies, tents, greenhouses, greenhouses and much more.

When using the assortment, it should be taken into account that some items are popular and can be purchased at almost any metal stock, while some items are rare and difficult to obtain, especially in the regions. You should also take into account the price range, because... sometimes it is more profitable to lay cheaper beams, which pays off even despite some overconsumption of metal.

The table shows prices at the beginning of 2022.

Types of equal angles

Equal-flange versions have become very widespread today. They are produced in various versions. Considering the types of metal corners, we note that the geometric dimensions and classification of products are regulated by two main regulatory documents:

- Hot-rolled equal-flange angles are obtained by using technology that involves exposure to high temperatures. GOST 8509-93 is used as regulatory documentation. Due to the use of special production technology, the resulting product has very high performance qualities. However, the production process is associated with a fairly large number of technological difficulties.

- Bent steel angles are also widely used. To standardize the main parameters in this case, GOST 19771-93 is used. Due to the use of cold bending technology, the production process is significantly accelerated.

Download GOST 19771-93. Equal-flange bent steel corners. Assortment."

A distinctive feature of equal-angle corners is that their shelves have the same geometric dimensions. Hot rolled products are produced by passing a hot billet through rollers. When pressure is applied to the softened alloy, a geometric shape and certain dimensions are formed. When cold bending, special equipment is used that can exert a significant mechanical effect. It is worth considering that in this case, only rolled sheets with a relatively small cross-sectional thickness can be used as a workpiece.

Hot rolled angle

Bent steel corner

Hot rolled products are characterized by the following advantages:

- high strength;

- more complex profile.

Bent ones have more precise geometric dimensions, which also determined their distribution. In addition, the use of sheet metal as a raw material made it possible to significantly reduce the weight of the product and expand the range. Classification is also carried out according to the type of material used in manufacturing. The following points depend on this indicator:

- Resistance of the material to environmental influences, for example, high humidity.

- Strength of structure and surface hardness.

- Density, which determines the ratio of weight and geometric dimensions.

- Processability degree.

The following metals can be used in the manufacture of equal angle angles:

- High strength steel. They have very high strength and can withstand significant mechanical stress. It is worth considering that in order to achieve certain indicators, heat treatment is carried out after obtaining the required shape and size.

- Alloyed metals with varying concentrations of impurities. By including various substances in the composition, the performance of the product can be significantly changed. For example, increasing the concentration of chromium increases the corrosion resistance of the surface. When alloying metal, it is taken into account that the resulting equal-flange materials must have high strength.

- Alloys that are characterized by high heat resistance, heat resistance or corrosion resistance. Some equal-shelf versions of building materials can be used in special operating conditions. To achieve the required qualities, high-alloy alloys can be used in their manufacture.

Steel corners

The most common metal used in the production of equal-flange angles is carbon steel. This is due to its high strength and relatively low cost, ease of production.

Equal angle corner GOST 8509

| TK STEEL-INTEX TRADE, LLC | EVRAZ METAL INPROM, OJSC | OMEGA METAL, GK | DIPOS, GC | METALLO-KOMPLEKT-M, JSC | ARIEL METAL, JSC | A GROUP, LLC | METAGOR, LLC | ATON-STEEL, LLC | AMG, LLC | SPECSTAL-SERVICE, LLC |

| 20x20x4.0 mm | ||||||||||

| 25x25x3.0 mm | 43 080 | 46 000 | 47 500 | 48 490 | 44 700 | 46 600 | 47 490 | 42 990 | 44 900 | |

| 25x25x4.0 mm | 43 080 | 45 400 | 45 500 | 45 800 | 45 490 | 45 900 | 46 000 | 47 490 | 43 490 | |

| 32x32x3.0mm | 43 880 | 46 600 | 45 800 | 48 490 | 46 600 | 46 490 | 44 490 | 44 900 | ||

| 32x32x4.0 mm | 43 380 | 44 800 | 46 000 | 47 500 | 44 990 | 45 700 | 46 000 | 46 490 | 43 490 | |

| 35x35x3.0 mm | 41 580 | 46 000 | 46 000 | 44 490 | 43 990 | |||||

| 35x35x4.0 mm | 45 400 | 46 000 | 43 900 | 44 990 | 46 000 | 44 490 | ||||

| 35×35x5.0 mm | 33 490 | |||||||||

| 40x40x3.0 mm | 45 580 | 46 000 | 46 600 | 47 990 | ||||||

| 40x40x4.0 mm | 43 880 | 44 400 | 44 700 | 44 700 | 43 990 | 44 700 | 44 700 | 45 490 | 44 490 | |

| 40x40x5.0 mm | 46 990 | 43 990 | ||||||||

| 45x45x3.0 mm | 45 000 | 45 000 | ||||||||

| 45x45x4.0 mm | 43 480 | 41 900 | 44 700 | 42 200 | 41 490 | 43 800 | 44 700 | 42 990 | 41 790 | |

| 45x45x5.0 mm | 42 480 | 42 600 | 38 200 | 41 990 | 45 700 | 45 000 | 43 490 | 42 990 | ||

| 50x50x4.0 mm | 41 580 | 41 500 | 42 000 | 44 200 | 42 490 | 42 000 | 42 990 | 41 790 | ||

| 50x50x5.0 mm | 41 580 | 41 900 | 42 500 | 42 000 | 42 700 | 42 490 | 46 000 | 42 000 | 42 990 | 41 490 |

| 63x63x4.0 mm | 43 380 | 42 490 | 45 000 | 43 490 | ||||||

| 63x63x5.0 mm | 43 480 | 41 900 | 42 000 | 42 000 | 42 500 | 42 490 | 44 000 | 42 000 | 43 790 | 42 990 |

| 63x63x6.0 mm | 43 480 | 42 000 | 42 700 | 42 000 | 43 500 | 42 000 | 42 990 | 42 990 | ||

| 70x70x5.0 mm | 42 780 | 42 300 | 45 000 | 45 500 | 44 490 | 45 000 | 46 490 | 44 490 | ||

| 70x70x6.0 mm | 42780 | 44900 | 44490 | 45100 | 45990 | 43490 | ||||

| 70x70x7.0 mm | 45490 | 42490 | ||||||||

| 75x75x5.0 mm | 42680 | 42300 | 42600 | 45200 | 44490 | 44700 | 42600 | 45490 | 42790 | |

| 75x75x6.0 mm | 42680 | 42300 | 42500 | 42300 | 44700 | 44490 | 44300 | 42300 | 44990 | 42790 |

| 75x75x7.0 mm | 42680 | 45000 | 44490 | 45000 | 46990 | 43990 | ||||

| 75x75x8.0 mm | 42680 | 44150 | 44900 | 43990 | 44900 | 44150 | 45990 | 43490 | ||

| 80x80x6.0 mm | 43880 | 42300 | 45600 | 44900 | 45490 | 46000 | 45600 | 45990 | 43490 | |

| 80x80x7.0 mm | 43880 | 45600 | 45600 | 45990 | 42490 | |||||

| 80x80x8.0 mm | 43880 | 45600 | 45200 | 45600 | 44490 | |||||

| 90x90x6.0 mm | 43380 | 42300 | 42300 | 44900 | 44490 | 44200 | 42300 | 42990 | ||

| 90x90x7.0 mm | 42780 | 42300 | 44000 | 42300 | 43500 | 43490 | 45700 | 42300 | 45490 | 42290 |

| 90x90x8.0 mm | 42900 | 45900 | 45490 | 46300 | 45900 | 46490 | 43490 | |||

| 90x90x9.0 mm | 45600 | 42790 | 45600 | |||||||

| 100×100x6.5 mm | 45680 | |||||||||

| 100x100x7.0 mm | 43480 | 42800 | 43500 | 42900 | 47900 | 43990 | 43900 | 42900 | 37990 | |

| 100x100x8.0 mm | 43480 | 42800 | 43500 | 42000 | 44700 | 44990 | 47800 | 42900 | 37990 | |

| 100x100x10.0 mm | 43480 | 42800 | 47700 | 48900 | 48490 | 48900 | 47700 | 44990 | ||

| 100x100x12.0 mm | 38990 | |||||||||

| 110x110x7.0 mm | 43580 | 49500 | 45700 | 49500 | 45990 | |||||

| 110x110x8.0 mm | 43080 | 42900 | 50500 | 49500 | 43990 | |||||

| 125x125x8.0 mm | 43080 | 45300 | 39200 | 49500 | 49500 | 51490 | 45700 | 49500 | 44990 | |

| 125x125x9.0 mm | 43080 | 45300 | 49500 | 48400 | 46000 | 49500 | 44490 | |||

| 125x125x10.0 mm | 43080 | 45300 | 49500 | 48500 | 48990 | 45700 | 49500 | 37990 | ||

| 125x125x12.0 mm | 46990 | 37990 | ||||||||

| 140x140x9.0 mm | 54180 | 53600 | 55000 | 55500 | 54950 | 55000 | 55950 | |||

| 140x140x10.0 mm | 54180 | 53600 | 55000 | 54950 | 55000 | 55950 | ||||

| 140x140x12.0 mm | 55000 | 55000 | ||||||||

| 160x160x10.0 mm | 54180 | 54800 | 55000 | 55500 | 54950 | 55000 | 55950 | 57200 | ||

| 160x160x11.0 mm | ||||||||||

| 160x160x12.0 mm | 52580 | 55000 | 54950 | 55000 | 58200 | 57200 | ||||

| 160x160x14.0 mm | 58200 | |||||||||

| 160x160x16.0 mm | 53580 | 54800 | 54950 | 58200 | 57200 | |||||

| 160x160x20.0 mm | ||||||||||

| 180x180x11.0 mm | 56800 | 57500 | 57200 | 57200 | 57500 | 58200 | ||||

| 180x180x12.0 mm | 57500 | 57500 | 58200 | |||||||

| 180×180x14.0 mm | ||||||||||

| 200x200x12.0 mm | 53580 | 55000 | 54950 | 55000 | 55950 | 54950 | ||||

| 200x200x14.0 mm | 51180 | 54000 | 55000 | 55000 | 55950 | 54950 | ||||

| 200x200x16.0 mm | 51180 | 54000 | 54950 | 55950 | 54950 | |||||

| 200x200x20.0 mm | 55950 | 54950 |

Corner sizes

The issue of dimensions was touched upon earlier when considering the main indicators that characterize a steel angle. The following points should also be noted:

- The weight of the product is indicated. Metal corners are used in the manufacture of critical products. That is why the weight of the material itself is also taken into account in the calculations.

- The main dimensions of the equal-flange angle are also indicated for the development of design documentation and selection of the most suitable product.

- Equal-flange steel angles are also characterized by profile cross-sectional area, flange width, radius of curvature, and wall thickness. All these indicators are maintained as standards and are not indicated by manufacturers; if necessary, they can be found in reference documentation.

An equilateral corner can have a variety of sizes. A wide range allows you to select the most suitable material for use in a particular case.