You are here: Using washers: why does the quality of fasteners improve when using them?

A washer is a product whose use can significantly improve the quality of a fastening joint. A large number of materials are used in the manufacture of these devices, and manufacturers also offer a wide selection of washers in appearance.

Why is it important to use washers?

By ignoring the installation of such a lining, you risk reducing the service life of the entire structure. Washers are used to prevent the fasteners from unwinding under loads. When properly sized and tightened, they will significantly improve surface contact. If the fasteners are constantly subjected to shaking, vibrations and impacts, then the washers will prevent the bolts from loosening and unwinding. Similar solutions can be found in airplane wings and parts of milling machines.

Read also: How to determine character by earlobe

Misalignment of the nut is dangerous not only due to possible rupture of contact between parts, but also damage to the main surface. In this case, the gaskets protect the paint layer on the structures from scratches and dents, and the hole itself from moisture. Without them, wear accelerates and the risk of irreversible damage increases. This is the main answer to the question of why a washer is needed in a bolted joint.

Areas of application

Washers are in demand in a variety of fields of activity. They are used in assembling furniture structures, connecting building elements, installing pipelines and linear communications. Elastic silicone options are in demand in everyday life. In industrial production, the main areas of use of washers can be called mechanical engineering, shipbuilding, and machine tool building.

Depending on the shape and design, the purpose of the washer is determined. For example, oblique ones are necessary to compensate for differences in angles of parts or planes; they are used to fasten I-beams. Contact ones improve the adhesion of fasteners to the surface. Stoppers are necessary to prevent parts from unscrewing; they are needed in one-piece structures. To compensate for dynamic loads and vibration in machines and mechanisms, spring washers are used.

Washer for bolt or nut?

The question that arises most often when assembling fasteners is whether the washer is placed under the nut or under the bolt head? Sometimes installers, not understanding the intricacies of fasteners, put one washer under both the bolt and the nut. First of all, you need to figure out why a washer is placed under the nut. This is done to increase the support area and reduce the pressure on the nut, which prevents spontaneous unscrewing. According to SP standards, there are features of installing fastening connections with and without controlled tension:

- Without controlled tension, according to GOST 11371-78, no more than two round washers are placed under the nut. It is permissible to install the third washer under the bolt head. If the drawing of a threaded connection does not indicate the use of spring washers or another method of preventing self-unscrewing of fastener elements, standard flat washers are installed.

- With controlled tension, washers are placed under the nut and bolt without fail. In this case, it is necessary to check the exact compliance of the fastening connection parameters with the drawings and record the result of the work in the appropriate journal of the reporting documentation.

Another common question is whether a washer is needed for a self-locking nut? In some areas, due to the specific operating conditions of the mechanisms, it is impossible to use locknuts and lock washers. In such cases, self-locking nuts are used, under which there is really no need to place a washer.

Subtleties of installation work

Assembly of fastening joints is carried out in accordance with the requirements of generally accepted standards. Procedure before tightening fasteners:

- Washing the fasteners in a special solution to depreserve and remove grease.

- Checking thread parameters and product geometry.

- Applying a special lubricant to each part of the future fastening joint. In accordance with the requirements of the drawing, the surfaces of the structures to be connected are prepared (oxidized, chemical or blast cleaning is used if necessary).

- Aligning fastener holes and channels, checking for accuracy and tightening using appropriate tools.

If there are several fastening connections in one plane, the tension of each fastener is carried out through a bolt. The final tension is carried out using a torque wrench, which provides precise control of the operating force.

In some cases, a specialized adhesive composition is used to fix the thread. The glue is not able to hold the fasteners together, but it does prevent the threads from coming loose in the event of constant vibration and variable loads. For the self-unscrewing protection effect to work, the adhesive composition must harden - after hardening, a solid polymer is formed at the joint.

Rings

Related to lock washers are lock rings. The relationship is so close that it is not always clear why some of them are washers and others are rings. Rings are also used for locking on shafts or holes. They are sometimes called Seger rings. Among several designs of retaining rings in the TsKI assortment, only eccentric rings in the normal version are presented.

Retaining ring for shaft, eccentric, external DIN 471.

Retaining ring for hole, eccentric, internal DIN 472.

The sealing ring DIN 7603 A is intended for threaded plugs. For high-quality sealing, the rings must be soft, so they are made of pure annealed metals - copper or aluminum. The TsKI assortment includes only copper rings. With a wide variety of diameters, they have only four thicknesses.

Read also: Why is rhetoric needed (page 1 of 2)

Lock washer with tooth

A more modern fastener to prevent self-unscrewing of a threaded connection is a lock washer with a tooth. Such fasteners are in demand, in particular in the production of household appliances and equipment. When assembling power tools, washing machines, dishwashers, and household construction equipment, a lock washer is placed under the head of the screw or bolt and the nut. This solution is inexpensive and quite reliable.

Structurally, a lock washer with a tooth has an inner or outer edge in the shape of a tooth and rotated relative to the main plane at an angle of up to 45 degrees. Teeth can be produced by notching or punching. The turning direction is right. Hardware is made from spring steels that have high hardness and high elasticity.

The fasteners are manufactured in accordance with GOST 10463, DIN 6798. The range of lock washers with teeth according to GOST is represented by small diameters - from 2 to 24 mm (according to DIN up to 30 mm). They are made of carbon steel, brass, and stainless steel.

Materials

Various materials can be used to produce washers. The most popular are:

- carbon steel;

- alloy steel;

- stainless steel;

- brass;

- copper;

- plastic;

- tree;

- cardboard;

- rubber.

Coated steel washer, as well as galvanized varieties, are the most popular parts, as they have good strength and resistance to various influences. Plastic options are considered a good alternative, since there is no need for additional processing during the production process.

Thanks to the use of different materials, you can select parts for different areas and achieve the best results.

Where is it used?

Washers are needed for reliable jointing of sheets of soft materials (panels, plywood, drywall, wood). In this case, it is advisable to install them on both sides of the hardware. Their functions are not limited to household use. When there are high requirements for connections, washers are used in industrial sectors:

- machine tool industry;

- aircraft manufacturing;

- mechanical engineering;

- production of devices;

- renovation of residential and commercial premises;

- construction of houses and temporary structures;

- construction of metal structures, etc.

The list of why washers are needed is not limited to this. They can be used in almost any construction and production task. Sometimes for this you have to create hardware according to the drawing, rather than purchasing ready-made ones. It is possible to produce any batch of washers to order.

Read also: Corvalol instructions for use

Production Features

To obtain flat washers, you can use rod or sheet material, which is sharpened with the necessary tools. During the creation process, products can undergo heat treatment, which ultimately produces stronger and more reliable parts. The best option is considered to be materials on which a protective layer has been applied - their service life is much longer. One of the important points is the galvanizing procedure, which can be carried out using two methods.

Galvanic - a thin layer of zinc is applied to the washers due to the action of a chemical substance, which makes it possible to obtain a smooth product with an evenly applied coating.

When it comes to aluminum washers, they are treated with yellow chromating, which prevents the metal from deteriorating due to corrosion. To obtain the best result, washers are washed, then pickled, washed again and chromed, then washed again.

Shapes and types of washers

Most often you can find the following types of products on the market:

- Flat - suitable for strengthening ordinary nodes.

- Square and enlarged are modifications of flat ones, used depending on the condition of the surface.

- Spring washers (Grover washers) - shock-absorb surfaces under shock and vibration loads and prevent damage.

- Stopper teeth - prevent the thread from unwinding due to the compression of the teeth.

- Threaded from the inside - help in adjusting the unit.

- Washers with a claw are similar to lock-toothed washers; the claw plays the role of a stopper when tightening.

- Corrugated - rough, have notches for better grip.

- Oblique - not only compact, but also conceal unevenness and differences in joint angles.

- Types of washers

- Bolt, washer and nut

- Washers: spring, flat, with petals

- Washer with claws

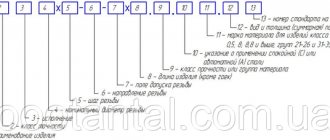

Washer classification

Washers are divided into different types according to a variety of criteria: material of manufacture, strength and accuracy classes, standard hole sizes and heights, level of smoothness of contacting surfaces. The generally accepted classification of washers, taking into account their external shape, looks like this:

- Flat - they are round, oval, rectangular and square, sometimes they have a one-sided chamfer.

- Spring (grower) - comply with GOST 6402, used to prevent self-loosening of bolted connections.

- Double-turn spring - used when laying railway tracks.

- Washers with an increased size (inner diameter is 3 or more times smaller than the outer diameter) - used when installing wooden and plumbing products.

- Washers for roofing work - have rubber sealing rings for a tight connection.

- Washers with tabs are locking products for nuts with a backing, used if there is vibration.

The type of washer for a particular connection is determined taking into account a large number of factors. The variety of washers is huge, you can choose the ideal part for any fastener.

Overview of species

For fastening polycarbonate and roofing structures, for wire tray and fixation in bolted joints and complete with screws, washers are used to reliably isolate or fix parts more firmly. There are highly specialized varieties of such products - for door hinges, electrical equipment, oil-resistant for machines and mechanisms.

Most often, washers for threaded bolts are made of stainless steel, galvanized, or non-ferrous alloys. They can also be non-metallic, made of silicone or textolite. All types of washers can be divided into groups according to their shape, size and other characteristics. Some of them are worth considering in more detail.

Insulating. This category of products must have dielectric properties, since they are used as a spacer between materials with high conductivity. Most often, a textolite washer is used, which has a fairly long service life.

Flat

The most common type of washers. Products can be round or square in shape, most often made of metal, but can be fluoroplastic, as well as other types of plastic. The size range of flat washers is the widest; they can be reinforced, reduced or enlarged.

Square options are most often used when assembling structures made of wood with a similar cross-section. Reinforced flat washers are thicker. This is a necessary condition for reducing the deformation effect on the plane of the part.

Reduced

They belong to the category of flat washers. They differ in the area of the contact surface. It is smaller than the standard options.

Enlarged

Large square or round flat washers of this type are used for assembly work. The increased contact surface area allows for a closer fit of the elements.

Spring

This washer can also be called a split washer or a groover. Usually it has the form of a spring of 1 turn, in which there is a gap directed against the direction of rotation. When installing spring washers, it is possible to obtain a threaded connection that provides maximum tightness without the risk of unscrewing. Fixation occurs using a special edge on the product. It crashes into the plane of the support, becoming wedged in it.

The double-turn spring washer is used in the installation of railway tracks. Single-turn has a broader purpose. For its manufacture, they choose not rods or metal sheets, but wire of only certain types of steel. Wavy spring washers are made of steel with zinc coating or oxidation.

Rectangular

This type of flat metal products is similar to square and round ones, but has a different cross-section. The main area of application is the installation of solid wood structures.

Grovers

This name hides the same spring washers, manufactured in accordance with GOST 6402. The ends of such fixing hardware are located in different planes.

Stopper

The locking washer is intended to lock the threaded connection. Such products have a serrated inner or outer surface. During the process of tightening the fastener, the self-locking part is deformed, acting as wedge clamps. A lock washer equipped with a tab or toe helps prevent the bolt from unwinding. During installation, its protruding element is bent towards the edges of the nut.

Lock washers also include crown washers that have a multi-claw design. They are made from steel and softer metals. The so-called “star” is also a lock washer and has external teeth. Locking varieties are used to prevent axial displacement.

Anti-vibration

A special category of washers is vibration-compensating. It is intended for installation in metal frames, in places of their contact with the base, to prevent the transmission of structural noise at fastening points. Such products are made from synthetic elastomers, most often rubber.

What to consider when choosing

High-quality fastening depends on careful selection of product parameters. Joints in which the bolt, nut and washer are made of the same material, such as metal, work best.

Aluminum, plastic elements or non-ferrous metal models will show high resistance to corrosion. If you do not take into account the chemical properties of materials, they will oxidize and destroy each other when interacting.

When choosing, pay attention to the following factors :

- the inner diameter of the washer must exactly match the outer diameter of the wrench bolt:

- the type of coating is selected in accordance with the explanations of the design documentation and drawings (protective and decorative, increased wear resistance, protective), there must be a certificate of compliance with GOST;

- Chips, crumpling, uneven thickness along the ring, delamination, and warping of the metal are not allowed on the surface

Elements used in household mechanisms must belong to the group of environmentally friendly materials.

Primary requirements

Washers are standardized products that must meet certain requirements. Among them is the absence of visible defects. The presence of burrs and sharp edges, cracks and tears is not allowed on the surfaces of products; traces of rust are also considered unacceptable. According to the accuracy class, products can be class A or C, have a flat round, oblique square or toothed shape.

Production can be carried out with or without coatings. Heat treatment of products in production is carried out on an individual basis. For steel washers of accuracy class A, hardness indicators are set at 140HV, for C - at least 100HV.